At our foundry, we often encounter clients who use the terms "casting" and "investment casting" interchangeably, assuming they refer to the exact same process. This confusion can be costly. We have seen order standard castings hoping for a mirror-polished finish, only to receive rough, grainy parts that require expensive additional machining. The frustration of delayed project timelines and budget overruns is real, but it is easily avoidable with the right knowledge.

Casting is the broad umbrella term for any manufacturing process where liquid material is poured into a mold, whereas investment casting is a specific, high-precision method within that category. While standard casting methods like sand casting are suitable for large, rough parts, investment casting (or lost wax casting) is essential for creating complex, smooth, and highly detailed components like architectural hardware.

To understand which method is right for your next project, we need to break down the mechanics, costs, and results of each process.

What is the "Umbrella" of Casting?

When we onboard new engineers at our facility, we often use the analogy that comparing casting to investment casting is like comparing a "vehicle" to a "Ferrari." One is the general category, and the other is a specialized, high-performance version. If you simply order a "casting" without specifying the type, you might end up with a process that is entirely unsuited for your tolerance requirements. We want to ensure you never face that quality mismatch.

Casting refers to the fundamental manufacturing technique of pouring molten material into a hollow mold to solidify into a specific shape, encompassing various methods like sand casting, die casting, and investment casting. Each specific method under this umbrella offers distinct advantages regarding surface finish, production speed, and material compatibility, determining its suitability for different industrial applications.

Understanding the General Concept

At its core, the concept of casting is ancient and simple: melt metal, pour it into a hole, let it freeze, and eject the part. However, how we create that "hole" (the ) changes everything. In our industry, we generally categorize casting into three main buckets based on the mold material.

The Main Types of Casting

It is crucial to distinguish between these types because they yield vastly different results.

-

: This method uses molds made of bonded sand. It is the "workhorse" of the industry. It is fantastic for massive parts like engine blocks or manhole covers where a rough surface texture is acceptable. It is generally cheaper for tooling but requires significant machining if you need precision.

-

: Here, we use reusable metal molds. This is built for speed and high volume, typically used for lower melting point metals like aluminum or zinc. It is not suitable for high-grade stainless steel.

-

Investment Casting: This uses . It is the method we prioritize for precision parts.

Comparison of Casting Methods

To help you visualize where each method fits, here is a breakdown of the key characteristics we observe on our production floor:

| Feature | Sand Casting | Die Casting | Investment Casting |

|---|---|---|---|

| Mold Material | Sand | Metal (Steel) | Ceramic Shell |

| Primary Advantage | Low cost, large parts | High speed, high volume | High precision, smooth finish |

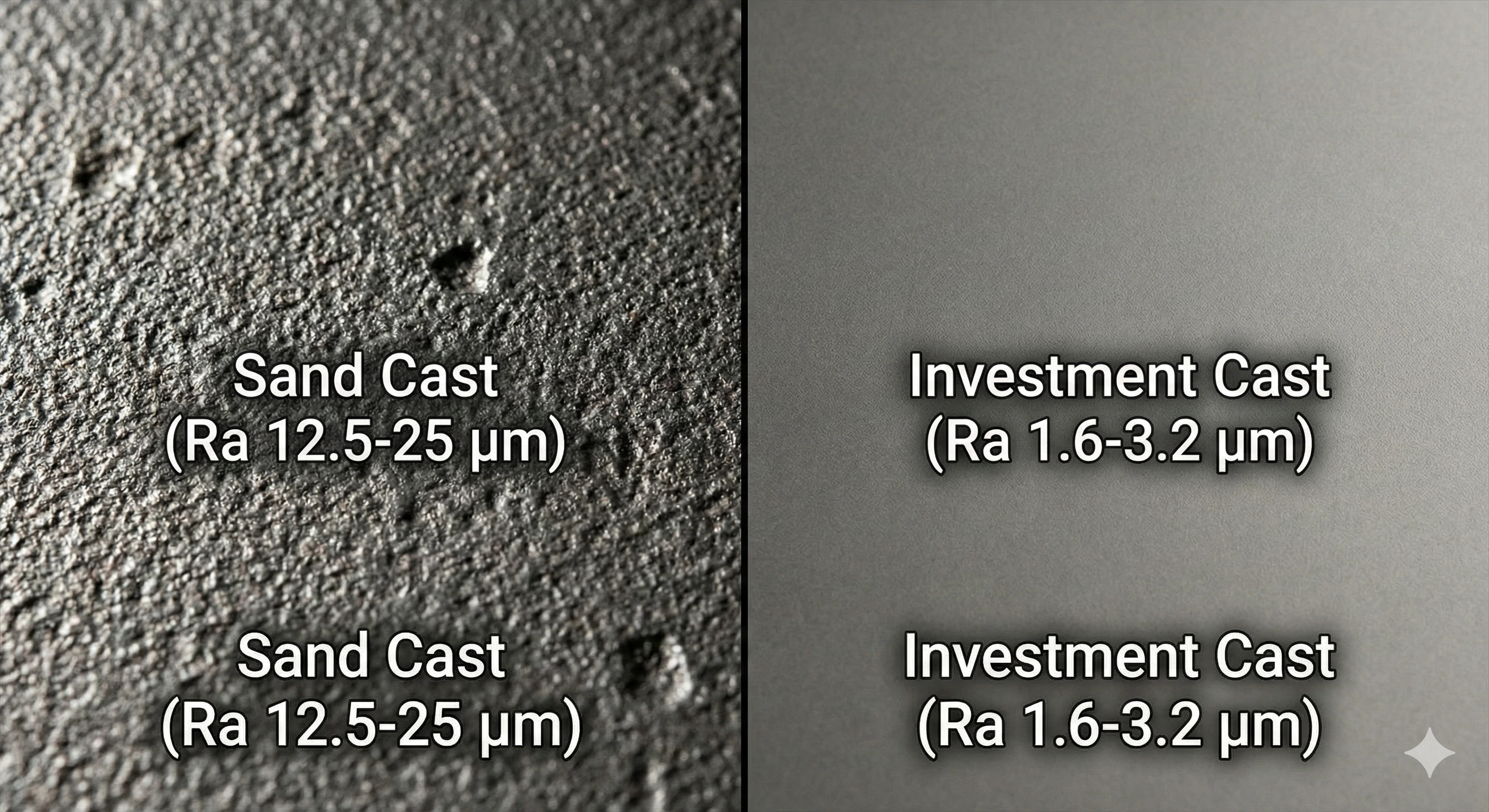

| Surface Texture | Rough, grainy (Ra 12.5-25) | Smooth | Excellent, glass-like (Ra 1.6-3.2) |

| Typical Metals | Iron, Steel, Bronze | Aluminum, Zinc | Stainless Steel, Carbon Steel |

| Tooling Cost | Low | High | Moderate to High |

Understanding this hierarchy prevents the common mistake of expecting "aerospace precision" from a "manhole cover" process.

What is Investment Casting?

In our experience exporting to the US and Europe, the term "investment" often confuses buyers who think it relates to finance. In reality, it comes from an old word meaning "to clothe" or "surround," referring to how the ceramic shell surrounds the wax pattern. When we produce high-end glass hardware, this is the only process that gives us the near-net shape we require without excessive waste. We use this method to ensure your final product looks as good as it performs.

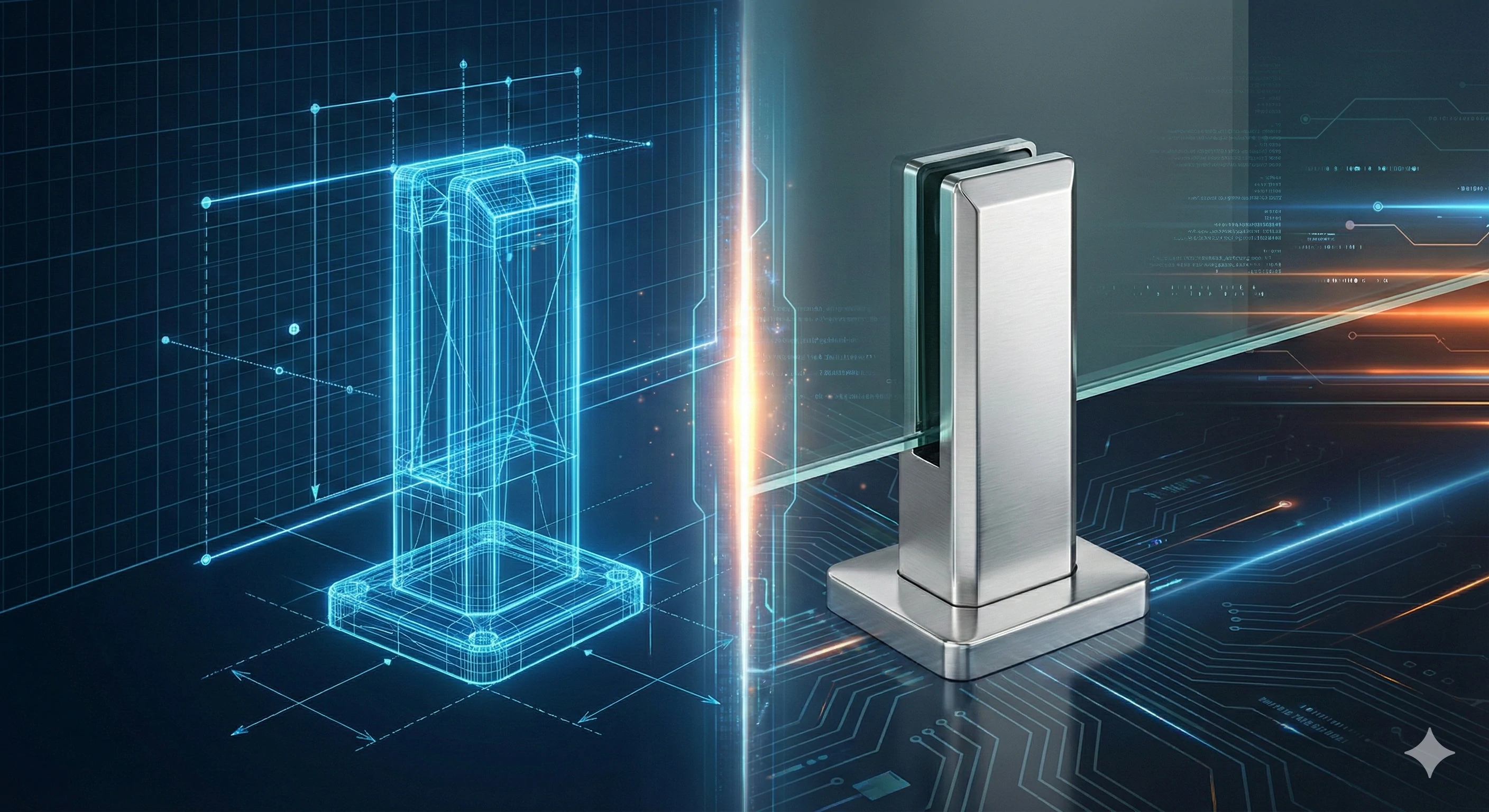

Investment casting, also known as lost wax casting, is a precision manufacturing process where a wax pattern is coated in a ceramic slurry to create a mold. Once the ceramic hardens, the wax is melted away, leaving a perfect cavity for molten metal, resulting in parts with exceptional surface quality and tight dimensional tolerances.

The "Lost Wax" Methodology

We often describe this process to clients as "copying a copy." It starts with injecting wax into a metal die to create a replica of the final part. We then attach these wax replicas to a central stick, creating what looks like a "wax tree."

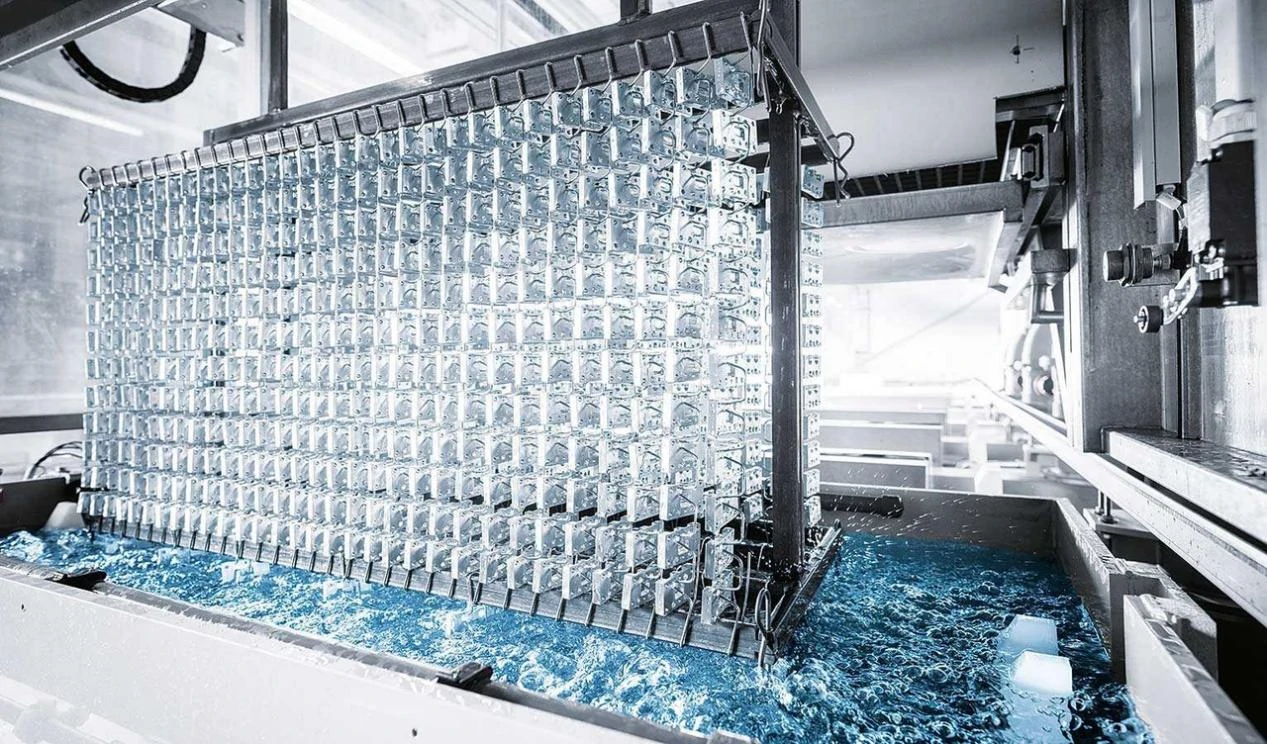

This tree is dipped—or "invested"—into a ceramic slurry multiple times. At our factory, we let this dry to form a hard shell. The magic happens next: we heat the shell, and the wax melts out (hence, "lost wax"). We are left with a hollow ceramic shell that is a perfect negative of your part. We pour molten stainless steel into this shell. Once it cools, we shatter the ceramic to reveal the metal parts.

Why It Is considered "Premium"

You might wonder why we go through so many steps. The answer lies in the detail. Because the mold is formed around a smooth wax pattern rather than packed sand, the internal surface of the mold is incredibly smooth.

Capability for Complexity

This method allows us to cast features that would be impossible with other methods.

-

Undercuts: We can cast complex internal geometries.

-

Thin Walls: We can achieve thinner sections than sand casting allows.

-

Logos and Text: Fine lettering comes out crisp and readable.

This capability is why we use investment casting for components like impellers, where the curvature of the vanes must be precise for , or for architectural hinges where the mechanism must fit perfectly.

What are the Key Differences Between Investment Casting and Standard Sand Casting?

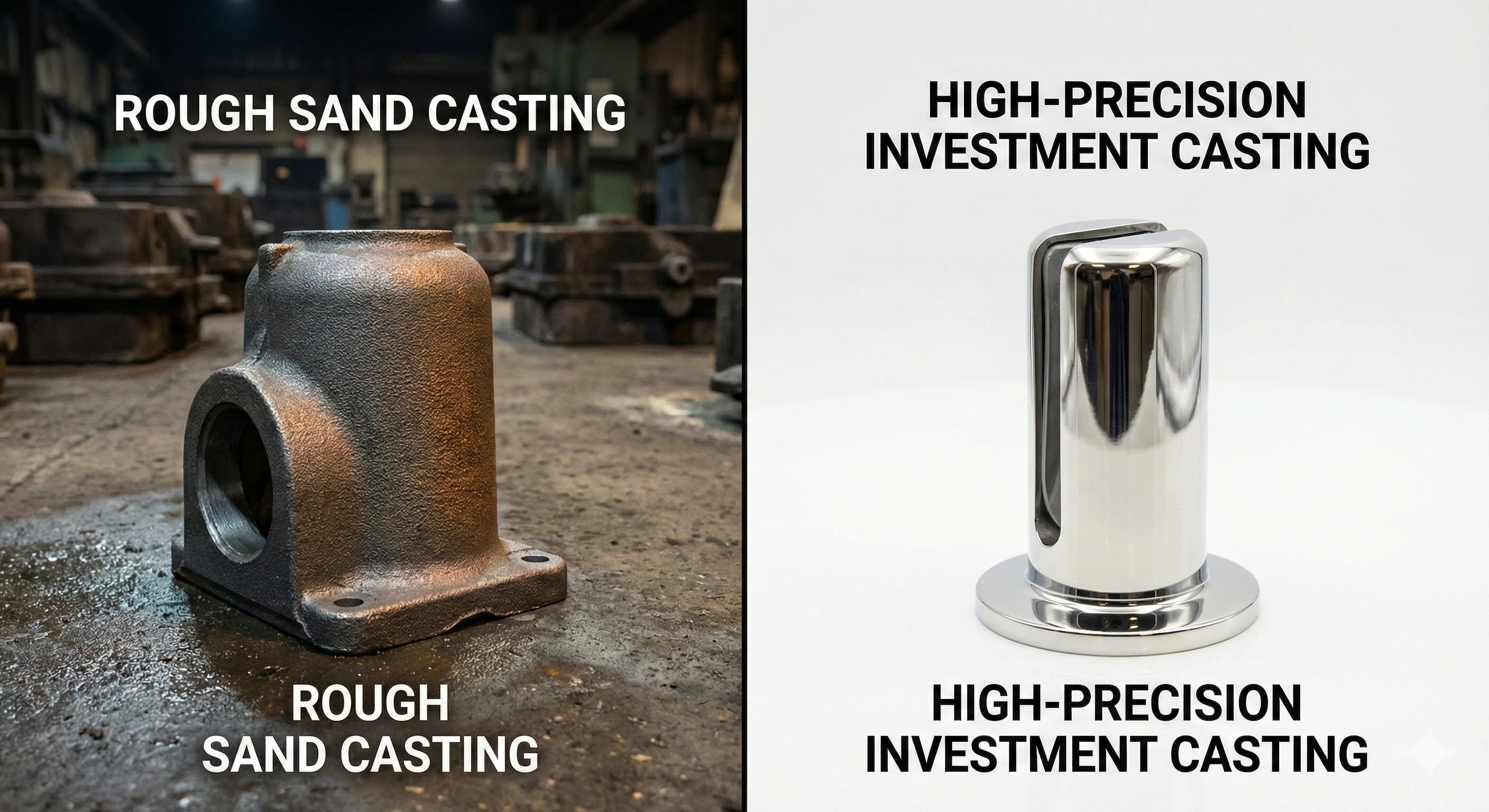

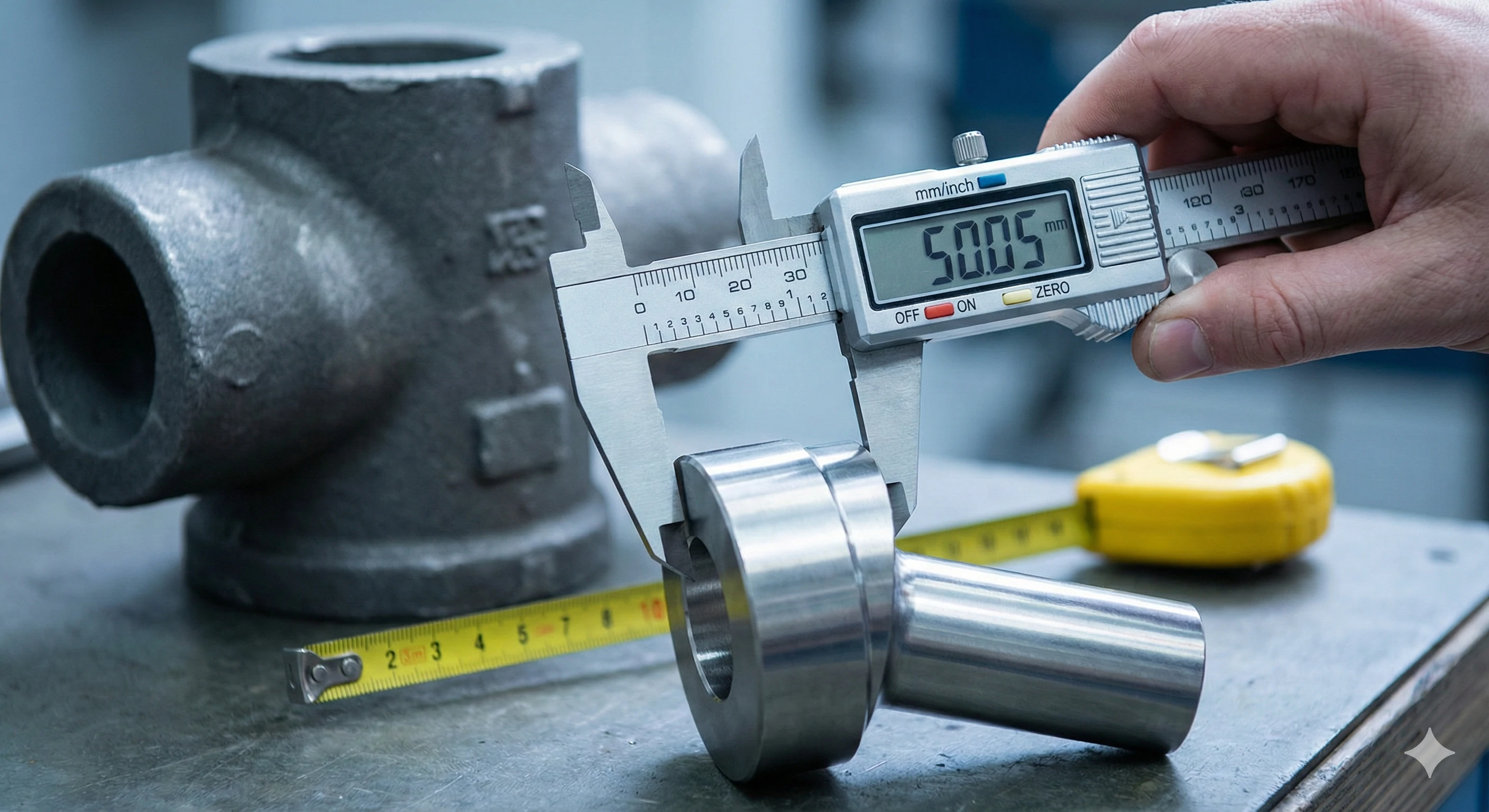

When we calibrate our , the difference between a sand-cast part and an investment-cast part is immediately visible to the naked eye. We know that for many of you, the choice comes down to budget versus quality. However, ignoring the physical limitations of sand casting can lead to parts that simply do not fit or look terrible in an architectural setting. We aim to help you balance cost with the necessary performance metrics.

The primary differences between investment casting and sand casting lie in surface finish, dimensional accuracy, and cost structure. Investment casting delivers a smooth surface with strict tolerances of roughly 0.1mm, ideal for detailed parts, whereas sand casting produces a rougher texture with looser tolerances of 1-3mm, making it better suited for large, heavy-duty components.

1. Surface Finish: The "Orange Peel" Effect

The most obvious difference is texture. If you pick up a sand-cast part from our reject pile (or a competitor's sample), it feels like sandpaper or an orange peel. It is gritty. To make it shiny, you would have to grind away a significant amount of metal.

In contrast, an investment cast part comes out of the mold with a matte but smooth finish. It is ready for polishing immediately. For our clients buying glass railings, this is non-negotiable. You cannot sell a gritty clamp to a homeowner.

2. Tolerance and Machining

Tolerance refers to how much the final part deviates from the design measurements.

-

Sand Casting: The sand can shift. You might see variances of +/- 1mm to 3mm. This means you must design the part with extra "meat" (metal) and then machine it down to size.

-

Investment Casting: We typically hold tolerances of +/- 0.1mm. This is "near-net-shape." You rarely need to machine the body of the part, only the mating surfaces (like a drilled hole).

3. Cost Analysis: Unit vs. Total Cost

This is where critical thinking is required. Sand casting has a lower unit price for the raw casting. However, if you have to spend 20 minutes machining that part to get it to fit, your total cost skyrockets. Investment casting has a higher unit price, but because it requires little to no machining, the total cost for a finished precision part is often lower.

| Attribute | Standard (Sand) Casting | Investment Casting |

|---|---|---|

| Surface Finish (RMS) | 250 - 500 (Rough) | 63 - 125 (Smooth) |

| Dimensional Tolerance | +/- 0.030 inch per inch | +/- 0.005 inch per inch |

| Minimum Wall Thickness | ~ 3mm - 5mm | ~ 1.5mm |

| Machining Required | High | Low / None |

Why Do We Use Investment Casting for Glass Hardware?

Our engineers have found that when dealing with architectural glass hardware, compromise is not an option. A glass balustrade is a safety barrier, but it is also a visual centerpiece in a home or commercial building. We have seen competitors try to cut costs by using sand-cast bodies for spigots, and the result is always disappointing: pitting, rust issues, and an ugly finish. We stick to investment casting because it is the only way to meet the aesthetic and functional demands of the market.

We exclusively use investment casting for glass hardware because it creates the smooth, defect-free surface necessary for high-quality mirror polishing and superior corrosion resistance. This process also allows us to effectively cast Duplex 2205 stainless steel, a high-melting-point alloy that offers maximum durability but is difficult to process using die-casting methods.

Aesthetics and the Mirror Polish

A glass railing system is designed to be beautiful. The hardware must match that beauty.

Because investment casting provides a smooth base, we can easily buff it to a "Super Mirror" polish. If we started with a sand casting, deep polishing would reveal porosity (tiny holes) under the surface, ruining the look.

Material Freedom: The Duplex 2205 Advantage

We specialize in for its incredible strength and rust resistance.

-

Die casting molds (made of steel) would melt if we poured molten stainless steel (1450°C+) into them.

-

Sand casting is too rough for the detail we need.

-

Investment casting uses ceramic molds which can withstand these extreme temperatures without deforming. This allows us to use the best marine-grade alloys available.

Corrosion Resistance

This is a technical point often overlooked. Rust starts in microscopic pits and crevices where salt and moisture hide. A rough sand-cast surface is a breeding ground for rust. The smooth surface of an investment casting allows water to run off, significantly extending the lifespan of the product in .

Suitability for Architectural Hardware

| Requirement | Why Investment Casting Wins |

|---|---|

| Visual Appeal | Provides a defect-free canvas for mirror or satin polishing. |

| Safety Strength | Creates a dense, solid grain structure without the air pockets found in die casting. |

| Complex Shapes | Allows for hollow designs (like handrail brackets) that reduce weight and cost. |

When Should You Choose Which?

We advise our clients to look at their project requirements holistically rather than just looking at the price per kilogram. There is a time and place for every method. If you are building a tractor weight, we would never suggest investment casting; it would be a waste of money. However, if you are sourcing components for a luxury hotel, sand casting would be a disaster. We want to help you align your with your end-goal application.

You should choose standard sand casting when manufacturing large, heavy parts where surface finish is not critical and budget is the primary priority, such as engine blocks or piping. Conversely, choose investment casting for small to medium-sized components that require intricate details, high dimensional accuracy, and a polished appearance, such as architectural hardware or medical instruments.

Decision Matrix: Making the Right Call

To simplify your decision, we have broken down common scenarios we see in the industry.

Choose Standard (Sand) Casting If:

-

Size: Your parts are huge (over 100kg).

-

Finish: The part will be buried underground or hidden inside a machine.

-

Quantity: You need a small run of very large parts.

-

Material: You are working with cast iron or bronze for heavy industrial use.

Choose Investment Casting If:

-

Application: You are making Architectural Hardware, Marine Parts, or Food Processing equipment.

-

Aesthetics: The part is visible to the end-user and needs to look premium.

-

Precision: You need tight fits (like a hinge) without spending a fortune on CNC machining.

-

Material: You need Stainless Steel (304, 316, or Duplex 2205).

Frequently Asked Questions (FAQ)

Is investment casting more expensive than sand casting?

Yes, the process itself is more labor-intensive. We have to make a wax pattern for every single part. However, because you save money on machining and polishing, the final cost for a precision part is often competitive.

Why is it called "Lost Wax"?

It is called this because the wax pattern is melted out and "lost" during the process. It is a sacrificial pattern. This is distinct from a permanent mold process where the pattern or mold is reused directly.

Can you investment cast aluminum?

We can, but it is less common. Aluminum has a lower melting point, so it is usually Die Cast because that process is much faster and cheaper. We reserve investment casting for high-melting-point metals like Steel and Titanium.

Conclusion

While "casting" is the general family name for pouring metal, "investment casting" is the specialized technique we rely on to deliver world-class glass hardware. Not all castings are created equal. If your project demands precision, durability, and a flawless finish—especially when using stainless steel—the lost wax method is your only viable option.

At Aleader, we understand that the quality of your hardware reflects on your reputation. We are here to ensure you get parts that fit perfectly and look stunning.

Need parts that look as good as they perform? We specialize in Precision Investment Casting for the architectural and industrial sectors. Get a quote for your high-precision project today.

Footnotes

1. Definition and key responsibilities of procurement professionals.

2. Guide to different mold materials and their applications.

3. Step-by-step explanation of the sand casting process.

4. Overview of die casting technology for high-volume production.

5. How ceramic shells facilitate the investment casting process.

6. Basics of fluid dynamics relevant to impeller manufacturing.

7. Principles of industrial quality control systems.

8. Technical properties and uses of Duplex 2205 steel.

9. Understanding marine corrosion mechanisms in coastal areas.