Introduction

Imagine this scenario: a glass pool fence installation is completed for a waterfront property in Miami. The design looks clean and modern, and the client is satisfied. Six months later, the installer receives a call — brown streaks are appearing on the stainless steel spigots, running down the glass panels.

This situation is more common than many contractors expect. The issue is often described as tea staining, and it frequently occurs even on hardware sold as “marine grade stainless steel”.

The reality is simple: stainless steel is corrosion-resistant, not corrosion-proof. In coastal environments, salt spray, humidity, and pool chemicals combine to create conditions that push many stainless steel grades beyond their limits. When the wrong material is specified, the result is callbacks, warranty disputes, and avoidable damage to a contractor’s reputation.

This article explains why stainless steel spigots rust, how tea staining develops, the real differences between SS304, SS316, and Duplex 2205, and how to select materials that perform reliably in marine and poolside environments.

What Is Tea Staining — and Why It Matters

Tea staining is the brown or reddish discoloration that appears on the surface of stainless steel. It often resembles dried tea marks or light rust and cannot be removed by simple washing once it becomes established.

Stainless steel resists corrosion because of a thin, invisible passive layer made of chromium oxide. This layer continuously repairs itself when exposed to oxygen, protecting the metal underneath.

Problems begin when the environment attacks this layer faster than it can regenerate. Common contributing factors include:

Chloride ions from saltwater spray

High humidity, which keeps surfaces wet for long periods

Pool chemicals, especially chlorine compounds

Air pollution, including sulfur and acidic particles

When these elements persist on the surface, the passive layer breaks down. Oxidation begins, and tea staining becomes visible. While this initially affects appearance, it can eventually lead to pitting and structural degradation if ignored.

The “Marine Grade” Label: What It Actually Covers

Not all stainless steel grades offer the same level of corrosion resistance. Understanding the differences is critical when specifying outdoor glass hardware.

SS304: Suitable for Indoor Use Only

Grade 304 stainless steel performs well in dry, controlled environments such as indoor railings and architectural fittings. However, it lacks resistance to chlorides.

SS304 should never be used for outdoor pool fencing or coastal installations. In these conditions, corrosion is not a possibility — it is inevitable.

SS316: Traditional Marine Grade

SS316 stainless steel includes 2–3% molybdenum, which significantly improves resistance to chloride-induced corrosion. For many years, it has been considered the standard choice for marine applications.

In moderate coastal areas and conventional chlorine pools, SS316 often performs adequately. However, it has limitations. In high-exposure environments — such as beachfront properties or heated saltwater pools — SS316 can still develop pitting corrosion over time.

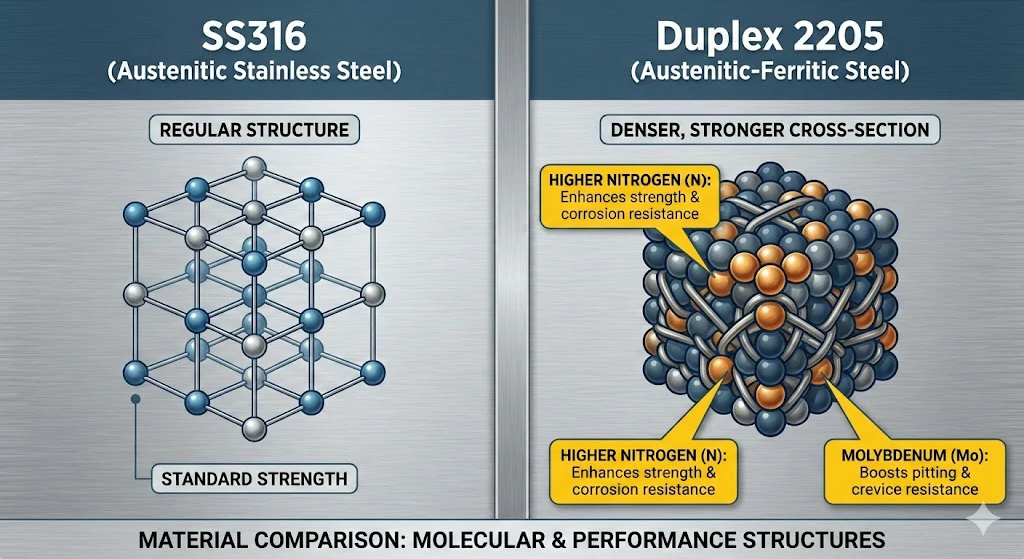

Duplex 2205: Designed for Harsh Environments

Duplex 2205 stainless steel offers a substantial improvement over 316, not a marginal one.

Its higher nitrogen and molybdenum content results in a much higher PREN (Pitting Resistance Equivalent Number). In practical terms, this means:

Significantly higher resistance to pitting and crevice corrosion

Better performance under constant chloride exposure

Approximately twice the tensile strength of SS316

For installers and specifiers, Duplex 2205 reduces long-term risk. While the upfront cost is higher, the material is far more forgiving in extreme environments where maintenance may be inconsistent and exposure conditions unpredictable.

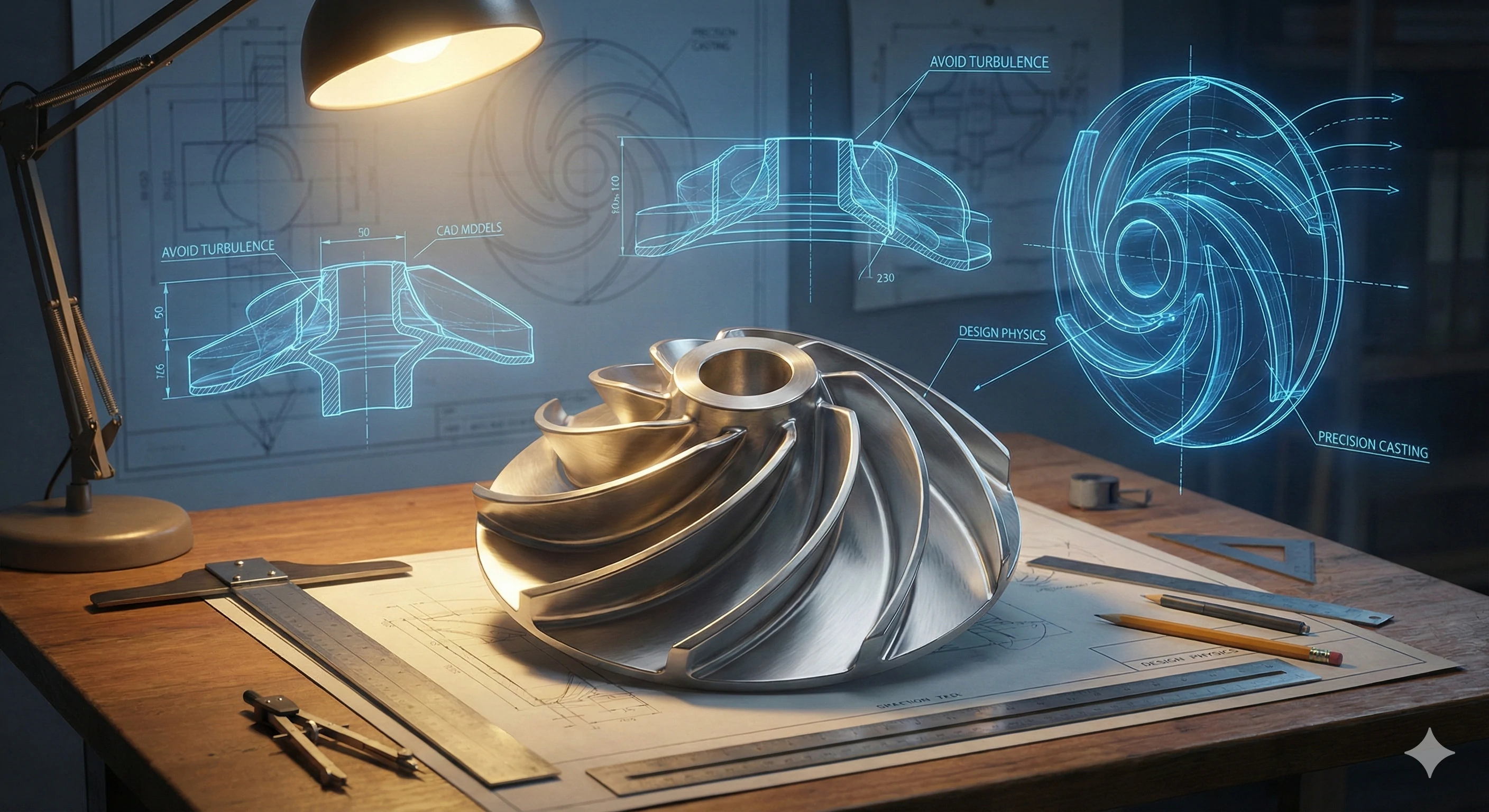

Why Surface Finish Is Just as Important as Material

Material selection alone is not enough. Surface finish plays a major role in corrosion resistance.

Brushed / Satin Finish

Brushed finishes are popular for their appearance, but quality varies widely. Poor brushing leaves deep grooves that trap salt and moisture. These trapped contaminants accelerate corrosion and often result in linear staining patterns that follow the brush marks.

Mirror Polish Finish

Mirror-polished surfaces provide fewer places for salt and debris to accumulate. Water drains more easily, reducing prolonged moisture contact. For coastal installations, mirror polish consistently outperforms brushed finishes in long-term corrosion resistance.

Black Coated Spigots

Black spigots are visually striking, but performance depends entirely on the base material and coating quality. High-quality black spigots use Duplex 2205 stainless steel combined with professional electrophoretic or powder coating systems.

Lower-cost versions often coat inferior stainless steel. When corrosion begins underneath, the coating bubbles or peels, exposing severe damage that cannot be repaired cosmetically.

Choosing the Right Spigot Based on Location

Use the environment, not marketing claims, to guide material selection:

More than 10 miles from the coast

SS316 is usually sufficient for standard pool installations.

Within 10 miles of the coast or poolside installations

Duplex 2205 is strongly recommended due to airborne salt and chemical exposure.

Direct beachfront or waterfront properties

Duplex 2205 with mirror polish or high-grade black coating is essential.

Saltwater pools should always be treated as high-risk environments, regardless of geographic location.

Maintenance Practices That Extend Service Life

Even high-grade stainless steel benefits from basic care:

Routine cleaning

Every 3–6 months, wash hardware with warm soapy water and a soft cloth. Rinse thoroughly and dry.

Early treatment of tea staining

Use citric-acid-based stainless steel passivation products at the first signs of discoloration.

Avoid abrasive tools

Steel wool and aggressive cleaners damage the passive layer and worsen corrosion.

After severe storms

Rinse hardware with fresh water to remove concentrated salt deposits.

Conclusion: Material Quality Protects More Than Hardware

The cost difference between standard and premium stainless steel is small compared to the expense of replacements, callbacks, and lost client trust.

Duplex 2205 stainless steel provides a margin of safety against harsh environments, unexpected exposure levels, and inconsistent maintenance. For contractors and distributors working in coastal and poolside markets, it is not an upgrade — it is risk management.

If long-term performance and professional credibility matter, material selection should reflect the realities of the environment, not the minimum specification.

Frequently Asked Questions

Does 316 stainless steel rust in saltwater pools?

Yes, 316 stainless steel can develop tea staining and pitting in saltwater pool environments, particularly if quality control during manufacturing was substandard or if maintenance is neglected. While 316 offers better corrosion resistance than 304, saltwater pools create aggressive chloride exposure that can overwhelm even marine grade 316 over time. For saltwater pools, Duplex 2205 provides significantly better long-term performance.

What is the difference between Duplex 2205 and 316 spigots?

Duplex 2205 offers approximately twice the tensile strength of 316 stainless steel and substantially higher corrosion resistance, particularly against pitting and crevice corrosion. This performance advantage comes from higher nitrogen and molybdenum content, which dramatically increases the material's PREN rating. In practical terms, 2205 spigots survive direct beachfront installations and saltwater pool environments that cause 316 hardware to fail prematurely.

How do I remove rust from my glass pool fence spigots?

For early-stage tea staining, wash the affected spigots with warm soapy water and a soft microfiber cloth, then rinse thoroughly with fresh water. If staining persists, use a stainless steel passivation product containing citric acid, following manufacturer instructions carefully. Apply the solution, allow appropriate dwell time, then rinse completely and dry. Avoid steel wool and harsh acid cleaners, which damage the protective chromium oxide layer. If deep pitting has occurred, the hardware may require replacement rather than restoration.

How often should I clean stainless steel pool fence hardware?

For coastal installations or poolside applications, clean glass spigots and stainless steel hardware every three to six months using warm soapy water, soft cloths, and thorough rinsing. After significant storm events or extended periods of heavy pool use, perform additional cleanings to remove accumulated salt and chlorine residue. Regular cleaning prevents the buildup of corrosive contaminants before they can compromise the passive protective layer.

Is marine grade stainless steel worth the extra cost?

Premium marine grade materials like Duplex 2205 eliminate the risk of premature hardware failure, callbacks, and reputation damage that result from corrosion issues. While initial material costs run higher than standard 316 or 304 grades, the total lifecycle cost including avoided replacements, warranty claims, and contractor reputation protection makes premium materials the economically sound choice for coastal and pool installations.