In the field of aluminum surface treatment, Painting Anodized Aluminum is a composite processing technology that combines performance and aesthetics. It first forms a hard, corrosion-resistant oxide film on the aluminum substrate through anodization, then imparts rich colors and appearance textures to the product through painting or coating treatment. This "double-layer protection" feature makes it highly favored in high-end cookware, architectural hardware, marine accessories and other fields. This article will detailedly break down its manufacturing process and core advantages, while sorting out key quality issues and control points for B2B buyers.

I. Why Combine Anodization and Painting? Analysis of Core Advantages

The combination of anodization and painting is not a simple superposition, but achieves a 1+1>2 effect through functional complementarity, becoming the preferred surface treatment solution for high-end aluminum products:

Superior Corrosion Resistance: The paint layer resists daily friction and external erosion, while the oxide film formed by anodization serves as a "second line of defense". Even if the paint layer is accidentally scratched, the dense oxide film can prevent the aluminum substrate from oxidizing and rusting (producing white rust), especially suitable for harsh environments such as humidity and salt spray.

Strong Paint Adhesion: The unsealed anodized layer is covered with tiny pores on the surface. These pores can firmly lock the paint like "anchors", improving adhesion by more than 30% compared to direct painting on bare aluminum and effectively preventing paint peeling.

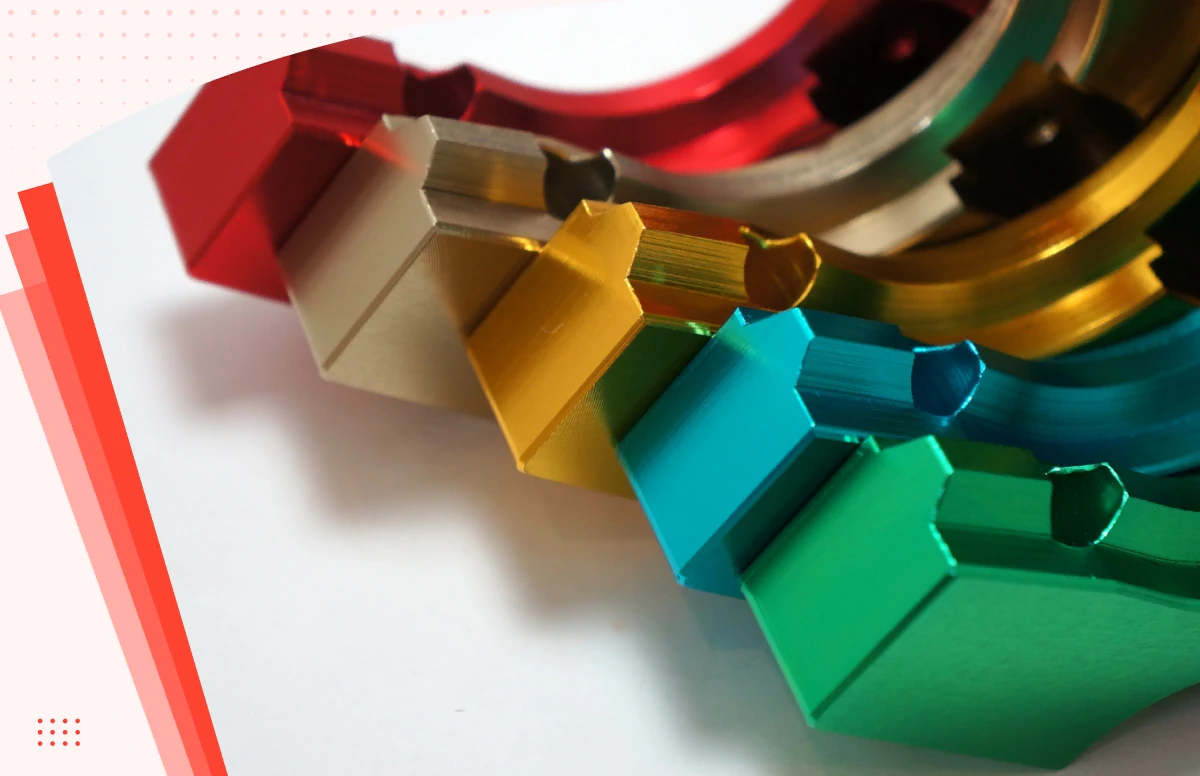

Diversified Color Aesthetics: Traditional anodization has limited color options (mostly basic tones such as natural color and black), while the painting process can achieve unlimited color customization such as matte black, pure white, and metallic colors. It also supports various texture requirements such as matte, high-gloss, and frosted, adapting to different product design styles.

Enhanced Physical Properties: The hardness of the anodized film can reach HV300-500, which can improve the surface wear resistance of aluminum products; after adding the paint layer, it can also increase scratch resistance and chemical corrosion resistance (such as oil stains and cleaning agents), extending the service life of the product.

II. Manufacturing Process of Painting Anodized Aluminum: Four Steps to Achieve Double Protection Precisely

Painting anodized aluminum is a sophisticated systematic project. The control of each link directly affects the final product quality. The specific process is as follows:

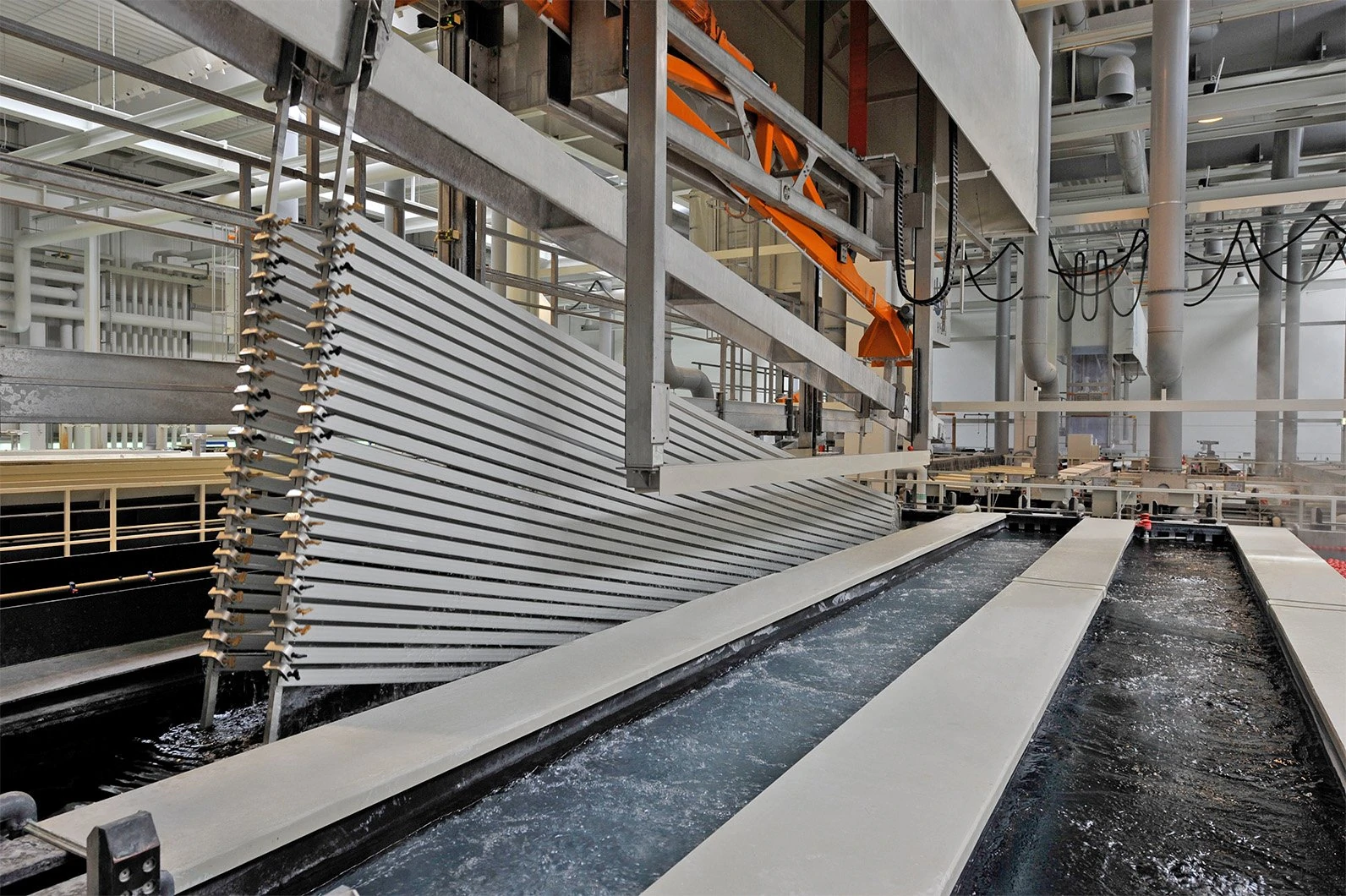

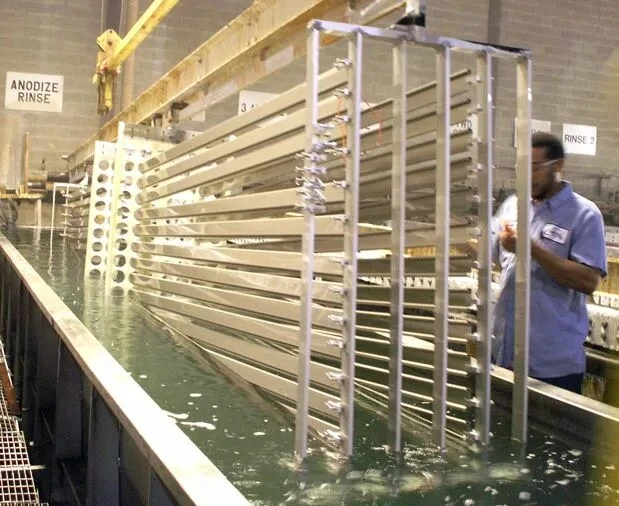

Step 1: Anodization Treatment (Core of Substrate Preparation)

First, put the aluminum product into an electrolyte solution such as sulfuric acid or oxalic acid, and form an oxide film on the surface through electrochemical reaction. The thickness of this oxide film is usually 5-20 microns, which not only has basic corrosion resistance, but its porous structure is also the key to subsequent paint adhesion.

Key Point: Anodization for painting needs to adopt an "unsealed" process to retain surface pores and enhance paint adhesion; for hard anodization (such as cookware applications), the oxide film thickness can be increased to 25-50 microns to further strengthen wear resistance.

Step 2: Pre-treatment and Cleaning (Removing Impurities to Ensure Adhesion)

After anodization, the product must be thoroughly cleaned to remove residual acid, oil and dust on the surface to avoid affecting the painting effect:

Routine Cleaning: Rinse with pure water and soak in alkaline degreaser to ensure no contaminants on the surface;

Special Treatment: For sealed anodized aluminum or old part renovation, chemical etching or sandblasting is required to create a rough surface (forming mechanical bonding points) for paint adhesion.

Step 3: Coating Application (Select Spraying Method as Needed)

Choose appropriate coating materials and spraying processes according to product usage and performance requirements:

Liquid Spraying (Wet Paint): Suitable for PVDF coatings, PTFE (Teflon) or ceramic coatings dedicated to non-stick pans. After spraying, the paint surface is delicate and uniform, suitable for products with high appearance requirements;

Powder Coating: Commonly used for architectural hardware (such as window frames and door handles). The powder coating is uniformly attached to the product surface through electrostatic adsorption, with uniform coating thickness, strong impact resistance, and environmentally friendly without volatile pollutants.

Step 4: Curing Treatment (High-temperature Crosslinking to Strengthen Bonding)

Put the sprayed product into an oven and achieve paint curing through high-temperature baking:

Curing Parameters: The temperature is usually 160-220℃, and the baking time is 15-30 minutes (adjusted according to the coating type);

Core Principle: Under high temperature, the paint undergoes crosslinking reaction and penetrates into the pores of the anodized layer, forming a stable structure of "physical embedding + chemical bonding" to ensure that the paint does not peel off for a long time.

III. Common Quality Problems and Defects: Essential Control Checklist for B2B Buyers

The painting process of anodized aluminum is complex, and improper operation in any link may cause defects. The following are the most common problems, their causes and detection methods:

Question 1: Paint Delamination (Peeling/Flaking)

Cause: The anodized layer is overly sealed, making the surface too smooth (similar to glass texture), resulting in insufficient adhesion points for the paint; or incomplete pre-treatment, with residual oil and acid on the surface;

Detection Method: Adopt the cross-hatch adhesion test (ASTM D3359 standard). Use a blade to scratch 1mm×1mm squares on the paint film, stick tape and tear it off, then observe the paint peeling area. The peeling rate of qualified products should be ≤5%.

Question 2: Paint Blistering

Cause: Moisture or contaminants remain in the pores of the anodized layer. During baking and curing, the moisture evaporates into water vapor, lifting the paint film to form blisters;

Prevention Measures: Add a pre-drying process before spraying (baking at 80-100℃ for 10 minutes) to fully discharge moisture in the pores; optimize the cleaning process to avoid residual contaminants.

Question 3: Microcracking (Crazing)

Cause: Mismatch in thermal expansion coefficients between the aluminum substrate and the oxide film. During baking, the aluminum substrate expands faster than the oxide film, leading to spiderweb-like microcracks in the paint film;

Appearance Characteristics: Difficult to detect with the naked eye, requiring observation under strong light. The cracks are mostly irregular and reticular, which will affect the protective performance of the paint film in severe cases.

Question 4: Color Inconsistency (Uneven Appearance)

Cause: Uneven thickness of the anodized film (affecting paint absorption); unstable spray gun distance and pressure during spraying; uneven temperature distribution in the oven, leading to differences in curing effects;

Control Points: Strictly control the anodization time and current to ensure the oxide film thickness deviation ≤2 microns; use automated spraying equipment to maintain consistent spraying parameters; regularly calibrate the oven temperature sensor.

IV. Special Application: Special Treatment of Hard Anodized Cookware

In the field of high-end cookware, painting anodized aluminum has a unique application scenario - the combination of hard anodization and non-stick coating:

Process Characteristics: First, form an ultra-thick oxide film of 25-50 microns through hard anodization, with a hardness of more than HV500, which has extremely strong wear resistance and deformation resistance;

Coating Selection: The "paint layer" sprayed on the surface is actually PTFE (Teflon) or ceramic non-stick coating, which is closely combined with the anodized layer through high-temperature curing;

Core Advantages: Even if the non-stick coating wears out after long-term use, the hard anodized layer can still ensure that the cookware does not rust or deform, extending the service life of the cookware. It is the core technical solution for high-end non-stick pans.

V. Our Quality Control Standards: Full-process Guarantee from Testing to Production

To ensure the stability of painted anodized aluminum products, we have established a full-process quality control system. The key measures are as follows:

Adhesion Testing: Randomly sample each batch of products for cross-hatch testing to ensure that the paint adhesion meets ASTM D3359 standard Grade 1 or above;

Salt Spray Testing: Put the product into a salt spray test chamber to simulate marine climate or humid environment, ensuring that it passes more than 720 hours of salt spray testing without rust or paint peeling;

100% Visual Inspection: Conduct 100% visual inspection on a professional QC strong light test bench to check for appearance defects such as blisters, pinholes, and color inconsistency;

Process Control: Real-time monitor the oxide film thickness and porosity during anodization; use automated equipment in the spraying stage to accurately control the coating thickness (deviation ≤3 microns); record the oven temperature curve throughout the curing stage to ensure stable parameters.

VI. Frequently Asked Questions (FAQ)

1. Can anodized aluminum be powder coated?

Yes, and it is a preferred solution with both durability and environmental protection. However, the anodized surface needs to be pre-treated (unsealed or chemically etched) to ensure effective adhesion of the powder coating. The final product's corrosion resistance and scratch resistance will be significantly better than a single spraying process.

2. Why does the paint on the surface of aluminum products peel off?

The most common reason is that the anodized layer is overly sealed or the surface is too smooth, resulting in insufficient adhesion points for the paint; the second most common reason is incomplete pre-treatment, with residual oil, dust and other contaminants on the surface, leading to ineffective bonding between the paint and the substrate.

3. Is painted aluminum better than anodized aluminum?

Not necessarily. A single painted aluminum product has weak corrosion resistance, and a single anodized aluminum product has limited color options; the composite process of "anodization + painting" combines the advantages of both, with super strong protective performance and diversified appearance, making it a better choice.

Conclusion

Painting anodized aluminum is a high-end surface treatment technology integrating "protection, wear resistance and aesthetics". Through the scientific combination of anodization and painting, it provides double protection for aluminum products, adapting to diverse application scenarios from high-end cookware to architectural hardware. For B2B buyers, mastering its process principles and quality control points can help screen high-quality suppliers more accurately.

If you are looking for an aluminum product surface treatment solution that combines durability and aesthetic value, or need to customize process parameters for specific products (such as cookware and architectural hardware), please contact our engineering team to discuss the personalized application of dual-coating technology!