In the food processing industry, the hygiene and safety of every machine is directly related to human health. From chocolate mixing paddles to can sealing molds, these metal parts not only need to resist corrosion and withstand high-temperature steam cleaning, but also must have a mirror-smooth surface, so that there is no place for bacteria to hide. The core technology to achieve this “food-grade quality” is silicone casting.

Why does food machinery need “silicone casting”?

Food processing equipment has three stringent requirements for metal parts:

Ultra-smooth surface: to prevent microorganisms from adhering (Ra < 1.6μm)

High corrosion resistance: to resist the erosion of acidic sauces and alkaline detergents

Zero risk of contamination: to avoid the precipitation of heavy metals or organic residues.

While traditional casting processes are prone to porosity and sand holes, silica sol casting forms a uniform and dense ceramic coating on the surface of the casting by virtue of the properties of silica nanocolloid (particle size 10-100nm), which perfectly matches the needs of the food industry.

Silica Sol Casting: The “Nano-Level Protective Coat” for Food Machinery

Nano-Coating: Making Bacteria “Unable to Take Hold”

When used as a binder, the colloidal particles of silica sol can penetrate into the microscopic pores of the mold, forming a silicon dioxide layer with a thickness of only a few micrometers. According to actual measurements, the surface roughness of silica sol castings can reach Ra 0.8 μm (e.g., stainless steel components of sausage filling machines), which is more than three times smoother than traditional castings, significantly reducing the risk of protein residue.

Chemical Inertness: An “Invisible Shield” Against Corrosion

The silica network structure in silica sol forms an amorphous glass body after high-temperature sintering, maintaining stability in acidic and alkaline environments with a pH range of 2-12. For example, after using silica sol casting, the 316L stainless steel molds at a German cheese processing plant saw a 40% increase in lifespan in a salt-cured environment.

Pure Material: Eliminates Heavy Metal Migration

Using water as the dispersing medium (no organic solvents) and purified via ion exchange, sodium ion content can be reduced to <50 ppm, fully compliant with FDA/EC 1935 food contact material standards.

Practical Case Study of Silica Sol Casting in Food Machinery: From Part Defects to Performance Breakthroughs

In the food machinery industry, traditional casting processes often result in part failures due to defects such as porosity, shrinkage, and structural deformation (e.g., stress fractures, corrosion leaks, and cleaning dead zones). Silica sol casting enhances part integrity from the source through nanometer-level mold shell precision and low shrinkage characteristics. The following are solutions for typical scenarios:

Beer Fermentation Tank Liner — The End of Microbial Growth at Weld Seams

Part Issue: Traditional welded liners are prone to micro-cracks (Ra > 3.2 μm) at weld seams, creating a breeding ground for yeast bacteria.

Silica Sol Solution:

One-piece molding process: Silica sol mold shells achieve CT4 precision (tolerance ±0.15 mm), enabling direct casting of weld-free liners;

Surface roughness Ra 1.2 μm: Nano-silica sol (particle size 5–20 nm) fills the micro-pores in the mold shell, eliminating surface defects;

Chocolate molding — Overcoming demolding adhesion and micro-pore residue

Part issue: Traditional castings with micro-pores (>50 μm) allow melted chocolate to seep in, resulting in a demolding damage rate as high as 15%.

Silica sol solution:

Zero-cutting complex flow channels: 3D-printed wax molds + silica sol shells achieve 0.2 mm precision flow channels (accuracy ±0.05 mm);

Low shrinkage characteristics: Aluminum-modified silica sol (FSIII type) reduces thermal expansion coefficient by 40%, preventing cooling deformation;

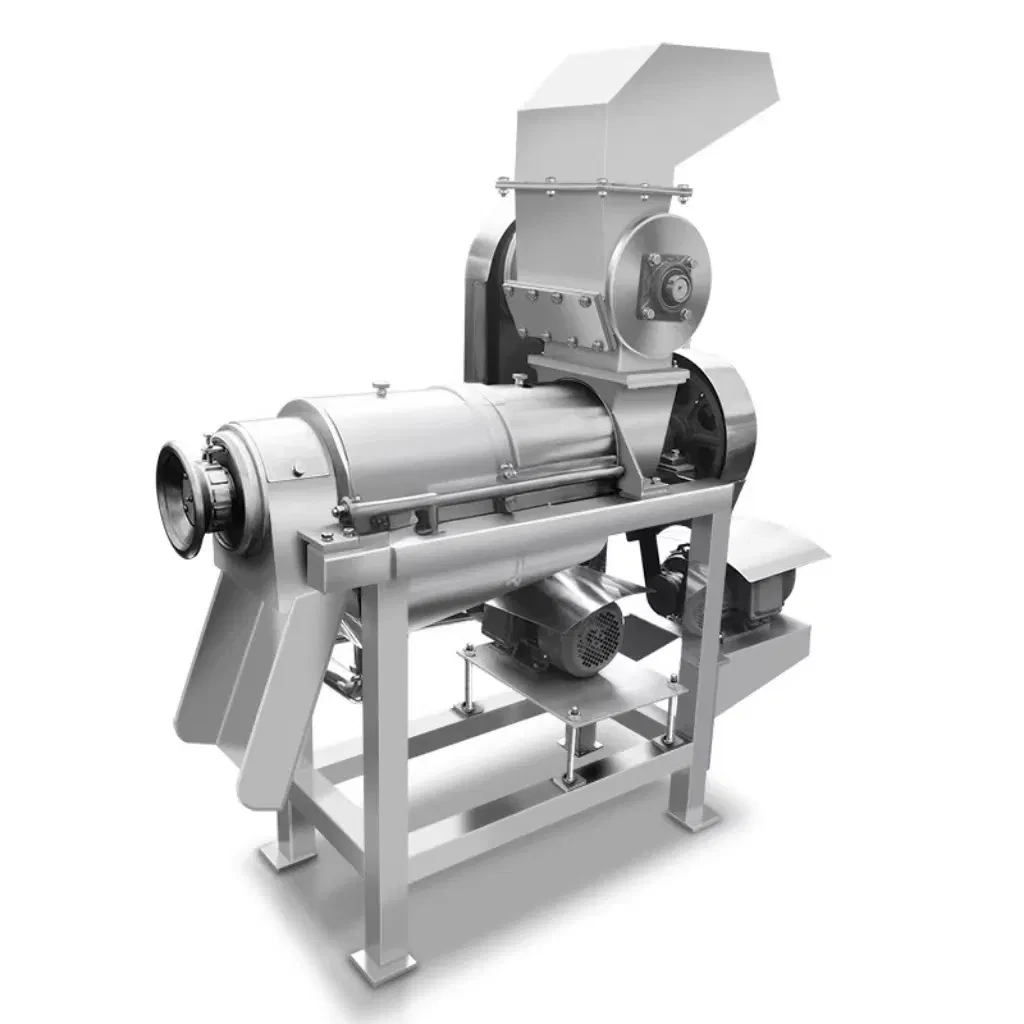

Juice Extraction Screw — Blocking Fruit Acid Corrosion and Metal Leaching

Parts issue: Traditional chromium steel screws release iron ions (>0.1 ppm) in fruit acid environments, causing off-flavors in juice.

Silica sol solution:

Pure 316L stainless steel substrate: Silica sol mold shell sodium content <50 ppm, eliminating heavy metal migration;

Structural reinforcement design: Optimized screw helix angle (error <0.5°), improving extraction efficiency and reducing stress corrosion

Cutting-edge technology: Next-generation solutions for food machinery casting

Hybrid-enhanced silica sol:

Add 1-3 wt% nano-ZrO₂ particles to increase high-temperature strength by 50%;

Composite PVA enhances toughness and doubles microcrack resistance (suitable for frozen food cutting tools).

3D printing + silica sol: The ultimate solution for complex flow channels

Photocurable resin blended with 40% silica sol enables direct printing of micron-level channels (precision ±0.05mm) such as cream piping tips, with design freedom increased by 300%.

Closed-loop environmental process:

Waste silica sol centrifugal recovery rate reaches 70%, supporting the EU's 2030 carbon neutrality target.

The Symbiotic Evolution of Casting Technology and Food Safety

Silica sol casting is redefining the “genetic expression” of food machinery—it is not only a metal forming process but also the foundational guarantee of food safety. When nanoscale silica permeates every crystal gap in metal, what we see is not only a mirror-like surface but also a food industry future characterized by zero risk, zero waste, and zero compromise.