At our factory in Dongying, we often receive inquiries from procurement managers who use terms like "mirror finish" and "passivation" interchangeably. It is a common confusion, but in the world of glass hardware manufacturing, these are two completely distinct stages of production. Mistaking one for the other can lead to products that look beautiful out of the box but fail quickly when exposed to coastal environments or heavy use.

Surface finishing acts as the cosmetic stage to alter appearance, while surface treatment is the scientific process that modifies physical properties like corrosion resistance. Understanding this distinction ensures you specify the right manufacturing processes for durable, high-quality glass hardware.

Let’s break down the science and the aesthetics so you can order with confidence.

What is Surface Finishing?

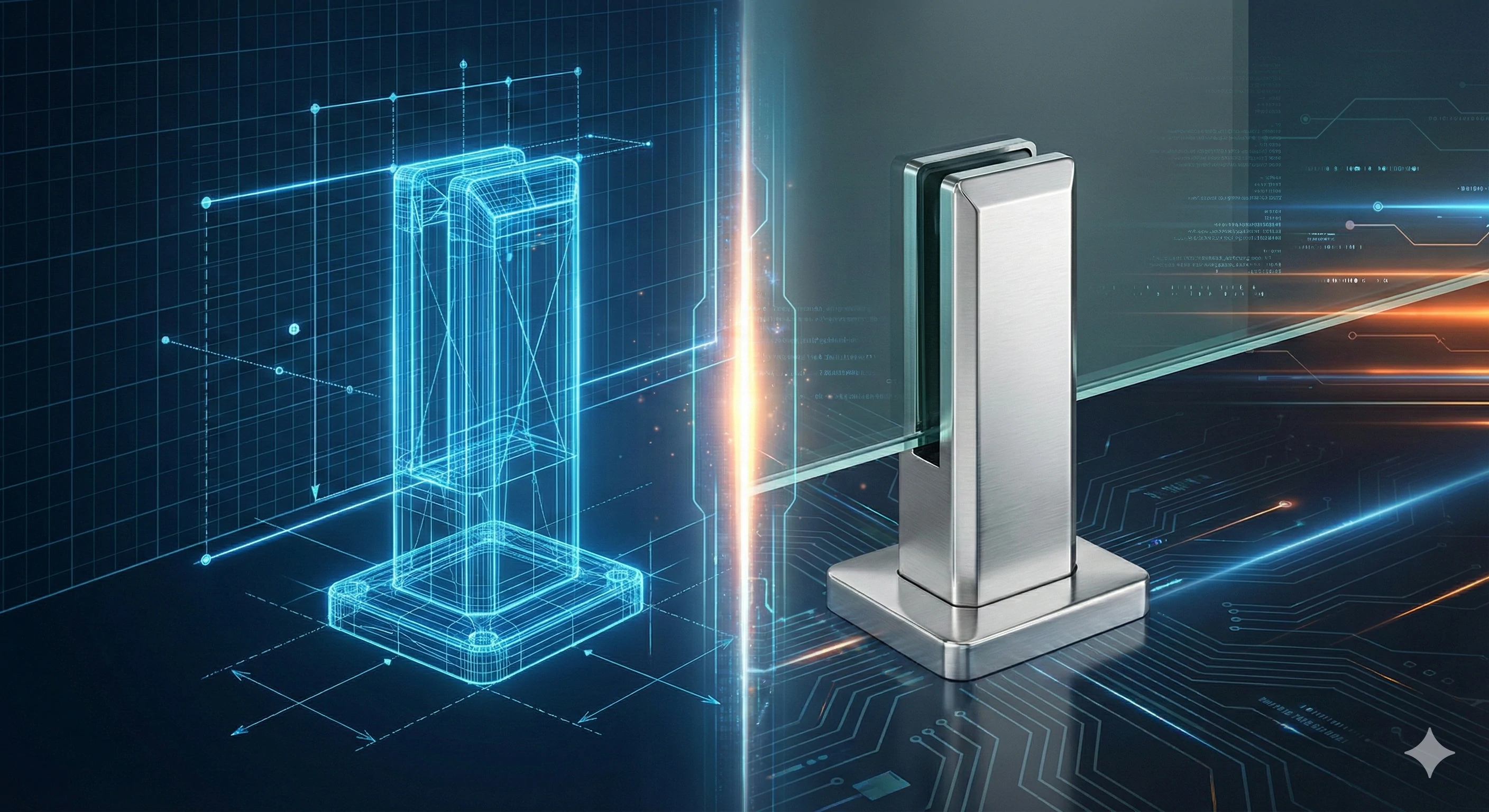

When we pull a raw casting off the line, it often has rough edges and "gate" marks that need immediate attention. Our engineers focus heavily on this stage to ensure the tactile experience of the product meets high-end standards. If you are looking for that premium shine on a glass spigot, you are looking for a finish.

Surface finishing is primarily a subtractive mechanical process used to improve aesthetics and texture. By removing surface imperfections through methods like mirror polishing or satin brushing, we create the specific visual look required for architectural applications.

Surface finishing is essentially the "makeup" of the manufacturing world. It is about how the product interacts with light and touch. At our facility, we categorize finishing into several specific mechanical processes.

The Mechanical Removal Process

Most finishing techniques are "subtractive," meaning we are removing material to achieve a result. For example, to achieve a mirror polish, we are not adding shine; we are removing the microscopic peaks and valleys on the metal's surface until it is flat enough to reflect light perfectly.

Common Finishes in Glass Hardware

We utilize different techniques depending on the final application of the glass railing or shower fitting.

| Finish Type | Process Description | Primary Benefit | Typical Application |

|---|---|---|---|

| Mirror Polish | Progressively finer sanding to remove micro-scratches. | High reflectivity; easiest to clean; best corrosion resistance for outdoors. | Coastal glass railings; swimming pool fencing. |

| Satin (Brushed) | Using abrasive belts to create uniform directional lines. | Hides fingerprints; modern, soft aesthetic. | Indoor staircases; office partitions. |

| Sandblasting | Bombarding the surface with glass beads. | Creates a uniform matte texture; non-reflective. | Decorative fittings; non-slip surfaces. |

| Grinding | Heavy material removal. | Removes casting gates and weld seams. | The first step for all cast products. |

Why Mirror Polish Matters Outdoors

We often advise our US clients to choose a mirror finish for outdoor projects. Scientifically, a smoother surface has fewer crevices. In a , salt and dirt can get trapped in the "grain" of the brush marks, leading to . A mirror finish offers nowhere for the salt to hide, making it the superior choice for longevity, not just looks.

What is Surface Treatment?

While the finish is what sells the product to your customer, the treatment is what keeps it sold. In our daily operations, we treat this stage as the "health check" for the metal. We have seen plenty of shiny products rust because they skipped this invisible but critical step.

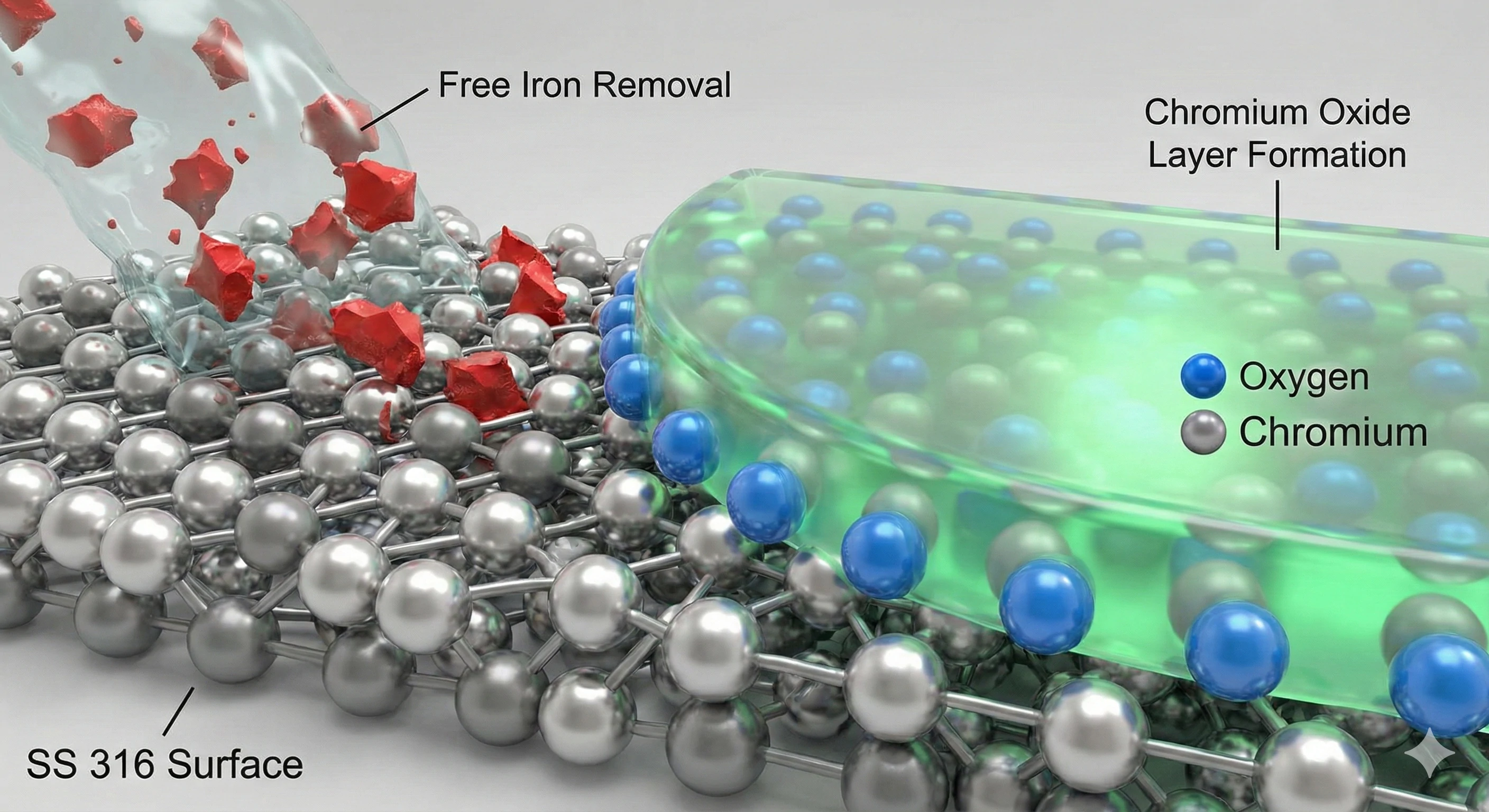

Surface treatment involves chemical or physical processes designed to alter the metal's internal or surface properties without changing its shape. We utilize methods like passivation to remove free iron, significantly enhancing the material's lifespan and rust resistance.

If finishing is the makeup, treatment is the vitamin regimen. It changes the chemistry of the surface to fight off environmental attacks.

The Power of Passivation

Many buyers assume that is naturally rust-proof. This is a dangerous misconception. During machining and polishing, free iron particles from the tools can embed themselves into the steel surface. If left untreated, these particles will rust, even on high-grade steel.

At our factory, we immerse the hardware in an acid bath—a process called . This removes the free iron and forces the chromium in the steel to react with oxygen, creating a passive chromium oxide layer. This invisible shield is what actually prevents rust.

Heat Treatment for Strength

Before we even get to the acid baths, we often use heat treatment (specifically for stainless steel). When metal is cast, it has internal stresses. By heating it to high temperatures and cooling it rapidly, we realign the crystalline structure. This ensures that a heavy glass door hinge won't crack under load.

Treatment Comparison Matrix

| Treatment Method | The Goal | How We Do It |

|---|---|---|

| Passivation | Corrosion Resistance | Dipping parts in citric or nitric acid solutions. |

| Pickling | Scale Removal | Using strong acids to strip weld burns and oxide scale. |

| Solution Annealing | Stress Relief | Heating metal to ~1050°C to homogenize the structure. |

How Do Coatings Like PVD Fit In?

We frequently get requests for "Gold" or "Matte Black" hardware to match modern interior designs. This brings us to a unique category that straddles the line between the two concepts. It is an area where we see significant growth in demand from the European and Australian markets.

Coatings represent a hybrid zone where aesthetic beauty meets physical protection. Processes like PVD add a durable, colored layer that serves as a finish by changing the color and a treatment by increasing surface hardness.

is not just paint. It is a method where we vaporize a solid metal (like titanium) and blast it onto the hardware.

Why PVD is Superior to Painting

Traditional painting or powder coating sits on top of the metal. If you scratch it, it peels. PVD, however, bonds at a molecular level.

-

As a Finish: It provides stunning colors like Gold, Rose Gold, and Black.

-

As a Treatment: It creates a layer of that is incredibly hard. This makes the surface resistant to scratches and wear, far beyond the capability of the raw stainless steel.

Electroplating vs. Powder Coating

We also offer other coating methods depending on the budget and requirement:

-

Electroplating: Using electrical current to coat the part in Chrome or Zinc. This is common for bathroom accessories but less durable than PVD for heavy wear.

-

Powder Coating: Spraying dry plastic powder and baking it. This is excellent for achieving specific RAL colors but can chip if impacted heavily.

Why Do Investment Castings Need Both?

It is rarely an "either/or" choice. When we plan our production schedule for a new order of glass clamps, we almost always include both finishing and treatment steps. Without this combination, the product is incomplete.

Investment castings require both processes because raw parts are naturally rough and vulnerable to corrosion. We must first smooth the surface for aesthetics and then chemically treat it to lock in protection against harsh environmental elements.

The Transformation Timeline

To give you a clearer picture of how a raw piece of metal becomes a premium product, here is the journey of a typical glass spigot on our production line:

-

The Raw State: The casting comes out of the shell with a matte grey, rough "skin." It looks industrial and unrefined.

-

Step 1 - Grinding (Finish): We grind off the gate marks where the molten metal entered the mold.

-

Step 2 - Polishing (Finish): We refine the surface. If we stopped here, the part would look shiny, but it would have microscopic iron contamination.

-

Step 3 - Passivation (Treatment): We treat the part chemically. This does not change the shine, but it "locks in" the quality.

-

Step 4 - Cleaning: A final wash to remove acid residues.

The Risk of Skipping Steps

We have seen competitors cut costs by skipping the passivation stage. The product looks identical to ours when it arrives at your warehouse. However, six months later, when your customer installs it near the beach, it starts to show "tea staining" rust spots. By ensuring both steps are taken, we protect your brand's reputation.

How Should Buyers Specify What They Need?

Communication is key in global procurement. We find that vague instructions are the leading cause of dissatisfaction. When you send us an inquiry, being specific about these two distinct categories helps us quote accurately and deliver exactly what you expect.

Buyers should specify finishes using measurable Ra roughness values and treatments using international standards like ASTM. This precision eliminates ambiguity, ensuring the factory delivers hardware that meets both your visual expectations and longevity requirements.

The Language of Quality

Don't just say "make it smooth." "Smooth" is subjective; numbers are not.

Measuring the "Look" (Roughness Average)

We measure surface finish using Ra (Roughness Average).

-

Satin Finish: Usually requires an Ra of < 0.8µm.

-

Mirror Polish: Requires an Ra of < 0.2µm (or even < 0.1µm for "Super Mirror").

If you specify "Ra < 0.2µm," our quality control team knows exactly when to stop polishing.

Measuring the "Life" (Standards)

For treatments, refer to international standards.

-

Passivation: Specify "Passivate per ." This tells us exactly which acid concentrations and durations to use.

-

Salt Spray Test: Always ask for a . We can provide reports showing that our treated products withstand 100+ or 500+ hours of salt spray without rusting.

| Specification Category | What to Ask For | Example |

|---|---|---|

| Visual Finish | Ra Value / Grit # | "Mirror Polish, Ra < 0.2µm" |

| Chemical Treatment | ASTM Standard | "Passivation per ASTM A967" |

| Verification | Test Reports | "Provide 48-hour Salt Spray Test Report" |

Conclusion

The difference between surface finishing and surface treatment is the difference between looking good and lasting long. Surface finishing creates the visual appeal that attracts your customers, while surface treatment provides the chemical protection that ensures the product endures the elements.

As a manufacturer committed to quality, we believe you need both. Whether you need a high-end mirror polish for a coastal hotel project or durable PVD coatings for a luxury home, understanding these processes helps you make better procurement decisions.

Need hardware that looks stunning AND survives the elements? We offer comprehensive Mirror Polishing and Acid Passivation services in-house. Get a finished sample today.

Footnotes

1. Comparison of brushed versus mirror finishes regarding maintenance and corrosion.

2. Causes of brown surface staining on coastal stainless steel applications.

3. Properties and industrial applications of marine-grade stainless steel.

4. Chemical process to improve corrosion resistance of stainless steel.

5. Heat treatment process to alter physical properties of metals.

6. Thin-film coating process for superior durability and aesthetic color.

7. Technology used to deposit coating layers atom-by-atom in vacuum.

8. Extremely hard ceramic material used in durable conductive coatings.

9. Standard specification for chemical passivation treatments of stainless steel.