In the complete process of casting manufacturing, "chemical treatment" serves as a pivotal link bridging upstream and downstream processes. Unlike casting that determines the shape of castings or machining that controls dimensional accuracy, chemical treatment modifies the surface state or internal composition of castings through chemical reactions, addressing practical issues like "rust-prone surfaces," "difficult-to-coat surfaces," and "poor wear resistance." Many practitioners view chemical treatment narrowly as "rust removal," yet lack clarity about the specific value of different techniques: "What's the difference between acid washing and phosphating?" "What's the purpose of chemical conversion coatings?" "How does metal infiltration treatment enhance casting properties?" Today, we'll focus on six core chemical treatment processes for castings, breaking down each technique's function, principle, and application scenarios in plain language to help you understand why different chemical treatments are selected for different needs.

Pickling: A transformative process that removes surface oxidation and impurities from castings

Acid washing is the most basic chemical pretreatment process of castings. Its core role is to remove oxide scale, corrosion, oil and dirt and casting residue impurities on the surface of castings, so as to "clear obstacles" for subsequent painting, electroplating or assembly, which is equivalent to "deep cleaning" of castings.

technical principle

The casting is immersed in an acidic solution (commonly used acids include hydrochloric acid, sulfuric acid, nitric acid, which should be adjusted according to the material of the casting), and the cleaning is achieved through the chemical reaction between the acid and the surface pollutants:

Oxides (such as Fe₃O₄ on cast iron surfaces and Al₂O₃ on aluminum alloy surfaces) react with acid to form soluble salts, which are carried away by the solution.

Corrosion products (such as Fe₂O₃) will be dissolved by acid, exposing the original surface of the casting substrate;

The oil will be separated from the surface and separated from the solution under the emulsification of acid.

After processing, the casting should be washed with clean water to remove the residual acid, and then dried to prevent secondary rust.

key role

Completely eliminate oxide scale and resolve paint peeling issues: After casting, dense oxide layers form on cast surfaces. Direct painting causes poor adhesion between coatings and substrates, leading to paint peeling and surface blistering. After acid washing removes oxide layers, cast surfaces achieve optimal roughness (Ra6.3-12.5μm) with coating adhesion improved by over 50%. For example, cast iron agricultural machinery components demonstrate enhanced adhesion grades post-acid washing: paint adhesion level upgrades from "Grade 3" (partial edge peeling) to "Grade 1" (no peeling) when recoated.

Remove rust and restore castings' surface condition: Moisture exposure during storage or transportation can cause rust formation (e.g., red rust on carbon steel castings, white spots on aluminum alloys). Acid washing effectively dissolves rust without damaging the base material. For example, stainless steel valve castings can regain their original metallic luster after mild rust exposure through nitric acid treatment, eliminating the need for additional polishing.

Removing Foundry Contaminants to Enhance Machining Accuracy: Residual sand particles and slag from casting processes may remain on cast surfaces. If left untreated, these contaminants can accelerate tool wear during machining and compromise dimensional precision. Acid washing effectively removes these impurities through chemical dissolution and mechanical flushing, significantly reducing machining risks. For example, acid washing can extend the service life of milling tools by 30% in aluminum alloy hub casting applications.

applicable scene

Castings with oxide scale and corrosion on the surface (such as carbon steel, cast iron, stainless steel castings);

Castings that need to be painted, electroplated, sprayed and other surface treatments;

Castings that have been slightly corroded after storage or transportation and need to restore the surface condition.

Phosphating: Applying a protective coating to castings to create a rust-resistant base layer for painting

Phosphating is a common supporting process after acid washing. Its core role is to form a dense phosphate conversion film on the surface of the casting. This film can not only play a short-term anti-rust effect, but also enhance the adhesion of the subsequent coating, which is equivalent to wearing a "ultra-thin protective clothing" for the casting.

technical principle

The castings after acid washing are soaked in phosphate solution (common components include zinc phosphate, manganese phosphate, iron phosphate), and a layer of water-insoluble phosphate crystal film (film thickness is usually 5-50μm) is formed on the surface of the castings through chemical reaction:

The phosphate ions in the solution react with the metal ions (such as Fe²⁺, Al³⁺) of the casting substrate to form phosphate precipitation;

The precipitation gradually accumulates on the surface, forming a uniform and dense crystalline layer, which is closely attached to the substrate.

After phosphating, the film layer should be "sealed" (such as dipping in rust inhibitor) to further improve the rust resistance of the film layer.

Core role

Short-term rust prevention and extended casting storage duration: The phosphate film isolates air, moisture, and the casting substrate, providing rust protection. For example, carbon steel fastener castings can extend their rust resistance period from "1 month" to "6 months" when stored indoors after phosphating, eliminating the need for additional rust-proof oil and reducing storage costs.

Enhance coating adhesion and prevent peeling: The surface of phosphate film contains fine pores. During subsequent painting, the coating penetrates these pores, forming a mechanical interlock that significantly improves adhesion. For example, cast iron automotive chassis components achieve Class 0 adhesion (zero peeling) after phosphating and electrophoretic coating, while the coating's salt spray resistance improves from 200 hours to 500 hours.

Enhances lubrication and facilitates subsequent processing and assembly: The phosphate film provides lubrication, reducing friction during stamping, drawing, or assembly of castings. For example, the friction coefficient of stamped steel plates (previously castings) decreases from 0.3 to 0.15 after phosphating, preventing deformation or mold wear caused by excessive friction.

applicable scene

Castings requiring subsequent painting and electrophoresis (such as automotive body parts and agricultural machinery casings);

Carbon steel and cast iron castings that need to be stored or transported for short-term rust prevention;

The casting blank to be processed by stamping, drawing and other plastic processes.

Chemical Conversion Coating: Tailored Protective Films for Non-Ferrous Metal Castings

The principle of chemical conversion film treatment is similar to that of phosphating, but it focuses more on non-ferrous metal castings such as aluminum alloy, magnesium alloy and zinc alloy. The core role is to form a special chemical conversion film on the surface to solve the problem of "easy oxidation and difficult protection" of non-ferrous metals.

technical principle

Different chemical solutions are selected according to the casting material, and targeted conversion films are generated through chemical reactions:

Aluminum alloy casting: commonly used chromate, chromium-free passivation agent (environmental protection), forming chromate film or chromium-free passivation film (film thickness 0.5-2μm), isolating air and moisture;

Magnesium alloy casting: commonly used hydrofluoric acid or fluoride solution, magnesium fluoride conversion film is generated to improve corrosion resistance;

Zinc alloy casting: commonly used chromate solution, forming zinc chromate film, prevent surface whitening and rust.

After treatment, the conversion film does not need high temperature baking and can be dried at room temperature, which is suitable for thin-walled non-ferrous metal castings sensitive to deformation.

key role

Addressing the "oxidation-prone" challenge in non-ferrous metals: Aluminum and magnesium alloy castings tend to form loose oxide films in air, which not only fail to provide effective rust protection but also compromise subsequent coating processes. Chemical conversion coatings create dense protective layers. For example, chromium-free passivation treatment for aluminum alloy smartphone frame castings reduces surface oxidation rates by 90%, maintaining a white-painted finish without discoloration even after three months of storage.

Improved corrosion resistance and adaptation to harsh environments: The conversion film can resist the erosion of corrosive media such as acid, alkali and salt spray. For example, the corrosion resistance of magnesium alloy UAV frame castings after magnesium fluoride conversion film treatment is improved from "50 hours" to "200 hours", which can adapt to outdoor humid and salt spray environment.

Compatible with various surface treatments and adaptable to diverse needs: The conversion film's smooth surface allows direct application as a final protective layer (ideal for exposed castings) or as a base layer for coating or electroplating. For example, zinc alloy sanitary fittings castings can undergo chromate conversion film treatment followed by chromium plating, which enhances adhesion and prevents chemical reactions between the zinc alloy and chromium layer.

applicable scene

Non-ferrous metal castings such as aluminum alloy, magnesium alloy, zinc alloy (e.g., mobile phone accessories, drone parts, bathroom products);

Exposed use, non-ferrous metal castings with requirements on appearance and corrosion resistance;

The non-ferrous metal casting requires subsequent electroplating and spraying for the underlying treatment.

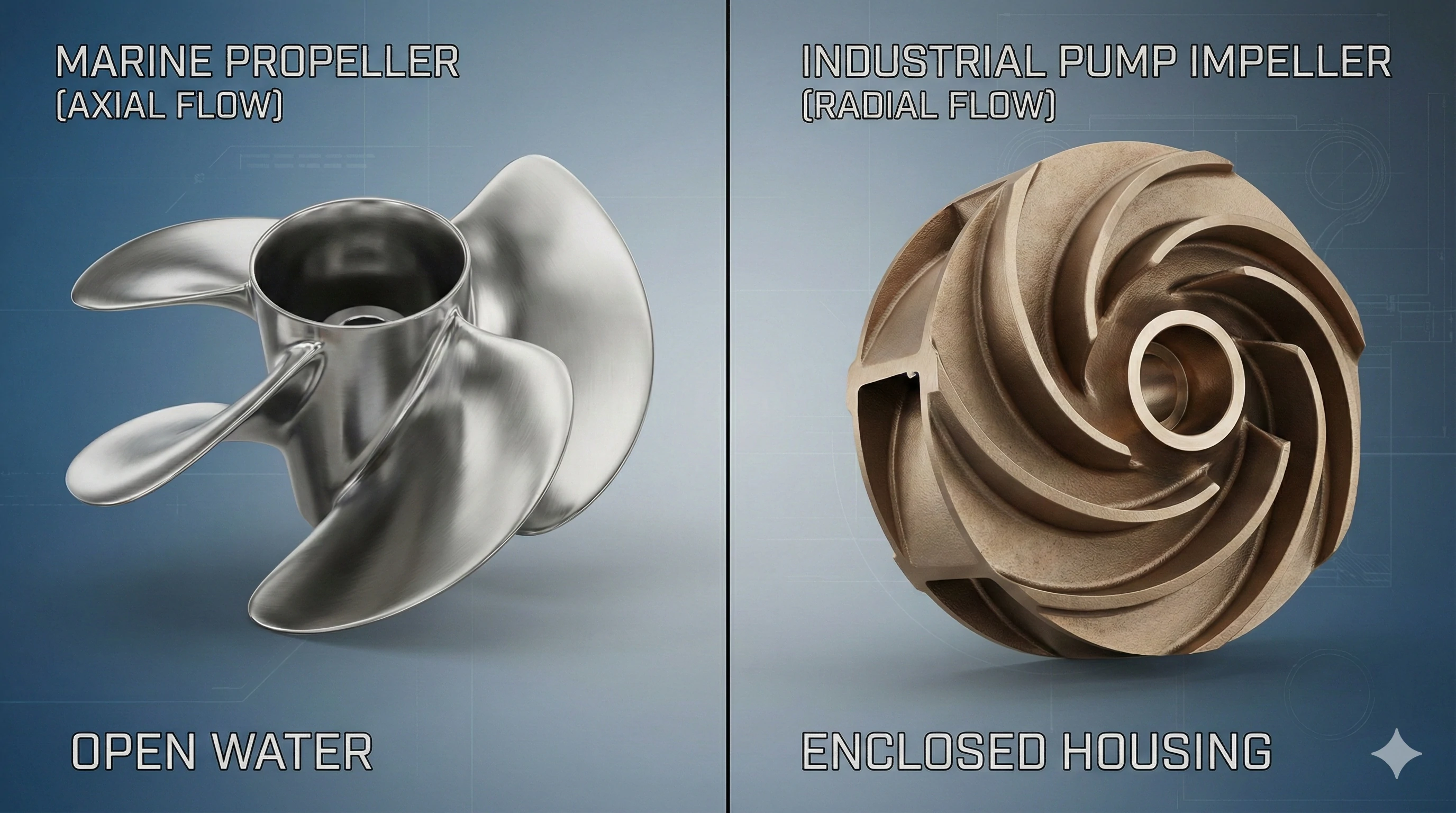

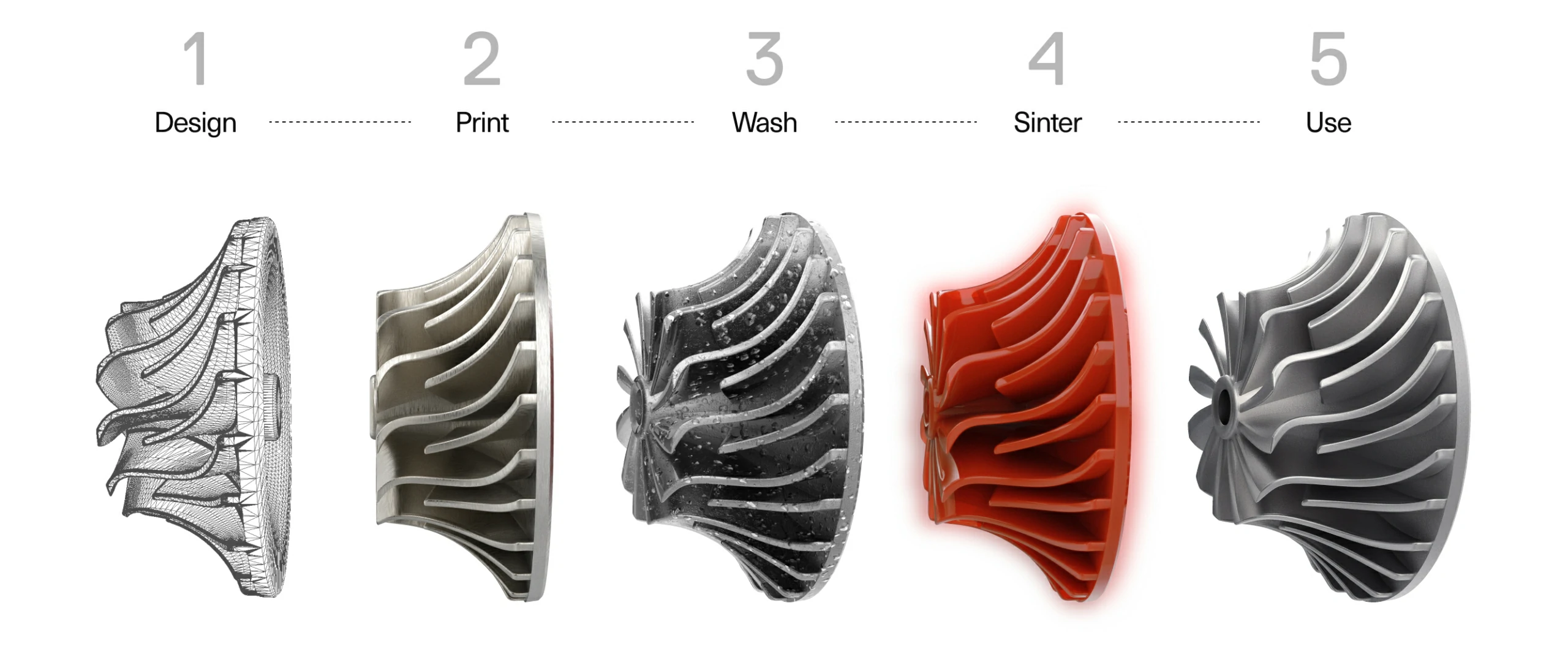

Electroless Plating: Creating a metallic coating on castings without electrodes

Chemical plating (also known as electroless plating) is a coating process that does not require external power supply. Its core function is to uniformly deposit metal coating (such as nickel, copper, gold) on the surface of the casting, which not only improves the appearance texture, but also enhances the wear resistance and corrosion resistance, especially suitable for complex shapes and deep cavities of the casting.

Process Principle

The casting is immersed in a chemical plating solution containing metal ions (such as chemical nickel plating solution containing Ni²⁺ and reducing agent sodium hypophosphite). Through chemical reaction, metal ions are reduced to metal elements on the surface of the casting and gradually deposited to form a coating:

The reducing agent in the plating solution (such as sodium hypophosphite) provides electrons to reduce Ni²⁺ to Ni atoms.

Nitrogen atoms are continuously accumulated on the surface of the casting to form a uniform and continuous coating (typically 5-50μm thick), and the thickness of the coating can be maintained consistently regardless of the complexity of the casting shape.

key role

Complex castings can now achieve "uniform coating" to eliminate "electroplating blind spots": Traditional electroplating relies on electric current, which often creates "current dead zones" in deep cavities and corners of castings, resulting in thin or absent coatings. Chemical plating, through chemical reaction deposition, enables "comprehensive uniform coating" — for example, in stainless steel valve castings with deep holes (5mm diameter, 50mm depth), the thickness deviation of the nickel coating between the inner and outer surfaces after chemical plating is ≤1μm, while electroplating can have deviations of 5-10μm.

Enhancing wear resistance and extending castings' service life: Metal coatings (such as nickel-phosphorus alloy coatings) are significantly harder than the base material. For example, the surface hardness of cast iron machine tool rails improves from HB200 to HV800 after chemical nickel plating, increasing wear resistance by 3-5 times and extending the service life from 3 years to 10 years.

Enhancing conductivity and aesthetics to meet specialized requirements: Chemical copper plating boosts electrical conductivity in castings (ideal for electronic components), while gold plating elevates visual appeal in decorative castings. For example, aluminum alloy electronic connector castings achieve 20% conductivity improvement through copper plating, ensuring stable signal transmission. Zinc alloy jewelry castings gain a glossy finish with gold plating, offering enhanced wear resistance and color retention.

applicable scene

Castings with complex shapes, deep cavities/turning corners, which are difficult to be coated uniformly by traditional electroplating;

Castings with high requirements for wear resistance and corrosion resistance (such as machine tool guide rails, valve sealing surfaces);

Electrical accessories and decorative castings that need to improve conductivity or appearance texture.

Metal Chemical Diffusion: Achieving uniformity in castings through internal material enhancement

Metal infiltration treatment is a "deep chemical treatment". Its core function is to infiltrate metal elements (such as chromium, aluminum and zinc) into the surface layer of the casting through chemical diffusion, change the chemical composition and microstructure of the surface layer, so as to improve the wear resistance and corrosion resistance. Moreover, the performance is gradually transferred from the surface layer to the interior, so as to avoid the problem of "easy detachment of the surface layer".

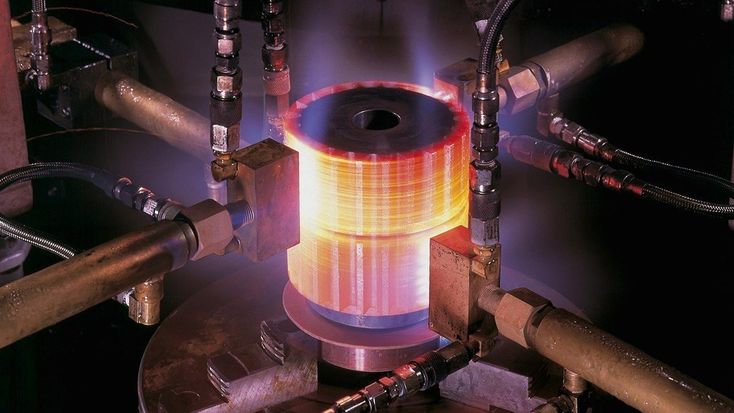

technical principle

The casting is placed in a medium containing the target metal elements (such as chromium powder for chromium infiltration, aluminum powder for aluminum infiltration), and kept at a certain temperature (usually 500-1000℃) for a certain period of time. Through chemical reaction and diffusion, the metal elements are infiltrated into the surface layer of the casting:

The metal elements in the medium first react with other components to form active ions (such as Cr³⁺);

At high temperatures, active ions diffuse into the surface layer of the casting, forming an alloy with the base metal (e.g., Cr-Fe alloy after chromium infiltration), creating an infiltration layer (typically 0.1-2mm thick).

key role

Significantly enhanced high-temperature and corrosion resistance, suitable for high-temperature scenarios: Aluminum and chromium infiltration treatments enable castings to form a stable oxide film under high-temperature conditions, resisting high-temperature oxidation and corrosion. For example, carbon steel castings for boilers show a 95% reduction in oxidation rate at 600°C after aluminum infiltration, extending service life from "1 year" to "5 years" without frequent replacement.

Enhancing wear resistance for high-friction applications: Chromed or boron-plated castings (where boron is a non-metal but shares similar processing characteristics) develop a high-hardness alloy layer on the surface. For example, a crusher hammer cast iron component achieves a surface hardness of HV1200 after chroming, compared to HB250, resulting in 4-6 times improved wear resistance. This enhancement allows the total crushing capacity to increase from 10,000 tons to 50,000 tons.

No additional coating required to prevent surface peeling: The metallurgical bond between the zinc infiltration layer and substrate eliminates surface detachment risks. This is exemplified by agricultural plowshares—when zinc-infiltrated, they maintain structural integrity even under prolonged soil friction, whereas conventional galvanized coatings typically wear away within six months.

applicable scene

Castings (such as boiler parts, chemical equipment accessories) that work in high temperature and corrosion environment for a long time;

Castings subjected to high friction and high wear (such as crusher hammer head, roll, plough);

Heavy machinery castings with high surface bonding strength and no allowance for coating detachment.

Chemical Cleaning: A precision cleaning process for castings to remove microscopic oil residues and impurities

Chemical cleaning is different from acid washing. It is a more refined surface cleaning process. Its core role is to remove micro oil, fingerprints, dust and other light pollutants on the surface of castings without removing oxide scale. It is suitable for castings that have been processed or have a good surface condition.

technical principle

Use weakly alkaline or neutral chemical cleaning agents (such as surfactants or chelating agents) to clean surfaces through emulsification, dissolution, and dispersion.

The surfactant can emulsify and decompose the oil and dirt, so that it is separated from the surface of the casting;

Chelating agents can bind with surface metal ions (such as slightly corroded Fe³⁺) to prevent the formation of new pollutants;

After cleaning, rinse with pure water to avoid residue of cleaning agent, and finally dry or blow dry.

key role

Removing Micro-Oil Contaminants for Assembly Accuracy: Machined castings may retain residual cutting fluid, fingerprints, and other contaminants on their surfaces. These residues can compromise assembly fit (e.g., oil contamination on sealing surfaces leading to poor sealing). Following chemical cleaning, surface oil residue can be controlled below 5mg/m². For example, in hydraulic valve block castings, the leakage rate of sealing surfaces decreased from "5%" to "0.1%" after cleaning, ensuring proper operation of hydraulic systems.

Precision Surface Cleaning for High-Tolerance Applications: High-precision castings (e.g., medical device components, electronic parts) require flawless surfaces free from contaminants, as even trace impurities can compromise functionality. Chemical cleaning achieves micron-level purity—take stainless steel surgical instruments: post-cleaning surfaces show no visible impurities, with bacterial residue levels meeting medical standards. This process eliminates the need for additional high-temperature sterilization (suitable for certain materials).

Protect finished surfaces from damage: For precision-finished castings (e.g., polished decorative components) with smooth surfaces, strong corrosive processes like acid washing may cause surface damage. However, chemical cleaning using neutral or weakly alkaline solutions preserves surface roughness and gloss. For example, polished aluminum alloy jewelry castings maintain their original gloss after chemical cleaning, with no scratches or corrosion marks remaining.

applicable scene

Precision castings with residual cutting fluid and oil after machining;

Clean the cast parts (such as hydraulic valve block and flange) on the sealing surface and joint surface before assembly;

Castings that are polished and electroplated and require careful cleaning and damage avoidance.

Conclusion

Chemical treatment of castings is not a "single choice", but a "solution matrix" customized according to the material of castings and subsequent requirements (anti-rust, painting, wear resistance):

Acid washing is the "basic cleaning" to clear the obstacles for the subsequent treatment;

Phosphating is the "protective base layer", which takes into account the anti-rust and coating compatibility;

The chemical conversion film is "exclusively protective for non-ferrous metals" to solve the pain point of oxidation;

Chemical plating is a "complex part coating scheme" to achieve uniform performance upgrade;

Metallized metal is "deep performance optimization", improving the material from the surface to the inside;

Chemical cleaning is "fine cleaning", suitable for precision assembly and appearance requirements.

Understanding the core functions of each chemical treatment is essential to select the optimal process for different castings, effectively addressing practical challenges while avoiding cost inefficiencies from "over-treatment". If you have questions about "chemical treatment options for specific material castings" or "process combinations for special scenarios", feel free to leave comments below. We'll keep sharing more practical knowledge on casting chemical treatments!