When we invite clients to tour our facility in Rizhao, they often arrive with a mix of excitement and confusion regarding . You might know you need a metal part, but do you need a casting plant, a forging shop, or a machining center? This confusion is common, but it can lead to costly mistakes if you select the wrong production method for your specific hardware needs. We have seen projects delayed simply because the buyer did not understand the capabilities of the specific factory type they engaged.

A factory that specializes in making castings is technically called a "foundry." While some foundries use sand for rough parts or die casting for aluminum, an investment casting foundry is the specific facility used to create precision stainless steel hardware through the lost wax process.

Let’s break down exactly what happens inside these facilities and how to identify the right partner for your project.

What Are the 3 Main Types of Casting Factories?

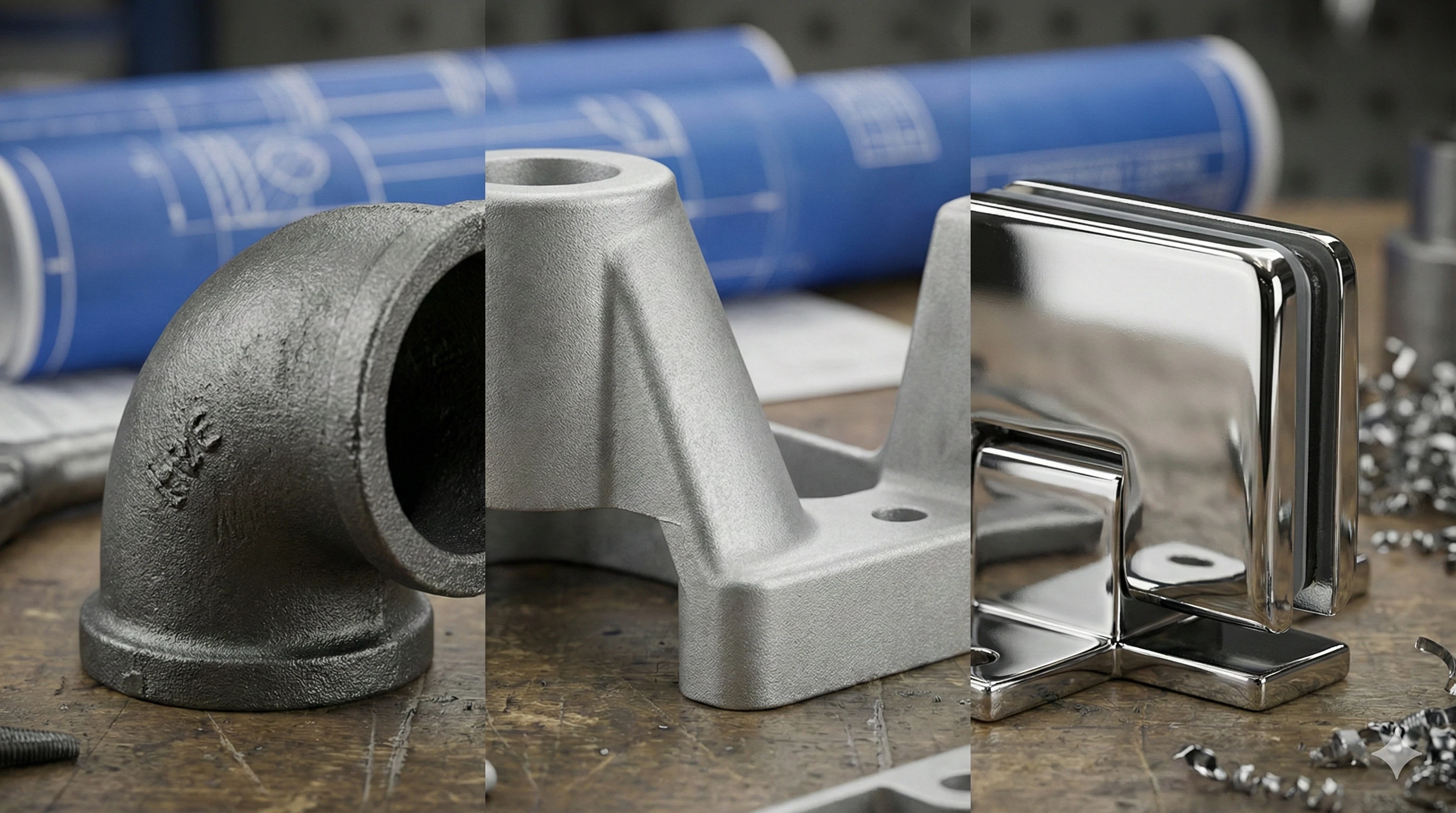

In our experience exporting glass hardware to the United States and Europe, we frequently encounter buyers who assume all casting factories are the same. This misconception often leads to disappointment when a factory specializing in heavy iron pipes is asked to produce a delicate, polished glass clamp. The results are usually poor surface finishes and loose tolerances that simply do not work for architectural applications.

The three main types of casting factories are sand casting foundries, which produce large, rough parts; die casting factories, which inject soft metals like aluminum into molds for high-volume consumer goods; and investment casting foundries, which use wax patterns to create high-precision stainless steel components.

To truly understand which partner fits your supply chain, we must look deeper into the specific mechanics of these three distinct factory types.

1. Sand Casting Foundries

This is the traditional image most people have of a foundry. Here, the molds are made of sand. While this method is excellent for massive components—think engine blocks or manhole covers—it lacks the refinement needed for architectural hardware. When we evaluate , we often find a rough, grainy surface texture that requires excessive machining and polishing to make presentable.

2. Die Casting Factories

If you are looking for parts for toy cars or phone cases, this is where you go. These factories inject molten metal into steel molds under high pressure. However, there is a catch: this process works best for metals with lower melting points, such as aluminum or zinc. In our industry, where strength and corrosion resistance are paramount, often falls short because it cannot easily handle the high temperatures required for stainless steel.

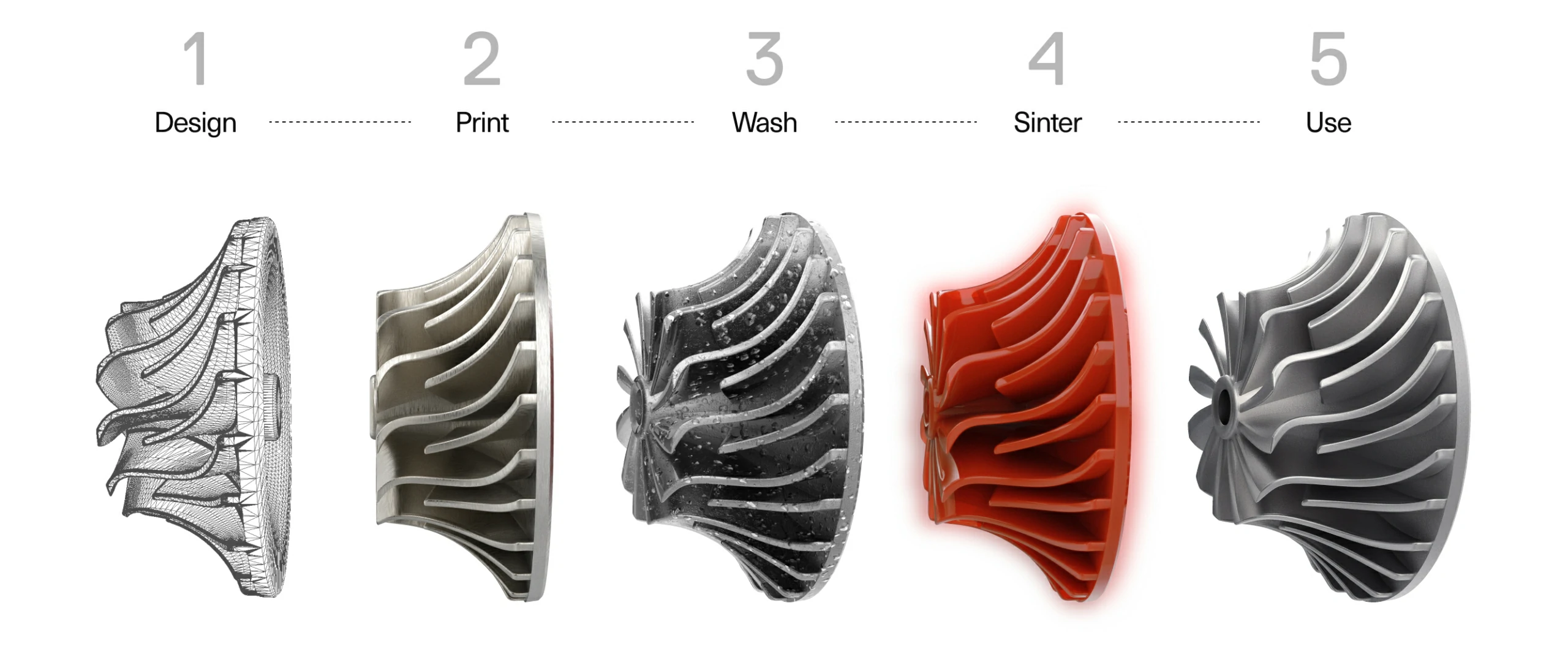

3. Investment Casting (Lost Wax) Foundries

This is our niche. Investment casting, or "" casting, involves creating a wax replica of the final part, dipping it in ceramic to form a shell, and then melting the wax out before pouring in stainless steel. It is the gold standard for producing items like glass spigots, hydraulic hinges, and spiders.

Comparison of Casting Factory Capabilities

To help you visualize the differences, we have compiled this comparison based on our manufacturing data:

| Feature | Sand Casting Foundry | Die Casting Factory | Investment Casting Foundry |

|---|---|---|---|

| Primary Material | Iron, Bronze | Aluminum, Zinc | Stainless Steel (304, 316, 2205) |

| Surface Finish | Rough, granular | Smooth, but limited materials | Superior, mirror-polish ready |

| Precision | Low | High | Very High |

| Typical Product | Manhole covers, Engine blocks | Phone cases, Car handles | Glass railing fittings, Aerospace parts |

For buyers engaging in the glass hardware market, the investment casting foundry is the critical partner. The ability to hold tight tolerances means the glass will fit securely without rattling, and the superior surface finish ensures the final product looks premium after polishing.

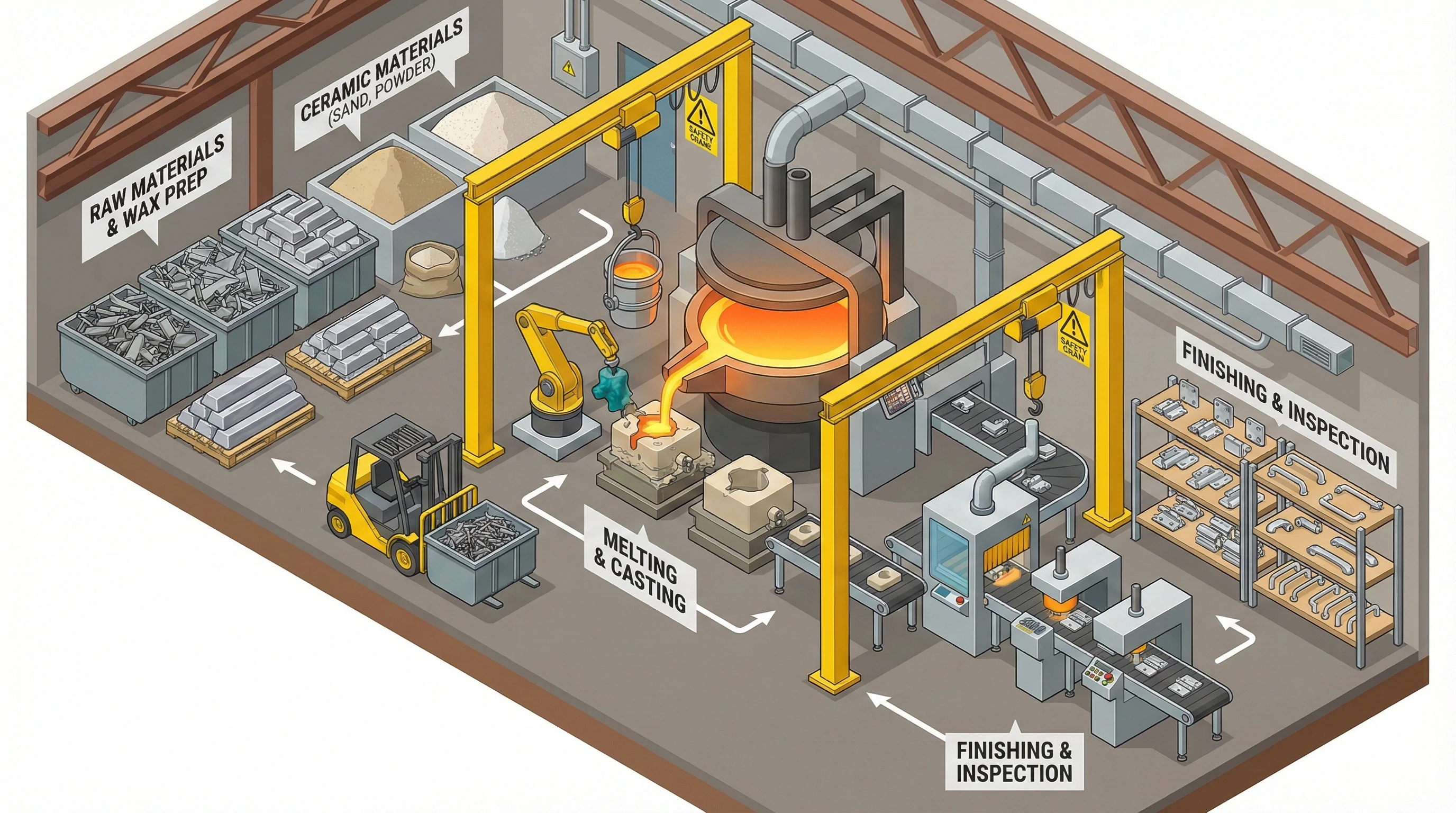

What Departments Exist Inside an Investment Casting Plant?

Walking through our production floor requires navigating several distinct environments, each with its own climate and smell. Clients are often surprised to see that a foundry is not just one big room with a furnace. It is a series of interconnected departments that must operate in perfect synchronization to ensure the final product meets safety standards.

An investment casting plant consists of four key departments: the wax room, where replicas are molded; the shell room, where ceramic molds are built; the melting shop, where steel is poured at 1600°C; and the finishing line, where parts are cut, ground, and polished.

Understanding the workflow of these departments helps you appreciate why lead times exist and where quality control is most critical.

The Wax Room: The Blueprint

Everything starts here. We inject liquid wax into a metal die to create an exact replica of the final product. These wax patterns are then assembled onto a central wax stick, creating what looks like a "tree." This room is usually climate-controlled because if the wax expands or contracts due to heat, the final steel part will be dimensionally incorrect.

The Shell Room: Building the Mold

This is perhaps the most time-consuming part of the process. The wax trees are dipped into a ceramic slurry and then coated with sand. We do this repeatedly—often 5 to 7 times—allowing each layer to dry completely. This creates a hard ceramic shell around the wax. If a factory rushes this drying process, the shell will crack when molten metal is poured in, ruining the batch.

The Melting Shop: The Transformation

Once the shell is hard, we heat it to melt the wax out (hence "Lost Wax"). Then comes the most dramatic moment: pouring. We melt stainless steel in reaching temperatures above 1600°C. The liquid metal is poured into the hollow ceramic shells.

The Finishing Line

After the metal cools, we break the ceramic shell away. The parts are cut off the "tree," and the gates (where the metal entered the part) are ground down. We then use shot blasting to clean the surface.

Typical Workflow Timeline

| Stage | Activity | Approximate Time | Critical QC Check |

|---|---|---|---|

| 1. Wax Injection | Creating wax patterns | 1-2 Days | Dimension check of wax |

| 2. Shell Making | Dipping and drying ceramic | 5-7 Days | Shell thickness and integrity |

| 3. Pouring | Melting and pouring steel | 1 Day | Chemical composition analysis |

| 4. Post-Processing | Cleaning and Grinding | 3-4 Days | Visual inspection for porosity |

What Critical Equipment Defines a Good Casting Factory?

Our engineers often tell clients that a shiny product does not always equal a strong product. In the world of stainless steel, visual appearance can be deceiving. A part might look like high-grade 316 stainless steel but actually contain high levels of carbon, which leads to rusting, or lack the nickel required for corrosion resistance.

A high-quality casting factory is defined by its testing equipment, specifically a spectrometer for chemical analysis, in-house CNC machining centers for precision drilling, and salt spray testers to verify the corrosion resistance of the final polished surface.

When you are auditing a supplier, do not just look at the furnaces; look for the "truth-telling" machines.

The Spectrometer: The Truth Teller

This is the most important machine in the building. Before we pour any metal, we take a small sample from the furnace and run it through the . It analyzes the chemical composition instantly. If the Carbon is too high or the Molybdenum is too low for , we adjust the mix immediately. Without this machine, a factory is just guessing.

In-House CNC Machining

Casting gets you 95% of the way there, but for glass hardware, the holes and threads must be perfect. Top-tier foundries don't outsource this; we have in-house. This ensures that the glass clamps or hinges fit perfectly when your customer installs them. Outsourcing this step adds lead time and reduces quality control.

Salt Spray Tester

For products destined for coastal areas or high-humidity environments, corrosion resistance is non-negotiable. We use machines to simulate years of exposure to harsh environments in just a few days. This confirms that the passivation and polishing processes were successful.

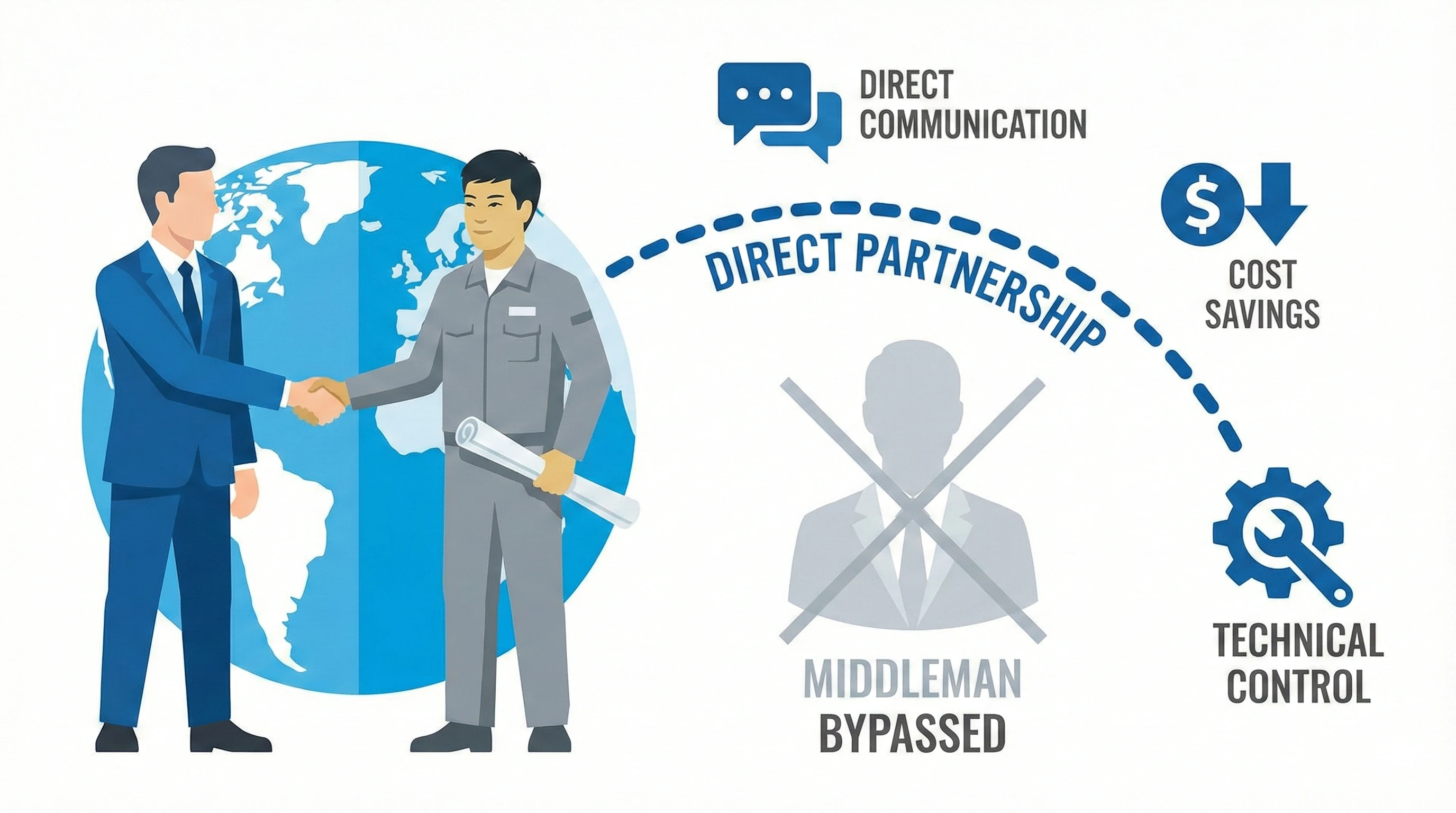

Should You Buy From a Manufacturer or a Trading Company?

We frequently hear from new partners who previously bought from traders and faced issues with transparency. They often didn't know who was actually making their products, or why the quality fluctuated from batch to batch. While trading companies have their place, understanding the distinction is vital for long-term business growth.

Buying from a trading company offers easier communication but often results in higher prices and less control; conversely, buying directly from a specialized OEM factory ensures lower costs, direct technical support from engineers, and greater flexibility for custom branding.

Deciding between the two depends on your business model and volume, but for those scaling up, the factory route is usually superior.

The Trading Company Model

Trading companies are essentially middlemen. They buy from factories like ours and resell to you.

-

Pros: They may speak better English and can source a wide variety of unrelated products (e.g., furniture and hardware together).

-

Cons: You pay a markup (usually 15-30%). If a quality issue arises, the trader has to relay messages back and forth to the factory, causing delays and miscommunication.

The Specialized Factory (OEM) Benefit

When you work directly with us, you are talking to the source.

-

Direct Cost: No middleman markup. You get the factory-gate price.

-

Technical Control: If you need to modify a design to make it stronger, you talk directly to the engineers who design the mold.

-

Customization: It is much easier to implement OEM branding (like adding your logo to the casting) when you control the tooling.

Manufacturer vs. Trading Company Checklist

| Aspect | Trading Company | Specialized Factory (OEM) |

|---|---|---|

| Pricing | Higher (includes commission) | Lower (direct cost) |

| Product Knowledge | General | Specialized/Technical |

| Quality Control | Third-party inspection | In-process monitoring |

| Problem Resolution | Slow (relays messages) | Fast (direct action) |

| Customization | Limited | High (Tooling control) |

What Should You Look for When Sourcing a Casting Supplier?

Before signing a contract or transferring a deposit, we always suggest that our potential clients perform a strict due diligence process. We have seen too many buyers get burned by factories that promised high quality but delivered scrap metal. The difference between a reliable partner and a risky liability often comes down to documentation and transparency.

When sourcing a casting supplier, you must verify they can provide Mill Certificates for every batch, confirm that you retain full ownership of any custom molds you pay for, and ensure they have in-house expertise in high-end surface polishing.

Material Certification

Ask the supplier: "Can you provide a Mill Certificate for every shipment?" A (or Material Test Report) proves the chemical composition of the steel. Honest factories provide this as a standard part of the shipping documentation. If they hesitate, it is a red flag.

Tooling Ownership

In investment casting, you often pay a "mold fee" or "tooling fee" to create the wax injection die. You must clarify that you own this mold. If you decide to switch suppliers or move production, you should be able to take that mold with you. We state this clearly in our contracts: the client pays for the mold, so the client owns the mold.

Surface Finish Expertise

Casting is only half the battle. For glass hardware, the visual finish is what sells the product. A casting comes out of the shell looking dull gray. It requires skilled laborers to grind and polish it to a satin or mirror finish. Look for a factory that treats polishing as a core competency, not an afterthought.

Conclusion

Understanding exactly what a casting factory—or foundry—does is the first step toward securing a reliable supply chain for your business. Whether you are a distributor in Europe or a contractor in the US, knowing the difference between sand casting and investment casting ensures you get the precision and durability your projects demand.

At Aleader, we pride ourselves on being more than just a facility that melts metal. We are a partner in engineering, quality control, and global logistics. If you are looking for a direct manufacturing partner who understands the nuances of glass hardware, we are ready to help you build your next successful product line.

Frequently Asked Questions

What is the difference between a foundry and a factory?

A foundry is a specific type of factory that deals with melting and pouring metal. All foundries are factories, but not all factories are foundries (e.g., a factory that just assembles parts is not a foundry).

What metals are used in investment casting factories?

Investment casting foundries typically specialize in high-melting-point alloys like Stainless Steel (304, 316, 2205), Carbon Steel, and Titanium.

Why is it called "Investment" casting?

It comes from the old English word "invest," meaning "to clothe" or "surround." The ceramic slurry "invests" (surrounds) the wax pattern to create the mold.

Footnotes

1. Guide to common industrial manufacturing terms and definitions.

2. Overview of sand casting processes for rough metal components.

3. Explanation of high-pressure die casting for consumer goods.

4. Detailed breakdown of the investment casting or lost wax technique.

5. How induction technology efficiently melts metals for casting.

6. Principles of optical emission spectroscopy for chemical analysis.

7. Properties and applications of Grade 316 stainless steel.

8. Introduction to Computer Numerical Control (CNC) machining technology.

9. Standard testing methods for evaluating corrosion resistance.