Chemical casting is a manufacturing process where a mixture of reactive resins and aggregates, like granite or quartz, is poured into a mold and cured at room temperature. This method creates heavy, vibration-proof machine bases without the high heat required for traditional metal casting. It is also known as mineral casting or epoxy granite.

This guide explains the process and helps you decide when to stick with metal and when to try the chemical route.

How Does Chemical Casting Work? (The Process)

When we cast stainless steel, we are battling temperatures up to 1600°C, but the chemical casting process feels more like mixing concrete or baking a complex cake. We have observed that the simplicity of this "cold" process is a major draw for manufacturers who want to avoid thermal shrinkage. The absence of extreme heat simplifies the tooling requirements significantly.

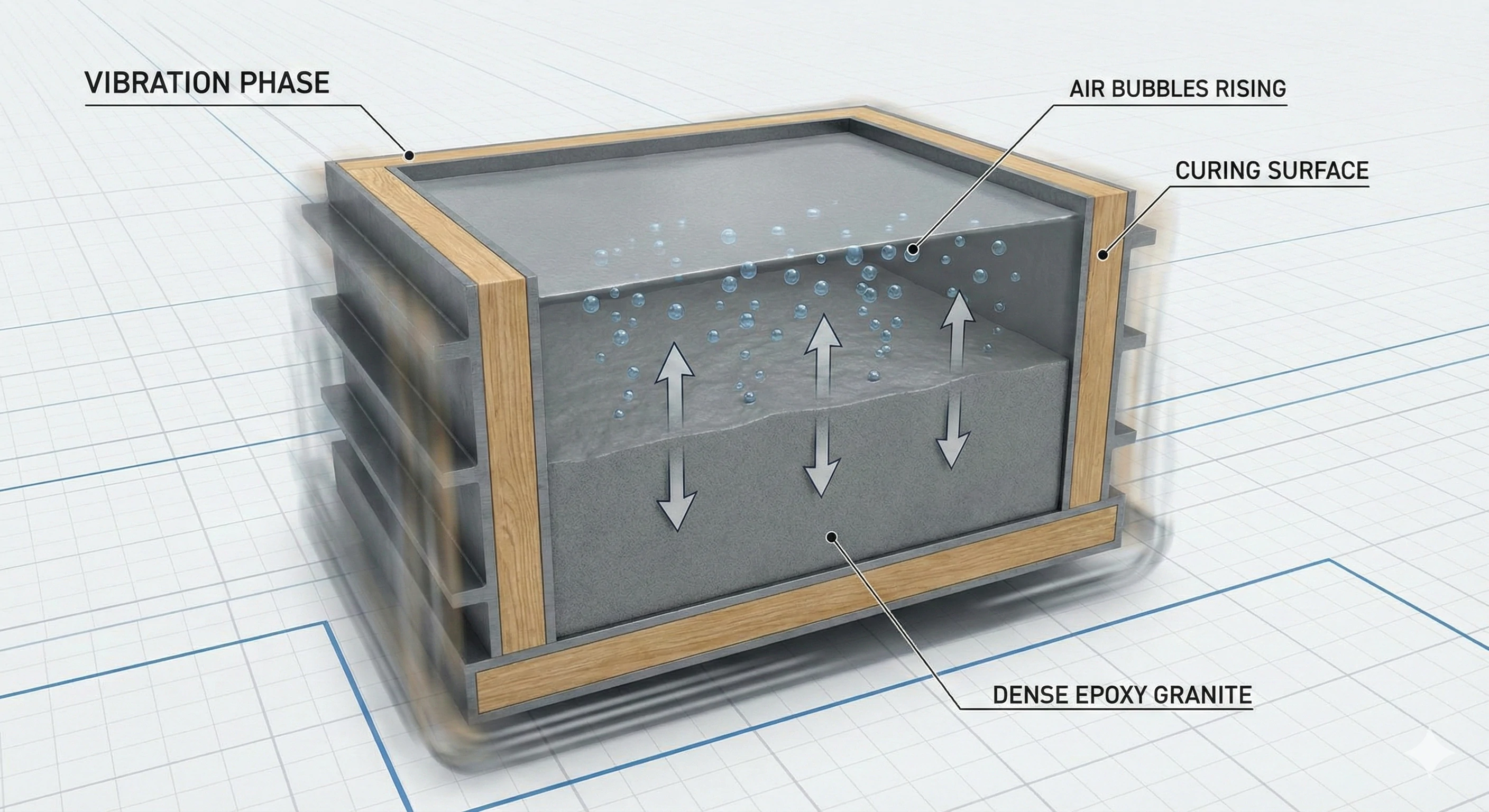

The chemical casting process involves mixing a binder, usually epoxy resin, with a precise recipe of stones and sand. This slurry is poured into a mold and vibrated vigorously to remove air bubbles. Finally, the mixture creates a chemical reaction that hardens the solid mass over 24 to 48 hours at room temperature.

To understand this process deeply, you have to look at the ingredients. It is not just pouring glue on rocks. The engineering happens in the mixture ratios.

The Ingredients: The Recipe Matters

The process starts with the mix. Engineers must create a specific recipe of aggregates. This usually includes gravel, sand, and fine powder. The goal is to minimize the gaps between the pieces. If you only used large rocks, you would have too much resin, which is expensive and weaker. By mixing large, medium, and fine particles, you create a dense structure. The acts as the binder that holds it all together.

The Shake: Compaction is Key

Once the slurry is poured into the mold—which can be made of wood or steel since there is no heat—the real work begins. You cannot just let it sit. The mold must be vibrated. In our experience with materials, air pockets are the enemy of strength. Vibration packs the stones tightly together and forces the air bubbles to the surface. This ensures a solid, void-free component.

The Cure: Patience Required

Unlike metal, which hardens as it cools, this material hardens through a chemical reaction. It takes about one to two days to fully cure. This slow cure at room temperature means the final part is incredibly dimensionally stable because it does not shrink from thermal shock like cooling iron does.

| Step | Action | Key Characteristic | Timeframe |

|---|---|---|---|

| 1. The Mix | Combine Epoxy Resin + Aggregate | Precise particle distribution | ~30 Minutes |

| 2. The Pour | Fill the mold | Ambient temperature (20°C) | Immediate |

| 3. The Shake | Vibrate the mold | Removes air, packs stone | ~1 Hour |

| 4. The Cure | Let reaction occur | Chemical hardening | 24-48 Hours |

The Main Application: Machine Tool Bases?

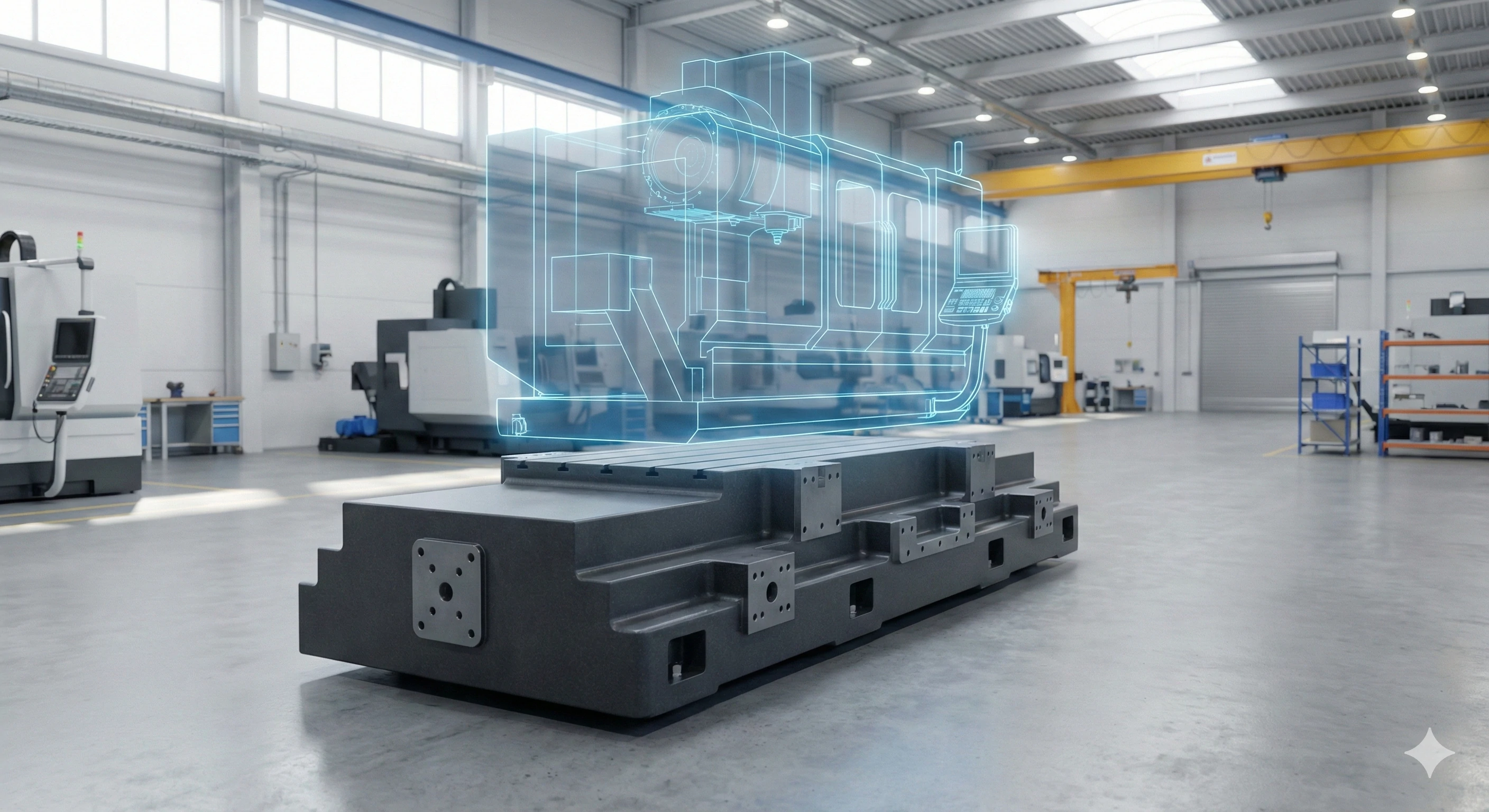

We supply investment cast components for high-end CNC machines, so we know that a machine is only as good as its foundation. If the base vibrates, the surface finish on the metal part suffers. While cast iron has been the standard for centuries, we have seen a massive shift toward mineral casting for the heaviest static parts of these machines.

Engineers primarily use chemical casting for machine tool bases because it absorbs vibration ten times better than cast iron. This superior damping capability ensures that high-precision equipment, such as CNC machines and CMMs, remains stable during operation. Additionally, the lack of heat prevents warping, leading to greater long-term precision.

Why are rocks replacing iron? It comes down to physics and the specific needs of modern manufacturing.

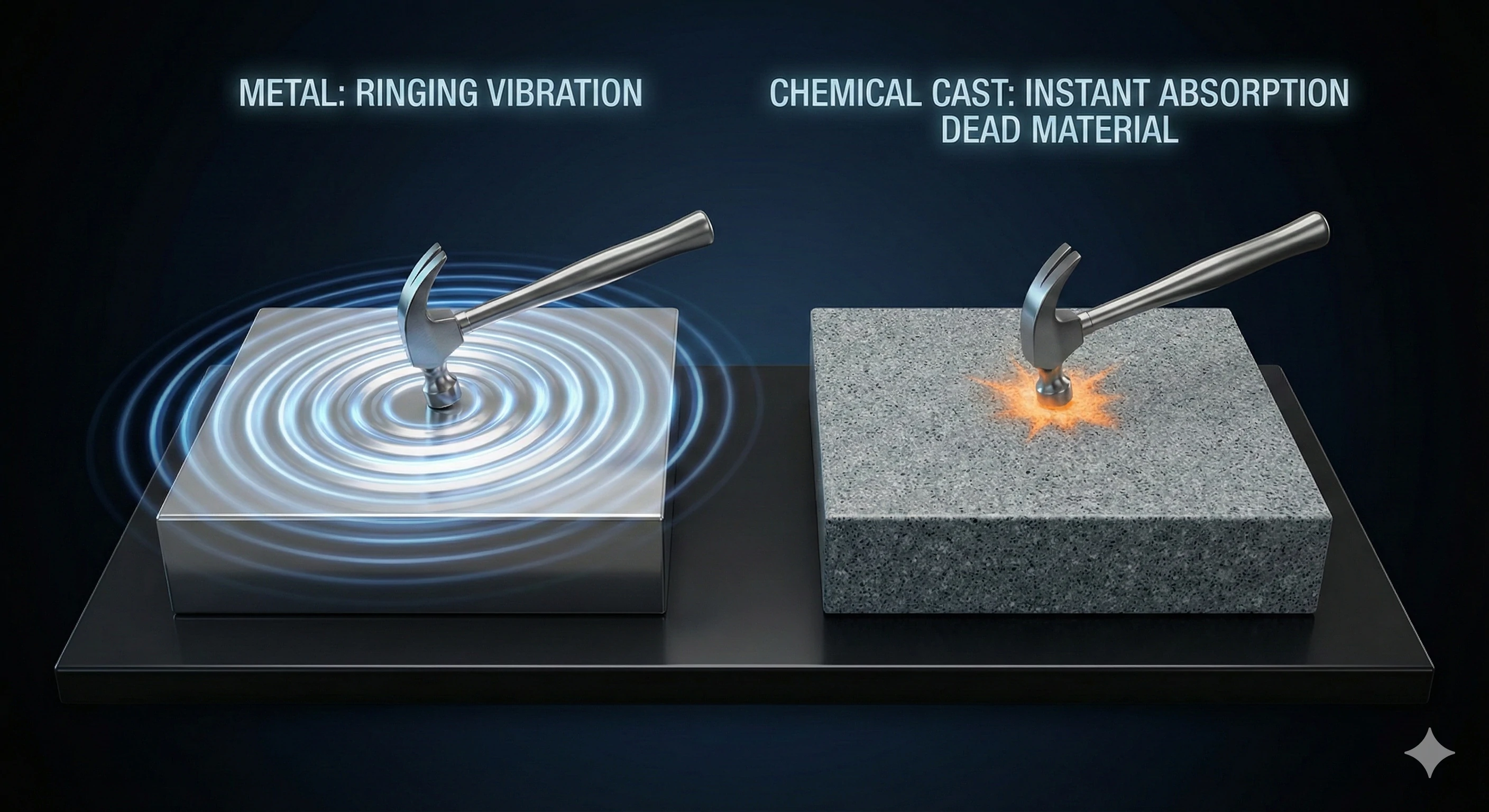

Vibration Damping: The "Dead" Material

In the machining world, "damping" is the ability of a material to stop shaking after an impact. Imagine hitting a steel bell; it rings for a long time. That is low damping. Now, imagine hitting a sandbag; it makes a thud and stops. That is high damping. Chemical casting behaves more like the sandbag. It has a factor 10 times higher than cast iron. For a CMM (Coordinate Measuring Machine) or a semiconductor machine, this "deadness" is perfect. It means external vibrations do not ruin the measurement.

Thermal Stability

In our metal foundry, we have to account for thermal expansion constantly. Metal grows when it gets warm. However, epoxy granite is an insulator. It does not conduct heat well. This means a machine base made of this material will not change shape significantly if the room temperature fluctuates. For high-precision work, this is a massive advantage.

Cost vs. Performance

It is not just about performance; it is about economics. While the material is cheaper per pound than iron, the real savings come from eliminating the stress-relieving processes. Cast iron bases often need to be aged or heat-treated to remove internal stresses. Chemical casting comes out of the mold .

| Material | Vibration Damping | Thermal Conductivity | Electrical Conductivity |

|---|---|---|---|

| Cast Iron | Moderate | High (Conductor) | Conductor |

| Steel | Low (Rings) | High (Conductor) | Conductor |

| Chemical Cast | Excellent (10x better) | Low (Insulator) | Insulator |

Chemical Casting vs. Metal Casting (The Comparison)?

Clients often ask us if they should switch all their parts to epoxy granite. We always answer with a firm "no." We know the strengths of steel and the weaknesses of plastic-stone mixtures. Understanding the trade-off between these two manufacturing worlds is essential for building a safe and functional machine.

The main difference lies in the process and physical properties: chemical casting is a cold process offering high compressive strength but low tensile strength. In contrast, metal casting involves high heat and produces parts with excellent tensile strength. Chemical casting insulates, while metal casting conducts both heat and electricity.

To visualize this, think of the "Concrete vs. Steel" analogy used in building construction.

The Foundry Perspective: Heat vs. Chemistry

The most obvious difference is energy. Metal casting requires melting steel at temperatures near 1600°C. This requires immense energy, furnaces, and ceramic shells. Chemical casting is a "cold process" usually done around 20°C. This lowers the energy footprint but introduces chemical handling requirements.

Strength Profiles: Push vs. Pull

This is the most critical engineering distinction.

-

Compressive Strength (Pushing): Chemical casting is fantastic here. You can put a massive CNC machine on top of it, and it will not crush. It holds weight very well.

-

Tensile Strength (Pulling): This is where chemical casting fails. If you try to stretch it or bend it, it will snap. Steel, on the other hand, is . It bends before it breaks.

Conducting Energy

In our line of work, we often need parts that can ground electricity or dissipate heat (like a ). Metal is the only choice there. Chemical casting is an electrical and thermal insulator. If you need to dissipate heat from a motor, mounting it directly to an epoxy block might cause overheating unless you add metal interfaces.

| Feature | Chemical Casting (Epoxy Granite) | Metal Casting (Investment/Sand) |

|---|---|---|

| Process Temp | Cold (~20°C) | Hot (>1000°C) |

| Primary Strength | Compressive (Load bearing) | Tensile (Bending/Pulling) |

| Ductility | Brittle (Snaps) | Ductile (Bends) |

| Best Use | Machine Bases, Static Loads | Moving Parts, Structural Components |

When to Use Which?

When we review technical drawings for a new project, we categorize parts based on their function. We advise our customers not to force a material into a role it wasn't designed for. You wouldn't build a hammer out of glass, and you shouldn't build a moving arm out of granite.

You should use chemical casting for static structures like machine bases and surface plates that must absorb vibration and hold heavy weight. Conversely, use metal investment casting for dynamic moving parts, such as impellers, hinges, and valve bodies, which must withstand high pressure, heat, or tension without snapping.

Let's break down the decision-making process for your project.

When to Choose Chemical Casting

Think static. If the part sits on the floor and never moves, but needs to hold up the rest of the machine, chemical casting is the winner.

-

Machine Bases: The heavy bottom part of a lathe or mill.

-

Surface Plates: Flat tables for measuring.

-

Precision Frames: Where thermal expansion would ruin the accuracy.

When to Choose Metal Casting (Our Specialty)

Think dynamic. If the part moves, spins, or clamps, you need metal.

-

Moving Gantries: A moving arm needs to be lightweight and stiff. Stone is too heavy and brittle.

-

Glass Hardware: Consider a glass spigot for a railing. It faces strong wind loads pushing against the glass. If you made this out of epoxy granite, the leverage would snap the spigot at the base. It must be Stainless Steel to handle that tension and bending moment.

-

High Heat/Pressure: Engine parts, , and valve bodies handle forces that would melt or crack epoxy.

Can They Work Together?

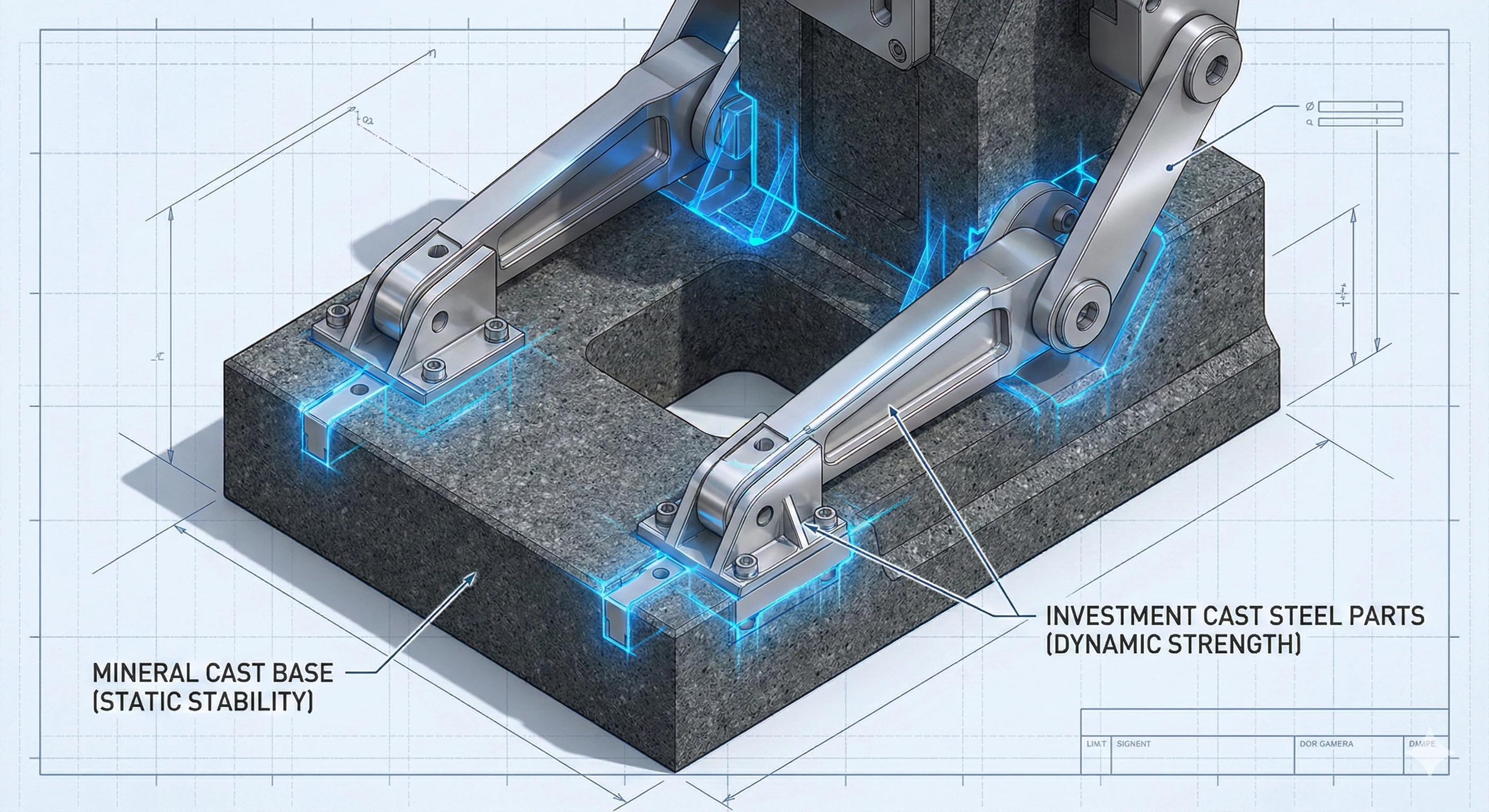

In our factory, we rarely see a machine that is 100% metal or 100% stone. The best machines in the world today are hybrids. We often manufacture the steel components that are inserted into or mounted onto the mineral bases produced by our partners.

Yes, they can and often do work together in a hybrid approach. Manufacturers frequently cast threaded steel inserts directly inside the chemical casting to provide strong bolting points. A common industry setup features a mineral cast base for stability, combined with investment cast steel or aluminum components for the moving parts.

The Hybrid Approach

The most effective designs leverage the "Stability" of chemical casting and the "Strength" of metal.

For example, a modern CNC machine often looks like this:

-

The Base: Made of Mineral Casting. It sits on the floor, absorbs the vibration from the cutting tool, and ensures the machine stays level.

-

The Moving Gantry: Made of Cast Aluminum or Steel. It needs to zip back and forth quickly. Metal is lighter and has the tensile strength to handle rapid acceleration.

-

The Brackets: Made of Investment Cast Steel. These hold the motors and cutting heads. They need to be incredibly tough and precise.

Inserts and Mounting

One challenge with epoxy granite is that you cannot easily cut threads into it. If you try to screw a bolt into rock, it will crumble.

To solve this, we provide Metal Inserts. These are threaded steel blocks or rails. During the "Pour" phase of the chemical casting, these steel blocks are placed into the mold. The resin hardens around them, locking them in place. This gives you a stone base with steel connection points—the best of both worlds.

Frequently Asked Questions (FAQ Schema)?

We constantly field questions from procurement managers who are trying to optimize their bill of materials. There is often confusion about cost and durability when comparing these very different technologies. Here is the reality of the situation.

Chemical casting material is generally cheaper than iron, but the molds can be expensive and the process is slower. However, for large complex bases, it is cost-competitive. Regarding lifespan, epoxy granite is impervious to oil and coolants, meaning it will never rust and has an extremely long service life.

Is chemical casting cheaper than cast iron?

It depends on volume and size. The raw material (rocks and resin) is cheaper than iron ingots. You also save money on energy since you do not need a furnace. However, the molds for chemical casting can be costly to fabricate, and the cycle time (24-48 hours to cure) is much slower than cooling metal. Generally, for massive, complex machine bases, the savings on machining and stress relief make chemical casting the cheaper option.

Can I use chemical casting for engine parts?

No. This is a common misconception. Chemical casting uses epoxy, which is a plastic polymer. If you exposed it to the heat of a , it would burn, melt, or lose all structural integrity. Engine blocks require the high-heat tolerance of Sand Cast Iron or Die Cast Aluminum.

How durable is it really?

In the right environment, it is nearly indestructible. It is excellent for wet environments. Since it contains no metal (unless you add inserts), it cannot rust. It is impervious to , coolants, and oils that typically corrode cast iron over time.

Conclusion

Chemical casting is the king of "Stability" for machine bases, while metal casting remains the king of "Strength" for components. Understanding this distinction is vital for any engineering project.

Building a machine? You might need a mineral base for that rock-solid foundation, but you definitely need High-Strength Metal Components for the moving parts. We specialize in Precision Investment Casting for the mechanical heart of your equipment.

Footnotes

1. Definitions and processes for high-accuracy manufacturing.

2. Guide to properties and applications of epoxy binders.

3. Explanation of energy dissipation in mechanical systems.

4. Impact of temperature changes on machinery alignment.

5. Heat treatment process to reduce internal residual stresses.

6. Ability of a material to deform under tensile stress.

7. Passive heat exchanger for dissipating thermal energy.

8. Rotating components used to increase fluid pressure/flow.

9. Basics of how internal combustion engines generate power.