Silica sol casting is a precision casting process based on a dispersion of nano-sized silica particles. Its core principle involves utilizing silica particles with a particle size of 5–100 nanometers to form a stable dispersion system in water. This seemingly milky-white liquid serves as the key binding material for casting molds.

During the casting process, silica sol penetrates the micro-pores of refractory materials. After dehydration, the silica particles form a three-dimensional network structure, firmly bonding refractory materials such as zircon sand or corundum powder. This nanoscale bonding mechanism enables the mold to precisely replicate complex structures while withstanding the impact of molten metal at 1600°C.

Key castings in chemical equipment

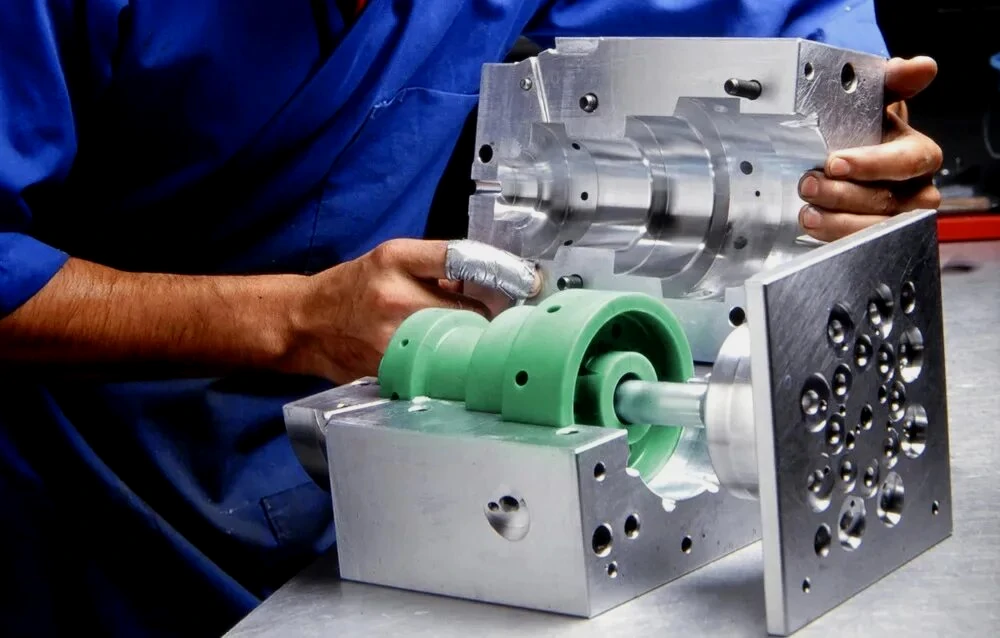

Fluid conveyance components

Chemical pump impellers face severe corrosion issues when conveying sulfuric acid media containing solids. Silica sol casting of 316L stainless steel impellers achieves flow channel precision of ±0.2 mm, extending service life by over three times compared to traditional processes. Typical examples include acid-resistant pump components developed by Jiangsu Shengpu Machinery.

Reaction system components

Reactor agitator blades made via silica sol casting enable hollow structures with wall thicknesses less than 3 mm, reducing weight by approximately 30%. Agitator components made from Hastelloy C276 material effectively resist corrosion in strongly oxidizing environments.

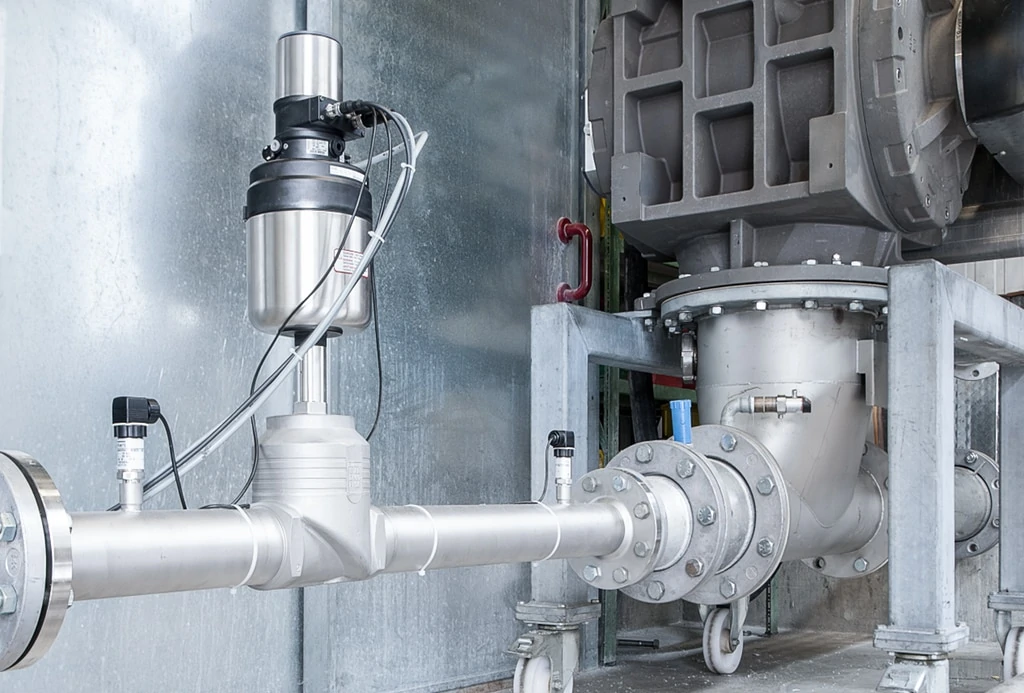

Separation system components

Centrifuge drums and membrane housings achieve precise inner wall finishing (Ra ≤ 0.4 μm) via silica sol casting, significantly reducing medium adhesion. These components can withstand a working pressure of 10 MPa and resist salt spray corrosion.

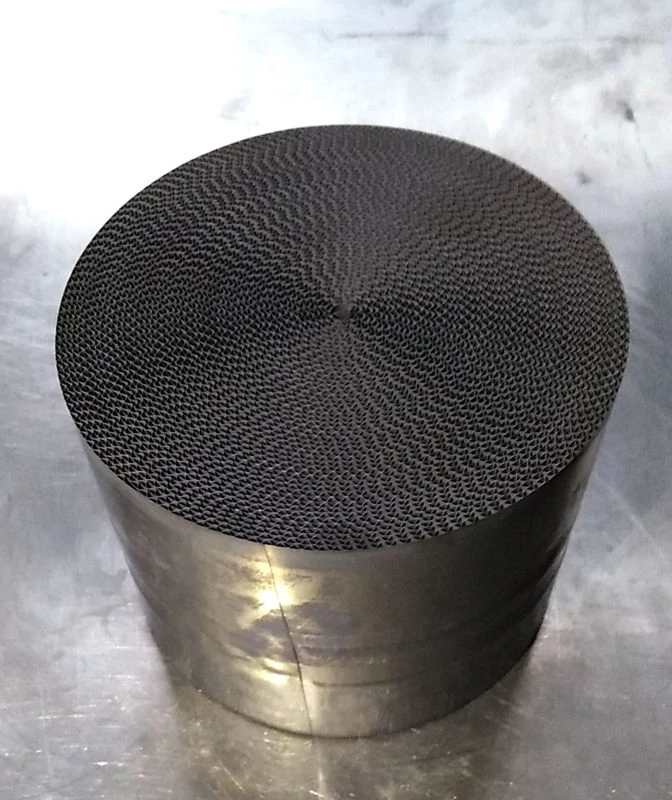

Catalytic reaction components

Silica sol-bonded honeycomb catalyst supports have a high specific surface area of 200–300 m²/g. The silica sol binder modified with aluminum maintains structural stability at high temperatures of 800°C.

Analysis of the sol-gel casting process

The entire process comprises four key technical stages

Coating stage

The model is immersed in a mixture of sol-gel and zirconium silicate powder slurry to form a base coating approximately 0.5 mm thick.

Curing stage

The coating is dehydrated and cured in a constant-temperature environment of 25–30°C (the fast-drying sol-gel reduces this to 2.5 hours).

Reinforcement stage

During the 950°C sintering process, the silica-oxygen network structure is reinforced, increasing the mold shell's compressive strength by 10 times.

Forming stage

Melted alloy is injected into the mold cavity, and after cooling, the ceramic mold shell is removed to obtain the precision casting.

Technological Development Trends

Silica sol casting technology is evolving toward higher efficiency, enhanced reinforcement, and sustainability

Quick-drying technology: Acidic quick-drying silica sol (e.g., Yuda FSK series) improves drying efficiency by 3 times

Material reinforcement: Shells containing 1-3% nano-Al₂O₃ can withstand temperatures up to 1800°C

Resource recycling: Waste shells can be recycled to produce refractory brick materials

Smart molding: Combining 3D-printed molds enables delivery of complex impellers within 72 hours

Conclusion

Silica sol casting technology, with its unique nano-scale silica dispersion system, addresses the special requirements of chemical industry equipment in terms of corrosion resistance, high-temperature stability, and structural precision. From pump impellers to reactor internal components, this technology is continuously enhancing the reliability and service life of chemical equipment. With the integration of fast-drying technology and smart manufacturing, the application value of silica sol casting in the chemical equipment manufacturing sector will further increase.