Investment casting is expensive because it is a labor-intensive, multi-step process requiring high-grade ceramic materials and significant energy consumption. Unlike mass-production methods, it demands a sacrificial wax pattern for every single unit and a 7-day shell-building cycle, but this upfront cost eliminates expensive machining and finishing later.

To help you make an informed procurement decision, let’s break down exactly where that money goes. We want to show you the "hidden" engineering and labor that turns raw metal into a near-net-shape component.

Factor 1: The "One-to-One" Ratio (The Wax Pattern)?

When we plan production for a new order of stainless steel spigots, our first step is not melting metal, but creating wax replicas. This stage often surprises clients who are used to other manufacturing methods. You might be wondering why we spend so much time handling fragile wax pieces before we even touch the steel. The answer lies in the unique "sacrificial" nature of this casting method, which directly impacts the initial cost structure.

The primary cost driver here is that for every single metal part you order, we must inject, assemble, and eventually destroy a unique wax pattern. Unlike die casting, where a permanent mold produces thousands of parts rapidly, investment casting consumes the mold every time, requiring continuous material and labor input.

The Inefficiency of Perfection

In our workshop, we refer to this as the "one-to-one" rule. If you order 1,000 glass clamps, we must physically create 1,000 individual wax patterns. This is fundamentally different from high-speed processes like . In die casting, you bolt a steel mold into a machine, and it shoots out parts every few seconds. The mold stays there, untouched and reused.

In investment casting, the "mold" is the wax pattern itself. To get your final steel part, we must melt that wax away—destroying it completely. This means we are effectively building a tool and destroying it for every single unit we sell you. This consumes significant amounts of wax material, which is not cheap, and requires delicate handling.

The Assembly Labor

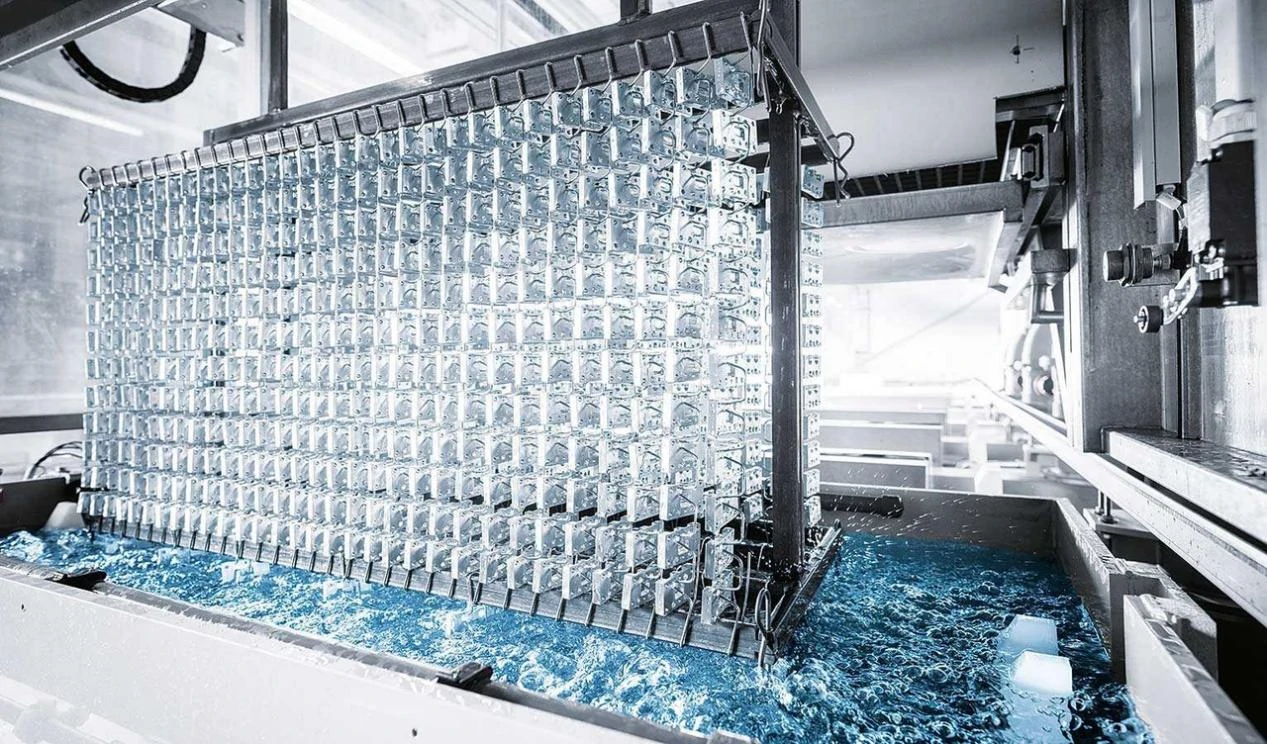

It is not just about the material; it is about the hands-on labor. After we inject the wax, our technicians must manually assemble these patterns onto a "tree" or sprue. This is not a job for robots. It requires a human eye to ensure the spacing is correct so the ceramic shell can coat every crevice. If we rush this, the casting fails. This manual assembly adds a layer of cost that automated processes simply do not have.

Comparison of Mold Usage

To visualize why this drives up the price, look at how the tooling usage differs between methods:

| Feature | Investment Casting | Die Casting |

|---|---|---|

| Mold Lifespan | 1 Cycle (Destroyed every time) | 100,000+ Cycles (Permanent) |

| Pattern Material | Wax (Consumed continuously) | None (Direct metal injection) |

| Labor Intensity | High (Manual tree assembly) | Low (Automated ejection) |

| Best For | Complex, low-to-medium volume | Simple, high volume |

Factor 2: The Shell Building Process (Time & Labor)?

Walking through our drying room, you would notice rows of wax trees coated in ceramic, sitting in temperature-controlled silence. It looks like nothing is happening, which can be frustrating when you are in a rush for delivery. However, this silent waiting period is the most critical bottleneck in the entire process. You might ask, "Why can't you just speed up the drying to lower the cost?"

Building the ceramic shell is a slow, repetitive process that cannot be rushed without ruining the casting. We must dip the wax tree in slurry and sand it 5 to 8 times, allowing each layer to dry perfectly for days, which ties up valuable factory floor space and labor.

The Art of Dipping and Sanding

We cannot simply dip the wax tree once and pour molten steel into it. The shell needs to be strong enough to hold 1600°C liquid metal without cracking. To achieve this, our workers dip the wax tree into a , then coat it with sand. This is just the first coat. We have to repeat this process 5 to 8 times depending on the size and complexity of the part.

The Cost of Time

Here is where the hidden cost lies: drying. Between each dip, the shell must dry completely. If we dip a wet shell, the moisture gets trapped. When the molten metal hits that moisture later, it turns to steam and explodes the shell, ruining the part and endangering our workers.

Therefore, a single shell takes 3 to 7 days just to prepare. During this time, your product is taking up climate-controlled floor space. We have to pay for the energy to keep the humidity and temperature constant. We cannot use that space for anything else. This extensive Work-In-Progress (WIP) time means our inventory turnover is slower than a stamping factory, and that carrying cost is reflected in the final price.

Layer-by-Layer Breakdown

To understand the labor involved, consider the specific steps for just one shell:

-

Prime Coat: Very fine zircon sand for surface detail (Critical for that smooth finish).

-

Intermediate Coats: Slightly coarser sand for strength.

-

Backup Coats: Rough material to build thickness.

-

Seal Coat: The final layer to lock everything in.

Each of these steps involves human handling and inspection. We are essentially building a high-tech pressure vessel around your part by hand, layer by layer.

Factor 3: High-Cost Consumables (Zircon & Ceramics)?

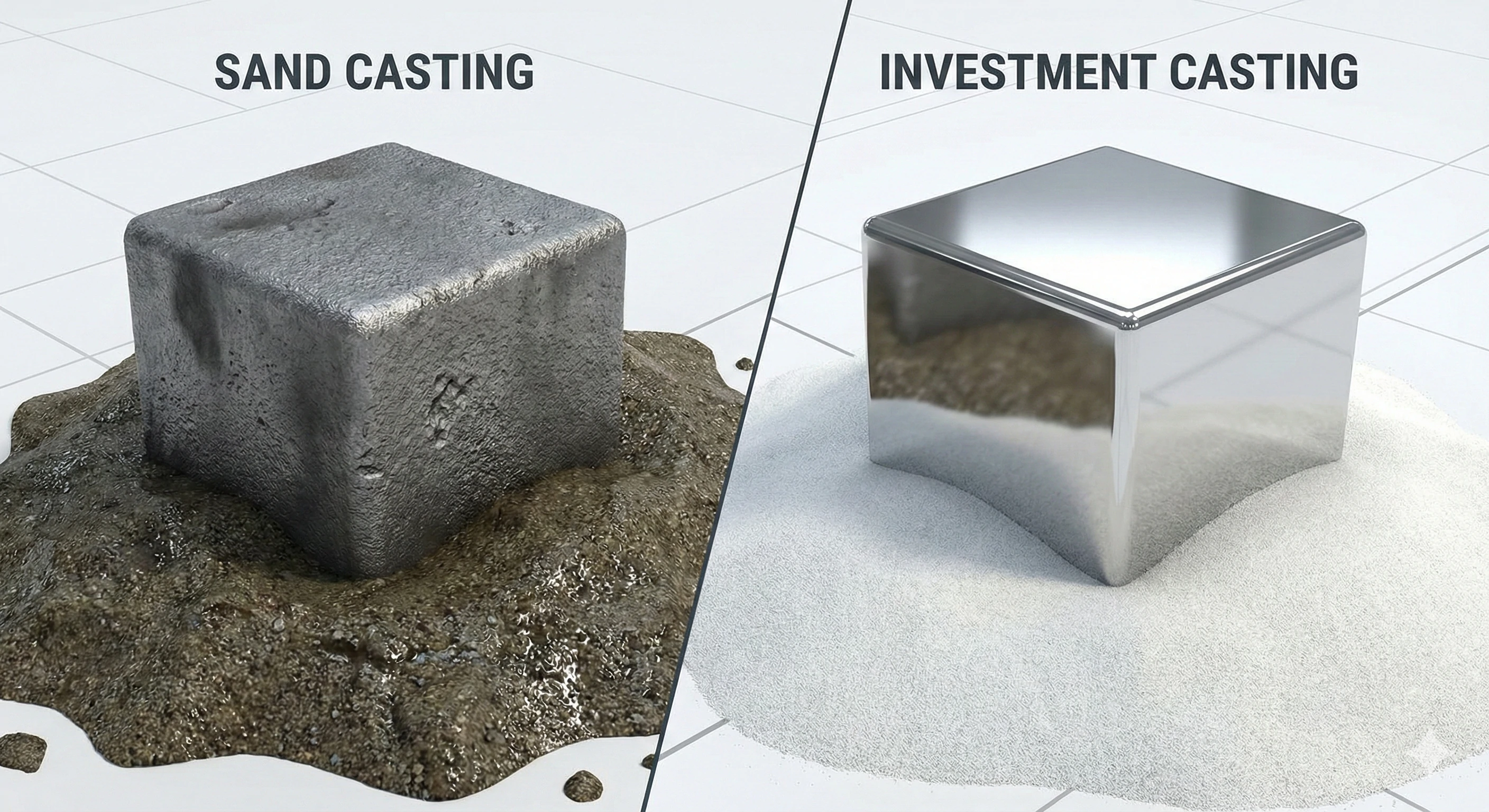

We source specific materials from specialized suppliers, and the invoices for these raw materials are significantly higher than standard foundry supplies. Clients often assume "sand is sand," confusing our process with traditional sand casting that uses cheap river sand. Why do we insist on using expensive minerals like Zircon instead of cheaper alternatives to bring the price down?

We use premium Zircon sand and high-grade silica binders instead of cheap river sand to ensure the shell can withstand extreme heat. These expensive materials prevent the molten steel from reacting with the mold, guaranteeing the smooth surface finish that defines investment casting quality.

Why We Don't Use River Sand

In traditional "Green Sand" casting, foundries use basic silica sand mixed with clay and water. It is cheap and abundant. However, it has a low melting point and a rough texture. If we used that for your stainless steel glass fittings, the result would be disastrous. The surface would be rough like sandpaper, and the metal might "burn on" to the mold, fusing with the sand.

The Zircon Difference

We use for the face coat—the layer that actually touches your part. Zircon is extremely stable at high temperatures and chemically inert. It does not react with molten stainless steel. This is the secret to why investment cast parts come out of the mold looking so smooth.

The Cost Implications

Zircon is a limited resource and carries a high market price compared to standard silica. Furthermore, once the shell is broken off to reveal the metal part, that ceramic material is largely waste. We cannot simply shovel it back up and reuse it like do. We are constantly purchasing new, high-grade ceramic binders and flours.

Material Cost Hierarchy

To give you a perspective on raw material inputs:

| Material Type | Used In | Relative Cost | Surface Result |

|---|---|---|---|

| Zircon Sand | Investment Casting | $$$$ (High) | Smooth, detailed |

| Colloidal Silica | Investment Casting | $$$ (High) | Strong shell |

| Green Sand | Sand Casting | $ (Low) | Rough, pitted |

| Resin Sand | Sand Casting | $$ (Medium) | Moderate |

Factor 4: Energy Consumption?

Our utility bills are a massive component of our monthly operational expenses, much higher than assembly-only factories. Casting metal is an energy-intensive business by nature, but investment casting is particularly thirsty for power. Why does this specific method require so much more electricity and gas compared to other metalworking processes?

Investment casting is an energy-intensive process because it requires three separate high-temperature heating stages. We must heat the autoclave to melt the wax, fire the kiln to 1000°C to sinter the ceramic shells, and finally power induction furnaces to melt the steel at 1600°C.

The Triple-Heat Cycle

Most manufacturing processes heat the material once. We have to heat different elements three separate times before we even get a finished part.

-

Dewaxing (The Autoclave): First, we have to melt the wax out of the shell. We use a steam that consumes significant energy to generate high-pressure steam. We cannot just burn the wax out; the expansion would crack the shell.

-

Sintering (The Kiln): Once the wax is gone, the ceramic shell is still fragile. We must fire it in a large kiln at roughly 1000°C. This sinters the ceramic, turning it into a hard, rock-like material. This kiln runs for hours to ensure the shells are fully cured and preheated.

-

Melting (The Furnace): Finally, we power up the to melt the stainless steel alloy, reaching temperatures over 1600°C.

Induction Efficiency vs. Cost

We use induction furnaces because they allow us to control the chemistry of the alloy precisely. They are cleaner and more precise than gas-fired crucibles, but they draw massive amounts of electricity. When you pay for an investment cast part, you are partly paying for the massive energy grid required to run these three thermal cycles simultaneously.

Environmental Controls

Beyond just heating, we also spend energy on environmental systems. Dealing with molten metal and ceramic dust requires powerful ventilation and filtration systems to keep our workers safe and meet environmental regulations. These fans and filters run 24/7, adding to the facility's overhead energy load.

The Pivot: Why It Actually SAVES You Money (Total Cost of Ownership)?

Our clients often ask us if there is a way to switch to a cheaper process, but they usually come back after realizing the alternative costs. While the "per piece" price of investment casting is higher, the "finished product" price is often lower. How can paying more for the raw casting possibly save you money on the final project budget?

Investment casting saves money long-term by delivering "Near-Net-Shape" parts that require almost no machining. While the casting itself costs more, you avoid the massive expenses of machining away excess metal and polishing rough surfaces, resulting in a lower Total Cost of Ownership.

The Iceberg Analogy

Think of the price as an iceberg. The casting price is just the tip you see above the water. The hidden costs—machining, finishing, waste, and assembly—are the massive chunk of ice below the surface.

-

Sand Casting: The tip (casting price) is small. But the bottom (machining) is huge. You might have to machine off 3mm of extra metal from every side.

-

Investment Casting: The tip is larger. But the bottom is almost non-existent. We cast to a precision of +/- 0.1mm.

Drastic Reduction in Machining

Machining is one of the most expensive processes in manufacturing. It takes time, expensive CNC machines, and skilled operators. If we can cast a hole or a slot directly into the part, you do not have to drill or mill it later.

For example, if you are making a complex door hinge:

-

Option A (Machining from Block): You buy a 1kg block of steel and machine away 70% of it to get a 300g part. You paid for 700g of scrap chips.

-

Option B (Investment Casting): We cast a 310g part. You only machine a tiny bit of critical surface. You pay for less material and far less machine time.

Surface Finish and Polishing

For hardware like glass spigots, aesthetics are everything. If you need a mirror finish, starting with a rough sand casting is a nightmare. It requires hours of grinding to smooth out the pits. Investment casting provides a surface right out of the mold. Polishing it to a mirror shine is fast and cheap.

Total Cost Analysis Example

Let’s look at the math for a hypothetical stainless steel bracket:

| Cost Component | Sand Casting | Investment Casting |

|---|---|---|

| Raw Casting Price | $5.00 | $12.00 |

| Machining Cost | $15.00 (High removal) | $2.00 (Drill one hole) |

| Polishing Cost | $8.00 (Heavy grinding) | $3.00 (Light buff) |

| Total Cost Per Part | $28.00 | $17.00 |

As you can see, the "expensive" casting is actually $11.00 cheaper in the end, offering a significantly lower .

Conclusion

When you look at the price of investment casting, remember that you are not just paying for metal. You are paying for a high-precision, 7-day craft that involves destroying a custom wax pattern, building a ceramic shell by hand, and consuming high-grade materials and energy.

However, this expense is an investment in efficiency. By paying for precision upfront, you eliminate the headaches and high costs of machining and finishing later. You get a part that is lighter, stronger, and better looking, often at a lower total project cost.

If you are looking to reduce your machining bill and improve your product quality, it is time to look past the sticker price. Switch to Precision Investment Casting. Let us quote your project to show you the Total Cost Savings.

Footnotes

1. Wikipedia overview of the investment casting manufacturing process.

2. Detailed breakdown of the sand casting process steps.

3. Industry explanation of die casting technologies.

4. Technical data on binders used in casting slurries.

5. Prohttps://www.google.com/search?q=%23perties of Zircon sand for high-heat applications.

6. Encyclopedia entry describing green sand mold characteristics.

7. Uses of industrial autoclaves in manufacturing and dewaxing.

8. Manufacturer details on high-efficiency induction melting systems.

9. Explanation of Near-Net-Shape manufacturing advantages.