The Battle Against Corrosion

Coastal salt spray in Barcelona’s cafes. De-icing chemicals on Colorado’s mountain lodges. These environments destroy ordinary protected metal. At ALeader, we fortify sub-5lb (2.2kg) hardware—door hinges, pool clips, precision brackets—using electrostatic powder coating. Unlike liquid paint, this dry process builds thicker, more uniform shields. Let’s explore how it works.

Stage 1: Degreasing – The Foundation of Longevity

The invisible enemy:

Microscopic oil residues (as little as 0.01mg/cm² – equivalent to a single fingerprint) cause most coating failures.

Our defense:

Ultrasonic tanks: Parts immerse in 122°F (50°C) alkaline solutions while 40,000 sound waves per second scour contaminants from pores – similar to deep-cleaning dental tools.

Static elimination: Ionized air jets neutralize dust-attracting charges, ensuring flawless powder adhesion later

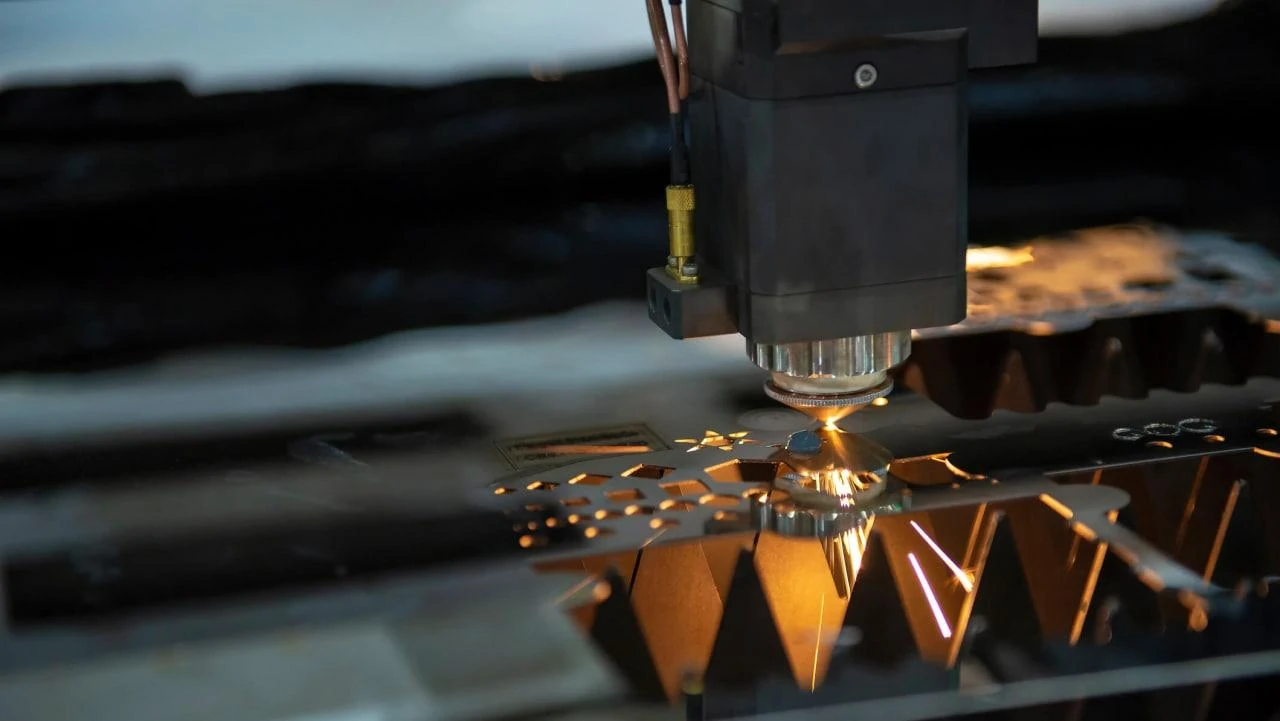

Stage 2: Electrostatic Deposition – Where Physics Reigns

Core principles:

1. Particle charging: Polymer powder (epoxy/polyester) gains negative charge (-50,000 volts) inside the spray gun.

2. Ground attraction: Positively grounded metal pulls powder onto every surface – even threading and 90-degree corners.

Robotic precision for small part

Six-axis arms position spray nozzles within 0.004 inches (0.1mm), adapting to complex curves like door handle contours. Micro-nozzles ensure consistent coverage on parts as small as a thumbtack.

Stage 3: Curing – From Powder to Polymer Armor

Molecular transformation:

Inside 392°F (200°C) ovens:

Powder particles melt into liquid film.

Resins chemically cross-link ("handshake").

Thermoset polymer forms – irreversible armor

Critical control:

Infrared heaters + convection fans maintain ±2°F (±1°C) uniformity – tighter than a commercial pizza oven. Zero solvents mean zero VOC emissions, surpassing EU’s strictest regulations.

Stage 4: The AI Quality Sentinel

Human limitation:

Naked eyes miss sub-0.002 inch (50 micron) defects – smaller than a grain of salt.

Our solution:

4K optical scanners: Capture surfaces under studio-grade lighting.

Deep learning AI: Compares each part against 100,000+ defect references, flagging:

Pinholes (potential salt entry points)

Thin coverage (<60 microns)

Color deviations

Real impact: Prevented early corrosion on yacht fittings by catching 0.004 inch (0.1mm) bubbles.

Why Powder Coating Outperforms Paint

1.For engineers:

Thicker protection: 60-80 micron layers versus paint’s 20-30 microns.

Superior edge coverage: Powder wraps sharp corners paint pulls away from.

Provable durability: 1,000+ hour salt spray resistance (ASTM B117) and 160 in-lb impact strength (ASTM D2794).

2.For procurement teams:

No minimum orders: Batches from 300 pieces.

Rapid color changes: 30-minute line cleans vs. paint’s 2+ hour solvent purge.

Global compliance: REACH, RoHS, and Qualicoat Class 2 certified.

3.For sustainability leaders:

95% powder reuse: Overspray captured via cyclones – annual savings equal 120 dumpsters of waste.

Carbon transparency: QR codes reveal environmental footprint per part.

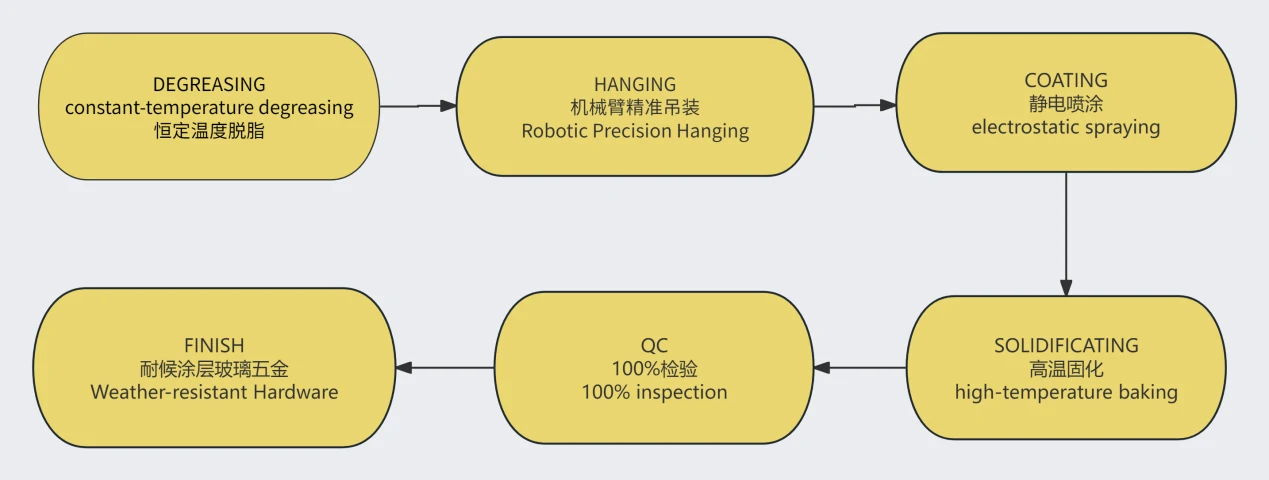

1.Pre-treatment, products enter the constant-temperature degreasing/ceramizing tank. Here, precise chemical treatment effectively removes grease and impurities, laying a solid foundation for the subsequent coloring process.

2.After cleaning, the components are carefully hung for the next surface treatment step.

3. Electrostatic spraying. Under the powerful electrostatic field, the paint is evenly attracted to the surface of the hardware, forming a smooth and fine coating.

4.After spraying, the components enter the high-temperature baking room. Precisely controlled temperature and time cure the coating, achieving optimal hardness and gloss.

5.Finally, our quality control team conducts a rigorous inspection of every single piece to ensure flawlessness.

6. Qualified weather-resistance finished products.

Conclusion

In essence, ALeader's powder coating transforms small metal hardware through electrostatic adhesion and thermal curing into corrosion-defying assets. The result: 60-80μm polymer shields—thicker and more uniform than liquid paint—protecting every thread and recess against salt, chemicals, and UV. With 95% powder reclamation, zero VOC emissions, and batch flexibility down to 300 pieces, we deliver industrial durability with environmental responsibility. Test this science yourself: request samples to witness how molecular-level protection keeps coastal balcony brackets and alpine lodge hinges flawless for decades. This isn't just coating—it's metal's lasting metamorphosis.