3D printing operates on the principle of layer-by-layer deposition, but "building in mid-air" is impossible—any protruding overhanging structures require support, otherwise gravity will lead to print failures. This gives rise to the core guideline in 3D printing design: the 45-Degree Rule. Simply put, if your design includes overhangs (parts sticking out), the angle between the overhang and the vertical should not exceed 45 degrees; otherwise, are a must. This blog breaks down the physics behind the rule, supplements popular science about 3D printing and casting, teaches you to achieve self-supporting prints through optimized design, and reveals seamless transition techniques from prototype validation to metal mass production—saving time and material costs.

The Physics: A Battle Between Gravity and Layer Adhesion (With 3D Printing Core Science)

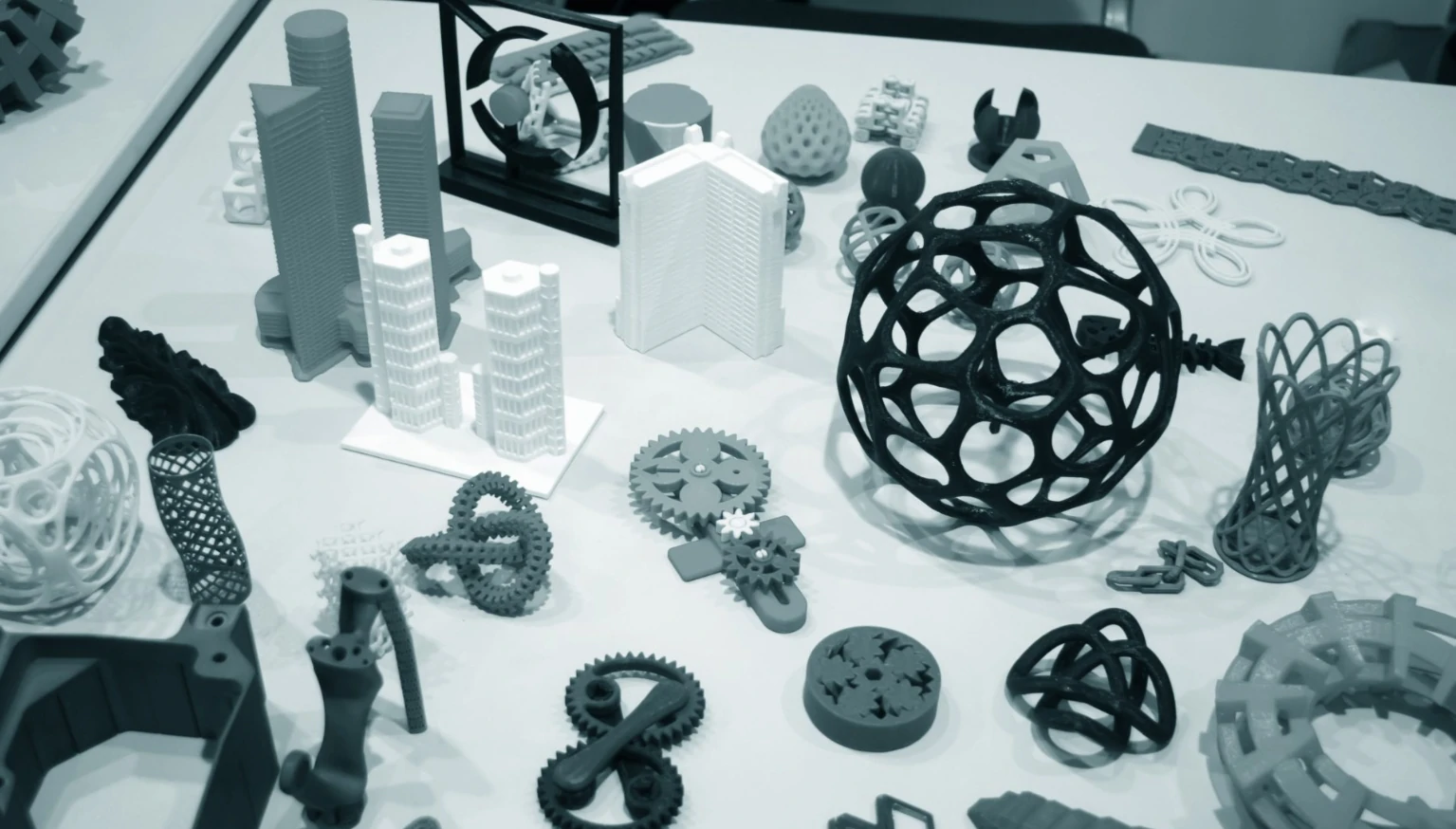

First, let’s clarify a basic concept: 3D printing, also known as (AM), is fundamentally different from traditional "subtractive manufacturing" (such as CNC milling or lathe work, which shapes parts by removing material). It builds objects "layer by layer, from scratch," with the key advantage of quickly producing prototypes of complex structures without the need for intricate molds. Both FDM (Fused Deposition Modeling), the most commonly used technology, and industrial-grade high-precision SLA ( ) rely on stable layer-to-layer bonding. The 45-Degree Rule essentially balances gravity and interlayer adhesion.

1. Underlying Logic of Two Mainstream 3D Printing Technologies (Science Extension)

Among mainstream 3D printing technologies, FDM and SLA are the most widely used. Their molding principles differ significantly, but both follow the core requirement of "layer-by-layer support":

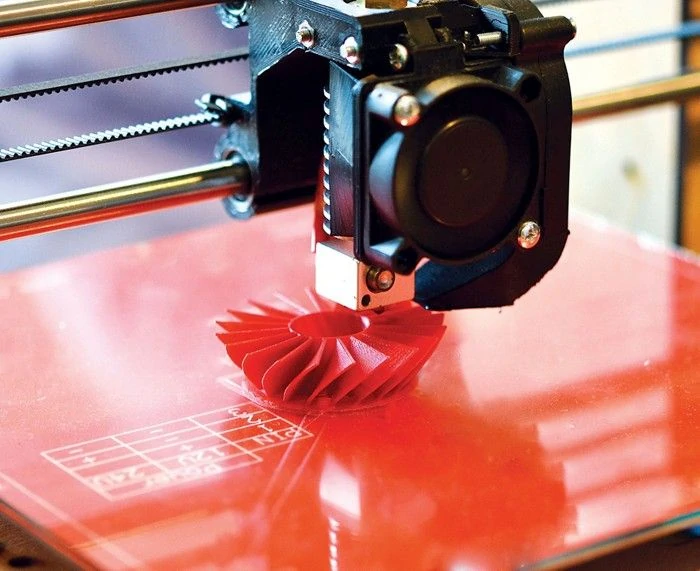

• FDM (Fused Deposition Modeling): The most common technology for consumer and entry-level industrial use, working similarly to "squeezing toothpaste." The printer heats a nozzle to melt like PLA or ABS into a semi-molten state, then extrudes and cools them layer by layer according to the design path to form the final part. Interlayer bonding in this technology relies on the viscosity of the cooled material, making support requirements the strictest—and the 45-Degree Rule most applicable.

• SLA (Stereolithography): An industrial-grade high-precision technology mainly used for precision prototyping. It uses laser light of a specific wavelength to irradiate liquid photosensitive resin, which solidifies instantly. Thanks to fast curing and strong adhesion, it has a higher tolerance for supports but still cannot escape the influence of gravity—large-area overhangs still require adherence to the 45-Degree Rule.

2. The Core Concept of "50% Overlap" (Key to the 45-Degree Rule)

This is the foundation of understanding the 45-Degree Rule and the key to self-supporting 3D prints: when an overhang forms a 45-degree angle with the vertical, each newly printed layer overlaps with at least 50% of the previous layer. This overlap provides sufficient interlayer adhesion to counteract the gravitational pull on the new layer, keeping the structure stable and deformation-free. Conversely, if the angle exceeds 45 degrees (closer to horizontal), the overlap drops below 50%, and gravity’s pull on the new layer surpasses interlayer adhesion. At this point, semi-molten plastic (FDM) or uncured resin (SLA) will sag, curl, or even collapse completely, resulting in print failure.

A real-life analogy helps: a staircase with a 45-degree incline is stable because each step provides adequate support for the one above. In contrast, a nearly horizontal "ladder" lacks effective support for each rung and cannot bear weight—exactly the same principle as overhangs in 3D printing.

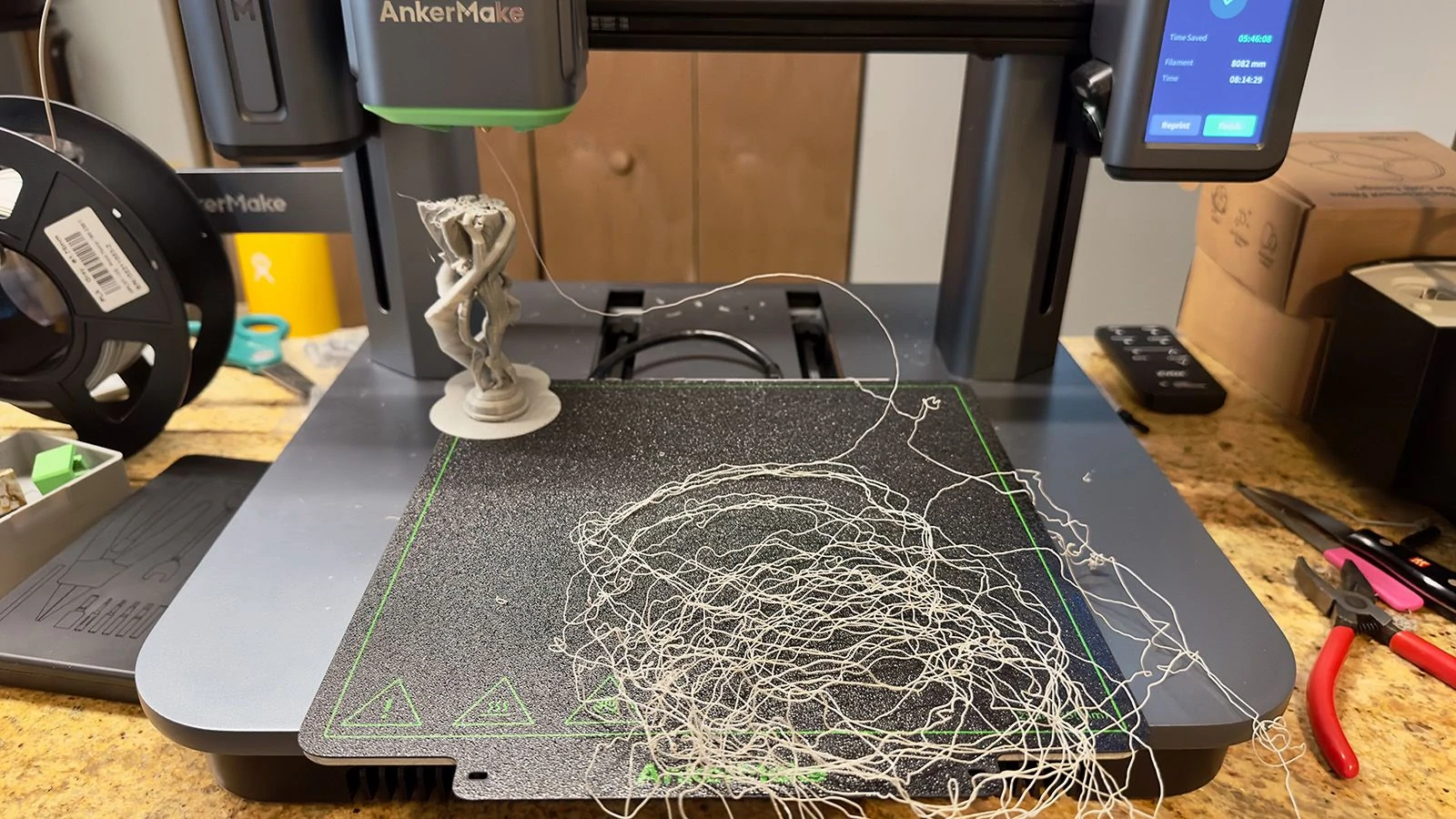

Consequences of Breaking the Rule: Support Structures—The Enemy of Printing

If an overhang’s angle exceeds 45 degrees, 3D printing slicing software (which converts 3D models into printer-readable instructions) will force you to add support structures. Here’s a key science note: supports are temporary auxiliary structures printed to secure overhangs and cantilevers. They serve no functional purpose and must be manually removed after printing— a process that brings unavoidable problems:

1. Wasted Material and Costs

Supports are made of pure printing material, whether FDM’s PLA/ABS plastic or SLA’s photosensitive resin. These materials are "single-use"—once removed, they can only be discarded, not reused. For large or complex parts, support material can account for over 30% of the total material used, significantly increasing printing costs.

2. Extended Printing Time

Printing supports adds extra workload for the printer, typically increasing total print time by 20%-50%. For complex parts with multiple overhangs or undercuts, support printing time can even exceed that of the part itself, seriously delaying R&D progress or small-batch production. This is one of the core reasons 3D printing excels at prototyping but not mass production.

3. Compromised Surface Quality

Supports attach tightly to the part, and their removal inevitably leaves ugly "scars," burrs, or rough patches on the surface. These imperfections require additional manual sanding and polishing, increasing labor costs and risking dimensional deviations from over-sanding—especially for precision prototypes, such damage may render them unusable for validation.

Design Solution: Chamfers vs Fillets

To avoid supports caused by violating the 45-Degree Rule, you don’t need to modify the part’s core functionality. A simple design optimization—prioritizing chamfers over fillets—eliminates the need for supports entirely, making it a key technique in 3D printing design.

1. Drawbacks of Fillets (Rounded Edges)

Fillets are common curved transitions in part design, used to avoid sharp edges and improve ergonomics. However, in 3D printing, fillets become "troublemakers." Since fillets are curved, their top gradually approaches the horizontal (nearing a 90-degree angle with the vertical), inevitably violating the 45-Degree Rule. For example, a fillet transition between a part’s base and side will form a distinct overhang when printed to the top of the curve. The slicer will force support addition, and removing these supports will leave scars on the fillet surface.

2. Advantages of Chamfers (Angled Edges)

Chamfers are straight 45-degree transitions. Compared to fillets, their greatest advantage is full compliance with the 45-Degree Rule, enabling self-supporting printing without any supports. Structurally, each layer of the receives over 50% overlapping support from the previous layer, ensuring stable interlayer bonding and no sagging or deformation during printing. Aesthetically and functionally, printed chamfers have a smooth, clean surface that requires no post-processing sanding or polishing, directly meeting prototype validation or basic usage needs.

Design Tip: For 3D printing applications, prioritize 45-degree chamfers for edges prone to overhangs—such as part bases, overhang transitions, and hole perimeters. This avoids support-related issues while maintaining structural integrity, achieving two goals at once.

Exception: Bridging Technology (Special 3D Printing Technique Explained)

Not all near-90-degree horizontal structures require supports. is a key exception to the 45-Degree Rule and a common special molding technique in 3D printing. Let’s clarify the core definition: bridging refers to printing horizontal spanning structures between two fixed anchors (similar to a bridge)—such as hollow holes in parts or horizontal connections between two columns.

1. Applicable Conditions for Bridging

Bridging is not universal; it has strict limitations, with span being the most critical. It only works for short spans, typically 5mm-10mm (the exact upper limit depends on printing material and printer precision). The molding principle is simple: the printer stretches material evenly between two fixed anchors like "pulling a tightrope." In FDM, the material cools and solidifies quickly; in SLA, the resin is instantly cured by the laser, forming a stable bridge structure.

If the span exceeds 10mm, the material will sag significantly under its own weight, causing deformation or collapse of the bridge—still requiring support structures. Additionally, the surface quality of bridges is usually slightly lower than other parts; if high surface smoothness is required, light sanding after printing is necessary.

From Prototype to Mass Production: Seamless Integration of 3D Printing and Casting (Industrial Application Science)

The 45-Degree Rule constraint mainly applies to prototyping. When transitioning from prototypes to metal mass-produced parts, this limitation can be easily overcome with casting technology— the mainstream industrial workflow of "prototype validation + mass production." Below, we explain key related knowledge and our specialized services for clients.

1. Mainstream Industrial Workflow: 3D Printed Prototype → Casting Mass Production

Many clients first create prototypes via 3D printing during product R&D. On one hand, 3D printing quickly transforms 3D design files into physical prototypes at low cost and short lead times, facilitating validation of dimensions, assembly accuracy, and usability. On the other hand, if the prototype has design flaws, the 3D file can be quickly modified and reprinted, significantly shortening R&D cycles. Once the prototype is validated, clients send their 3D design files to us for mass production of metal parts via — a process that perfectly combines the "speed and flexibility" of 3D printing with the "efficiency of mass production" of casting.

2. Technology Comparison Science: Limitations of 3D Printing vs. Advantages of Casting

The core differences between 3D printing and Investment Casting lie in overhang handling, materials, mass production efficiency, and structural complexity. Understanding these differences helps you choose the right production method:

• Overhangs: 3D printing is constrained by the 45-Degree Rule, requiring supports for steeper angles. Investment casting has no angle limitations, easily accommodating complex overhangs, undercuts, and hollow structures without support concerns.

• Materials: 3D printing primarily uses plastics and resins; metal 3D printing exists but is extremely costly and inefficient. Investment casting can produce parts from stainless steel, , aluminum alloys, copper alloys, and other metals, meeting industrial strength requirements.

• Mass Production: 3D printing’s layer-by-layer process makes it inefficient and costly for mass production, suitable only for small-batch prototyping. Investment casting enables mass production via molds, with higher efficiency and decreasing costs as production volume increases— ideal for large-scale manufacturing.

• Structural Complexity: 3D printing is limited by supports and angles, unable to achieve overly complex internal structures. Investment casting can accurately replicate complex designs via wax patterns, even internal hollows and intricate curves that 3D printing struggles with.

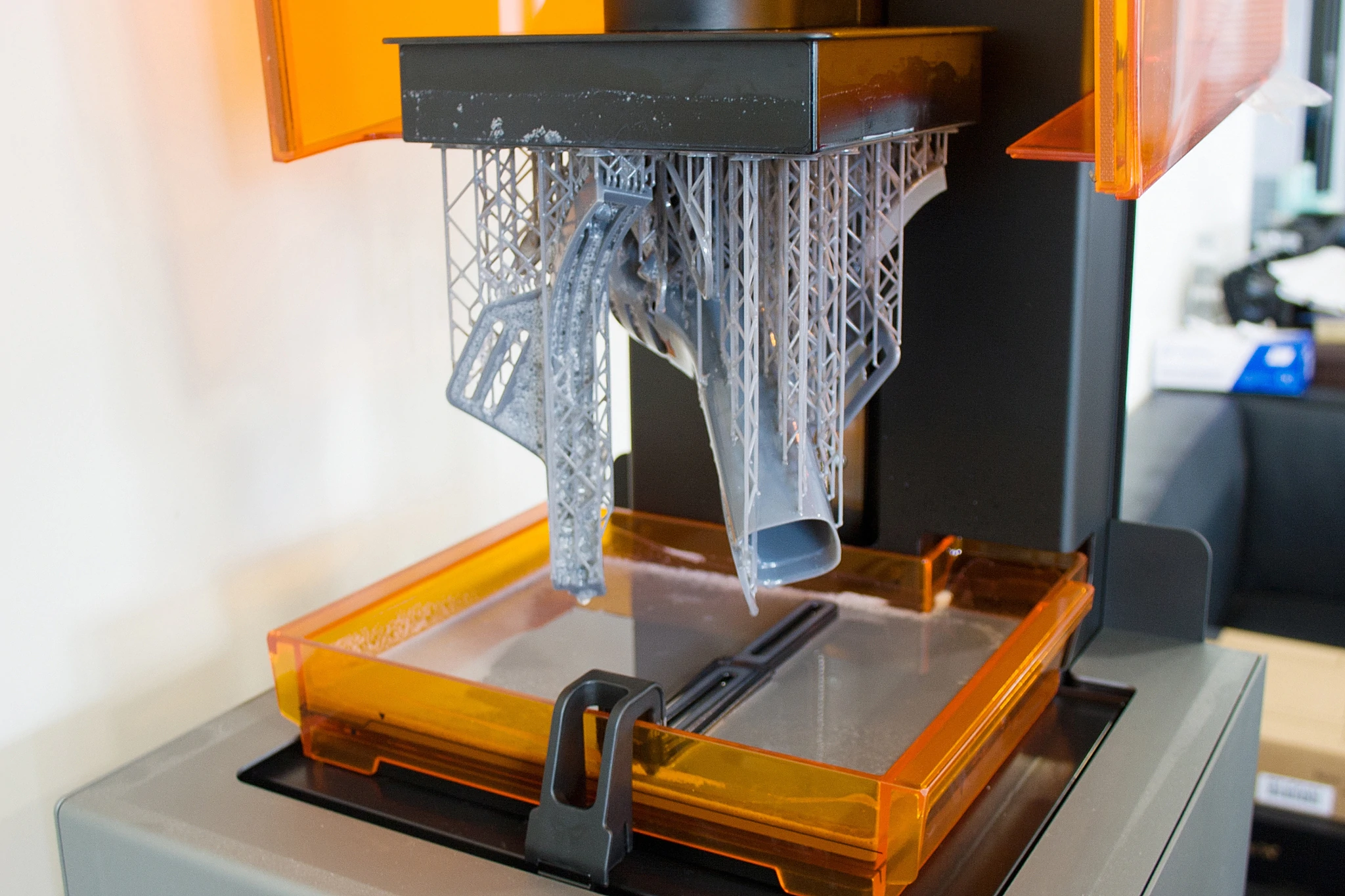

3. Our Specialized Service: SLA Wax Pattern Printing (Core Technology Linking 3D Printing and Casting)

Let’s introduce a specialized SLA application: SLA wax pattern printing— the core technology we use to bridge 3D printed prototypes and Investment Casting. Traditional Investment Casting requires metal molds to produce wax patterns. In contrast, our SLA wax pattern printing directly converts clients’ 3D design files into wax patterns ready for casting, eliminating the need for metal molds. The key advantage: even if supports are required for wax pattern printing, both the wax pattern and supports melt completely during the subsequent casting process (known as "" ), leaving no residue on the final metal part. This means clients don’t need to modify complex 3D designs— even those with numerous overhangs or undercuts violating the 45-Degree Rule. We seamlessly transform digital files into metal finished products, bridging prototype validation and mass production while significantly shortening R&D and production cycles and reducing costs.

Frequently Asked Questions (FAQ)

1. Does the 45-Degree Rule apply to SLA 3D printing?

Yes, but SLA is more forgiving. Thanks to instant resin curing via laser, SLA printers can typically handle overhangs at 30-40 degrees from horizontal (50-60 degrees from vertical). However, large-area, large-size overhangs still require supports due to "peel force" (the force required to separate cured resin from supports), which can cause delamination or detachment.

2. How to measure overhang angles in CAD software?

In mainstream CAD software like or Fusion 360, overhang angles are measured relative to the vertical axis (Z-axis, the direction of 3D printing layer deposition): 0 degrees is a vertical wall (no overhang), 90 degrees is a horizontal top (full overhang), and 45 degrees or less is the "safe zone" requiring no supports. Angles exceeding 45 degrees need careful design or support optimization.

3. Can I print 90-degree overhangs without supports?

Only if the structure is a "bridge" (anchored on both ends) with a span ≤5-10mm. Cantilever structures (anchored on one end only) will collapse immediately without supports, regardless of span.

4. Why can Investment Casting wax patterns ignore the 45-Degree Rule?

Because wax patterns use different molding principles than 3D printing. Wax patterns are typically produced via injection molding or SLA printing and melt completely during subsequent casting, so interlayer adhesion is irrelevant. Casting relies on "liquid metal filling molds"— as long as the mold can replicate complex structures, liquid metal will fill them, eliminating the need for the 45-Degree Rule.

Conclusion

The 45-Degree Rule is the "law of gravity" for 3D printing design. Following it avoids material waste, time loss, and surface defects caused by supports, enabling efficient prototype production— a core skill for every 3D printing designer and product developer. However, when transitioning prototypes to metal products or designing parts with complex overhangs/undercuts, there’s no need to compromise: Investment Casting easily overcomes 3D printing limitations for mass production. Our SLA wax pattern printing service directly connects 3D design files to casting, eliminating intermediate steps.

If you’ve completed 3D printed prototype validation and are ready to transition to metal mass production, send us your STL/STEP design files. We’ll provide accurate casting quotes and professional design optimization advice!

Footnotes

1. The role of support structures in maintaining stability during printing.

2. Overview of additive manufacturing technologies and industrial applications.

3. How stereolithography uses light to cure liquid resin.

4. Properties of thermoplastic materials used in FDM printing.

5. Engineering definition of chamfers and their design utility.

6. Techniques for printing horizontal spans without support structures.

7. Industrial process guide for precision investment casting.

8. Characteristics and applications of Duplex 2205 stainless steel.

9. Historical and technical overview of the lost-wax casting method.