Marine pipeline systems serve as the "circulatory system" of ships, responsible for transporting key media such as fuel oil, seawater, steam, and hydraulic oil, running through various areas including the engine room, deck, and accommodation cabins. In the marine environment characterized by wind and wave turbulence, seawater corrosion, and pressure fluctuations, pipeline leakage is a "fatal hazard"—it may cause equipment shutdown at the least, and lead to serious accidents such as marine pollution from fuel leakage and mechanical damage from seawater ingress at the worst. As the "switches and barriers" of pipeline systems, the sealing performance of valves and fittings directly determines the safety of ship navigation. Precision casting technology is precisely the core support for manufacturing high-sealing and high-reliability valves and fittings, becoming the "key code" for leak prevention in marine pipelines.

The "Extreme Tests" for Marine Pipelines: Why Must Valves and Fittings Achieve "Zero Leakage"?

The complexity of the ship navigation environment imposes stricter requirements on valves and fittings than on land-based equipment, and the importance of sealing performance is magnified infinitely:

- Diverse and Corrosive Media: Marine pipelines need to transport media including high-sulfur fuel oil, salt-containing seawater, high-temperature steam, and hydraulic oil. Among them, the chloride ion concentration in seawater can exceed 3.5%, and sulfides formed after the combustion of high-sulfur fuel oil will form acidic corrosive media. Long-term exposure will erode the sealing surfaces of valves, leading to seal failure;

- Severe Fluctuations in Pressure and Temperature: When the ship's power system starts, accelerates, or decelerates, the pressure inside the pipeline may fluctuate rapidly between 0.1MPa and 10MPa, and the temperature may vary significantly from -20℃ (marine low-temperature environment) to 400℃ (steam pipelines). This requires valves and fittings to maintain stable sealing structures without deformation or cracking under alternating extreme temperatures and pressures;

- Strict Vibration and Space Constraints: Wind and wave turbulence during ship navigation will cause continuous vibration of the pipeline system, and valves and fittings must withstand high-frequency vibration without loosening; at the same time, the space on ships is limited, and valves are mostly compactly designed. The sealing structure must achieve efficient sealing in a small space and be easy to maintain;

- High Safety and Environmental Requirements: The International Maritime Organization (IMO) has increasingly strict environmental standards for ship leakage. Fuel oil and lubricating oil leakage not only face huge fines but also cause serious marine pollution; seawater and steam leakage may trigger chain failures such as short circuits of electrical equipment and corrosion of mechanical components, directly threatening navigation safety.

Under these tests, valves and fittings manufactured by ordinary casting or mechanical processing are prone to leakage caused by wear of sealing surfaces and casting defects. Precision casting technology solves these pain points from the root through process upgrades.

Precision Casting: Full-Process Control from "Forming" to "Sealing"

Precision casting (especially silica sol investment casting) relies on its characteristics of "near-net shaping, high precision, and low defects" to comprehensively guarantee the sealing performance of valves and fittings through material selection, structural design, and process control, which is specifically reflected in three core dimensions:

1. Precise Material Adaptation: Dual Guarantee of Corrosion Resistance and High Strength

The foundation of sealing performance lies in the stability of materials. Precision casting can select targeted corrosion-resistant and high-strength alloy materials according to the medium type of marine pipelines, avoiding seal failure caused by material corrosion or insufficient strength:

- Valves for Seawater Pipelines: Duplex stainless steel 2205, Hastelloy, and other seawater corrosion-resistant materials are selected. These alloys contain elements such as chromium, molybdenum, and nickel, which can form a dense passive film in the seawater environment. The chloride ion corrosion rate is less than 0.05mm/year, which is far superior to ordinary stainless steel;

- Valves for Fuel Oil Pipelines: Sulfur-resistant steel (such as A182 F53) or nickel-based alloys are used to resist acid corrosion from high-sulfur fuel oil, while possessing excellent high-temperature strength to maintain stable hardness of the sealing surface at fuel oil temperatures of 150-200℃;

- Valves for Steam Pipelines: Heat-resistant steel (such as ZG20CrMoV) is selected, which still maintains a tensile strength of over 400MPa at 400℃ and has excellent creep resistance, avoiding seal surface deformation and leakage at high temperatures.

Through processes such as vacuum casting and inoculation treatment, precision casting ensures uniform composition and refined grains of alloy materials, reduces impurities and pores, further improves the corrosion resistance and deformation resistance of materials, and lays the foundation for sealing performance.

2. Integrated Structural Forming: Eliminating Weak Sealing Points

Seal failure of valves and fittings often occurs at weak parts such as welded joints and assembly gaps. The "near-net shaping" technology of precision casting can realize the integrated forming of complex sealing structures, eliminating leakage hazards from the structure:

- Integrated Sealing Surfaces: Core sealing components of valves such as valve cores and valve seats are directly formed by precision casting. The sealing surfaces do not require welding or splicing, avoiding leakage caused by weld corrosion and cracking. The surface roughness of the sealing surface can be controlled at Ra≤1.6μm, and with subsequent precision grinding, the fitting degree of the sealing surface reaches over 99%;

- No Dead Ends in Flow Channels and Cavities: Precision casting can accurately replicate the complex flow channels and diversion structures inside the valve. The inner walls of the flow channels are smooth without burrs, reducing medium flow resistance and avoiding corrosion caused by medium accumulation in dead ends; for structures such as gate valves and ball valves, the integrated design of valve stems and valve cores can be realized, reducing assembly gaps and improving sealing reliability;

- Coordination of Thin Walls and Reinforcing Ribs: Under the constraint of limited ship space, precision casting can realize the thin-wall design of valve housings (minimum wall thickness 3mm), and at the same time improve structural strength through built-in reinforcing ribs, avoiding housing deformation caused by vibration or pressure fluctuations, and ensuring that the sealing surface always maintains precise fitting.

3. Strict Dimensional Accuracy Control: "Micron-Level" Control of Sealing Gaps

The core of sealing performance is "gap control". Precision casting controls the dimensional tolerance of valves and fittings at the micron level through the whole-process process control, ensuring that the fitting gap of the sealing surface meets the design requirements:

- Mold Precision Transmission: Silica sol investment casting uses high-precision wax pattern molds. The dimensional tolerance of the wax pattern can reach ±0.03mm. After shell making and pouring, the dimensional tolerance of the casting can be controlled at ±0.05mm, which is far superior to the ±0.5mm of sand casting, ensuring that the fitting gap between the valve core and the valve seat is accurately controlled at 0.005-0.01mm;

- Precise Control of Deformation: By simulating the temperature field and stress field during the pouring process, the gating system and cooling process are optimized to reduce the deformation of the casting during the cooling process, so that the flatness error of the sealing surface is ≤0.02mm/m, avoiding uneven sealing gaps caused by deformation;

- Surface Quality Optimization: The surface of precision castings is smooth, and can meet the sealing requirements without a lot of machining, reducing the damage to the precision of the sealing surface caused by machining, and at the same time reducing processing costs and cycles.

Practical Application: "Leak-Proof Performance" of Precision Cast Valves and Fittings

In key parts of marine pipeline systems, the leak-proof performance of precision cast valves and fittings has been fully verified, especially in the following two typical scenarios:

1. Valves for Marine Seawater Cooling Systems

The seawater cooling system is the "cooling core" of the ship's power system. Valves need to be immersed in seawater for a long time, withstand working pressures of 0.8-1.2MPa, and frequent switching operations. The duplex stainless steel 2205 ball valve manufactured by silica sol precision casting adopts a hard-sealing structure (tungsten carbide coating) on the sealing surface. Practical navigation verification shows that after 5 years of continuous use and more than 10,000 switching times, the leakage rate is still lower than 0.01MPa·L/s, which is far below the 0.1MPa·L/s standard specified by the International Maritime Organization, and there are no obvious corrosion or wear marks on the sealing surface.

2. Globe Valves for Marine Fuel Oil Transmission Pipelines

Globe valves for fuel oil transmission pipelines need to work under pressures of 1.5-3.0MPa and temperatures of 120-180℃, requiring "zero drip" sealing. The sulfur-resistant steel globe valve manufactured by precision casting has an integrated valve core and valve seat formed by silica sol investment casting, combined with a conical surface sealing design. After 3 years of use in high-sulfur fuel oil medium, the sealing performance has not deteriorated, and no fuel leakage has occurred, effectively avoiding fuel waste and environmental pollution.

Selection and Maintenance: Making the "Leak-Proof" of Precision Cast Valves and Fittings More Durable

To give full play to the sealing advantages of precision cast valves and fittings, selection and daily maintenance are also crucial:

- Select Models Matching Media and Working Conditions: Choose corresponding corrosion-resistant materials according to pipeline media (seawater, fuel oil, steam, etc.), and select appropriate sealing structures (hard seal, soft seal) according to working pressure and temperature to avoid seal failure caused by "material mismatch";

- Regularly Inspect the Condition of Sealing Surfaces: During navigation, regularly monitor the sealing performance of valves through pressure gauges. After berthing, disassemble and inspect whether there are scratches, corrosion, or wear on the sealing surfaces, and perform grinding and repair in a timely manner to avoid the expansion of small defects;

- Do a Good Job in Anti-Corrosion and Lubrication: Perform anti-corrosion treatment (such as spraying anti-corrosion coatings) on exposed valve components, and regularly apply special grease to moving parts such as valve stems to reduce friction and wear and improve sealing reliability;

- Choose High-Quality Casting Manufacturers: Prioritize precision casting enterprises with marine industry certifications (such as ABS, DNV, CCS) to ensure that the material, dimensional accuracy, and sealing performance of castings meet marine industry standards.

Conclusion

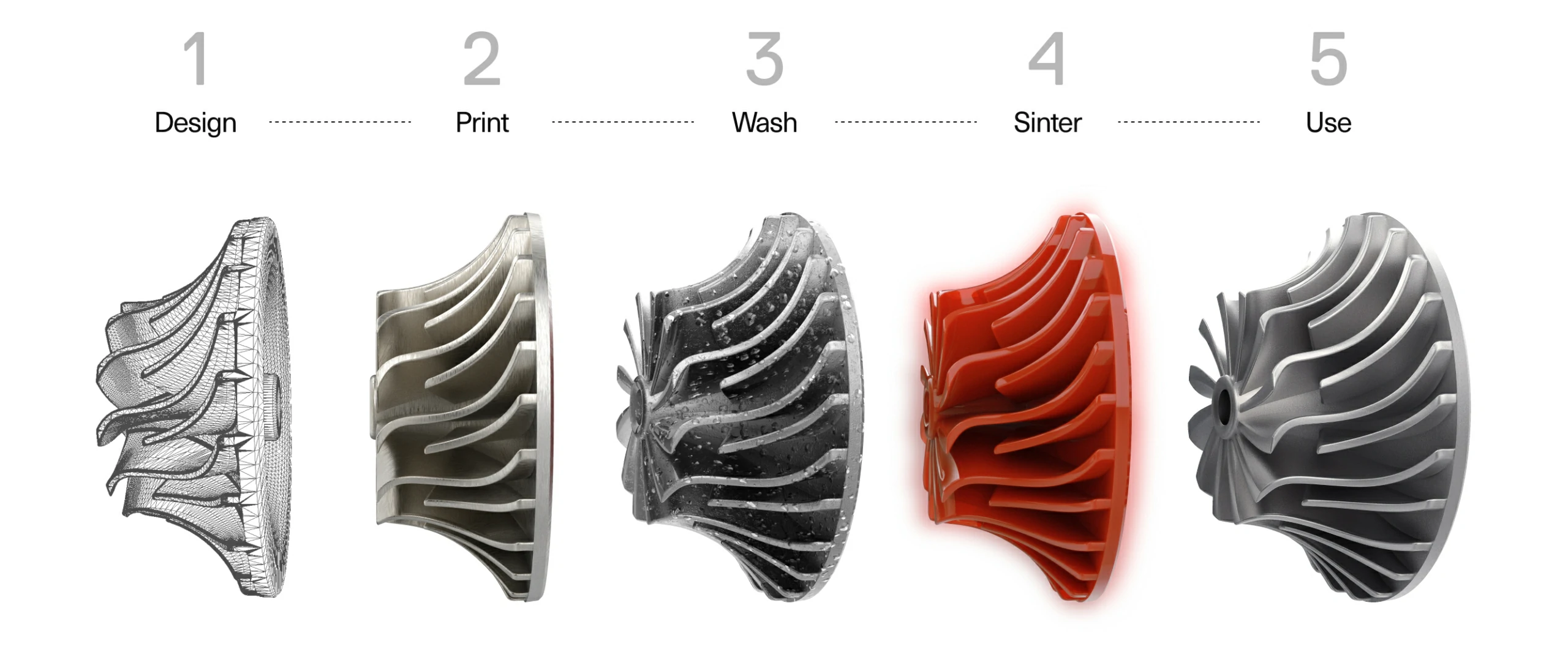

In marine pipeline systems, precision cast valves and fittings have become a "solid barrier" against leakage risks with their core advantages of "material adaptation, structural optimization, and precision control". From seawater cooling systems to fuel oil transmission pipelines, from low-temperature environments to high-temperature and high-pressure working conditions, these seemingly insignificant precision castings silently guard the navigation safety of ships and the marine environment. With the development of the marine industry towards large-scale and high-end directions, the requirements for the sealing performance of valves and fittings will be further improved. The continuous innovation of precision casting technology (such as 3D printed wax patterns and intelligent pouring control) will provide stronger technical support for the "zero leakage" goal of marine pipeline systems.