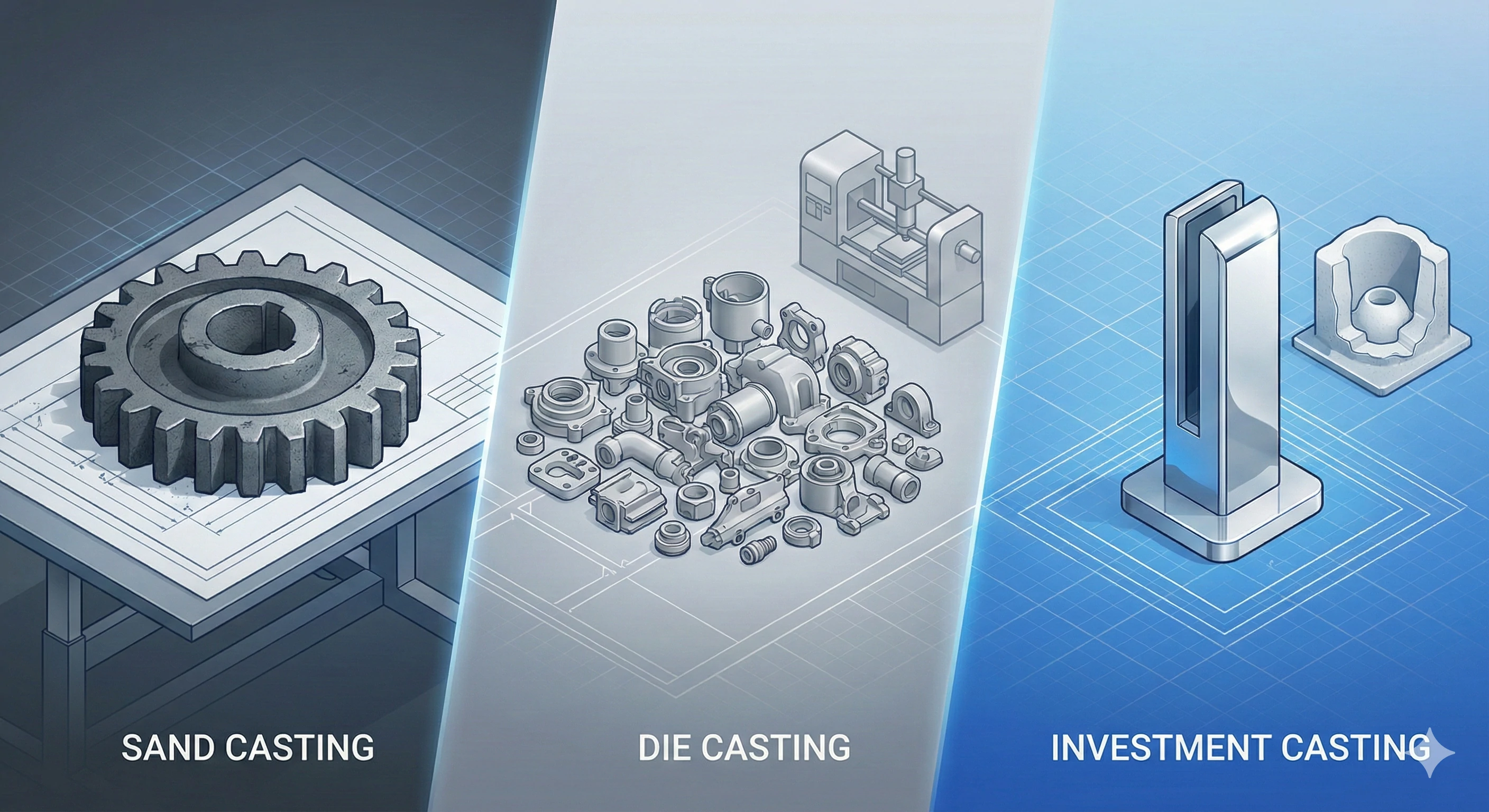

When we receive inquiries at our factory, one of the most common points of confusion involves selecting the right production method. Clients often ask us which casting process is the "standard" or most popular, assuming that the most common method must be the best choice for their specific hardware. However, having analyzed thousands of project requirements—from massive industrial pumps to the delicate glass railing fittings we manufacture—we know that "popularity" is a relative term in .

In terms of total tonnage of metal poured globally, sand casting is the undisputed leader, accounting for over 60% of all metal castings. However, die casting leads in terms of total unit volume for consumer goods, while investment casting is the primary standard for high-precision stainless steel components.

Understanding this distinction is vital for your . Let’s break down the data to help you identify which method actually dominates your specific industry.

1. Sand Casting (The Heavyweight Champion)?

When we look at the raw data of global metal production, the numbers are heavily skewed by massive industrial components. In our interactions with heavy machinery suppliers, we see that projects requiring sheer size and weight almost exclusively rely on one ancient but effective method.

Sand casting dominates the global market by weight, responsible for producing roughly 60% to 70% of all metal tonnage worldwide. It is the number one choice for large-scale iron and steel parts, such as engine blocks and heavy pipe fittings, primarily due to its low tooling costs and material versatility.

Why Sand Casting Moves the Most Metal

While we focus on precision hardware, we cannot ignore the sheer scale of sand casting. It is the "workhorse" of the world. The process involves creating a mold from a sand mixture and then pouring molten metal into the cavity. Once the metal cools, the sand is broken away.

Extreme Versatility

The primary reason this method holds the title for "most widely used by weight" is that it has almost no size limitations. We have seen sand casting used for small 1kg brackets and massive 100-ton ship anchors. If you are manufacturing a massive pump base for a water treatment plant, sand casting is often the only viable option.

Cost Implications

For many of our peers in the heavy industry sector, cost is the driving factor. Sand is cheap, and the tooling required to make the sand molds is significantly less expensive than the hardened steel molds used in other processes.

The "Rough" Reality

However, quantity does not equal precision. The trade-off for this versatility is . As engineers, we know that parts coming out of a sand mold have a rough texture (often compared to sandpaper). To get a smooth finish or tight tolerances, the part requires heavy secondary machining.

Pros and Cons of Sand Casting

| Feature | Advantage | Disadvantage |

|---|---|---|

| Size Capability | Can cast massive parts (tons) | Not suitable for thin-walled small parts |

| Material | Excellent for Iron and Steel | Surface finish is very rough (Ra 12.5+) |

| Cost | Low tooling and startup costs | High machining costs per unit |

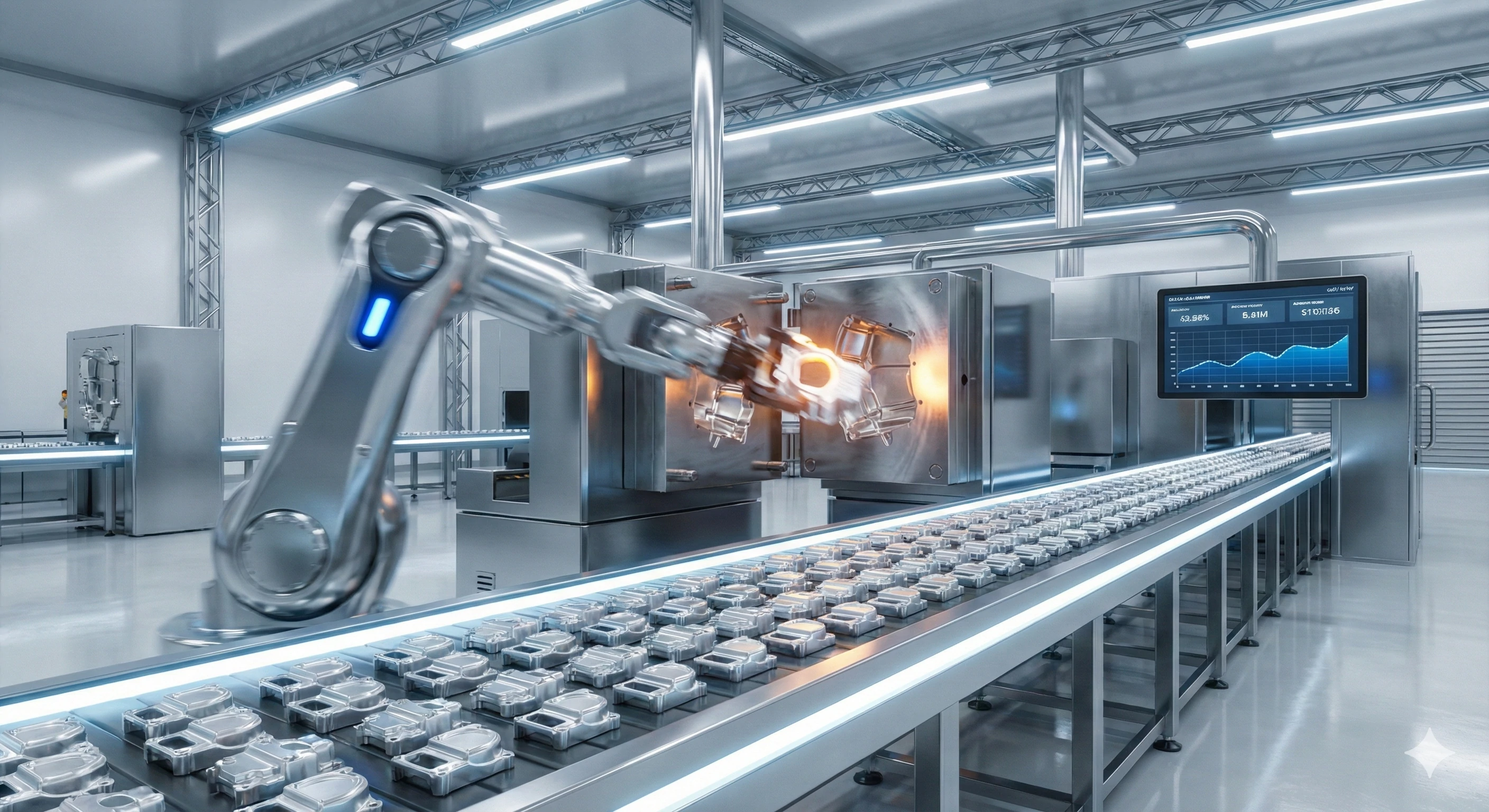

2. Die Casting (The Mass Production King)?

If you look around your office or home, you are likely surrounded by objects made via this method. From the zipper slider on your jacket to the housing of your laptop, these parts are produced in millions. When we source components for non-structural applications, we often look to this method for its incredible speed.

Die casting is the most widely used process for high-volume production of non-ferrous metals like aluminum and zinc. It dominates the market in terms of unit quantity because it is highly automated and can produce parts every few seconds, making it ideal for consumer electronics and automotive housings.

The Speed of High-Pressure Injection

Unlike the slow, manual process of making sand molds, die casting is all about speed and automation. Molten metal is forced under high pressure into a reusable steel mold.

Unit Volume vs. Tonnage

While sand casting wins on weight, die casting wins on count. A single die casting machine can pop out a part every 30 seconds. This is why, if you are making 500,000 toy cars or 100,000 aluminum window frames, die casting is the most economical choice.

The "Steel" Limitation

You might wonder, why don't we use this fast method for our glass hardware? The answer lies in physics. Die casting generally only works with low-melting-point metals:

-

Aluminum

-

Zinc

-

Magnesium

Why You Can't Die Cast Stainless Steel

This is a critical distinction we emphasize to our clients. Steel melts at roughly 1370°C. The molds used in die casting are made of , which melts at a similar temperature. If we tried to die cast stainless steel, the molten metal would weld itself to the mold or melt the tooling entirely. Therefore, despite its popularity, die casting is physically impossible for the stainless steel products we manufacture.

Die Casting Material Suitability

| Material | Suitability | Common Application |

|---|---|---|

| Aluminum | Excellent | Automotive parts, window frames |

| Zinc | Excellent | Zippers, small gears, toys |

| Stainless Steel | Impossible | Requires Investment Casting |

3. Investment Casting (The Precision Specialist)?

This is where our expertise lies. When we develop our glass railing systems and shower hinges, we require a method that handles high-melting-point materials like stainless steel while maintaining architectural beauty. There is really only one contender for this specific set of requirements.

Investment casting is the most widely used method for manufacturing high-precision, complex components from stainless steel and superalloys. While it accounts for less global tonnage than sand casting, it is the industry standard for critical applications requiring tight tolerances, complex internal geometries, and mirror-polished surface finishes.

The Standard for "High-Value" Parts

Also known as casting, this process is less about moving massive amounts of metal and more about crafting specific, high-quality solutions. We use this method for our glass spigots because it allows us to cast stainless steel with incredible precision.

Handling Complex Geometries

One of the reasons we rely on investment casting is the ability to create undercuts and internal channels that sand or die casting simply cannot achieve. We inject wax into a mold, coat the wax in , and then melt the wax out. This ceramic shell can withstand the extreme heat of molten stainless steel.

Surface Finish Excellence

For architectural hardware, aesthetics are non-negotiable. Parts coming out of an investment cast mold have a smooth finish (Ra 3.2 - 1.6) right from the start. This allows us to polish the items to a mirror finish much faster than if we were starting with a rough sand-cast part.

Comparison: Why We Choose Investment Casting

| Feature | Investment Casting Performance |

|---|---|

| Precision | High tolerances (±0.1mm) |

| Finish | Smooth, ready for polishing |

| Material | Perfect for Stainless Steel (304, 316, 2205) |

| Design Freedom | High (allows complex shapes) |

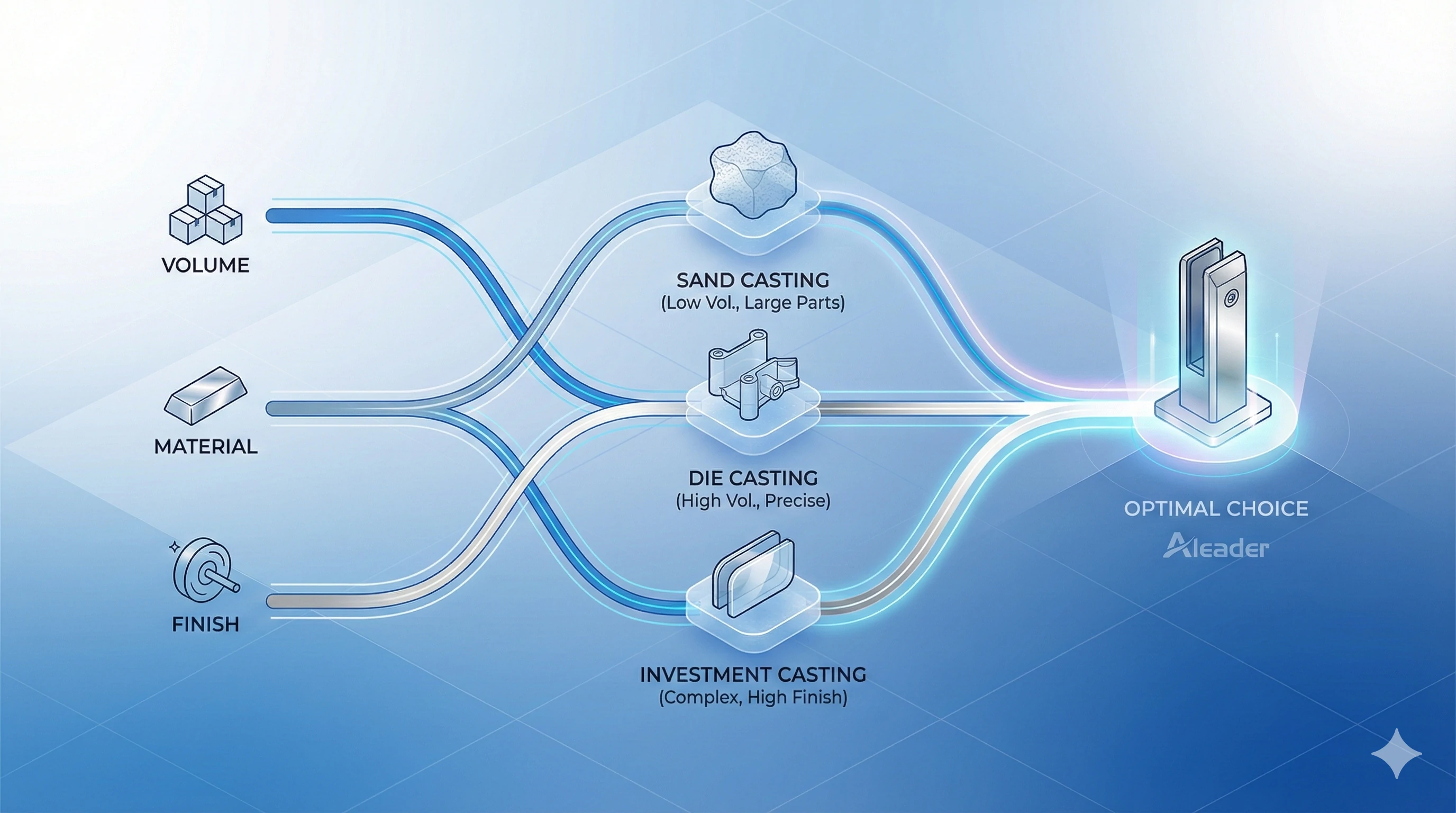

How to Choose the Right Process for Your Project?

Our engineering team often guides procurement managers through this decision matrix. We have found that the "best" process is entirely dependent on three variables: the material you need, the volume you are ordering, and the surface finish you expect.

To choose the right process, you must prioritize your constraints: use sand casting for heavy iron parts and low tooling costs; choose die casting for high-volume aluminum runs to save unit costs; and select investment casting for stainless steel parts requiring precision, durability, and a high-quality aesthetic finish.

The Decision Matrix

We have simplified the decision-making process into three common scenarios we see in the industry.

Scenario A: High Volume, Low Melting Point

If a client comes to us needing 10,000 brackets and they are okay with Aluminum, we point them toward Die Casting. The mold cost is high ($20,000+), but the unit cost will be pennies.

Scenario B: Heavy Industrial, Iron

If a client needs 50 huge pump bases made of Iron, Sand Casting is the answer. It is cheap, handles the weight, and the rough finish doesn't matter for a pump base buried underground.

Scenario C: The "Aleader" Specialty

If a client says, "I need 500 stainless steel glass clamps that must look beautiful and resist corrosion," the only answer is Investment Casting.

The "Big Three" Comparison Table

Below is a summary table comparing these three major processes to help you visualize where your project fits.

| Feature | Sand Casting | Die Casting | Investment Casting (Our Focus) |

|---|---|---|---|

| Global Usage | #1 (By Weight/Tonnage) | #1 (By Quantity/Volume) | #1 (By Precision/Value) |

| Surface Finish | Rough (Ra 12.5) | Good (Ra 1.6) | Excellent (Ra 3.2 - 1.6) |

| Tooling Cost | Low ($) | Very High ($$$$) | Medium ($$) |

| Primary Materials | Iron, Steel | Aluminum, Zinc | Stainless Steel, Superalloys |

| Production Speed | Slow | Very Fast | Medium |

Frequently Asked Questions about Metal Casting?

We often receive emails asking for technical clarification regarding why a certain drawing cannot be produced using a specific method. These questions are crucial for optimizing your and avoiding costly manufacturing errors during the design phase.

The most common questions revolve around the limitations of die casting for steel and cost comparisons. Die casting cannot handle steel due to melting temperatures, sand casting is generally the cheapest for low volumes, and investment casting dates back 5,000 years, making it one of the oldest yet most precise methods.

Why isn't die casting used for steel?

This is the most frequent question we encounter. Clients want the speed of die casting with the strength of steel. However, as mentioned earlier, the physics don't work. Steel melts at ~1370°C. Since die casting molds are also made of steel, the molten metal would destroy the mold instantly. This is why we use Investment Casting (which uses ceramic molds) for all our stainless steel products.

Which casting process is the cheapest?

"Cheapest" depends on your quantity.

-

Low Volumes: Sand Casting is the cheapest because the tooling cost is very low.

-

High Volumes (100k+): Die Casting becomes the cheapest per unit because the high speed offsets the expensive tooling.

-

Value: Investment casting sits in the middle. It isn't the cheapest per pound, but it provides the best value for parts that need to be precise and beautiful without expensive secondary machining.

What is the oldest casting method?

While sand casting is ancient, Investment Casting (Lost Wax) actually dates back over 5,000 years. It was used in ancient Egypt and China to create intricate jewelry and art. Today, we apply that same ancient wisdom to modern industrial manufacturing.

Conclusion

While sand casting moves the most metal globally by weight, and die casting produces the highest volume of units, "widely used" is subjective to your material needs. If your project requires the durability and corrosion resistance of stainless steel combined with architectural precision, Investment Casting is the standard.

Does your project require the precision of Investment Casting? We specialize in high-quality Stainless Steel and Duplex 2205 components. Contact us for a manufacturing consultation to ensure your hardware is built to last.

Footnotes

1. Definition and scope of the study of metallic elements.

2. Overview of networks between companies to produce and distribute goods.

3. Explanation of facilities that produce metal castings.

4. Technical data on measuring surface texture and roughness (Ra).

5. Definition of electronic devices intended for everyday use.

6. Properties of carbon and alloy steels suited for tool manufacturing.

7. Technical datasheet on the properties of Duplex 2205 stainless steel.

8. Historical and technical overview of the lost-wax casting process.

9. Details on the ceramic shell building process in investment casting.