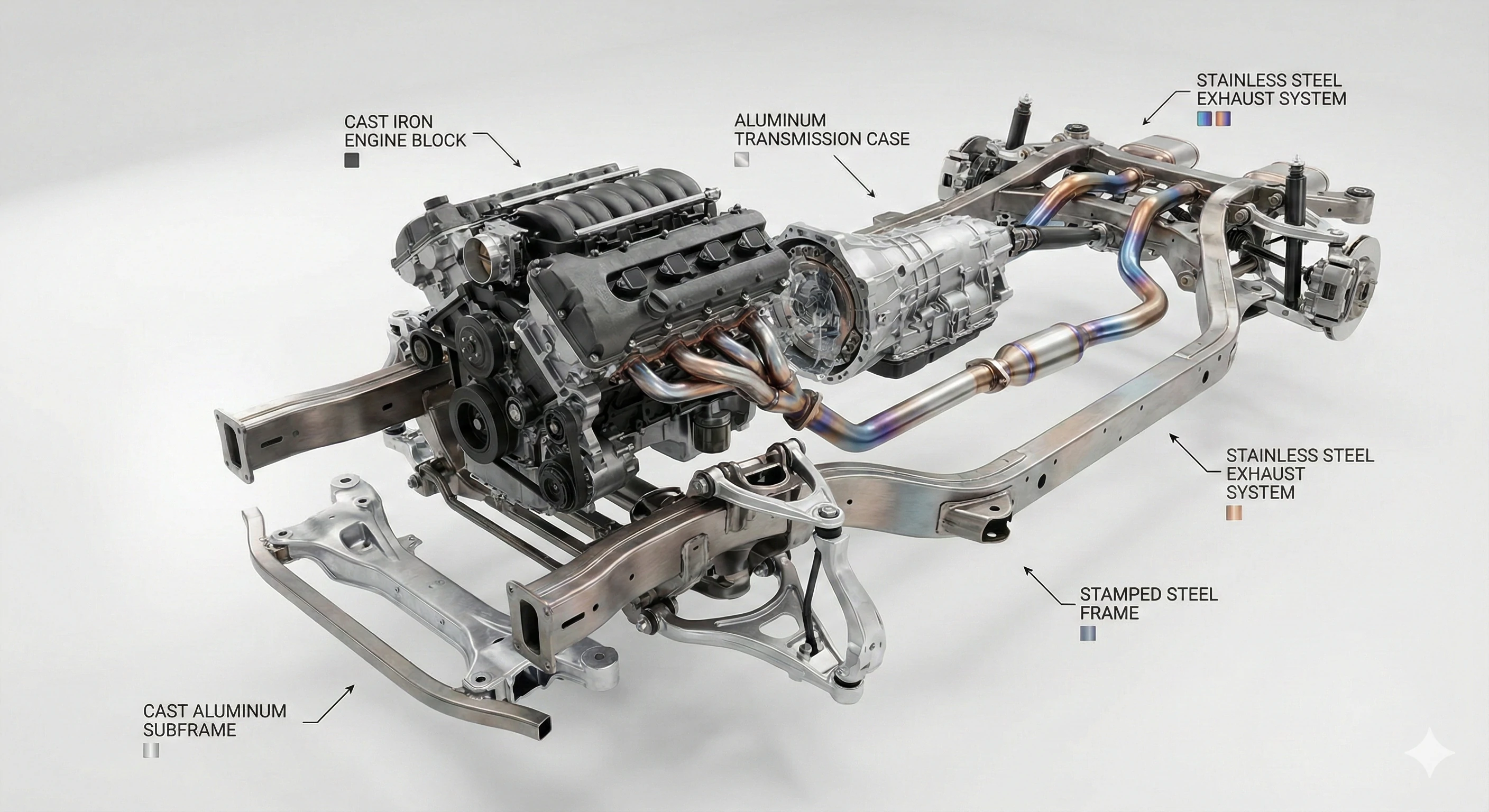

When we analyze the bill of materials for a modern vehicle in our engineering department, we look at over 30,000 individual parts working in unison. From our perspective on the factory floor, the most critical structural and heat-resistant components aren't stamped or machined—they are cast. We frequently guide our clients through the complexity of choosing between sand, die, and investment casting, knowing that roughly 15% to 20% of a vehicle's total weight comes from these liquid metal processes.

Automobile parts made by casting range from massive iron engine blocks and aluminum transmission cases to precision stainless steel exhaust manifolds. Manufacturers utilize sand casting for heavy structural components, die casting for lightweight housings, and investment casting for high-performance, heat-resistant parts like turbocharger wheels and fuel system components.

Let’s break down the vehicle by manufacturing method so you can understand exactly which process builds which part.

1. The Heavyweights: Which Parts Require Sand Casting?

At our foundry, we often describe sand casting to our automotive partners as the "heavy lifting" method. It is not about the highest surface precision; it is about creating massive, durable structures that can withstand the explosion of internal combustion. When we pour grey iron or aluminum into these sand molds, we are typically targeting high-volume production where internal complexity—like coolant passages—is more important than a mirror-like finish.

Sand casting is primarily used for manufacturing heavy engine blocks, cylinder heads, and brake discs (rotors). This method allows engineers to create complex internal voids using sand cores, making it the standard for producing large cast iron or aluminum components that serve as the structural foundation of the vehicle.

To understand the application of sand casting in the automotive sector, we must look at the "heart" of the car. The engine block is the single largest cast component in a standard vehicle. We use or Lost Foam processes here because they are the most cost-effective ways to form the intricate internal geometries required for cylinders and oil galleries. If we tried to machine an engine block from a solid billet, the cost would be astronomical, and the waste material would be unacceptable.

Brake discs (rotors) are another classic example. In our experience, is the material of choice here. It has excellent thermal conductivity and damping capacity. When you hit the brakes, that kinetic energy turns into massive heat. A sand-cast iron rotor absorbs and dissipates that heat without warping, which is vital for safety. While ceramic brakes exist for supercars, the sand-cast iron rotor remains the industry standard for 99% of passenger vehicles.

Below is a breakdown of why we select sand casting for these specific components:

Key Characteristics of Automotive Sand Castings

| Component | Material | Why Sand Casting? |

|---|---|---|

| Engine Block | Cast Iron / Aluminum | Allows for "Cores" to create internal cooling jackets and cylinder cavities. |

| Brake Discs | Grey Iron | Cost-effective for heavy parts; excellent heat absorption properties. |

| Camshafts | Chilled Iron | Creates a hard, wear-resistant surface on the cam lobes while keeping the core tough. |

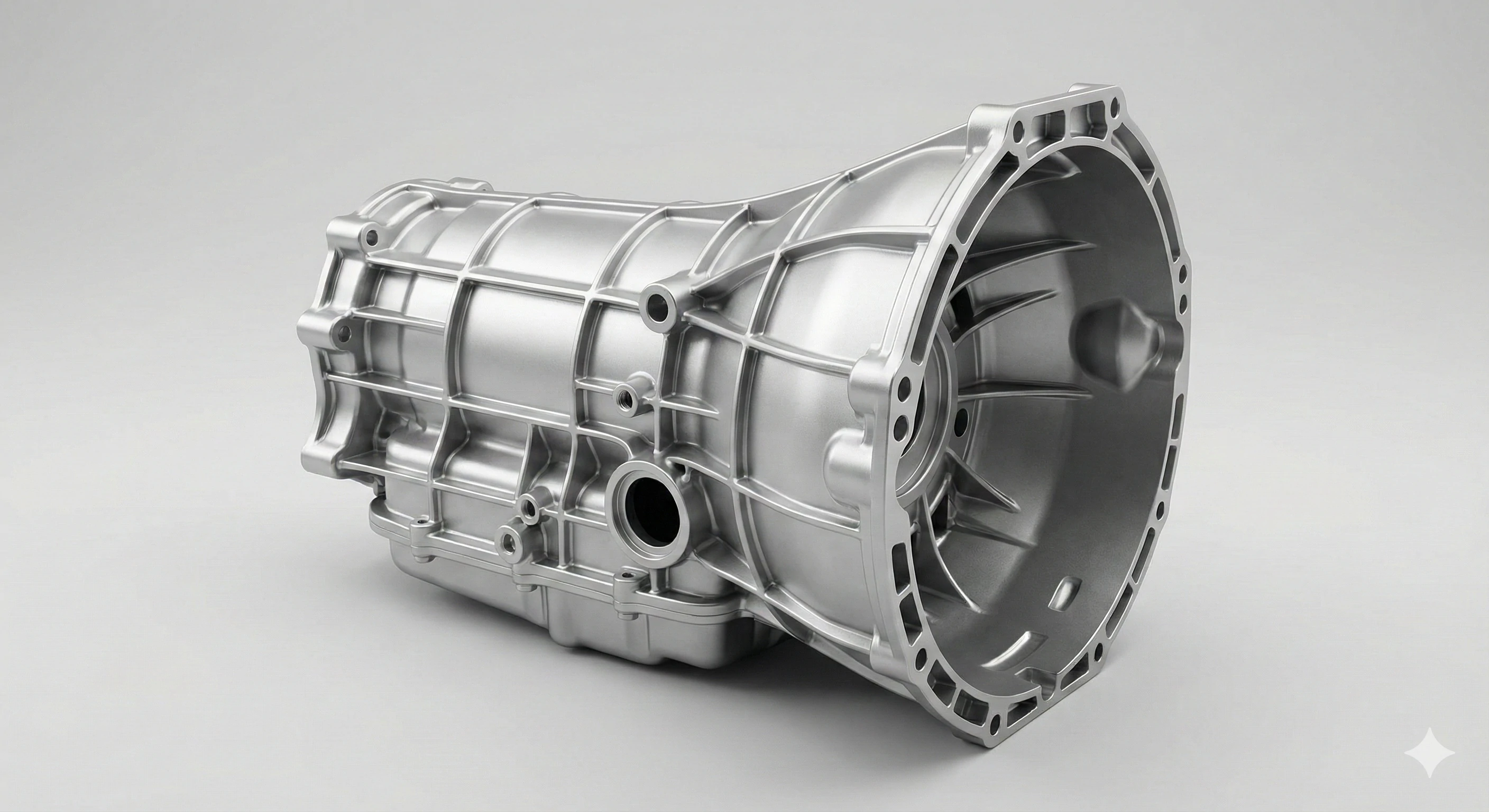

2. The Shells: What Components Rely on Die Casting?

When we shift our focus to the "skin" and housings of mechanical systems, we turn to die casting. In our production planning, we reserve this method for high-speed manufacturing of non-ferrous metals like aluminum, magnesium, and zinc. The cycle times here are incredibly fast—often measured in seconds rather than minutes. We utilize to force molten metal into steel molds, creating parts with thinner walls and tighter tolerances than sand casting can achieve.

Die casting is used to manufacture transmission cases, alloy wheels, and instrument panels. By injecting molten aluminum or magnesium at high pressure, manufacturers produce lightweight, thin-walled housings that protect internal gears and electronics while significantly reducing the vehicle's overall curb weight.

The transmission case is the most prominent die-cast part in a modern car. If you crawl under a vehicle, that complex, silver-colored housing holding the gears is almost certainly aluminum die cast. We prefer this method because it allows us to cast very thin walls (often under 4mm), which is a critical factor in "lightweighting"—the number one buzzword in automotive engineering today. Every ounce saved in the transmission housing improves fuel economy.

Beyond the powertrain, we see zinc die casting ( ) used extensively for cosmetic and functional exterior parts. Door handles, side mirror brackets, and lock mechanisms are typically zinc die cast before being chrome plated or painted. Zinc offers a smooth surface finish that is easy to plate, giving the car a premium feel.

Wheel Manufacturing: Cast vs. Forged

A common question we get is regarding wheels. While high-end racing wheels are forged, the vast majority of OEM alloy wheels are made via . This balances cost and strength.

Die Casting Material Applications

| Material | Typical Automotive Parts | Benefit |

|---|---|---|

| Aluminum | Transmission cases, Engine mounts, Alternator housings | High strength-to-weight ratio; good corrosion resistance. |

| Magnesium | Steering wheel cores, Seat frames, Instrument panels | 33% lighter than aluminum; dampens vibration. |

| Zinc (Zamak) | Door handles, Key fobs, Mirror brackets | High precision; excellent surface for plating/chroming. |

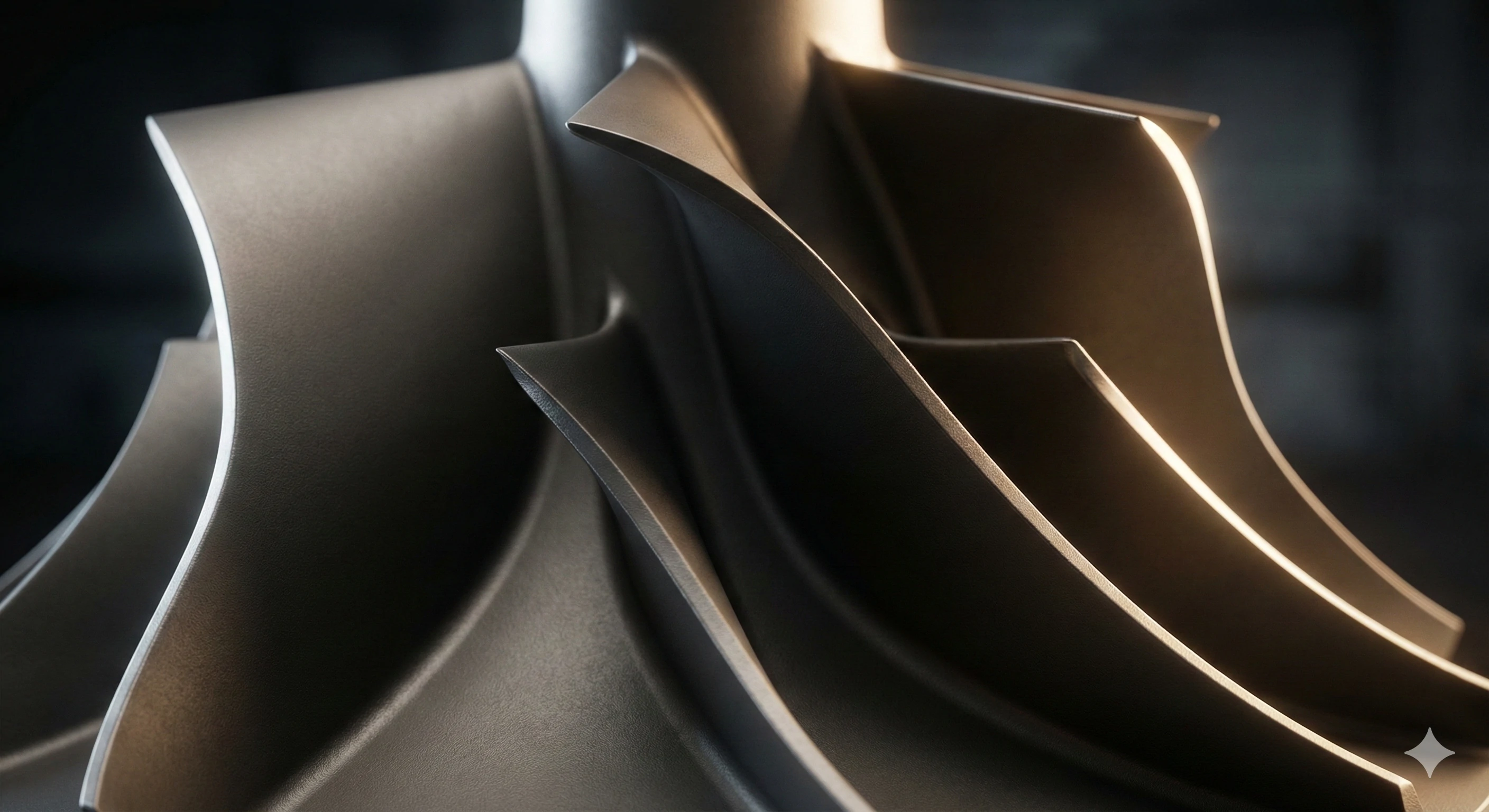

3. The High-Performance Parts: Why Use Investment Casting?

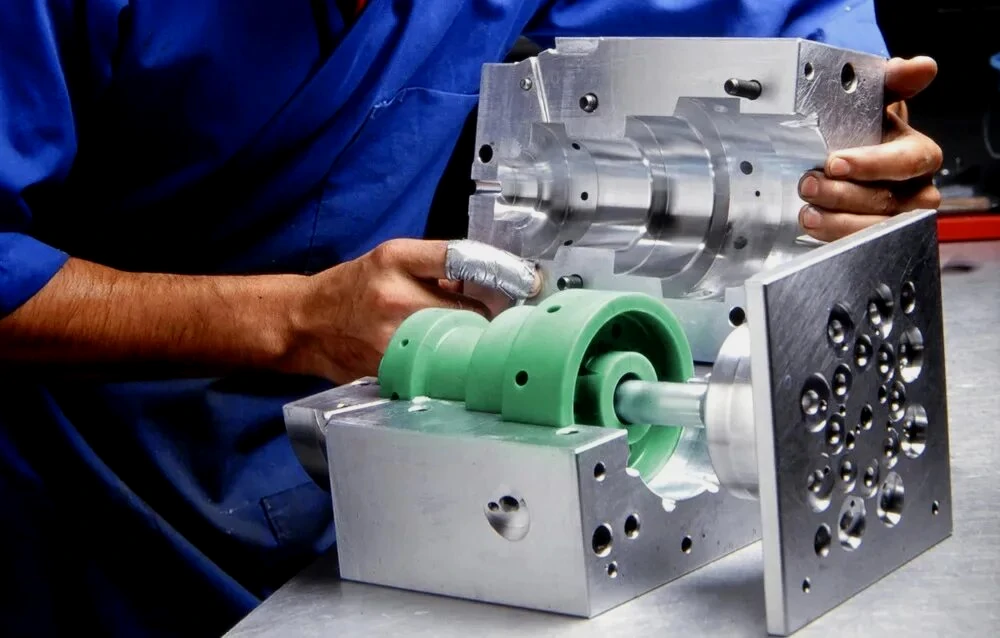

This is where our engineering team gets excited—the realm of high precision and superalloys. We designate (lost wax casting) for parts that must survive extreme environments or require intricate aerodynamic shapes. Unlike die casting, which struggles with high-melting-point metals like steel, or sand casting, which lacks fine surface detail, investment casting allows us to pour stainless steel and nickel-based superalloys with near-net-shape precision.

Investment casting is essential for manufacturing turbocharger wheels, exhaust manifolds, and fuel system components. This process handles high-melting-point alloys like Stainless Steel and Inconel, which are required to withstand temperatures exceeding 900°C and corrosive environments within the exhaust and fuel systems.

The turbocharger turbine wheel is perhaps the ultimate test of casting capability. These wheels spin at over 200,000 RPM while being blasted by exhaust gases at 900°C. We cannot use aluminum (it would melt) or standard steel (it would weaken). We must use vacuum investment casting with (like Inconel). The blades are curved and aerodynamic, a shape that is nearly impossible to machine. Investment casting is the only viable manufacturing method for this critical component.

Exhaust Systems and Valve Bodies

For high-performance exhaust manifolds, we are moving away from cast iron and toward investment cast stainless steel. This shift achieves two things:

-

Weight Reduction: We can cast thinner walls with stainless steel than with iron.

-

Flow Efficiency: The smoother surface finish of investment casting reduces backpressure, helping the engine breathe better.

Furthermore, in the fuel system, cleanliness is godliness. High-pressure fuel pump housings and valve bodies require smooth internal channels to prevent turbulence and fuel contamination. Sand casting leaves a rough surface that could trap debris; investment casting leaves a pristine finish, ensuring the longevity of the fuel injectors.

Strategic Advantages of Investment Casting

-

Design Freedom: We can cast undercuts and complex internal passages that die casting tools cannot release.

-

Material Versatility: We can cast almost any alloy, from carbon steel to exotic superalloys.

-

No Draft Angles: Unlike sand casting, we can minimize draft angles, reducing the need for secondary machining.

4. The Future: How is Casting Changing for EVs?

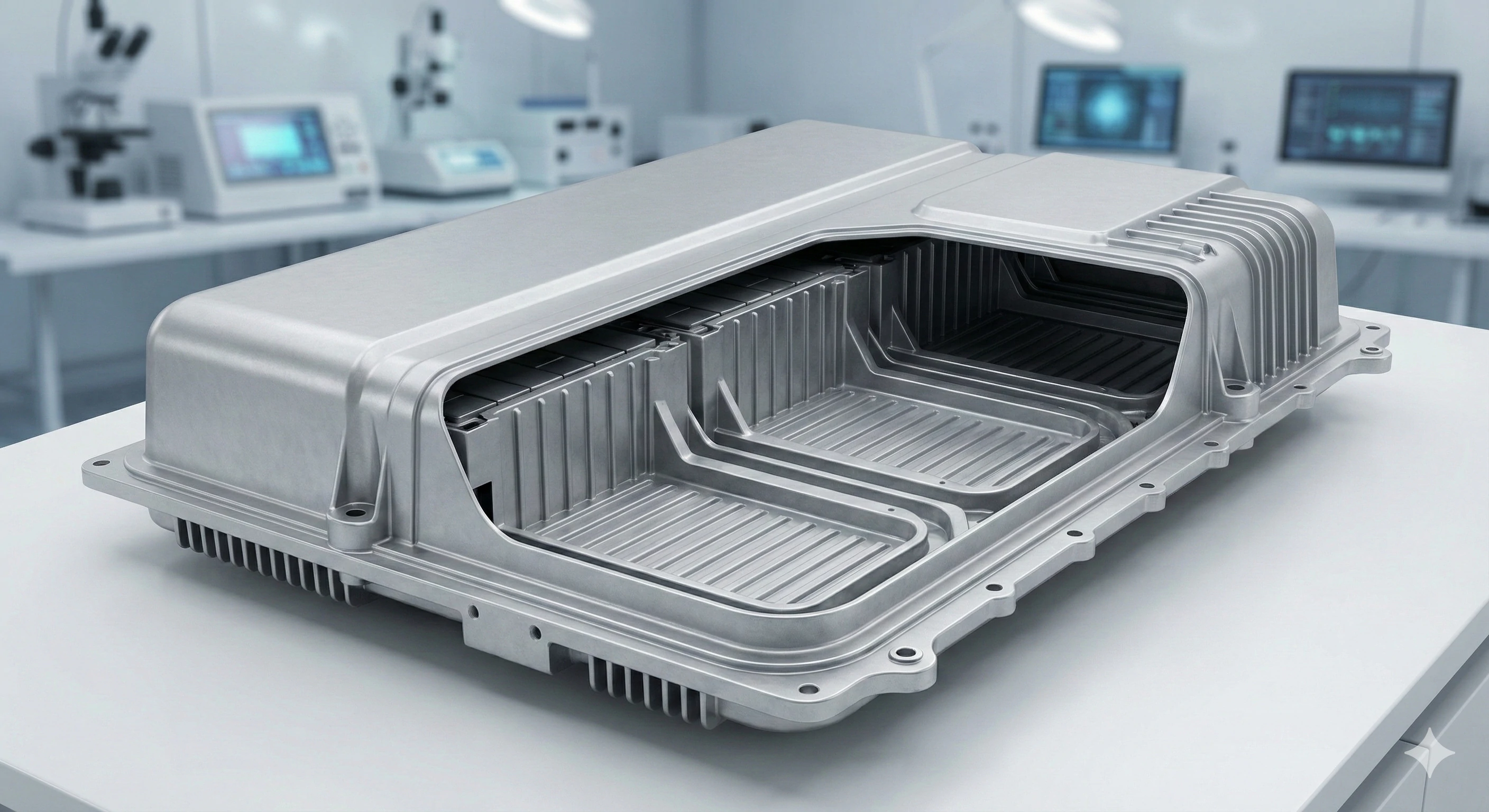

As we adapt our production lines for the Electric Vehicle (EV) revolution, the types of parts we cast are changing, but the volume is not decreasing. The internal combustion engine may be disappearing, but the need for structural integrity remains. We are seeing a massive shift toward structural aluminum castings and specialized copper casting for electrical components. The "engine block" is being replaced by the motor housing, but the foundry remains central to the supply chain.

Electric Vehicles utilize large-scale casting for battery trays, electric motor housings, and structural sub-frames. The industry is trending toward "Gigacasting," where massive sections of the chassis are die-cast as a single piece to replace dozens of welded stamped parts and increase manufacturing efficiency.

The most significant trend we are monitoring is "" , popularized by Tesla. This involves casting the entire rear or front frame of the car in one shot using a massive die-casting machine. This replaces roughly 70 stamped and welded parts with a single casting. For us as manufacturers, this demands stricter quality control and larger machinery, but it drastically reduces assembly time for the automaker.

However, smaller precision parts remain vital. The battery tray, for instance, is often a complex aluminum casting designed to protect the battery modules from road debris and accidents. It serves as a structural member of the car's chassis.

EV Specific Castings

-

Motor Housings: These are the new "engine blocks." They are typically water-cooled aluminum castings that house the stator and rotor.

-

Inverters & Converters: These generate heat and require aluminum heat sinks, which are often die-cast with intricate fin patterns to maximize cooling.

Why Automakers Choose Investment Casting for Critical Parts?

We often have to explain to procurement managers why they should pay a premium for investment casting over other methods. The answer always comes down to the "Triad of Performance": Heat Resistance, Design Freedom, and Weight. When we review a drawing for a new exhaust component or a convertible top mechanism, we assess if the part will face high stress or high temperatures. If the answer is yes, cheaper methods usually fail.

Automakers select investment casting for critical components to achieve superior heat resistance, complex geometries, and significant weight reduction. This method allows for the use of stronger alloys like stainless steel, enabling thinner wall sections that lighter, cheaper casting methods cannot support without structural failure.

Let's look deeper into the "Why."

1. Heat Resistance

You simply cannot die cast steel. The melting point of steel is too high for the reusable metal dies used in die casting—the mold itself would melt or degrade rapidly. Therefore, if a part is part of the exhaust stream (Manifolds, Turbo housings, EGR valves), investment casting is the primary option for high-volume, high-precision steel parts.

2. Design Freedom & Machining

Turbocharger blades have complex 3D curves. Machining these from a solid block is possible but incredibly slow and expensive ( ). Investment casting produces the near-net shape in seconds. We estimate that using investment casting reduces machining requirements by 40-60% compared to sand casting, which offsets the higher initial tooling cost.

3. IATF 16949 Compliance

In the automotive world, quality is non-negotiable. Suppliers like us must adhere to standards. Investment casting offers high repeatability. Once the wax mold injection tool is perfected, every subsequent part is virtually identical. This process stability is crucial for meeting the "Zero Defect" targets demanded by major OEMs.

Casting Method Decision Matrix

| Feature | Sand Casting | Die Casting | Investment Casting |

|---|---|---|---|

| Primary Metal | Iron, Steel, Aluminum | Aluminum, Zinc, Magnesium | Steel, Stainless, Superalloys |

| Precision | Low | High | Very High |

| Surface Finish | Rough (Ra 12.5) | Good (Ra 1.6) | Excellent (Ra 3.2 - 6.3) |

| Tooling Cost | Low | Very High | Moderate |

| Best For | Massive structural parts | High volume housings | Complex, heat-resistant parts |

Conclusion

A modern automobile is a symphony of different casting methods working together. We rely on sand casting for the heavy block, die casting for the lightweight shell, and investment casting for the precision heart of the turbo and exhaust systems.

If you are an automotive supplier looking for high-performance components that meet rigorous industry standards, we specialize in Stainless Steel & Superalloy Investment Casting. Our facility is equipped to handle the complex demands of exhaust, fuel, and turbo systems. Contact our engineering team today for a TS16949/IATF 16949 compliant quote.

Footnotes

1. Explanation of the Green Sand process and its benefits for foundry efficiency.

2. Properties of Grey Cast Iron for thermal conductivity and damping.

3. Overview of the die casting process and high-pressure metal injection.

4. Composition and uses of Zamak zinc alloys in manufacturing.

5. How low-pressure die casting is utilized for high-quality components.

6. Detailed guide to the investment (lost wax) casting process.

7. Technical data on Nickel-Based Superalloys for high-temperature applications.

8. Information on the Giga Press and its impact on car frame manufacturing.

9. Guide to 5-axis machining techniques and their advantages over traditional methods.