When we review project specifications at our factory in Dongying, we often notice a common point of confusion among procurement managers and contractors: the choice between tempered and laminated glass. We frequently see initial design drawings calling for standard tempered glass in high-rise applications where safety codes strictly demand lamination. This oversight can lead to costly delays when the hardware—like our glass spigots—doesn't match the final glass thickness specified by the local inspector. Navigating terms like "toughened," "interlayer," and "monolithic" can be frustrating when you just want to ensure safety and compliance for your client's balcony or pool fence.

Tempered glass is a single sheet of heat-treated safety glass that shatters into blunt crumbs upon impact, while laminated glass consists of two sheets bonded with a plastic interlayer that holds the pieces together if broken. Tempered is ideal for ground-level pools, whereas laminated is required for fall protection.

In this guide, we will break down the physics, the safety regulations, and the hardware implications to help you make the right purchasing decision.

What is Tempered Glass? (The "Monolithic" Standard)?

In our daily production runs, we process thousands of square meters of through our tempering furnaces. We heat the glass to over 600°C and then blast it with cold air, a process that changes its molecular structure. From our perspective as exporters, tempered glass is the "bread and butter" of the industry—it is cost-effective, durable, and significantly safer than raw annealed glass. However, we often have to remind our clients that while it is strong, it has a specific breakage characteristic that makes it unsuitable for every location on a building site.

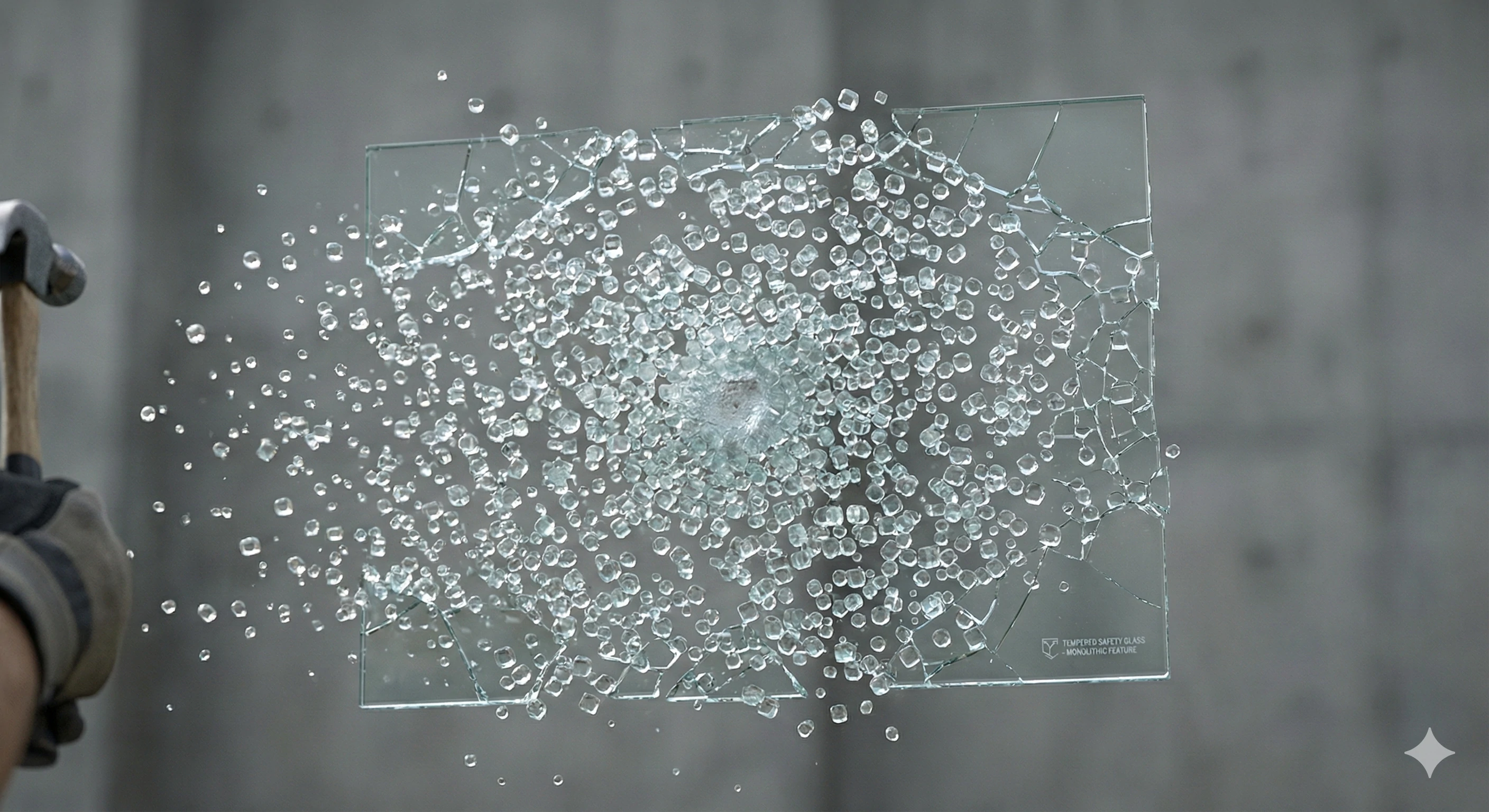

Tempered glass, also known as toughened glass, is a monolithic safety glass processed by controlled thermal treatments to increase its strength compared to normal glass. When broken, it crumbles into small granular chunks instead of jagged shards, reducing injury risk, but leaving an open void in the barrier.

To understand why tempered glass is the standard for so many applications, we need to look at how it behaves under stress. When we manufacture this glass, the rapid cooling creates surface compression. This tension is what gives the glass its incredible strength—roughly 4 to 5 times stronger than untreated glass of the same thickness.

The "Pop" and the Aftermath

The most distinct feature of tempered glass is its failure mode. If you were to strike the edge of a tempered panel with a hammer, the entire sheet would instantaneously shatter. We call this the "pop." The energy stored in the tension layer is released all at once, turning the panel into thousands of tiny, pebble-like crumbs.

From a safety perspective, this is excellent for preventing deep lacerations. If a child runs into a glass door and breaks it, they won't be injured by large, guillotine-like shards. However, from a fall protection perspective, this presents a problem. Once the glass breaks, the barrier effectively vanishes.

Ideal Applications

Because the barrier disappears upon breakage, we generally recommend tempered glass for areas where a "hole" in the fence doesn't result in a catastrophic fall.

-

Swimming Pool Fences: If a panel breaks, the risk is that someone might walk into the pool area, not fall off a cliff.

-

Shower Doors: The primary goal is to prevent cuts, not to stop a fall from height.

-

Partitions: Internal office dividers where wind load isn't a factor.

Structural Limitations

It is important to note that tempered glass is "monolithic"—it acts as a single unit. It lacks the redundancy of laminated systems. If you are procuring materials for a project that involves high wind loads or significant elevation, relying solely on the tensile strength of a single sheet of glass is often a code violation.

What is Laminated Glass? (The "Sandwich" Upgrade)?

When we assemble orders for high-rise balconies or public commercial spaces in Europe and the US, the specifications almost exclusively call for laminated glass. Creating this product involves a different section of our facility where we utilize a "clean room" environment to lay up the glass. We sandwich a specialized plastic interlayer between two sheets of glass and then bond them permanently under high heat and pressure in an autoclave. This process creates a composite material that solves the primary weakness of tempered glass: retention.

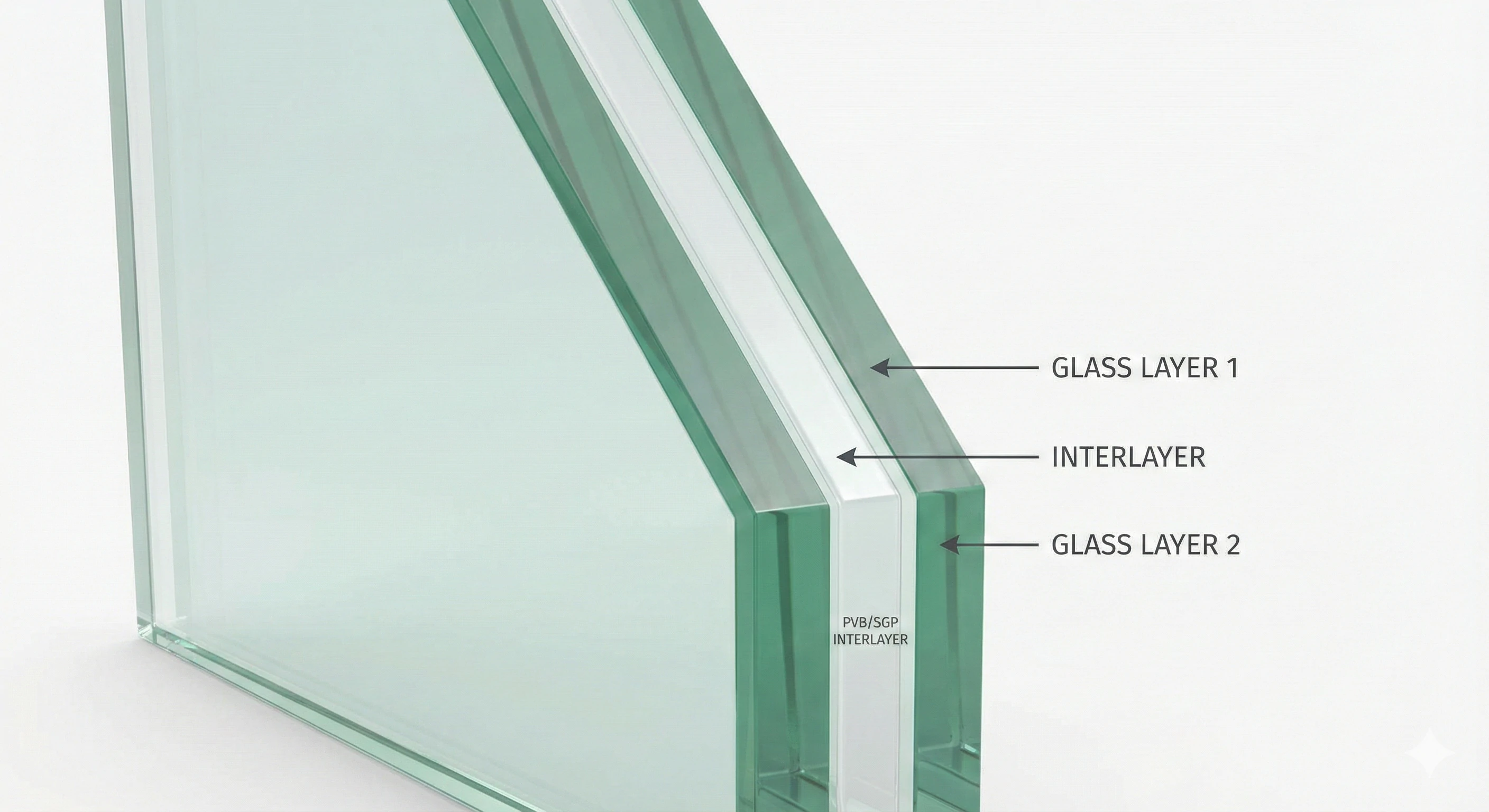

Laminated glass is a safety glazing material made by bonding two or more sheets of glass together with a durable plastic interlayer, usually PVB or SGP. If the glass breaks, the fragments adhere to the interlayer, keeping the panel intact and preventing people or objects from falling through.

Think of laminated glass like the windshield of your car. If a rock hits it, the glass cracks, but it doesn't fly into your face, and the wind doesn't blow through the hole. That is the "sandwich" effect in action.

The "Spiderweb" Breakage Pattern

Unlike tempered glass which crumbles to the floor, laminated glass retains its structure. When impacted, the glass sheets may shatter, but they stay glued to the interlayer. This creates a "spiderweb" pattern. Crucially, the panel remains rigid enough to stay in the railing channel or spigots.

-

Barrier Integrity: The railing continues to function as a barrier even after breakage.

-

Fall Protection: It prevents a person from falling through the glass.

-

Debris Containment: It stops falling glass shards from injuring pedestrians below (vital for overhead canopies).

Composition Variations

We can manufacture laminated glass using different combinations. The most common for railings is Tempered-Laminated. This uses two sheets of tempered glass for strength, bonded with an interlayer.

-

Annealed Laminated: Uses raw glass. If it breaks, it cracks like a window pane but stays held. Used mostly in soundproofing or cutting-stock.

-

Heat-Strengthened Laminated: Stronger than annealed but not fully tempered.

Comparison of Physical Properties

| Feature | Tempered Glass (Monolithic) | Laminated Glass (Tempered-Laminated) |

|---|---|---|

| Structure | Single layer of glass | Two layers + Interlayer |

| Impact Strength | High (4-5x raw glass) | High (Double layer protection) |

| Breakage Result | Crumbles into loose pebbles | Cracks but stays in one piece |

| Barrier After Break | None (Open hole) | Maintained (Prevents falls) |

| Edge Aesthetics | Clean, polished edge | Visible "sandwich" lines on edge |

| Moisture Risk | None | Risk of delamination if edges exposed |

Deep Dive: The Interlayers (PVB vs. SGP)?

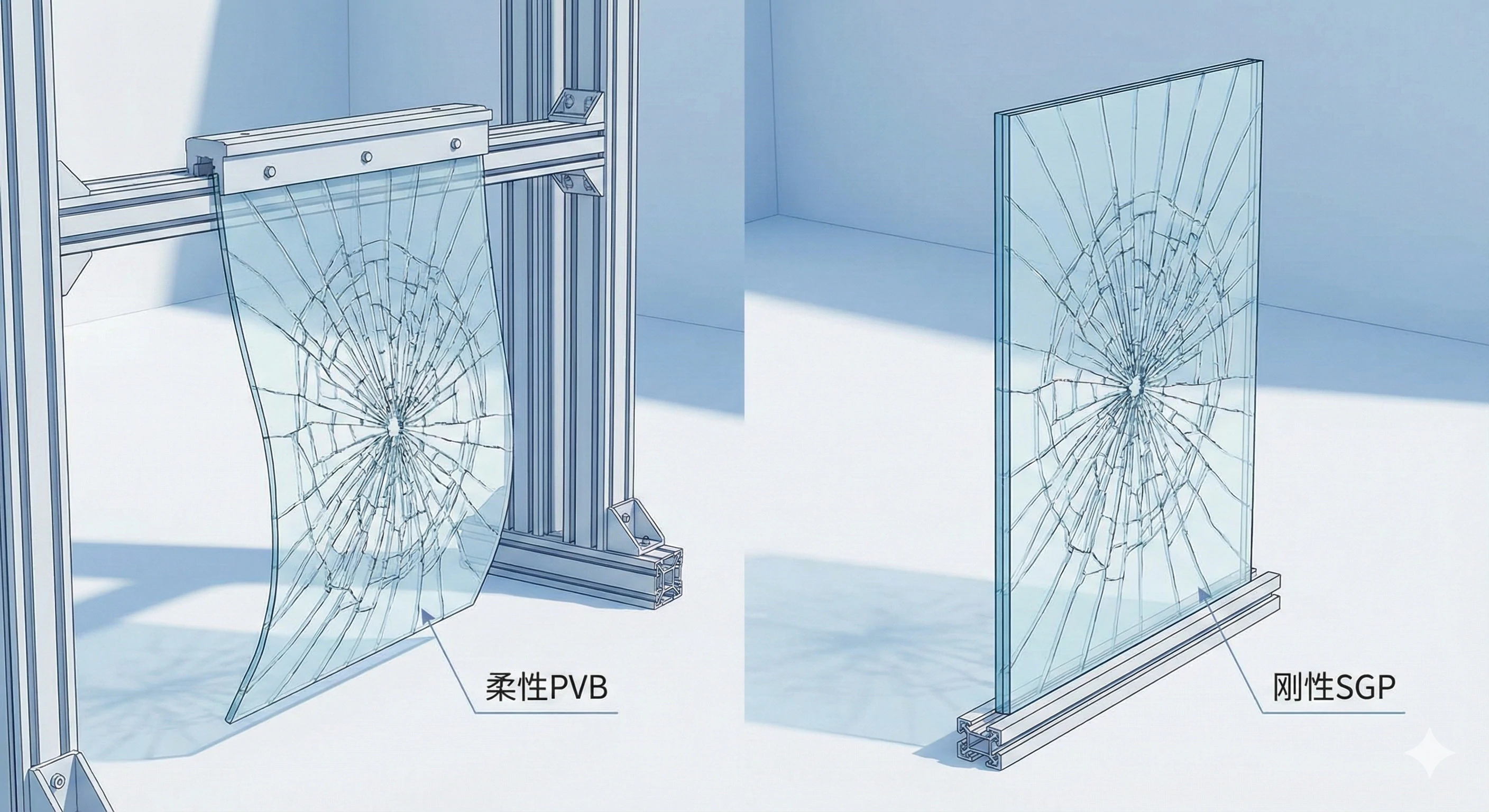

A frequent issue we troubleshoot with our clients involves the specific type of interlayer used. Not all "plastic" middles are the same. We have seen instances where a client specifies a standard interlayer for a frameless railing in a hurricane zone, only to find the panels flapping dangerously in the wind. This usually comes down to the choice between and SentryGlas® Plus (SGP). Understanding this difference is critical when you are importing glass hardware that needs to support heavy, structural loads without a top handrail.

PVB is a standard, flexible interlayer suitable for supported railings, while SGP (SentryGlas) is a rigid ionoplast interlayer that is 100 times stiffer and 5 times stronger. SGP keeps glass standing upright after breakage, making it essential for frameless or high-wind applications.

The choice of interlayer dictates the structural engineering of the entire railing system. It is not just a matter of price; it is a matter of physics.

1. PVB (Polyvinyl Butyral)

PVB is the industry standard. It is soft, flexible, and has excellent sound-dampening properties.

-

The "Wet Blanket" Effect: Because PVB is soft, if both sheets of glass break, the interlayer cannot support the weight of the glass. The panel will fold over like a wet blanket.

-

Usage: PVB is perfectly fine if the glass is fully framed or if there is a structural handrail connecting the panels. The handrail holds the glass up if it breaks. However, for a fully frameless view, PVB can be risky.

2. SGP (SentryGlas® Plus)

SGP is an ionoplast interlayer developed originally by DuPont (now Kuraray). It is a game-changer for architects.

-

Rigidity: It is 100 times stiffer than PVB.

-

Post-Breakage Strength: If both glass sheets shatter, the interlayer is strong enough to hold the glass essentially vertical on its own. It does not fold over.

-

Durability: SGP is more resistant to moisture and yellowing, making it better for open-edge applications near the ocean.

Engineering Your Selection

When we supply glass hardware like our Aleader Hydraulic Hinges or Heavy Duty Spigots, we need to know the interlayer. If you are using SGP, we can often use fewer spigots per meter because the glass itself is acting as a structural beam.

Interlayer Performance Matrix

| Feature | PVB Interlayer | SGP (SentryGlas) Interlayer |

|---|---|---|

| Stiffness | Flexible (Elastic) | Rigid (Structural) |

| Post-Breakage | Collapses/Folds | Remains Upright |

| Moisture Resistance | Average (Can delaminate) | Excellent (Marine grade) |

| UV Resistance | Good | Superior (Non-yellowing) |

| Cost | Standard | Premium (High) |

Building Codes: When Do You HAVE to Use Laminated?

We invest significantly in keeping our team updated on international building standards, specifically the for the US and the NCC (National Construction Code) for Australia. In recent years, we have observed a massive shift in regulations. Previously, tempered glass was acceptable almost everywhere. Now, inspectors are rejecting projects that use monolithic tempered glass in elevated areas. This is a critical detail for procurement managers; buying cheaper tempered glass now might mean tearing it all down later if the code requires lamination.

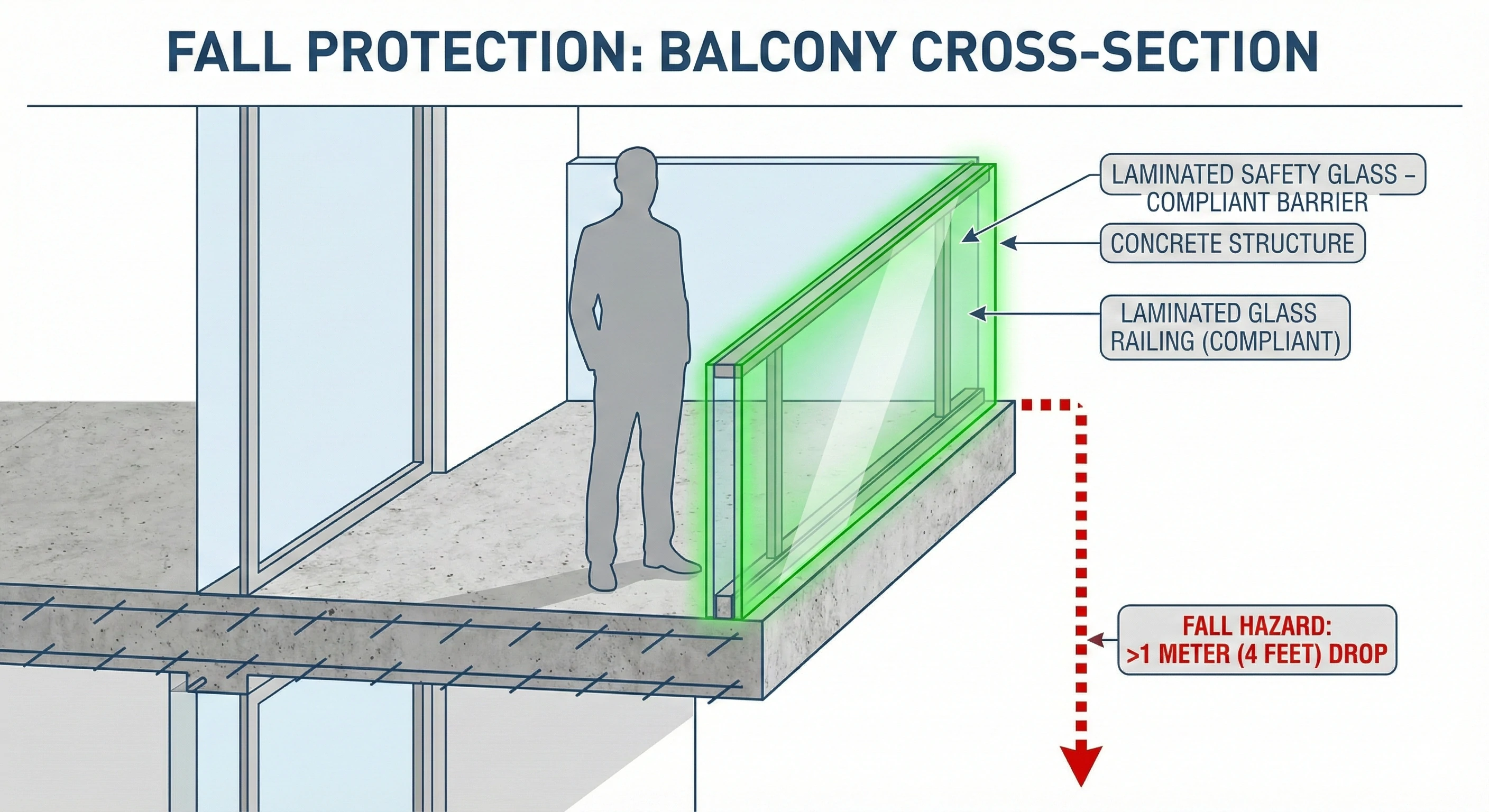

Building codes generally mandate laminated glass for any railing protecting a drop of 1 meter (4 feet) or more where there is no top rail. This ensures that if the glass breaks, the barrier remains in place to prevent a person from falling through the void.

The logic behind these code changes is grim but necessary. There have been incidents where tempered glass on high-rise balconies shattered due to nickel sulfide inclusions (spontaneous breakage) or impact. Once the glass crumbled, people leaning against it lost their balance and fell.

The "Fall Protection" Rule

If the glass is the only thing stopping a fall, it must be laminated.

-

USA (IBC 2015+): Requires laminated glass for handrails and guardrails. There is an exception: you can use tempered glass if there is a top rail that can support the load even if the glass is gone. But for the popular "frameless" look without a metal top cap, laminated is mandatory.

-

Australia (AS 1288): Extremely strict. Any continuous drop requires laminated glass, or a structural top rail that bridges three panels. Please refer to the for specific amendments.

The Overhead Glazing Rule

This is another area where we see confusion. Any glass that is installed overhead (like a canopy, skylight, or pergola roof) must be laminated.

-

Why? If a tempered skylight breaks, 50kg of glass pebbles rain down on people below.

-

The Laminated Solution: If laminated glass breaks overhead, the sheet stays in the frame, protecting the people below until it can be replaced.

Avoiding Rejection at Customs or Site

We always advise our clients to double-check their local amendments. While we manufacture to the highest standard, the "suitability" is determined by the local code. We can mark the glass with the necessary or CE stamps, but the type of glass must be correct for the elevation.

Hardware Compatibility (Why This Matters to You)?

As a manufacturer of glass hardware, this is the section where we see the most practical errors occur on the job site. You cannot simply swap tempered glass for laminated glass and expect the same fittings to work. Laminated glass is thicker and has different chemical properties that interact with our stainless steel clamps and spigots. We often receive urgent emails from installers asking for different rubber gaskets because they didn't account for the extra thickness of the interlayer when ordering their spigots.

Laminated glass is thicker than tempered glass due to the interlayer, requiring hardware with compatible dimensions and gaskets. Additionally, compatibility with chemical grouts is limited, as standard cement can cause the interlayer to delaminate over time.

The devil is in the details. A slight miscalculation in glass thickness can mean the difference between a secure installation and a wobbling panel.

Thickness Creep

Standard tempered glass comes in nice round numbers: 10mm, 12mm, 15mm.

Laminated glass is the sum of the glass plus the interlayer.

-

Common Spec: Two sheets of 6mm glass + a 1.52mm interlayer.

-

Total Thickness: 13.52mm.

-

The Problem: If you bought a clamp designed strictly for 12mm glass, a 13.52mm panel might not fit, or it will compress the rubber gaskets so tightly that the clamp fails.

-

The Solution: We provide Adjustable Spigots and specialized gasket sets (e.g., 13.52mm specific rubbers) to accommodate this variance.

The "Grout" Problem

For base shoe channels, installers often use a cement-based grout to lock the glass in place.

-

Risk: Cement is highly alkaline. If it touches the exposed PVB interlayer at the bottom edge of the glass, it can cause a chemical reaction that makes the plastic turn white and separate from the glass (delamination).

-

Mitigation: When using laminated glass, you must use a or a specific non-expanding grout approved for laminated glass. Alternatively, use dry-glaze mechanical clamping systems (tapers) which avoid chemicals entirely.

Edge Alignment

With monolithic tempered glass, the edge is a single smooth surface. With laminated glass, you have two sheets. During manufacturing, if these two sheets aren't aligned perfectly before the autoclave, you get "offset" or "stepped" edges.

-

Aesthetic Impact: High-end projects require "polished flush edges." We ensure our alignment tolerance is within +/- 1mm to ensure the edge feels smooth to the touch, which is critical for handrails where users run their hands along the glass.

Hardware Checklist for Laminated Glass

| Hardware Component | Issue with Laminated Glass | Solution / Requirement |

|---|---|---|

| Glass Spigots | Slot width is too narrow | Order spigots with 13.52mm or 17.52mm plates/gaskets. |

| Base Shoes | Grout reacts with interlayer | Use mechanical dry-glaze systems or neutral grout. |

| Handrail Tube | Rubber slot is too tight | Ensure the rubber insert is sized for the actual thickness. |

| Glass Clamps | Safety pin hole misalignment | Ensure holes in glass are drilled to accommodate interlayer thickness. |

Cost Comparison?

We understand that price is a decisive factor for our distributors and wholesale partners. When we provide quotes, there is often a "sticker shock" when moving from a standard tempered pool fence to a laminated balcony railing. The manufacturing process for laminated glass is roughly three times longer than tempered glass, involving more energy, expensive raw materials (the interlayer), and lower yield rates. It is vital to communicate the value proposition to your end customers so they understand where the money is going.

Tempered glass is the most affordable base option, while laminated PVB glass costs approximately double, and SGP laminated glass can cost 3 to 4 times as much. This price increase reflects the added manufacturing steps, material costs, and superior safety performance.

While everyone wants to save money, "safety tax" is a non-negotiable part of modern construction.

The Cost Breakdown

Why is the price difference so high?

-

Material: You are literally buying two pieces of glass instead of one. That immediately doubles the raw float glass cost.

-

Processing: We have to polish the edges of two sheets, wash them, assemble them in a clean room (humidity controlled), and run them through an that takes several hours.

-

The Interlayer: SGP is a proprietary material and is significantly more expensive than generic PVB.

Long-Term Value Calculation

When debating the cost with a client, consider the liability.

-

Scenario A: You install cheaper tempered glass on a balcony. It breaks. You have to pay for emergency boarding up, rush-ordering a replacement panel, and labor to reinstall it. Plus, you have the liability risk of the open hole.

-

Scenario B: You install laminated glass. It cracks. The barrier is still safe. You can order a replacement on a standard lead time. No emergency boarding is needed.

Choosing the "Sweet Spot"

For many residential projects, PVB Laminated Glass is the sweet spot. It offers the safety compliance required by code without the extreme cost of SGP. We generally only recommend SGP for:

-

Hurricane/Cyclone zones.

-

Completely frameless railings (no top cap) in high-wind areas.

-

Commercial projects with high crowd loads.

Conclusion

Choosing between tempered and laminated glass is rarely just a stylistic preference—it is usually dictated by safety codes and the physical location of the installation.

-

Choose Tempered Glass for ground-level applications like pool fencing or internal partitions where a fall is not a risk.

-

Choose Laminated Glass for any balcony, mezzanine, or raised deck where protecting human life from a fall is the priority.

-

Check Your Interlayer: Use PVB for standard framed/handrail applications, and upgrade to SGP for high-performance frameless looks.

At Aleader, we don't just bend steel; we help you engineer safe, compliant, and beautiful glass railing systems. Ensuring you have the correct glass specification protects your business from liability and ensures your customers get a product that lasts.

Ordering glass? Make sure you have the right hardware to support it. Shop our Adjustable Spigots for Laminated Glass (fitting 13.52mm - 21.52mm).

Frequently Asked Questions

Is laminated glass stronger than tempered glass?

Not necessarily "stronger" against impact, but it is "safer." Laminated glass is actually two sheets of tempered glass bonded together, so it has the impact strength of tempered glass with the retention safety of the interlayer.

Can I use laminated glass for a pool fence?

Yes, but it is often overkill. Standard tempered glass is the industry standard for pool fencing because the drop risk is low, and moisture can sometimes damage the exposed edges of laminated glass over time (delamination).

What does 6+1.52+6 mean?

This is a common glass code seen on architectural plans. It means: 6mm glass sheet + 1.52mm interlayer + 6mm glass sheet. Total thickness = 13.52mm. Please verify specific thickness requirements in AS 1288 or your local code.

Footnotes

1. History of the float glass manufacturing process. ↩︎

2. Specifications for Saflex PVB interlayers. ↩︎

3. Technical data for structural SentryGlas ionoplast. ↩︎

4. Official site of the International Code Council. ↩︎

5. Access the Australian National Construction Code. ↩︎

6. Certification procedures for safety glazing materials. ↩︎

7. Solutions for structural glazing and weatherproofing. ↩︎

8. Overview of glass heat treatment technologies. ↩︎

9. Articles on glass lamination failure modes.