At our foundry, we often see clients struggle with material selection. You might have a design that works perfectly on paper, but choosing the wrong alloy can lead to unnecessary costs or premature part failure. We have spent years refining our for glass hardware and industrial components, and we know that the success of a project often hangs on selecting the right metal before the first mold is even made. Whether you are dealing with marine environments or high-stress structural applications, understanding the nuances of each alloy is crucial.

The best metals for investment casting depend heavily on your specific application, but Stainless Steel (304, 316, and Duplex 2205) is generally the industry standard due to its corrosion resistance and detail capability. Carbon Steel is the top choice for cost-effective structural parts, while Aluminum and Superalloys serve specialized aerospace and high-temperature needs.

Finding the perfect balance between cost, strength, and corrosion resistance requires a deeper look at each material category.

Why Is Stainless Steel the Most Popular Choice for Investment Casting?

When we walk through our production floor, the vast majority of parts cooling on the racks are stainless steel. From our experience manufacturing glass railing fittings and shower hardware, we find that customers prefer stainless steel because it offers an incredible surface finish right out of the mold. It eliminates the need for heavy post-processing, which is a massive advantage when you need aesthetically pleasing parts that also resist rust.

Stainless steel is the preferred choice for investment casting because it flows exceptionally well in its molten state, capturing intricate details from the ceramic mold. It offers a superior balance of corrosion resistance, mechanical strength, and aesthetic appeal, making it ideal for everything from architectural hardware to medical devices.

The Versatility of Stainless Grades

Stainless steel is not a single material; it is a family of alloys. In our daily operations, we primarily work with three specific categories that cover 90% of market needs. Understanding the difference between these grades is vital for ensuring your product lasts in its intended environment.

Austenitic Stainless Steel (300 Series)

This is the workhorse of the industry. You will see used everywhere.

-

304 Stainless Steel: This is the standard grade. It is excellent for indoor applications or environments with low moisture. However, we always advise clients that if the part is going near the ocean, 304 might eventually show tea-staining.

-

316 Stainless Steel: Often called "Marine Grade," this alloy includes Molybdenum. We use this extensively for our outdoor glass clamps and impellers because it resists pitting corrosion caused by chloride (saltwater). If your project is within 10 miles of the coast, we strongly recommend 316.

Duplex Stainless Steel (2205)

We call this the "Super Material." has a microstructure that is part austenite and part ferrite. This gives it roughly twice the yield strength of 316 stainless steel. We often recommend this for structural spigots where high load-bearing capacity is required without increasing the physical size of the part. It also has superior stress corrosion cracking resistance.

Precipitation Hardening (17-4 PH)

While less common for decorative hardware, we utilize for clients in the aerospace or military sectors. It can be heat-treated to achieve incredibly high strength and hardness levels that standard 300-series steels cannot match.

Comparison of Common Stainless Grades

| Grade | Primary Characteristic | Typical Application | Relative Cost |

|---|---|---|---|

| 304 | Good corrosion resistance, lower cost | Indoor hardware, food processing | $$ |

| 316 | Excellent corrosion resistance (Molybdenum) | Marine hardware, chemical pumps | $$$ |

| Duplex 2205 | High strength, superior corrosion resistance | Structural spigots, oil & gas | $$$$ |

| 17-4 PH | High strength, heat treatable | Aerospace components, gears | $$$$ |

Is Carbon Steel a Viable Option for Budget-Conscious Projects?

We frequently receive inquiries from industrial clients who need thousands of brackets or gearboxes where aesthetics are secondary to function. In these cases, our engineering team usually steers the conversation toward carbon steel. It is a material that allows us to produce robust parts at a fraction of the cost of stainless steel, provided you plan for its surface protection.

Carbon steel is an excellent, cost-effective option for investment casting when corrosion resistance is not the primary concern. It offers high tensile strength and is easy to heat treat, making it perfect for industrial brackets, automotive parts, and machinery components that will be painted or galvanized later.

Balancing Cost and Performance

Carbon steel is the "workhorse" of the ferrous casting world. It is significantly cheaper than stainless steel because it lacks expensive alloying elements like nickel and chromium. However, the trade-off is oxidation.

The Rust Factor

If you walk into our raw material storage, you will notice carbon steel ingots can develop surface rust just from humidity. When we cast carbon steel parts, they must undergo a secondary surface treatment immediately.

-

Painting/Powder Coating: This is standard for automotive parts.

-

Galvanizing: We often carbon steel parts for construction use to provide a thick protective zinc layer.

Common Carbon Steel Grades

-

WCB (Wrought Carbon B): This is the standard cast steel grade suitable for valves and fittings. It has good weldability and toughness. You can learn more about properties for heavy-duty applications.

-

Low Alloy Steels: By adding small amounts of other elements, we can tweak the mechanical properties for specific uses, such as increasing wear resistance for mining tools.

Why Not Just Use Carbon Steel for Everything?

Fluidity is a challenge. Carbon steel tends to be sluggish compared to stainless steel when molten. This means for very thin-walled parts or extremely fine details, carbon steel might result in "misruns" (where the metal doesn't fill the mold completely) unless we adjust the gate design significantly. Stainless steel flows like water by comparison, which is why we prefer it for decorative items.

Comparison: Carbon Steel vs. Stainless Steel

| Feature | Carbon Steel | Stainless Steel |

|---|---|---|

| Raw Material Cost | Low | High |

| Corrosion Resistance | Poor (Rusts easily) | Excellent |

| Surface Finish | Rougher, requires coating | Smooth, shiny |

| Post-Processing | Painting/Galvanizing required | /Polishing only |

When Are Copper Alloys the Right Material for Your Parts?

Walking through our sample room, visitors are always drawn to the golden and reddish hues of our copper alloy castings. While they don't make up the bulk of our volume like stainless steel, we find that for specific industries—particularly marine and high-end architecture—there is simply no substitute for the unique properties of bronze and brass.

Copper alloys like bronze and brass are ideal for investment casting when you need natural corrosion resistance combined with low friction or unique aesthetics. They are frequently used for marine propellers, non-sparking safety tools, and decorative architectural hardware that develops a desirable patina over time.

The Aesthetic and Functional Appeal

Copper alloys offer a unique combination of beauty and utility. They are naturally antimicrobial and resist biofouling, which is why they have been used in maritime history for centuries.

Aluminum Bronze

This is the toughest copper alloy we work with. It is incredibly strong and resistant to wear and corrosion. We cast this primarily for:

-

Marine Propellers: It resists the corrosive effects of seawater and the physical erosion of .

-

Bearings and Bushings: Its low friction coefficient makes it excellent for parts that slide against other metals.

Silicon Bronze

If you see a beautiful, gold-like statue or a high-end door handle in a luxury hotel, it is likely Silicon Bronze. It has excellent fluidity, allowing us to capture artistic details that other metals might miss. Over time, these parts develop a "patina"—a green or brown oxidation layer that protects the metal and gives it an antique look. Many of our architectural clients specifically request this "living finish."

Processing Considerations

From a manufacturing standpoint, copper alloys melt at lower temperatures than steel, which is easier on our ceramic molds. However, they can be prone to gas porosity if not degassed properly. Our team has to carefully control the melting environment to ensure the final casting is solid and defect-free.

Does It Make Sense to Use Aluminum in Investment Casting?

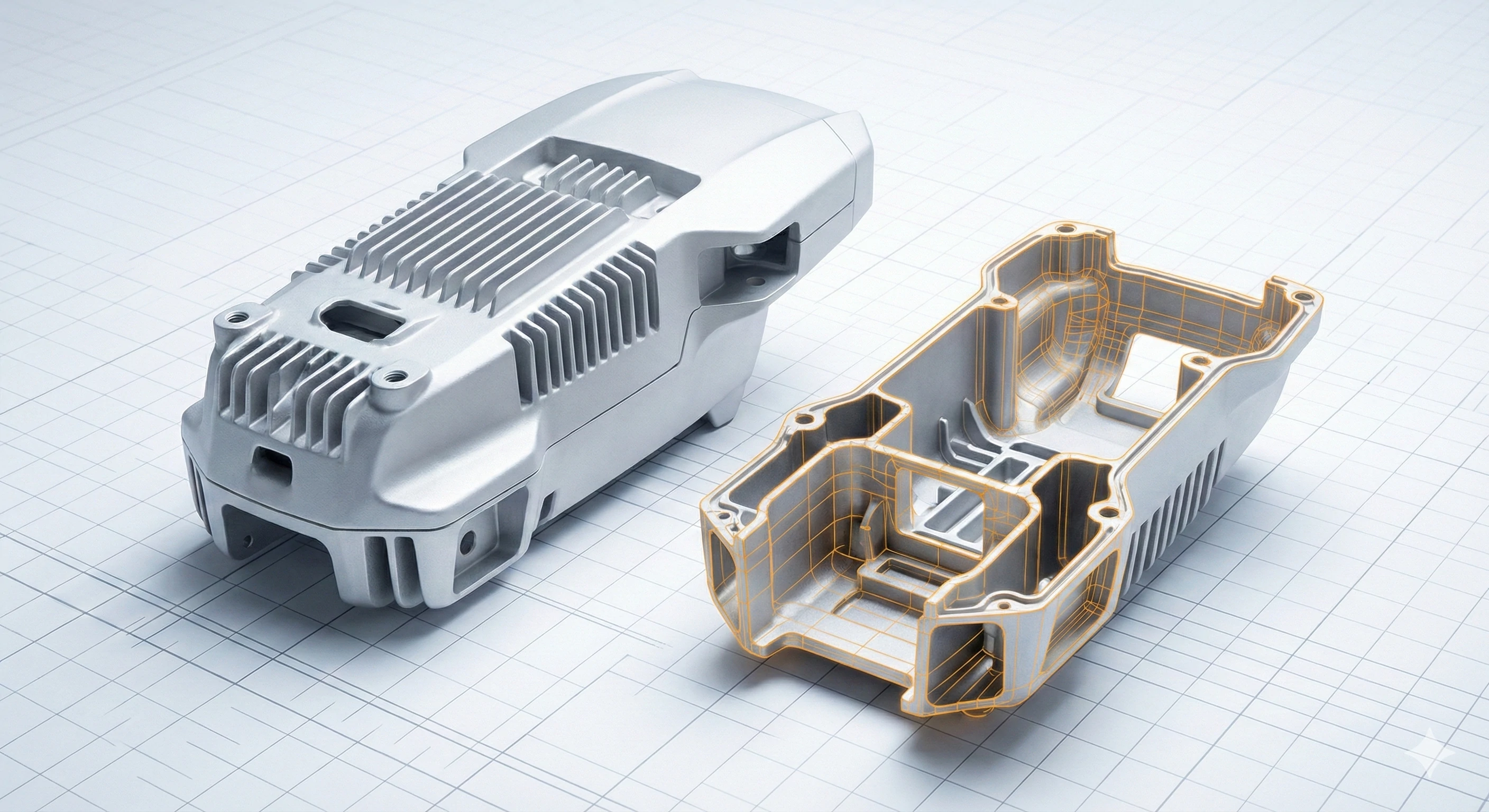

We often face a dilemma when clients request aluminum parts: should we investment cast them or die cast them? Usually, die casting is faster and cheaper for high volumes. However, our engineers know that there are specific scenarios where investment casting is the only viable path for aluminum, particularly when the design is impossible to eject from a rigid steel die.

Investment casting is the right choice for aluminum parts when they feature complex internal geometries, undercuts, or thin walls that die casting cannot achieve. It is also preferred for low-to-medium production runs where the high tooling cost of die casting is not justifiable.

The "Die Casting vs. Investment Casting" Debate

Most aluminum parts you see (like phone cases or engine blocks) are die-cast. Molten aluminum is forced into a reusable steel mold at high pressure. So, why do we use the lost wax process for aluminum?

-

Undercuts and Internal Channels: A die cast mold must open to eject the part. If your design has an internal hollow or a shape that locks it into the mold, fails. With investment casting, we melt the wax pattern out and break the ceramic shell away, so the geometry can be incredibly complex.

-

Alloy Selection: Die casting is limited to specific alloys (like A380) that don't stick to the steel die. Investment casting allows us to use high-strength aerospace grades like , which can be heat-treated (T6) for superior mechanical properties.

Applications

We see high demand for aluminum investment casting in:

-

Aerospace Brackets: Where weight reduction is critical, but strength cannot be compromised.

-

Electronics Housings: Specifically those with complex heat sink fins that are too deep for die casting.

Weight Advantage

Aluminum is roughly one-third the weight of steel. For our clients building drones or portable equipment, replacing a stainless steel bracket with an A356 aluminum one can be a game-changer for their product's performance.

How Do Fluidity and Shrinkage Impact Your Design?

Before we start mass production, our engineering team spends a significant amount of time analyzing the geometry of your part. We don't just look at the shape; we look at how the molten metal will behave as it enters the mold. Different metals have different "personalities" when they melt and cool, and ignoring these factors leads to defects.

Fluidity and shrinkage are critical design factors; fluidity determines how well the metal fills fine details, while shrinkage dictates how much we must oversize the mold. Stainless steel generally has excellent fluidity, whereas carbon steel shrinks significantly, requiring precise compensation to ensure dimensional accuracy.

Understanding Fluidity

Fluidity is the ability of the liquid metal to flow into the tiniest crevices of the ceramic shell before it freezes.

-

High Fluidity: Stainless steel and bronze flow very well. This allows us to cast lettering, logos, and thin textures with crisp definition.

-

Low Fluidity: Carbon steel is sluggish. If your design has thin walls (under 3mm) and you choose carbon steel, we might need to add extra "gates" (entry points) to ensure the metal fills the mold before it solidifies.

The Shrinkage Challenge

All metals expand when hot and shrink when they cool. This is physics. But they shrink at different rates. When we create the metal tool to inject the wax patterns, we must scale it up.

-

Steel Shrinkage: Typically around 2-3%. If you want a 100mm part, we might tool the wax mold at 102.5mm.

-

Distortion: It is not just linear shrinkage. Thick sections cool slower than thin sections, which can cause the part to warp. We often use "straightening fixtures" after the cast is cooled to press the part back into tolerance.

Metal Shrinkage Rates Overview

| Metal Type | Approximate Shrinkage Rate | Fluidity Rating |

|---|---|---|

| Stainless Steel (304/316) | 2.5% - 3.0% | Excellent |

| Carbon Steel | 2.0% - 2.5% | Fair/Poor |

| Aluminum | 1.0% - 1.5% | Good |

| Bronze/Brass | 1.5% - 2.0% | Excellent |

How Do These Metals Compare in Cost and Performance?

We know that for many procurement managers, the final decision often comes down to a spreadsheet comparing performance metrics against unit cost. To help you make a quick decision, we have compiled a matrix based on our manufacturing data. This guide helps our clients align their budget with their technical requirements without over-engineering or under-specifying.

When comparing casting metals, stainless steel offers the best all-around performance but at a higher price point, while carbon steel wins on cost for structural parts. Aluminum is the clear winner for weight-sensitive applications, and copper alloys excel in specialized marine or aesthetic environments.

The Decision Matrix

Use this table to quickly identify which material fits your project's constraints.

| Metal Category | Corrosion Resistance | Tensile Strength | Weight | Raw Material Cost | Best For |

|---|---|---|---|---|---|

| Stainless Steel | High | High | Heavy | $$$ | Glass hardware, food industry, exterior parts |

| Carbon Steel | Low (Needs coating) | High | Heavy | $ | Structural brackets, machinery, automotive |

| Aluminum | Medium (Oxides) | Low/Med | Light | $$ | Aerospace, drones, handheld devices |

| Bronze/Brass | High | Medium | Heavy | $$$$ | Marine props, decorative architecture, bearings |

| Superalloys | Extreme | Extreme | Heavy | $$$$$ | Turbine blades, chemical processing |

Final Recommendations from the Factory Floor

-

If your part is visible and needs to look good for years: Stick to 316 Stainless Steel.

-

If your part is hidden inside a machine and needs to be strong: Go with Carbon Steel.

-

If your part flies or moves fast: Choose Aluminum.

Conclusion

Investment casting is a remarkably versatile process, capable of handling almost any metal that can be melted. While we can cast aluminum and bronze, the true superpower of this method lies in its ability to cast high-melting-point ferrous metals like Stainless Steel 316 and Duplex 2205. These materials allow you to create complex, durable, and corrosion-resistant parts that die casting simply cannot match.

Choosing the right alloy is about understanding the trade-offs between cost, environment, and mechanical needs. If you are still unsure which material fits your specific project budget and strength requirements, don't guess.

Contact us for a material consultation and quote. Our metallurgists are ready to help you navigate these choices to ensure your production run is a success.

Footnotes

1. Comprehensive guide to the investment casting process and applications.

2. Overview of stainless steel families and their specific properties.

3. Technical datasheet detailing Duplex 2205 strength and resistance.

4. Material properties of 17-4 PH precipitation hardening steel.

5. Educational resource on the hot-dip galvanizing process for steel.

6. Details on WCB steel characteristics for industrial use.

7. Explanation of passivation for improving corrosion resistance.

8. Definition and causes of cavitation erosion in marine environments.

9. Industry standards and capabilities of high-pressure die casting.