Introduction: When Failure Is Not an Option

Imagine a balcony on the 10th floor. It’s a windy afternoon. Children are playing nearby, a cup of coffee sits on the table, and everything looks perfectly normal—until the glass railing begins to vibrate.

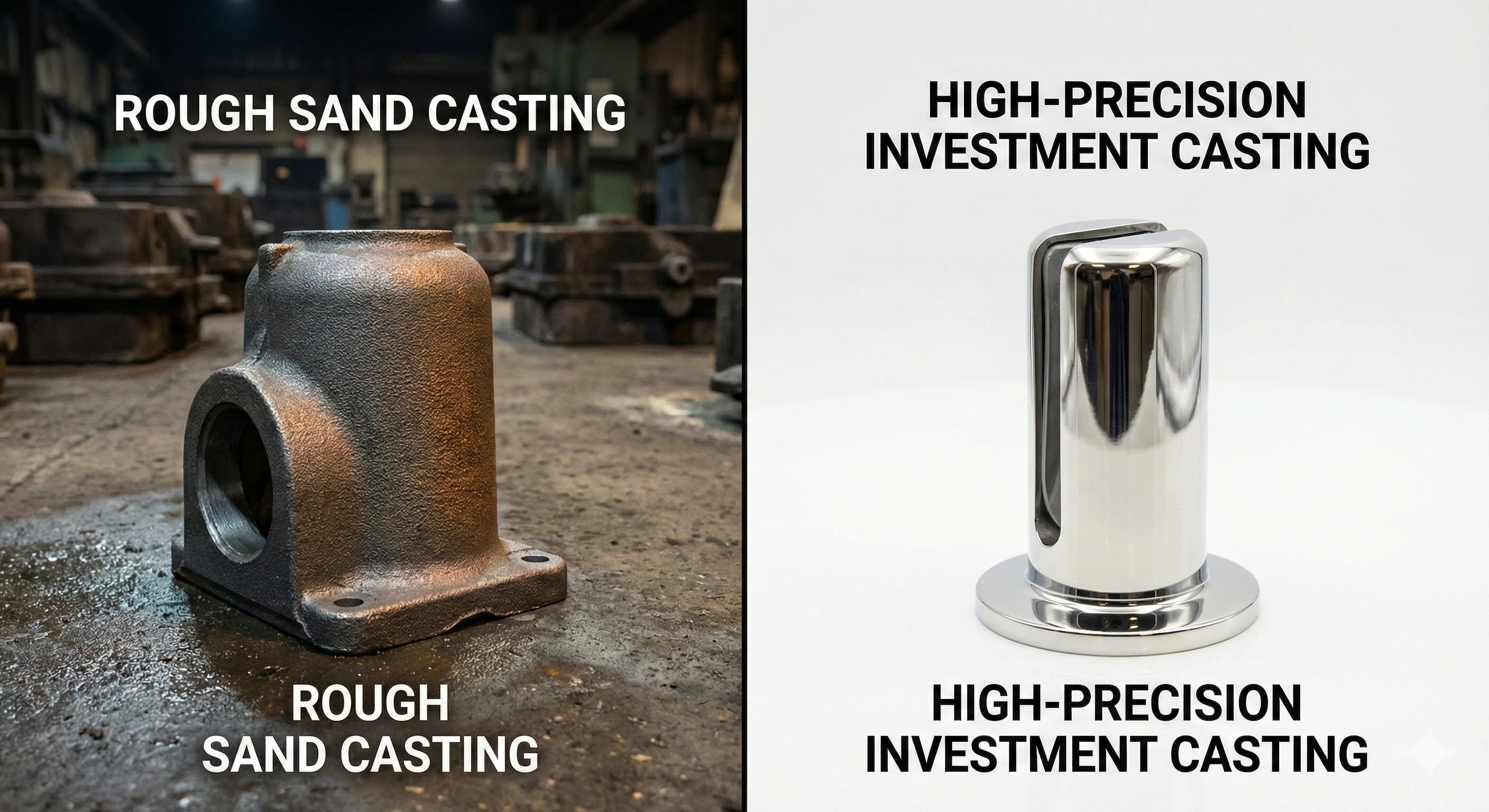

In high-wind environments, this situation is far from rare.

On elevated balconies and coastal properties, glass railing hardware is exposed to forces that can be three times higher than those at ground level. Hardware that performs well around swimming pools or low-rise homes can become a serious safety risk when installed 30 meters above ground or in hurricane-prone regions.

The challenge is often underestimated.

Wind pressure doesn’t increase gradually—it increases exponentially with height and exposure. What works inland may fail along the coast. What feels solid at ground level may not survive sustained wind loads at elevation.

This guide explains how to correctly specify heavy-duty glass spigots, understand balcony wind load requirements, and select materials designed for high-wind and coastal conditions. It is written for architects, contractors, and building owners who need solutions that meet code—and continue to perform long after inspection.

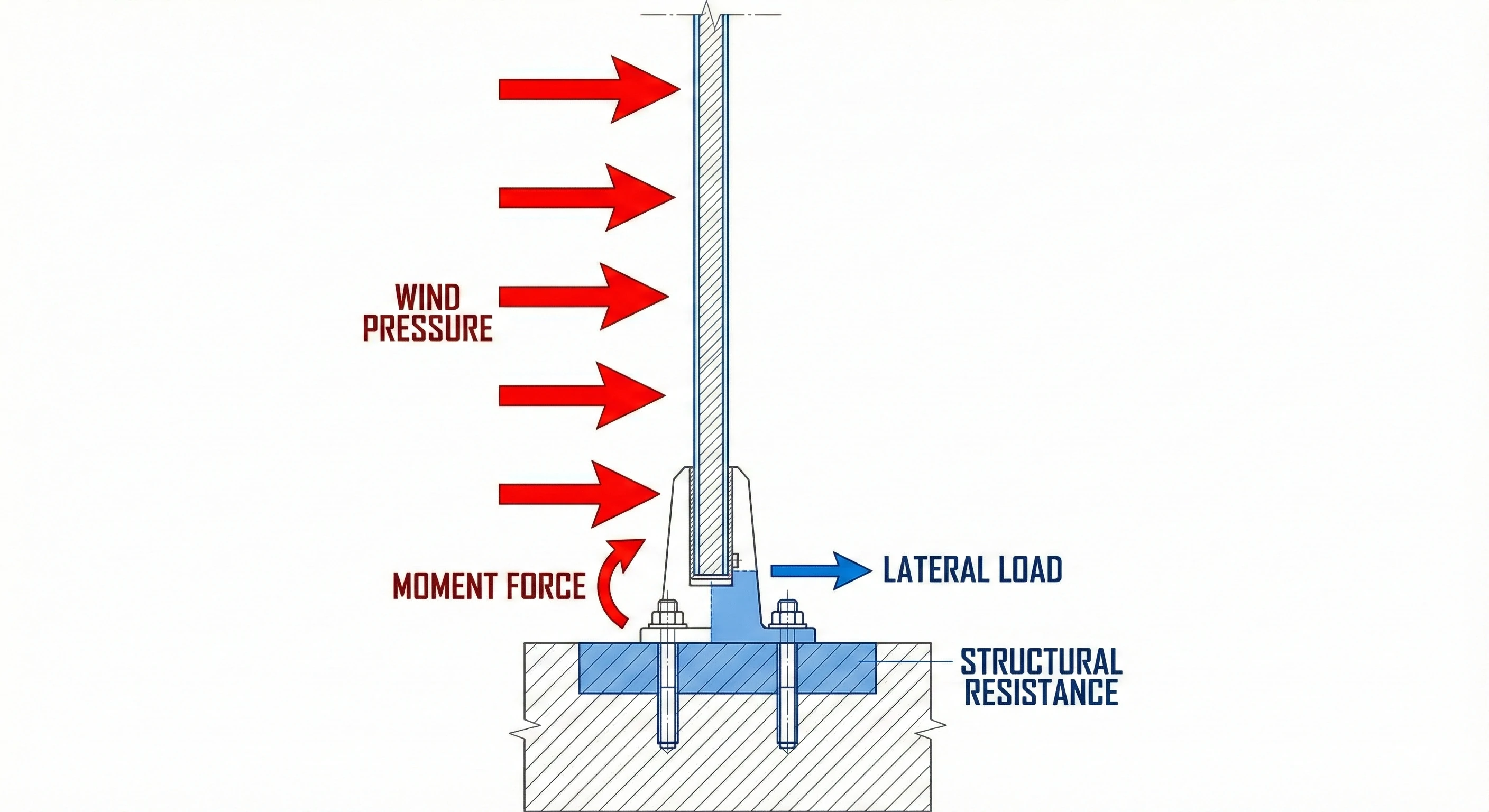

Understanding Wind Loads: What’s Really Acting on Your Glass Railing

Wind Is Not Just “Pressure”

Wind creates a lateral load—a horizontal force measured in PSF (pounds per square foot) or pascals. For glass railings, this load results in:

Direct pressure on the wind-facing side

Suction on the leeward side (often stronger than expected)

Continuous vibration from gusts and turbulence

In frameless glass systems, every square inch of glass effectively acts like a sail, transferring force directly into the spigots and anchors.

Three Factors That Dramatically Increase Wind Load

- Height Above Ground

Wind speed increases with elevation. A 20 mph breeze at street level can exceed 35 mph on higher floors. Codes such as IBC and ASCE 7 account for this using height multipliers, but the hardware must still be able to handle the resulting loads. - Exposure Category

Building codes classify exposure as:

Category B: Urban areas with surrounding buildings

Category C: Open terrain or suburbs

Category D: Coastal zones with unobstructed wind paths

Category D sites experience sustained high winds and airborne salt, making both strength and corrosion resistance critical.

- Design Wind Speed

In hurricane regions, design wind speeds can exceed 140 mph, translating to lateral loads of 50 PSF or moreon glass railing systems.

Code Compliance: The Baseline, Not the Goal

At a minimum, glass railing systems must comply with:

IBC 1607.8: 50 lbs per linear foot horizontal load

ASCE 7: Project-specific wind load calculations

Local amendments: Often stricter in coastal regions

Compliance means the glass must remain secure—without slipping, excessive deflection, or permanent deformation—under the required loads.

Hardware Selection for High-Wind Applications

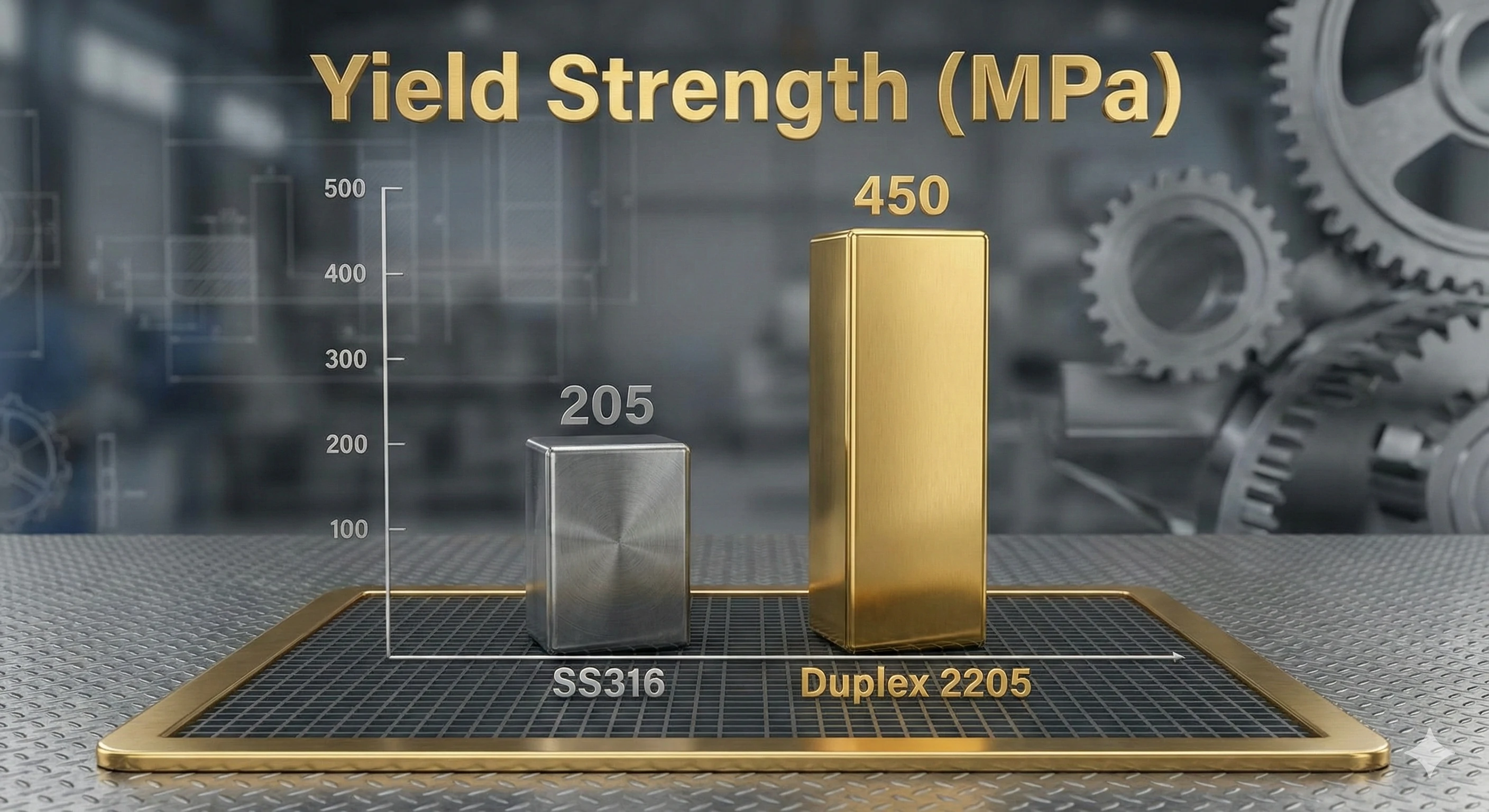

1. Material Strength: Why SS316 Is Often Not Enough

For high-wind installations, material choice is a structural decision, not an aesthetic one.

|

Material |

Yield Strength |

Performance in High Wind |

|

SS316 |

~205 MPa |

Can permanently deform under extreme gusts |

|

Duplex 2205 |

~450 MPa |

Maintains rigidity under sustained loads |

Standard SS316 works well for pool fencing and low-rise applications. However, on balconies and coastal decks, repeated wind loading can lead to fatigue and long-term deformation.

Duplex 2205 offers clear advantages:

Significantly higher stiffness

Better resistance to cyclic loading

Superior corrosion performance in chloride-rich environments

For high-rise balconies and hurricane-rated glass fencing, Duplex 2205 should be considered the minimum structural standard, not an upgrade.

2. Clamping Force & Spigot Design: Preventing Glass Movement

Glass slippage rarely happens suddenly.

It starts with micro-movements caused by vibration. Over time, those movements accumulate until the glass loosens inside the clamp.

Well-designed heavy-duty spigots address this through:

Thicker sidewalls (6 mm or more) to prevent clamp flex

Multi-point pressure plates that distribute force evenly

Higher overall mass, indicating reinforced internal geometry

As a rule of thumb, a spigot weighing 2.0 kg provides noticeably better wind resistance than a “heavy-duty” model weighing closer to 1.2 kg.

Specification tip: Always request third-party test data confirming slip resistance above 3 kN lateral load.

3. Top Rails: A Critical Safety Redundancy

In high-wind and elevated applications, top rails are often mandatory—and for good reason.

Without a top rail, each glass panel relies entirely on its own spigots. If one connection weakens, that panel bears the full wind load alone.

A continuous top rail provides:

Load sharing across multiple panels

Redundancy if one fitting loosens

Reduced vibration and resonance

Many codes also require top rails to resist 200 lbs of concentrated load, further reinforcing system stability.

Glass Specification: Strength Beyond Thickness

Hardware alone cannot compensate for flexible glass.

PVB vs. SentryGlas (SGP)

Standard PVB interlayers allow noticeable deflection under wind pressure. SentryGlas (SGP), by contrast, is up to 100 times stiffer, forcing laminated layers to act as a single structural unit.

This can reduce deflection by 60% or more under the same wind load.

Recommended configurations:

Minimum: 13.52 mm SGP laminated tempered glass

High exposure: 17.52 mm SGP laminated glass

Heavy-duty Duplex 2205 spigots are designed to accommodate both thicknesses with appropriate inserts.

Installation Spacing & Anchoring: Often Overlooked, Always Critical

Reducing panel width and increasing spigot count significantly improves rigidity in high-wind zones.

|

Application |

Typical Practice |

High-Wind Recommendation |

|

Pool fence |

2 spigots |

Acceptable |

|

Mid-rise balcony |

2 spigots |

Add third spigot for wide panels |

|

Coastal / high-rise |

3 spigots |

Reduce panel width if possible |

Anchoring must penetrate structural concrete, not tile beds or screed layers.

Embedment depth: ≥ 75 mm

Anchor type: Stainless expansion or epoxy-set rods

Edge distance: ≥ 100 mm

On post-tensioned slabs, always coordinate with the structural engineer before drilling.

Conclusion: Design the System, Not Just the Parts

High-wind glass railing safety depends on the entire system working together:

Duplex 2205 spigots for structural strength

SentryGlas laminated glass for stiffness

Proper spacing and anchoring

Continuous top rails for redundancy

Using standard hardware in high-risk environments is not a cost-saving measure—it is a liability.

The price difference between adequate and inadequate systems is small.

The cost of failure is not.

Frequently Asked Questions

Do I need a top rail for a glass balcony?

In most high-wind or high-rise applications (typically above 3 stories or in coastal exposure categories), building codes require a continuous top rail. This ensures the glass panels remain structurally connected if individual glass panels break or mounting fittings loosen. The top rail acts as a secondary load path, distributing wind forces across multiple support points rather than isolating loads to individual spigot connections. Always verify with your local building department, as requirements vary by jurisdiction and specific site exposure.

What is the maximum wind load for frameless glass railings?

The maximum wind load capacity depends on multiple variables: glass thickness and type (PVB vs. SentryGlas laminate), spigot material and design (Duplex 2205 heavy-duty vs. standard SS316), installation spacing, and panel dimensions. Properly engineered systems using our Duplex 2205 heavy-duty spigots with 17.52mm SentryGlas laminated glass can be rated for design wind pressures exceeding 50 PSF—suitable for coastal Category D exposure zones. Each installation requires project-specific engineering calculations per ASCE 7 standards to determine exact ratings.

Can I use friction spigots on a 10th-floor balcony?

Yes, but only with heavy-duty friction spigots specifically engineered for high-load applications. Standard friction spigots rated for 1kN lateral loads are inadequate. You must specify:

- Heavy-duty models rated for 3kN+ lateral loads

- Duplex 2205 construction for yield strength

- SentryGlas (SGP) laminated glass—never use PVB laminate in elevated applications

- Proper installation with structural concrete anchoring

Additionally, verify that your local building code permits friction-fit systems for the specific height and exposure category. Some jurisdictions require through-bolt spigots above certain elevations.

How do I know if my project is in a high-wind zone?

Consult ASCE 7 wind speed maps (available in your local building code) or contact your building department. Projects typically require enhanced wind-load engineering if:

- Located within 1 mile of a coastline(Exposure Category D)

- Building height exceeds 60 feet

- Site is in a designated hurricane zone(design wind speeds >115 mph)

- Local terrain provides minimal wind obstruction(open fields, waterfront)

Your structural engineer should perform site-specific wind load calculations per ASCE 7 Chapter 27-30 requirements.

What's the difference between Duplex 2205 and Super Duplex in glass hardware?

Duplex 2205 (UNS S32205) offers 450 MPa yield strength and excellent corrosion resistance—ideal for most coastal and high-wind applications. Super Duplex (UNS S32750/S32760) provides even higher strength (550+ MPa) and superior resistance to pitting corrosion in extreme chloride environments.

For most glass railing applications, Duplex 2205 provides the optimal balance of performance and cost. Super Duplex is specified when:

- Installing within direct splash zones(boardwalks, piers)

- Extreme temperatures (tropical or arctic)

- Facilities with chemical exposure(industrial sites near ocean)