As a leading precision manufacturing company, we delivers premier high quality, cost effective parts to a wide range of industries.

Silica Sol Technics, Lost-wax Process

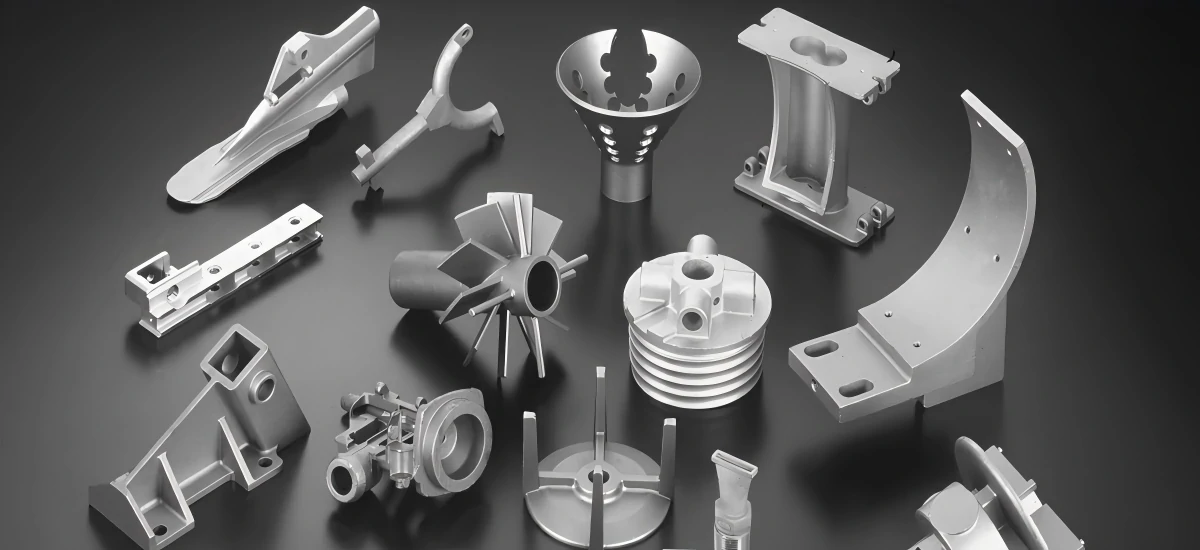

construction hardware, auto parts, pump & valve parts, impellers, marine hardware, and some other machinery parts

construction industry, chemical machinery, ship building equipment, medical industry, food machinery, and water & waste water treatment industries, etc.

stainless steel, carbon steel, alloy steel, and brass,etc.

0.005kg-100kg

Tooling Lead Times 2 to 4 weeks

Less than 20 days for as Cast Parts

Average Lead Time less than 7 weeks

400mm x 500mm x 500mm, single dimensionis no larger than 700mm

1mm

R0.3

Min. through hole diameter: 2mm

Max. through hole depth: 4mm

Min. blind hole diameter: 2mm

Max.blind hole depth: 2mm

Ra3.2-6.3

Normally can achieve CT6, best to achieve CT4 as per standard GBT6414-2017

Auto CAD (DWG, DWZ), UGNX, DXF, IGES, JPG, Pro-E (DRW, PRT, XPR), Solid Works (SLDPRT, SLDDRW, SLDDRT), STEP