At our production facility, we often encounter clients who wonder why we still rely on pouring liquid metal when advanced exist. It is a valid question. Modern technology is impressive, but it often hits a wall when faced with intricate internal geometries or specific high-performance alloys. We see firsthand how relying solely on machining can lead to excessive material waste and design compromises that limit product performance.

The three key importances of casting are unlimited design freedom, extensive material versatility, and superior economic efficiency through near-net-shape production. This manufacturing process allows for complex internal structures impossible to machine, supports virtually any alloy type regardless of hardness, and drastically reduces raw material waste, making it the backbone of modern industrial fabrication.

To help you understand why this ancient yet evolving technique remains crucial, we have broken down its specific advantages below.

How Does Casting Enable Complex Design Freedom?

When we sit down with engineers to review new product blueprints, we frequently identify features that are simply impossible to cut with a tool. Standard machining works in straight lines and cannot reach around corners to create curved internal chambers. This limitation forces designers to simplify their vision, often sacrificing efficiency or performance just to make the part manufacturable.

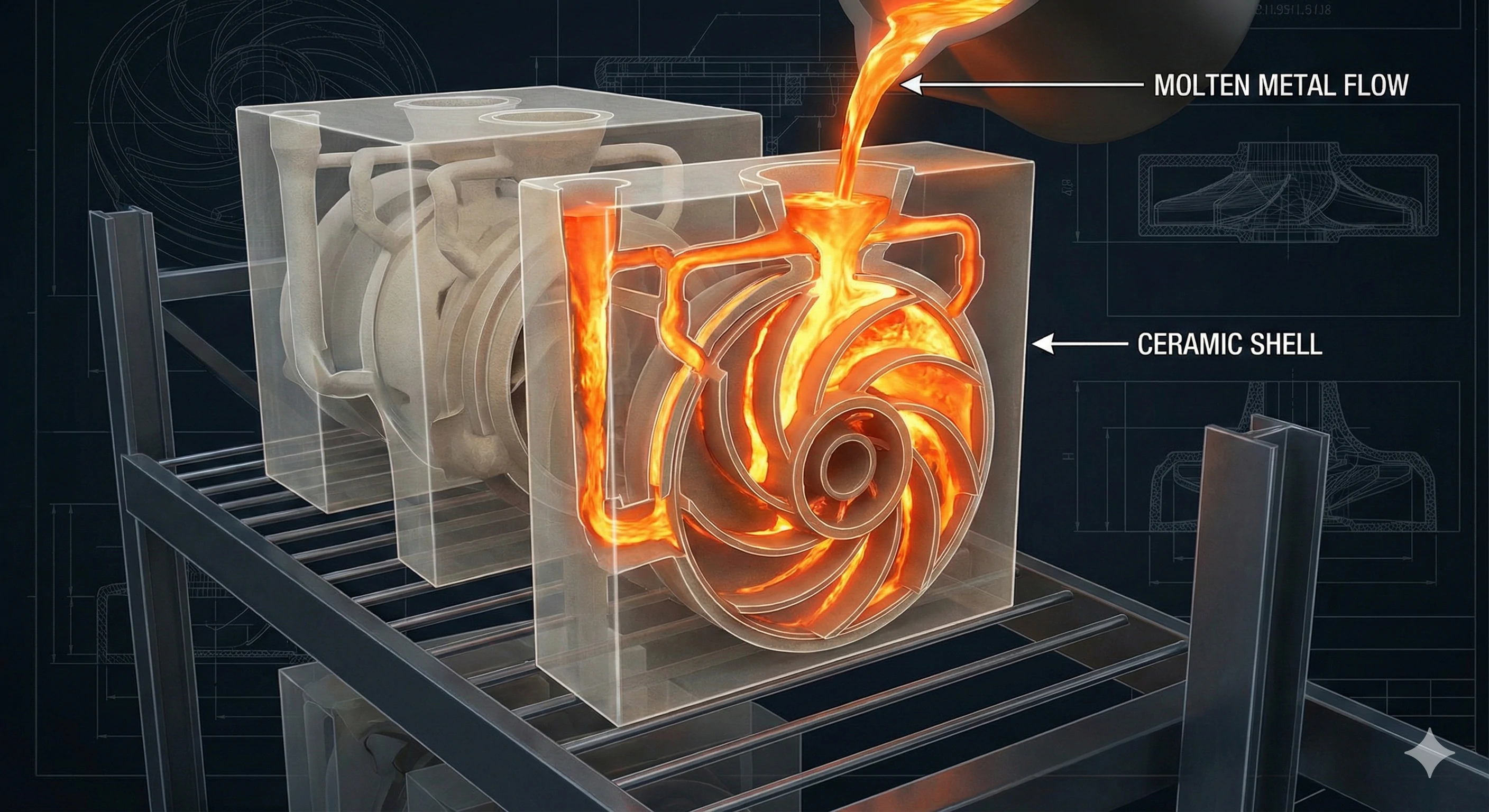

Casting eliminates geometric restrictions by allowing molten metal to flow into any shape defined by a mold, regardless of complexity. This capability enables the creation of intricate internal channels, hollow structures, and organic curves found in components like pump impellers, which are physically impossible to fabricate using subtractive manufacturing or forging methods.

The primary reason we champion this method is its ability to create the "impossible." In the world of , you are limited by the path of the cutting tool. If a drill bit cannot reach a specific area, you cannot machine it. This is a significant hurdle for parts like valve bodies or pump impellers, which require smooth, curved internal vanes to move fluids efficiently.

Breaking the Line-of-Sight Barrier

In our foundry, gravity does the work that a CNC machine cannot. Liquid metal flows into every crevice of the ceramic shell or sand mold. This allows us to produce hollow parts with internal strengthening ribs—features that reduce weight without sacrificing structural integrity. For example, when we design bases for heavy-duty hardware, we can hollow out the core to save material while keeping the external dimensions robust.

If you were to try and machine these hollow, ribbed structures from a solid block, you would spend hours cutting away material, and you still would not be able to create the undercuts. The table below highlights where casting wins over other methods regarding shape complexity.

Comparison of Manufacturing Geometric Capabilities

| Feature | CNC Machining | Forging | Casting |

|---|---|---|---|

| Internal Cavities | Limited (Line of sight only) | Impossible | Unlimited |

| Under-cuts | Difficult (Requires special tools) | Impossible | Easy |

| Hollow Sections | Expensive (Requires assembly) | No | Standard |

| Organic Curves | Time-consuming (3D surfacing) | Limited | Natural |

Why Is Material Versatility a Key Benefit of Casting?

In our daily melting operations, we handle a vast array of alloys, from standard carbon steel to exotic superalloys. We often see designs specified in materials that are incredibly difficult to cut or shape using force. When a project demands a metal that is too hard for tooling or too brittle to be hammered, manufacturers who rely on forging or machining hit a dead end, leading to sub-optimal material substitutions.

Material versatility allows engineers to select the exact alloy required for a specific environment without worrying about machinability or formability. Whether the application demands heat-resistant superalloys, corrosion-resistant stainless steel, or lightweight aluminum, casting accommodates metals that are otherwise too hard, brittle, or difficult to weld, ensuring the final product meets all performance criteria.

This flexibility is a game-changer for industries requiring high-performance materials. In machining, the "machinability rating" of a metal dictates production speed and cost. Harder metals wear out tools faster, driving up prices. In our process, however, hardness is irrelevant during the forming stage because the metal is liquid. If we can melt it, we can cast it.

Beyond Standard Metals

This freedom allows us to work with materials that would be nightmares for other processes. For instance, Nickel-based superalloys like are essential for high-heat environments but are notoriously difficult to machine. Similarly, is excellent for vibration dampening but is too brittle to forge. By using casting, we ensure that the material choice is dictated by the part's function—such as corrosion resistance or heat tolerance—rather than the limitations of the manufacturing equipment.

We categorize our material capabilities to help clients understand their options:

Common Casting Alloy Categories

| Category | Common Alloys | Key Properties | Best Application |

|---|---|---|---|

| Ferrous | Carbon Steel, 304/316 Stainless | Strength, Corrosion Resistance | Structural hardware, Marine parts |

| Non-Ferrous | Aluminum, Bronze, Zinc | Lightweight, Anti-sparking | Aerospace, Decorative fittings |

| Superalloys | Inconel, Hastelloy | Extreme Heat Resistance | Turbine blades, Chemical processing |

How Does Near-Net-Shape Production Drive Economic Efficiency?

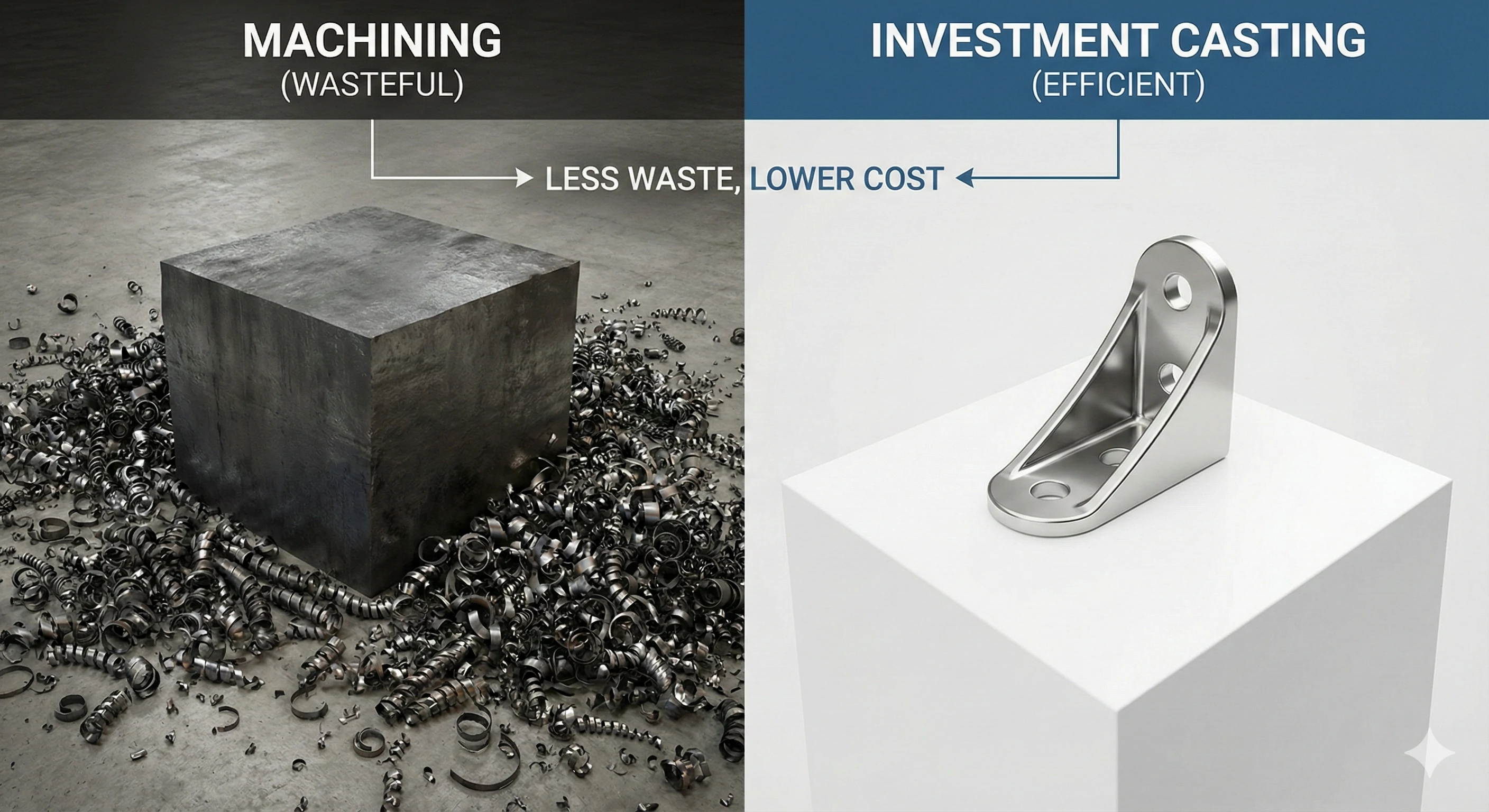

We constantly calculate the cost of raw materials versus the weight of the finished product to keep our prices competitive. It is painful to watch a machining process turn a massive block of expensive stainless steel into a pile of scrap metal just to reveal a small part inside. This "subtractive" approach is inherently wasteful and drives up costs, especially when working with high-value alloys.

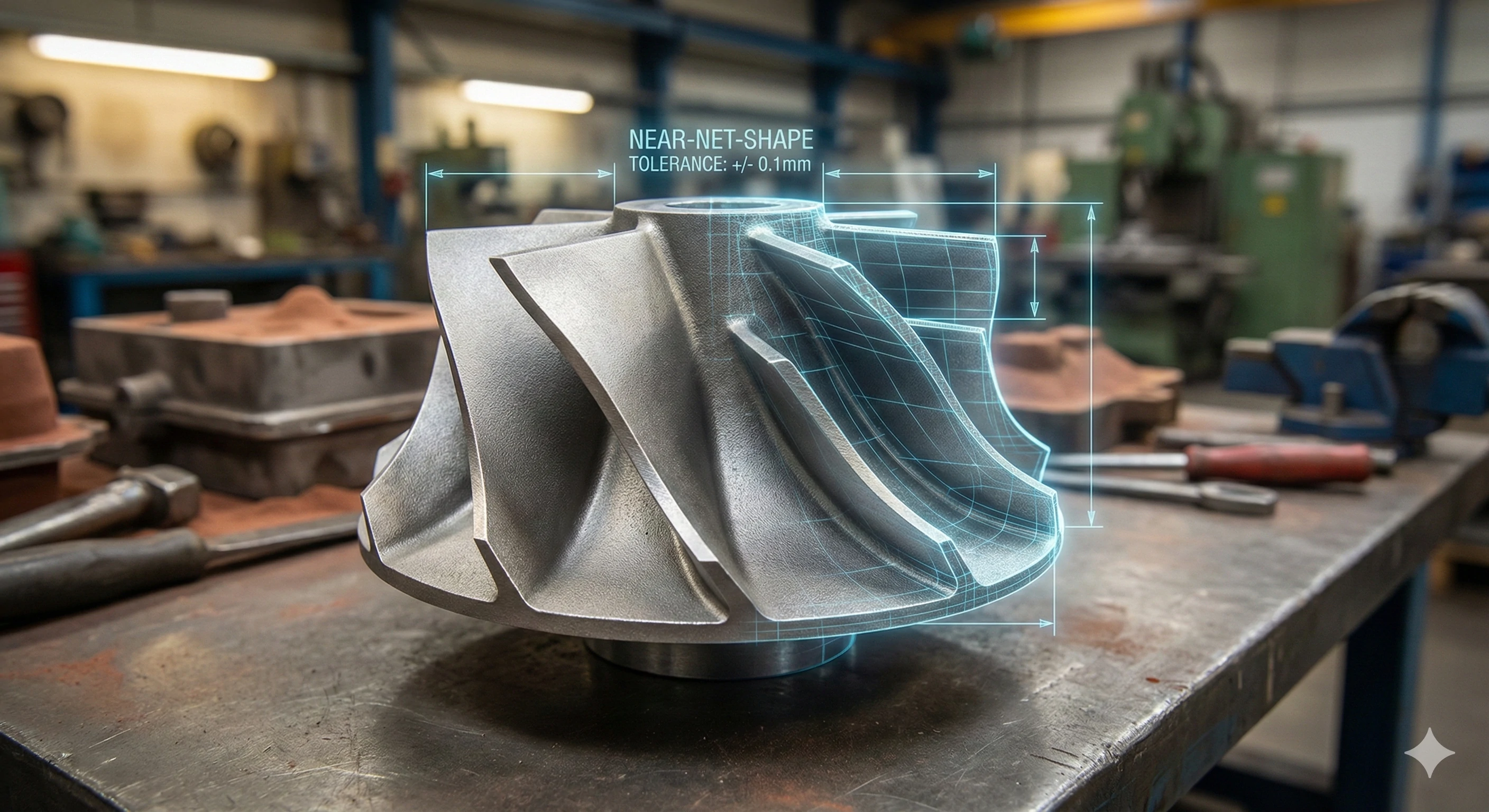

Near-net-shape manufacturing significantly reduces production costs by minimizing raw material usage and virtually eliminating machining time. Unlike subtractive methods that can turn up to 80% of stock material into scrap chips, casting produces components that emerge from the mold very close to their final dimensions, resulting in a much lower buy-to-fly ratio.

The economic advantage here is driven by the —the weight of the raw material you buy versus the weight of the final part that "flies" (or is used). In machining, this ratio is often poor. You might buy a 10kg block to make a 2kg part, wasting 8kg of material. In our factory, if we need a 2kg part, we pour roughly 2.5kg of metal. The waste is minimal, and the sprue (the funnel where metal enters) can often be remelted and recycled immediately.

Scaling for Mass Production

Once we create the mold tooling, the cost per unit drops dramatically. Making 10,000 copies of a complex shape becomes fast and cheap. With precision methods like , tolerances are so tight (+/- 0.1mm) that many parts require no machining at all. They are ready to use right after cleaning. This saves huge amounts of labor hours that would otherwise be spent facing, turning, and drilling.

The Cost of Waste: Machining vs. Casting

| Cost Factor | CNC Machining from Solid | Investment Casting |

|---|---|---|

| Material Usage | High Waste (Chips/Scrap) | Efficient (Near-Net-Shape) |

| Buy-to-Fly Ratio | Often 5:1 or higher | Typically 1.2:1 |

| Machining Labor | High (Roughing + Finishing) | Low (Finishing only) |

| Tooling Cost | Low (Standard tools) | Moderate (Mold required) |

Why Is Isotropic Strength Critical for Safety?

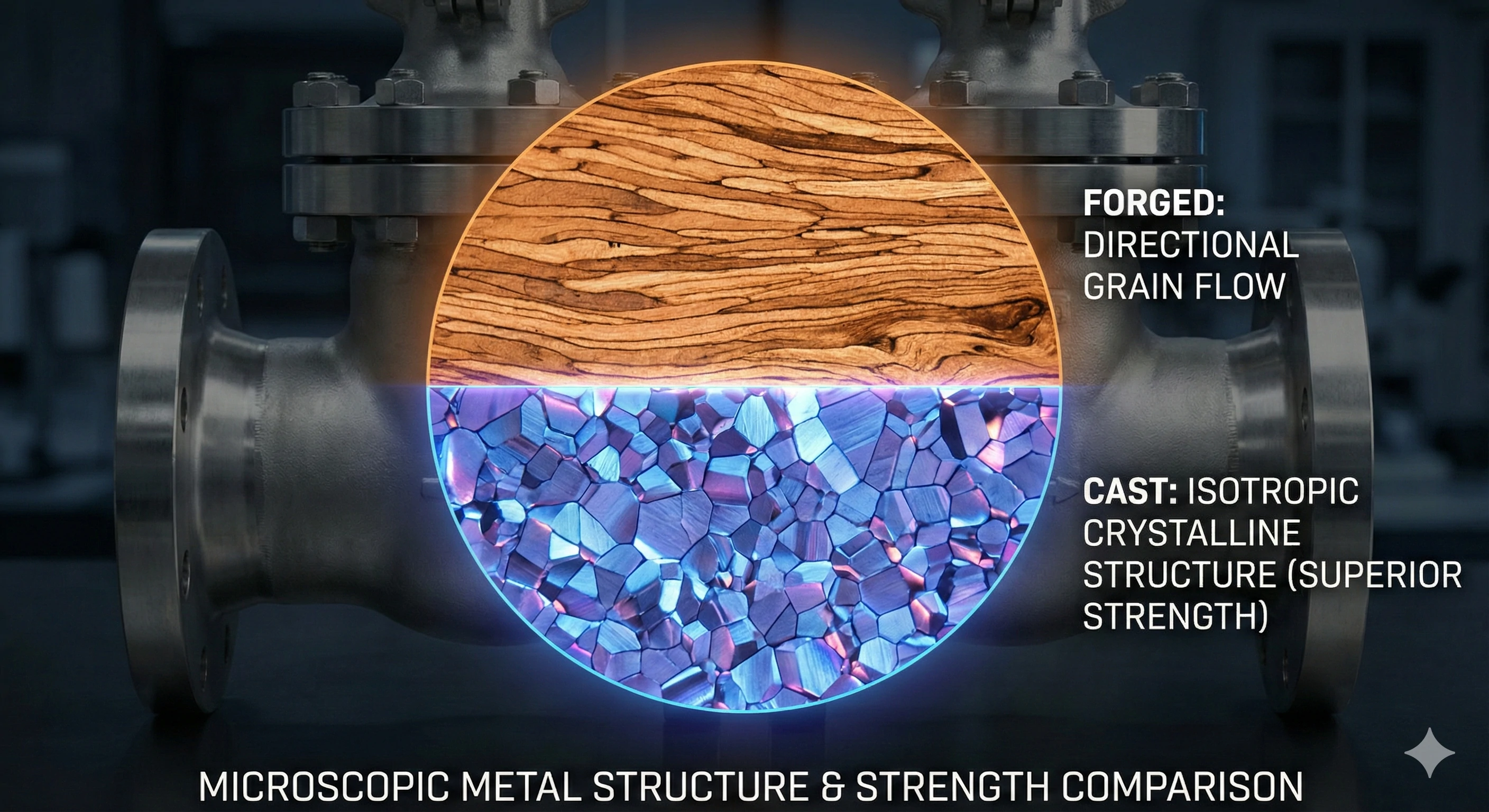

During our quality control checks, we pay close attention to how a part handles stress from different directions. We know that forged parts have a "grain," similar to wood, making them strong in one direction but potentially weak in another. This directionality can be a hidden risk in components that face pressurized loads from multiple angles, leading to unexpected failures in the field.

Isotropic strength ensures that a metal component possesses equal physical properties and durability in all directions, preventing weak points associated with directional grain flow. While forging creates strength aligned with the metal's deformation, casting provides a uniform crystalline structure, making it the safer and more reliable choice for pressurized parts like valve bodies that experience stress from all sides.

This is a technical point that engineers deeply appreciate. When you forge a part, you are hammering the metal, which elongates the grain. While this makes the part very strong against impact in the direction of the hammer blow, it creates susceptibility to transverse stress.

Uniform Safety Factors

In our casting process, the metal solidifies uniformly as it cools. This creates an isotropic structure, meaning the mechanical properties— , elongation, and hardness—are the same regardless of which way you test them. For components like our glass hardware or high-pressure valves, this is non-negotiable. A valve body does not just take pressure from top to bottom; it expands outward in all directions. Isotropic strength ensures there is no "weak side" that could burst under pressure.

Case Study: Why Do We Choose Casting for Glass Spigots?

Looking at our own catalog, specifically our glass spigots, helps illustrate these benefits in a real-world scenario. Our customers demand a product that holds heavy tempered glass panels securely, resists the corrosive outdoor elements, and looks like a piece of jewelry. We realized early on that fabricating these from welded plates would result in an ugly, vulnerable product.

We utilize investment casting for our glass spigots to achieve a seamless, corrosion-resistant stainless steel body without unsightly weld lines. This manufacturing choice guarantees the high structural integrity needed to support heavy glass railings while delivering the smooth, mirror-polished aesthetic required for high-end architectural projects.

This is where the theory meets the road. A glass spigot needs to be made of or 316 Stainless Steel to survive in coastal environments. If we tried to machine these spigots from a solid block of stainless steel, the cost would be astronomical due to the wasted material and the time required to mill the complex clamping slot.

The Problem with Welding

Alternatively, if we tried to weld pieces of steel plate together, we would introduce a (HAZ) at every seam. These seams are prone to rusting and are structurally weaker than the base metal. By casting the spigot as a single, monolithic piece, we solve three problems at once:

-

Aesthetics: No weld seams to grind or hide.

-

Durability: No heat-affected weak points.

-

Cost: We pour the exact shape needed, minimizing expensive stainless steel waste.

Conclusion

Casting is not just a legacy method; it is the only manufacturing process that successfully combines geometric complexity with material freedom and economic efficiency. By choosing this route, we ensure that our products—from intricate to robust glass hardware—are safe, durable, and cost-effective.

If you have a design that seems impossible to machine or requires a specific alloy for better performance, do not compromise your vision. Utilize the Design Freedom of Investment Casting. Send us your drawing today for a manufacturing review, and let's discuss how we can bring your complex parts to life efficiently.

Footnotes

1. Definition and history of Numerical Control (CNC).

2. Overview of subtractive manufacturing processes and tools.

3. Technical properties and uses of Inconel alloys.

4. Encyclopedia Britannica entry on cast iron properties.

5. Explanation of buy-to-fly ratio in aerospace and manufacturing.

6. Detailed guide to the investment casting process.

7. Testing methods for determining material tensile strength.

8. Material science breakdown of Duplex 2205 stainless steel.

9. Technical analysis of HAZ in welded materials.