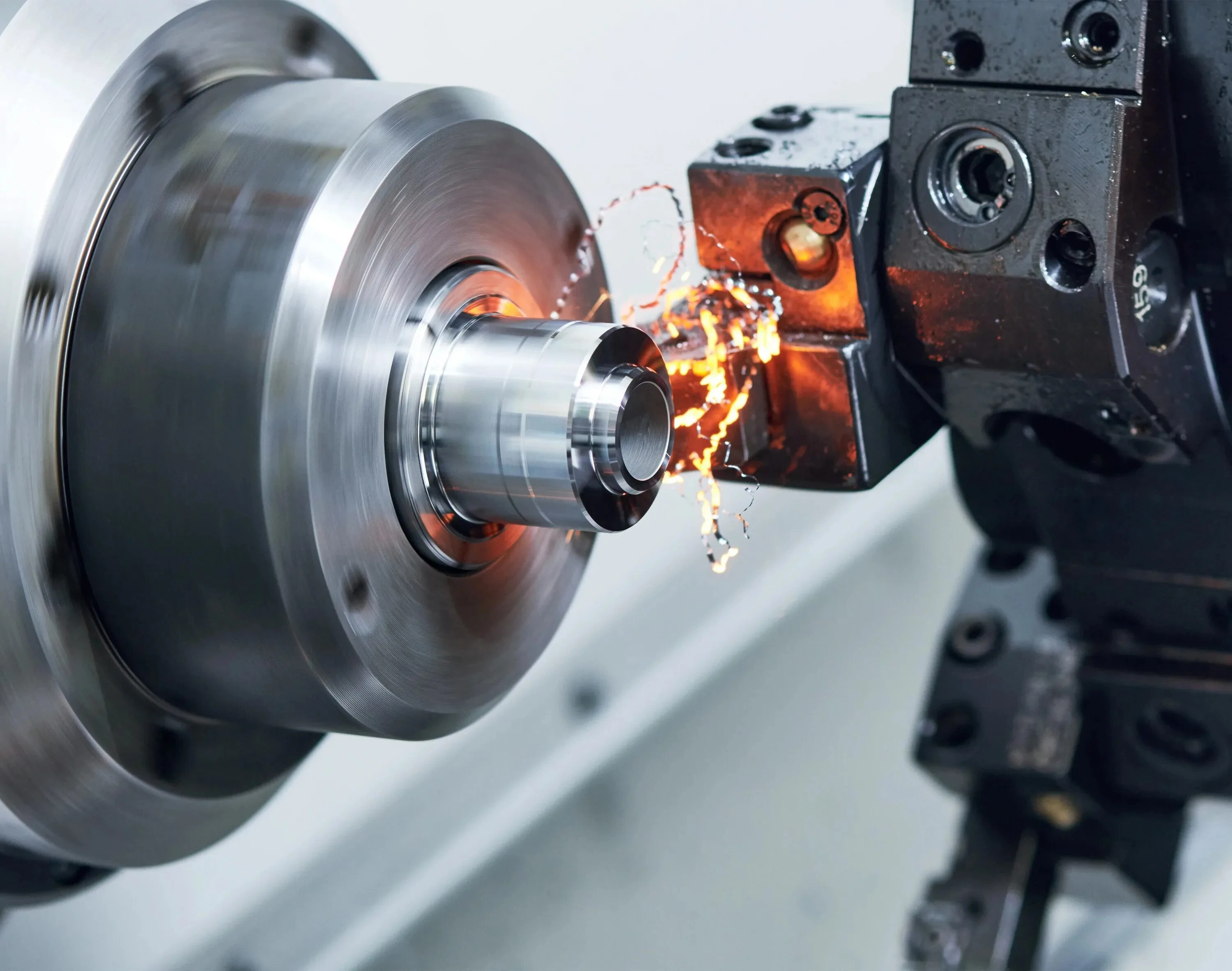

In precision manufacturing, castings serve as the "prototypical carriers" of fundamental components. Their machining processes directly determine the final product's accuracy, performance, and service life. Whether it's automotive engine blocks, hydraulic valve blocks in construction machinery, or complex structural components in aerospace engineering, none can be achieved without the meticulous refinement of casting machining. However, inherent material characteristics (such as the brittleness of gray cast iron and the tool adhesion properties of aluminum alloys), variations in surface roughness, and internal defects like sand holes and pores all pose unique challenges for machining. Today, we'll discuss how to optimize casting machining from three dimensions: process selection, quality control, and efficiency enhancement, providing actionable insights for manufacturers to reduce costs and improve productivity.

The core process of casting machine processing: "tailor-made" according to the material and demand

The machining process paths for castings with different materials vary significantly. Blindly applying generic procedures not only leads to excessive tool wear but may also compromise processing accuracy due to improper cutting parameters —— a common pitfall many manufacturers fall into.

1. Material adaptation: process differentiation from cast iron to aluminum alloy

Gray Cast Iron / Ductile Cast Iron Components: These castings exhibit high hardness (HB 180-250) but are brittle, making them prone to chip breakage during machining. It is recommended to prioritize using carbide tools (e.g., WC-Co alloy), maintaining a cutting speed of 80-150 m/min with appropriate feed rate 0.15-0.3mm/r, while incorporating a high-pressure cooling system to minimize tool wear caused by thermal generation during operation.

Aluminum alloy castings: Although aluminum alloys are relatively soft (HB60-120), they tend to cause "knife sticking" during machining, resulting in reduced surface finish. To address this, use coated cutting tools (e.g., TiAlN-coated high-speed steel), increase the cutting speed to 200-400m/min, and employ emulsion cooling to prevent chip adhesion on the cutting edge.

Stainless steel castings: Stainless steel exhibits high strength at elevated temperatures but poor thermal conductivity, making it prone to work hardening during machining. It is recommended to use ultra-fine-grained cemented carbide tools with low-speed cutting (50-100m/min) and high feed rates (0.2-0.4mm/r), while implementing enhanced chip removal design to prevent workpiece entanglement.

2. Key process: "division of labor" between rough machining and finishing

Die machining is usually divided into three stages: rough machining, semi-finishing and finishing. The objectives of each stage are different and the process focus should be distinguished.

Rough machining: The core is to quickly remove the sprue, flash and excess material on the surface of the casting for subsequent "shaping" processing. In this stage, deep cutting (3-10mm) and large feed can be used, but attention should be paid to avoid deformation of the casting due to excessive cutting force (especially thin-walled castings);

Semi-finishing: Mainly targets the key surfaces of castings (such as locating holes, reference surfaces) for processing, ensuring surface roughness Ra6.3-12.5μm, providing a precise benchmark for finishing. It is recommended to use milling, boring, etc., with a control of machining allowance between 0.5-2mm;

Precision machining: The critical process determining final product accuracy requires maintaining dimensional tolerances within IT7-IT9 grades and surface roughness Ra0.8-3.2μm. For high-precision holes and shaft components, grinding or honing processes are recommended. Complex curved surfaces should utilize five-axis machining centers to ensure precise alignment between actual machining paths and design specifications.

Quality control: avoid "hidden defects" and maintain the bottom line of accuracy

Quality issues in casting machining often stem not from the process itself, but from overlooking "pre-processing risks". For instance, internal sand holes and shrinkage cavities in castings—if undetected during pre-processing—may lead to post-processing defects like "over-machining" or "dimensional deviations", potentially causing workpiece rejection. Therefore, quality control must be implemented throughout the entire lifecycle: from pre-processing through manufacturing to post-processing.

1. Before processing: do a good job of "physical examination" of castings to eliminate congenital defects

Initial inspection of appearance and size: visually check whether there are cracks and flash on the surface of the casting, measure the size of the casting blank with calipers and micrometers, and judge whether the allowance is uniform (it is recommended that the allowance deviation does not exceed ±0.5mm);

Internal defect detection: For key castings under high pressure and high temperature (such as engine cylinder head), nondestructive testing technology (such as ultrasonic testing, X-ray testing) should be used to investigate internal defects such as sand hole, porosity and shrinkage, so as to avoid the defects entering the processing process.

2. Processing: real-time monitoring to avoid "process deviations"

Tool condition monitoring: through the tool wear monitoring system (such as vibration sensor, current sensor), the wear degree of the tool is fed back in real time. When the tool wear exceeds 0.2mm, it should be replaced in time to prevent the machining accuracy from being reduced due to tool edge blunting;

Dimension accuracy feedback: in batch processing, 1-2 pieces of workpieces are randomly selected for size detection (using a three-coordinate measuring instrument) every 10-20 pieces. If the dimensional deviation exceeds the tolerance range, machine tool parameters (such as feed and cutting speed) should be adjusted in time.

3. After processing: full inspection to ensure "zero defects out of the factory"

Dimension and form tolerance inspection: focus on the detection of key dimensions (such as hole diameter, shaft diameter), parallelism, perpendicularity, coaxiality and other form tolerance of the workpiece to ensure that it meets the requirements of the design drawings;

Surface quality inspection: measure the Ra value with a surface roughness meter, visually check whether there are scratches and vibration marks on the surface, and perform air tightness test for workpieces with sealing requirements (such as hydraulic valve block) to prevent leakage.

Efficiency upgrade: from "passive processing" to "active optimization" of cost reduction

Under the current trend of "cost reduction and efficiency increase" in the manufacturing industry, casting machine processing should not only stop at the level of "completing the processing", but also realize the balance between efficiency and cost through process optimization, equipment upgrading and management improvement.

1. Process integration: reduction of processes and shortening of processing cycles

Traditional casting processing often requires multiple clamping and multi-machine collaboration, which is not only time-consuming, but also prone to affect the accuracy due to positioning errors. It is recommended to adopt the "process integration" idea:

For complex castings (such as gearbox housing), the five-axis machining center can complete milling, boring, drilling, tapping and other processes in one time, reducing the number of clamping times (from 3-4 to 1), and the processing cycle is shortened by more than 30%;

The use of "composite tools", such as a drill with chamfer function, integrated milling and boring tools, to achieve "one tool, many functions", reducing tool change time.

2. Equipment upgrade: Replace manual with automation to improve stability

Manual operation is not only inefficient, but also prone to poor product consistency due to human error. It is recommended to gradually introduce automation equipment:

Equipped with CNC lathes, machining centers and other automation equipment, through programming to achieve standardized processing, the product qualification rate increased from 85% to more than 98%;

For large batch castings (such as auto parts), an "automatic production line" is built, with robots for loading and unloading and automatic detection system, to achieve 24 hours of continuous production, and the per capita production capacity is increased by 2-3 times.

3. Cost control: "full chain savings" from tools, coolant to scraps

Tool life extension: by optimizing cutting parameters (such as reducing cutting speed 5%-10%) and using tool coatings (such as AlCrN coating), tool life can be extended by more than 50% and single tool cost reduced by 30%;

Coolant recycling: The coolant filtration system (such as magnetic separator, paper filter) is used to increase the number of coolant reuse from 5 times to 15 times, saving the coolant cost of 20,000-30,000 yuan per year;

Edge material recycling: cast iron and aluminum alloy edge materials produced by processing are classified and recycled, and sold to professional recycling enterprises, which can create tens of thousands of yuan of income every year.

Future trend: digital, intelligent lead to new changes in casting machining

With the advancement of industry 4.0, casting machining is developing towards "digital and intelligent":

Digital twin technology: by establishing a digital model of casting processing, the temperature and stress changes in the cutting process can be simulated to optimize the process parameters in advance and reduce the number of trial cuts;

AI visual inspection: use AI visual system to detect the surface quality of processing in real time, identify scratches, chipped edges and other defects, the detection efficiency is more than 10 times that of manual;

Green processing: promote green processes such as low temperature cutting and dry cutting to reduce the use of coolant, reduce environmental pollution, and reduce subsequent processing costs.

Conclusion

While casting machining may appear as a "traditional process," it actually embodies precise material characteristic control, meticulous pursuit of technical details, and smart balancing of efficiency and cost. For manufacturing enterprises, only through continuous process optimization, strict quality control, and embracing new technologies can they gain competitive advantages in fierce market competition. In the future, with ongoing technological advancements, casting machining will achieve higher precision, greater efficiency, and lower costs, injecting stronger momentum into the precision manufacturing industry.

If you encounter specific problems in the machining process of castings (such as wanting to understand our machining capacity between conventional sizes such as small and medium parts and oversized castings, and how to control the cost), please leave a message in the comment section, we will provide you with targeted solutions!