Important Disclaimer:

Building codes differ by country, state, and even municipality. Before purchasing materials or starting construction, always confirm requirements with your local building department or inspector.

The Reality Check: Beauty Must Meet Code

A glass railing can instantly elevate a deck or balcony, creating a clean, modern look while keeping sightlines open. However, many homeowners and contractors only realize too late that visual appeal alone isn’t enough. If a glass balustrade fails to meet local building regulations, the consequences can include failed inspections, fines, project delays, or in extreme cases, mandatory removal and reconstruction.

More importantly, the issue goes beyond money. Building regulations exist because these systems are life-safety components. Two railings may look identical at a glance, yet perform very differently when someone leans against them or when a child applies pressure in an unexpected way.

This guide explains the core safety principles behind glass balustrade regulations. While references are made to the International Building Code (IBC) and International Residential Code (IRC) commonly used in the United States, similar requirements exist under Australia’s NCC, UK Building Regulations, and comparable standards worldwide. Across jurisdictions, compliance generally comes down to three critical factors: minimum height, structural load resistance, and glass specification.

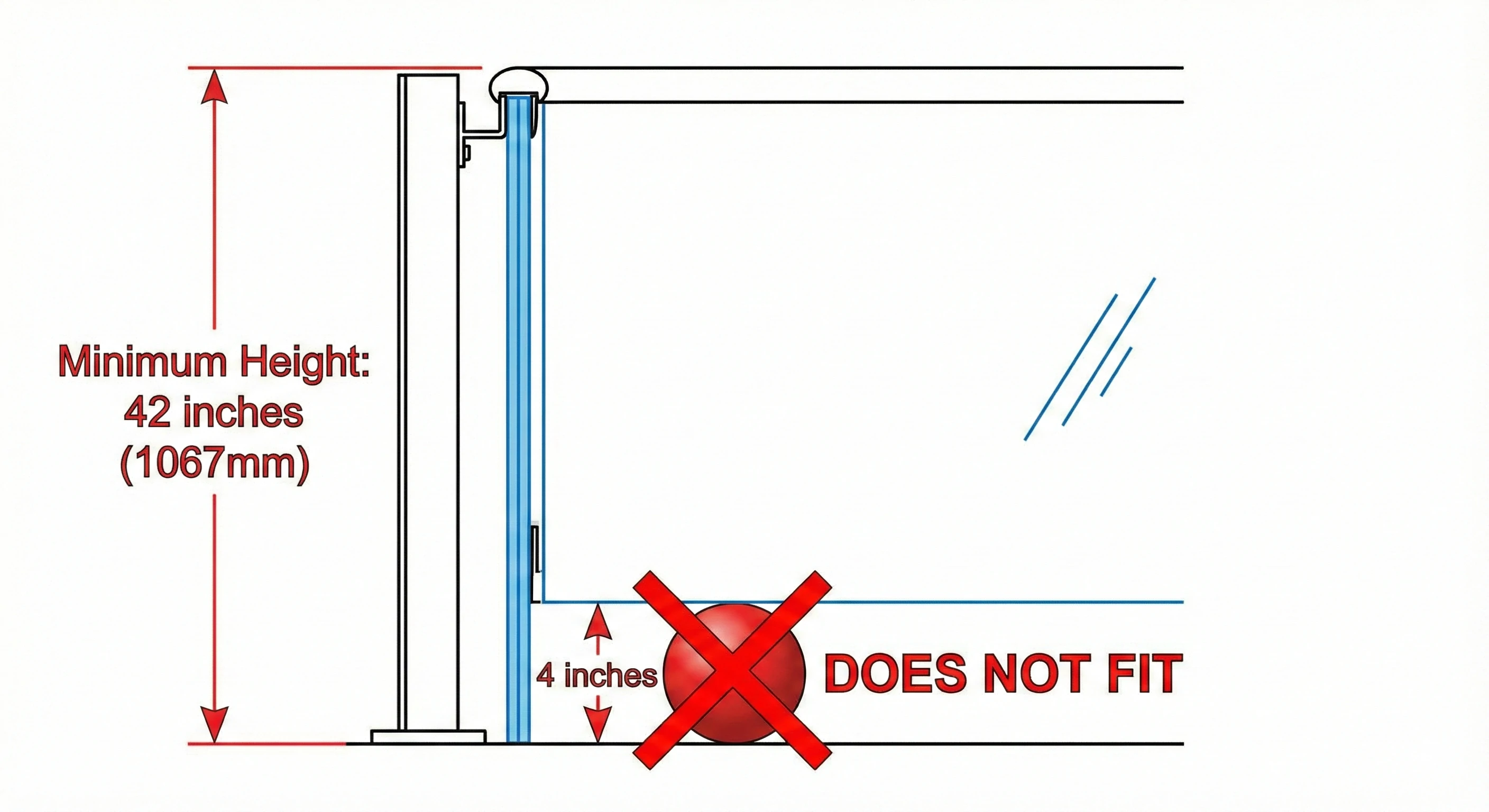

1. Minimum Height Requirements: How Tall Must Your Glass Railing Be?

Height requirements depend on how and where the railing is used. Accurate measurement is essential, as inspectors measure from the surface a person can actually stand on—not from framing or structural subfloors.

Residential Decks and Balconies

For residential decks, balconies, and terraces, glass balustrades are typically required to be between 36 inches (914mm) and 42 inches (1067mm) high when measured from the finished floor. Under the IRC, 36 inches is often the minimum, though many local jurisdictions now require 42 inches to align with commercial standards.

Measurement errors are a common reason for inspection failures. If a deck includes a raised threshold, finished flooring, or any elevated surface where someone could stand, the height must be measured from that point. Inspectors will always reference the highest walkable surface.

Commercial and Multi-Family Buildings

Commercial buildings, offices, hotels, and multi-family residential properties are subject to stricter standards. Under the IBC, guards in these settings must be at least 42 inches (1067mm) high.

In some regions, residential buildings above a certain height or number of stories are also classified under commercial guard requirements. Always review local amendments rather than relying on the base code alone.

Swimming Pool Barrier Fences

Swimming pool fencing falls under the most stringent rules. To reduce the risk of unsupervised access by children, pool barriers usually require a minimum height of 48 inches (1200mm), with some jurisdictions mandating up to 60 inches (1500mm).

In addition to height, pool fencing must comply with non-climbable zone requirements, discussed later in this guide. Together, these rules create an effective physical and behavioral barrier.

Key takeaway:

Never assume the required height. Confirm the exact requirement for your application and measure from the correct reference point.

2. Structural Load Requirements: How Strong Must the System Be?

A railing’s appearance is irrelevant if it cannot perform under real-world loads. Building codes specify minimum force levels that glass balustrade systems must resist without excessive deflection, glass failure, or hardware disengagement.

The Concentrated Load Test

IBC Section 1607.8.1 requires guards to withstand a 200-pound (0.89 kN) concentrated load applied at any point along the top edge, in any direction. This simulates scenarios such as a person falling or leaning heavily against the railing.

For glass balustrades, particularly frameless systems, this test is demanding. The load is transferred through spigots, standoffs, or base channels directly into the mounting surface. If the hardware deforms or loosens, the entire system fails—regardless of whether the glass itself remains intact.

Passing the test means more than avoiding breakage. Excessive movement, hardware rotation, or glass pull-out also constitute failure.

Uniform Load Requirements

In addition to concentrated loads, the IBC requires guards to resist a uniform horizontal load of 50 pounds per linear foot along the top edge. This represents multiple people leaning against the railing at the same time, a common scenario in commercial spaces.

Uniform load requirements influence glass thickness, panel width, and support spacing. Longer glass spans typically require thicker or laminated glass and more robust hardware.

Wind Load Considerations

Exterior installations in coastal, hurricane-prone, or high-rise environments must also account for wind loads. Wind pressure and suction forces can exceed basic load requirements, especially on tall buildings or exposed balconies.

Wind load compliance almost always requires calculations and certification by a licensed structural engineer. Self-assessed ratings are rarely accepted by inspectors.

3. Glass Types: Tempered vs. Laminated - Why It Matters

Glass selection is the single most critical safety decision in any balustrade system. Codes have evolved significantly, and understanding why is essential for compliance.

Tempered Glass: The Traditional Standard

Tempered (toughened) glass is heat-treated to increase its strength, making it roughly four times stronger than annealed glass. When it breaks, it shatters into small, blunt fragments rather than sharp shards—an important safety feature in many applications.

However, in railing systems, this behavior introduces a serious risk. When tempered glass fails, it disappears entirely, instantly removing the protective barrier. Anyone relying on that railing at the moment of failure is exposed to a fall hazard.

Laminated Tempered Glass: The Modern Requirement

To address this risk, newer building codes increasingly require laminated tempered glass. Laminated glass consists of two tempered panes bonded with an interlayer such as PVB or SGP.

When laminated glass breaks, fragments adhere to the interlayer instead of falling away. Even in a damaged state, the panel continues to function as a barrier. This post-breakage performance is the key reason for updated code requirements.

IBC Section 2407.1.2 now requires laminated glass for guards unless a compliant top rail or handrail is present.

PVB vs. SGP Interlayers

While PVB laminated glass provides good safety performance, it can lose stiffness after breakage, especially in high-temperature environments. For frameless systems, engineers often specify SGP because it remains significantly more rigid and maintains structural integrity even after glass failure.

For installations without a top rail, SGP laminated glass is often the only practical option for meeting code requirements.

4. The Top Rail Question: Is It Mandatory?

Whether a top rail is required depends on glass type, system design, and local interpretation of the code. The underlying rule is simple: the barrier must still function if the glass fails.

Option A: Systems with a Cap Rail or Handrail

A cap rail creates a continuous structural element across the top of the glass panels. If a panel breaks, the rail maintains the barrier.

When using monolithic tempered glass, a top rail is almost always mandatory. In these systems, the glass acts as infill, while the rail provides the actual fall protection.

The rail itself must meet load requirements. Decorative rails without structural capacity are not compliant.

Option B: Frameless Systems Without a Top Rail

Frameless, top-rail-free designs are allowed in many jurisdictions, but only with the correct glass specification. Typically, this means SGP laminated tempered glass with engineering documentation demonstrating post-breakage performance.

Local inspectors may require sealed engineering calculations before approving this design approach.

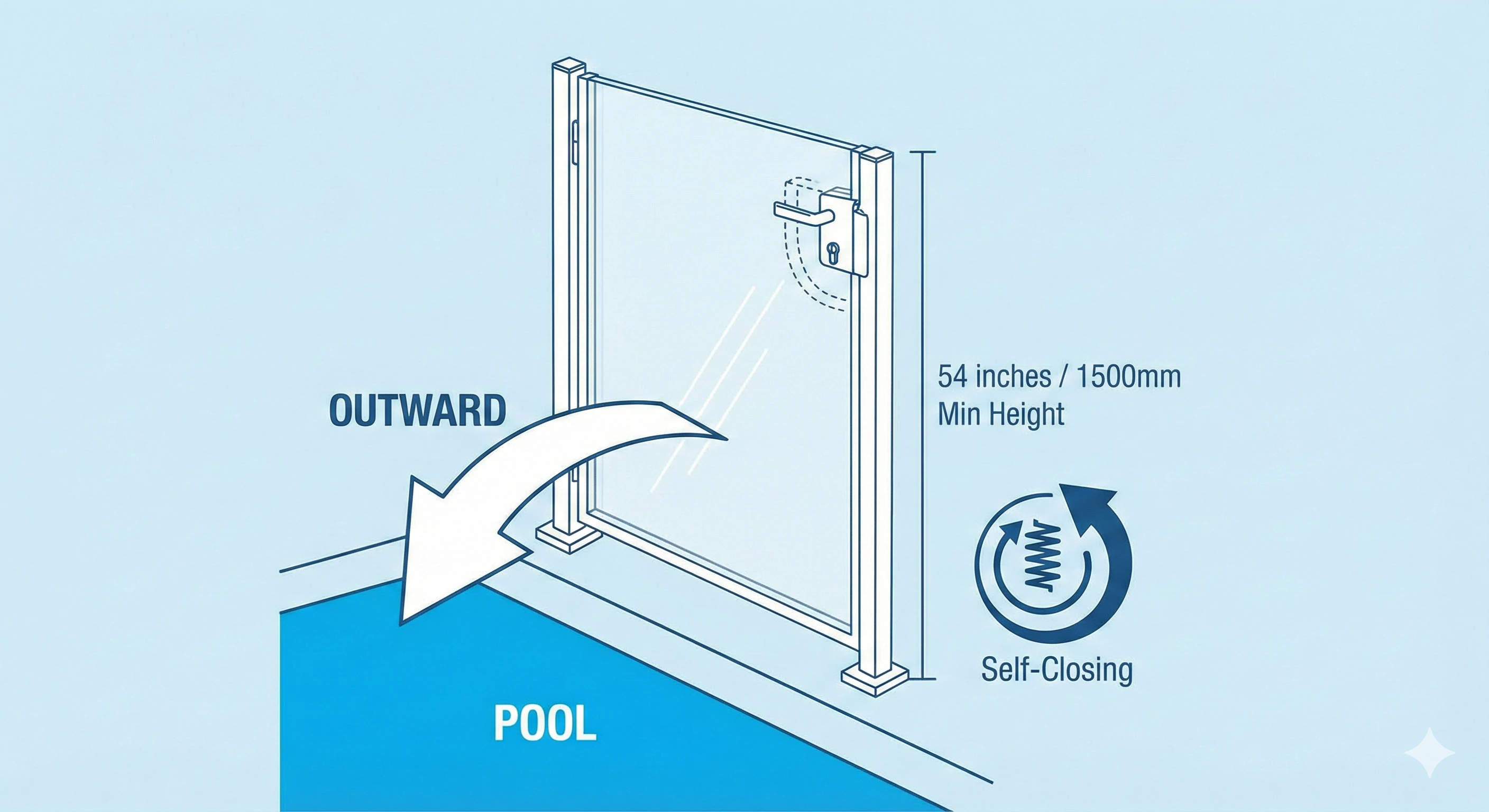

5. Swimming Pool Glass Fence Requirements: Special Considerations

Pool fencing regulations are among the strictest due to the risk of child drowning. These rules go beyond standard balustrade requirements.

Non-Climbable Zone (NCZ)

The non-climbable zone typically extends 900–1200mm (36–45 inches) from the barrier. Within this area, there must be no footholds, horizontal rails, or objects that assist climbing.

For glass fences, this affects hardware placement, landscaping, and nearby furniture.

Gate, Latch, and Opening Requirements

Pool gates must be self-closing, self-latching, and open outward from the pool area. Latch mechanisms must usually be at least 54 inches (1500mm) above ground on the pool side.

All openings must comply with the 4-inch sphere rule, ensuring that no gap can allow a child’s head to pass through.

Why Hardware Selection Determines Compliance

Even the best glass will fail inspection if the mounting hardware is inadequate.

Quality spigots and clamps are engineered to transfer loads safely into the structure. Look for solid construction, tested load ratings, corrosion-resistant materials (such as 316 stainless steel), and documented certifications.

Friction alone is never enough. Code-compliant systems rely on positive mechanical locking, ensuring the glass remains captured even if clamping pressure changes over time.

Final Thoughts: Why These Codes Exist

Building codes are the result of real failures and real injuries. They are not arbitrary rules, but lessons learned through engineering analysis and accident investigation.

A code-compliant glass balustrade is an investment in safety, durability, and long-term peace of mind. Cutting corners almost always leads to higher costs later—whether through failed inspections, liability exposure, or replacement work.

Consult your local building authority, choose certified materials, and work with experienced professionals.