When we analyze the blueprints for a new casting project at our foundry, we often see that a valve looks deceptively simple from the outside. It might appear to be just a solid lump of metal installed in a pipeline. However, once we look at the internal design, it becomes clear that every valve is a precision-engineered machine. Industrial systems rely on these devices to manage immense pressure and dangerous fluids without failure. If you do not understand how these components work together, it is impossible to select the right product for your project or ensure long-term safety.

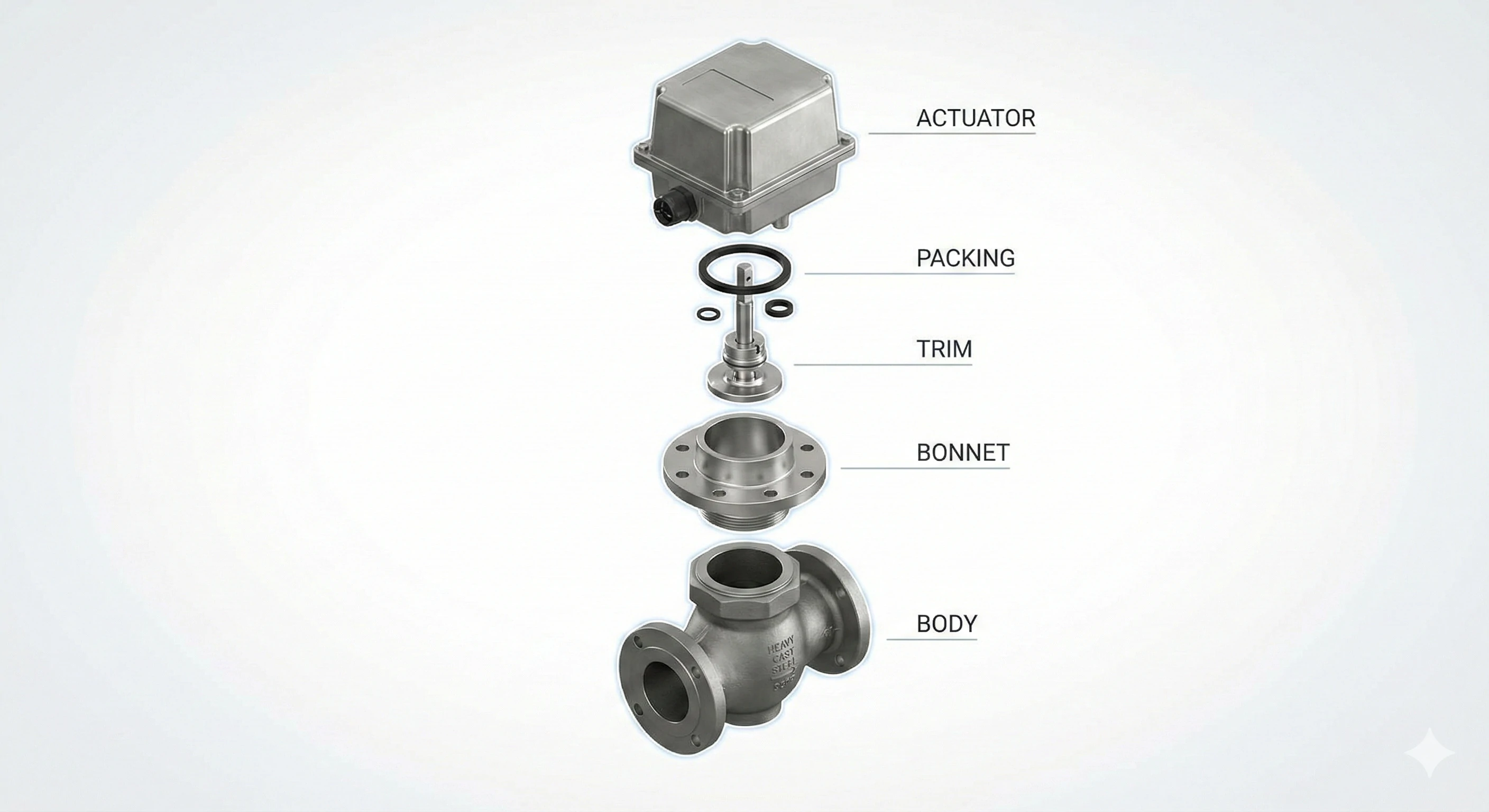

Regardless of the specific type, such as a ball, gate, or globe valve, almost all industrial valves share five core components that ensure proper operation. These essential parts are the Body (the shell), the Bonnet (the cover), the Trim (the internal moving parts), the Actuator (the handle or motor), and the Packing (the sealant).

Understanding these five pillars is the first step to mastering flow control.

What Is the Valve Body and Why Is It Critical?

In our production line, the valve body is always the first priority because it serves as the primary pressure-containing vessel. We treat this component with extreme care during the casting process because it holds the entire system together. If the body fails, the fluid escapes, and the entire piping system is compromised. It acts as the first line of defense against internal pressure and external corrosion.

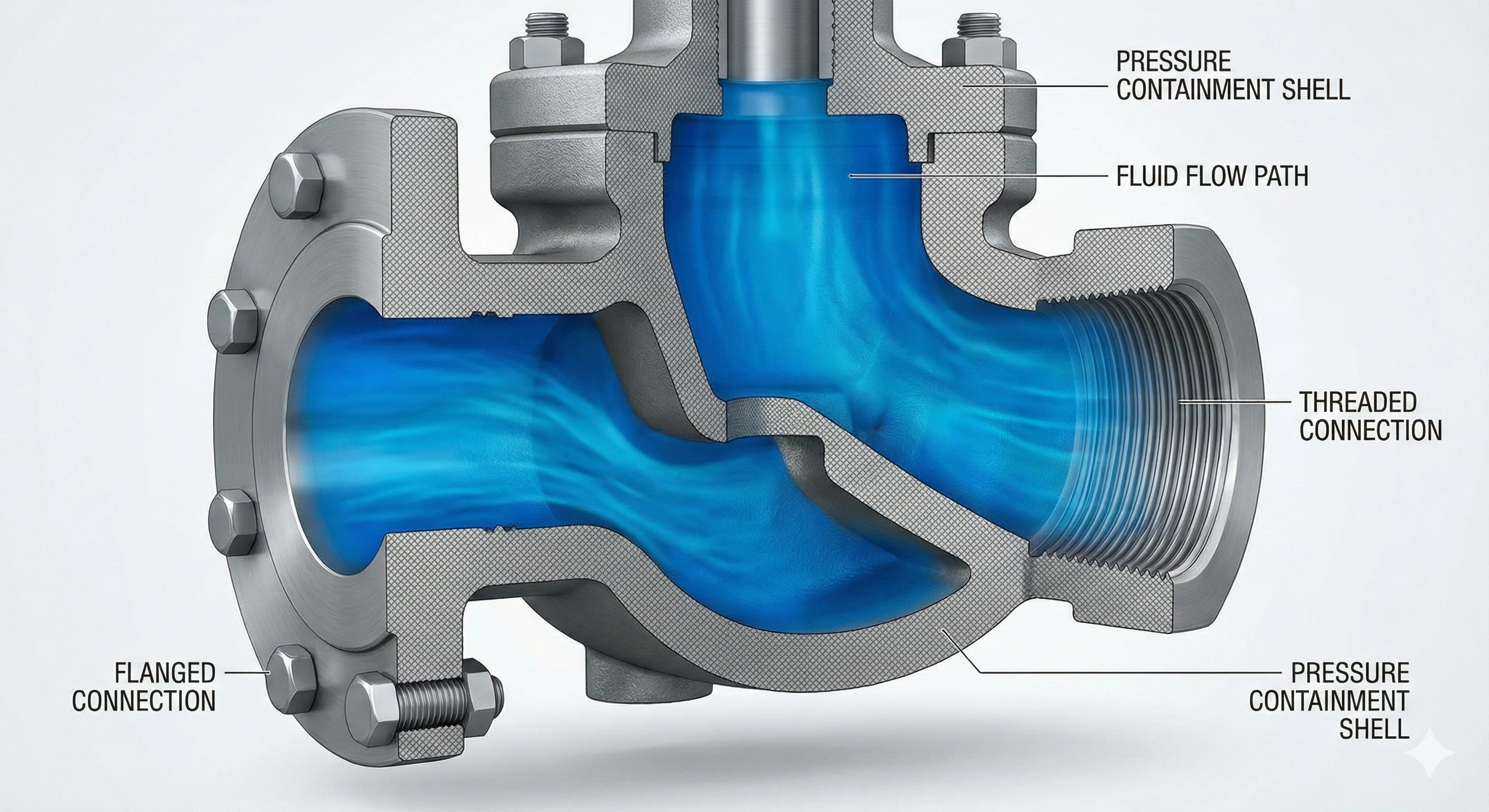

The valve body is the outer shell that houses all internal parts and connects directly to the piping system via threaded, flanged, or welded joints. Its primary function is to contain the fluid pressure and provide a rigid framework that allows the fluid to flow through or be stopped.

The Backbone of the Valve

The body, often called the "shell," is the most substantial part of the assembly. When we cast these parts, we focus heavily on the "Pressure Boundary." This is a professional engineering term referring to the parts that keep the liquid inside the pipe.

Material Selection Matters

Because the body is in constant contact with the fluid, the material choice is non-negotiable. At our factory, we use to create bodies from high-grade alloys. This method allows us to create complex internal flow paths that machining from a solid bar cannot achieve.

-

Stainless Steel (316/304): We use this for environments where corrosion is a risk. It is standard for food processing or chemical industries.

-

Carbon Steel (WCB): This is the workhorse for high-pressure and high-temperature applications where corrosion is less of a concern.

Connection Types

The body must connect seamlessly to the rest of your pipes. The design of the dictates how this happens.

Comparison of Connection Styles

| Connection Type | Description | Best Application |

|---|---|---|

| Threaded | Screwed directly onto the pipe. | Small, low-pressure valves (under 2 inches). |

| Flanged | Bolted to a matching pipe flange with a . | Industrial lines; easy to remove for maintenance. |

| Butt Welded | Welded directly to the pipe. | High-pressure/High-temp systems where zero leakage is required. |

By choosing the right body material and connection, you ensure the safety of the entire installation.

What Is the Function of the Valve Bonnet?

We often describe the bonnet to our clients as the "lid" of the valve. While the body allows flow, the bonnet is necessary to close the pressure boundary while allowing you to put the internal parts inside. During maintenance, our technicians appreciate a well-designed bonnet because it dictates how easily you can repair the valve without cutting it out of the line.

The valve bonnet acts as a cover for the opening in the valve body, completing the pressure-tight seal for the system. It supports the stem and actuator assembly and can be removed to allow technicians access to internal components for maintenance, cleaning, or repair.

The Second Barrier

Like the body, the bonnet is part of the pressure boundary. It must withstand the same forces as the body. If the bonnet is weak or poorly attached, the valve will blow its top under pressure.

Common Bonnet Designs

Depending on the size and pressure rating of the valve, we manufacture different bonnet styles.

-

Bolted Bonnet: This is the most robust option. We use heavy bolts to secure the bonnet to the body. It is standard for large industrial valves because it can handle high pressure and is easy to open with a wrench.

-

Screwed Bonnet: This screws directly into the body. It is simple and cheap, but we generally only recommend it for small valves. It can be hard to unscrew after years of service.

-

Union Bonnet: This design uses a separate ring nut to hold the bonnet. It allows you to take the valve apart frequently without damaging the sealing surfaces.

Why Casting Is Essential Here

Just like the body, the bonnet often has an irregular shape. It needs to house the stem packing and provide a mounting point for the actuator. Casting is the most cost-effective way to produce these shapes with high structural integrity.

Bonnet Selection Guide

| Bonnet Style | Pressure Rating | Maintenance Ease | Typical Use |

|---|---|---|---|

| Bolted | High | Medium | Oil & Gas, Large Water Lines |

| Screwed | Low | Low | Residential Plumbing |

| Union | Medium | High | Labs, Frequent Cleaning Lines |

What Does Valve Trim Consist Of?

When we discuss the "heart" of the valve, we are talking about the Trim. This is where the actual work happens. In our experience, the body lasts for decades, but the trim takes the beating. It faces erosion, , and constant friction. Therefore, the specification of the trim is often more complex than the body itself.

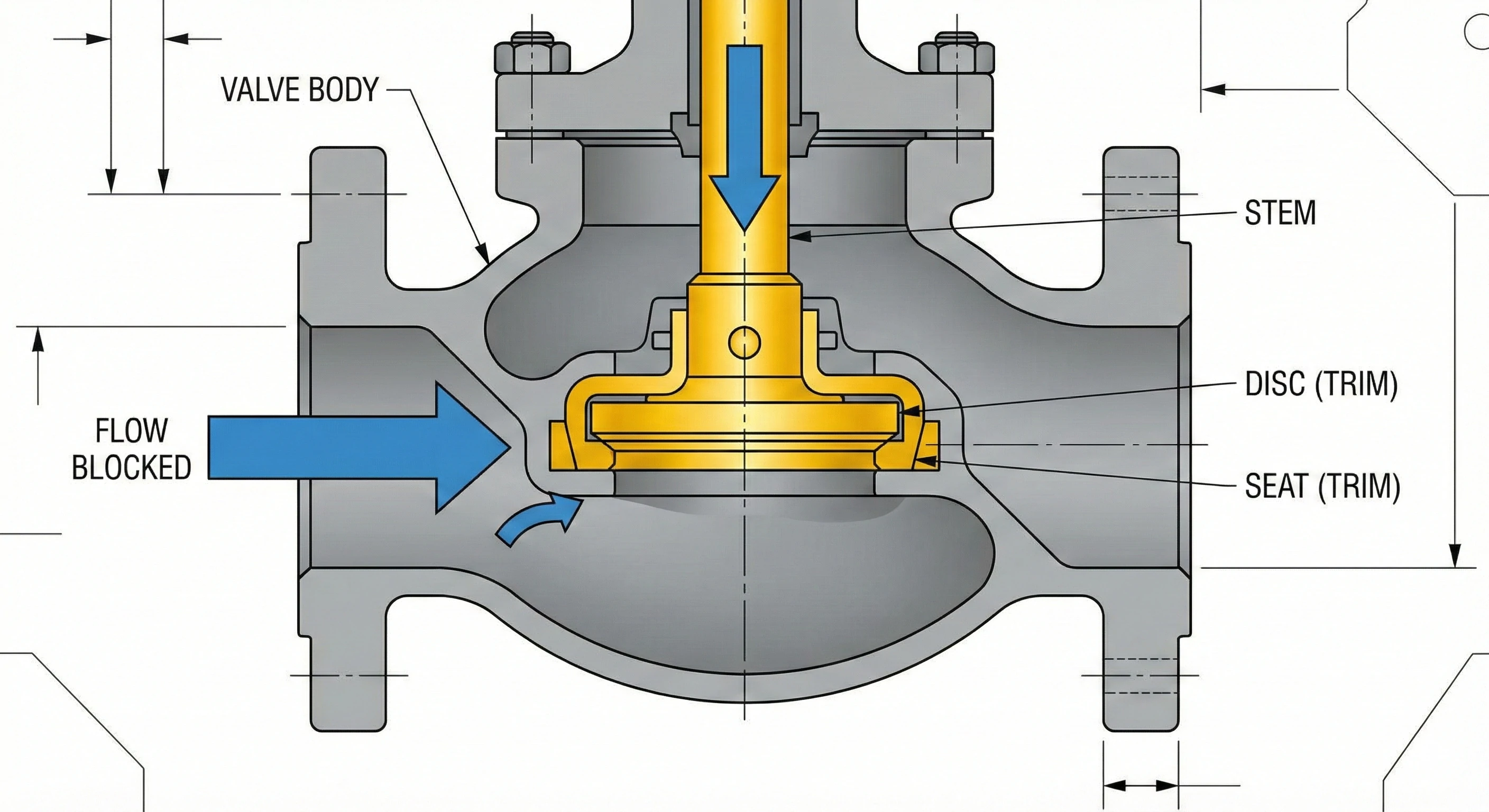

Valve trim refers collectively to the internal operating parts that come into direct contact with the flow to control the movement of fluid. The three primary components of the trim are the Disc (or ball), the Seat (sealing surface), and the Stem (connector rod).

The Wet Parts

"Trim" is industry shorthand for "wet parts" that move. If you order a valve, you must specify the trim material. A carbon steel body might be fine, but if the trim is soft brass, it might erode in weeks.

Breakdown of Trim Components

1. The Disc (Ball or Plug)

This is the part that physically blocks the flow.

-

In a Ball Valve, it is a sphere with a hole.

-

In a Gate Valve, it is a sliding gate.

-

In a Globe Valve, it is a plug.

We cast these parts to near-perfect shapes to minimize the machining needed to get a tight seal.

2. The Seat

The seat is the surface the disc pushes against to stop the leak.

-

Soft Seats (PTFE/Teflon): Great for tight sealing in clean water or gas.

-

Metal Seats: Necessary for high heat or abrasive sludge. We often apply hard-facing materials like to these surfaces to prevent scratching.

3. The Stem

The stem is the rod that connects the handle (outside) to the disc (inside). It must be strong enough to push the disc against the flow pressure without bending.

Why Material Hardness Counts

The trim must be harder than the body. If they are the same hardness, they might "gall" (stick together) when they rub against each other. We ensure our trim packages use compatible materials that resist wear.

How Do Actuators and Packing Ensure Control and Safety?

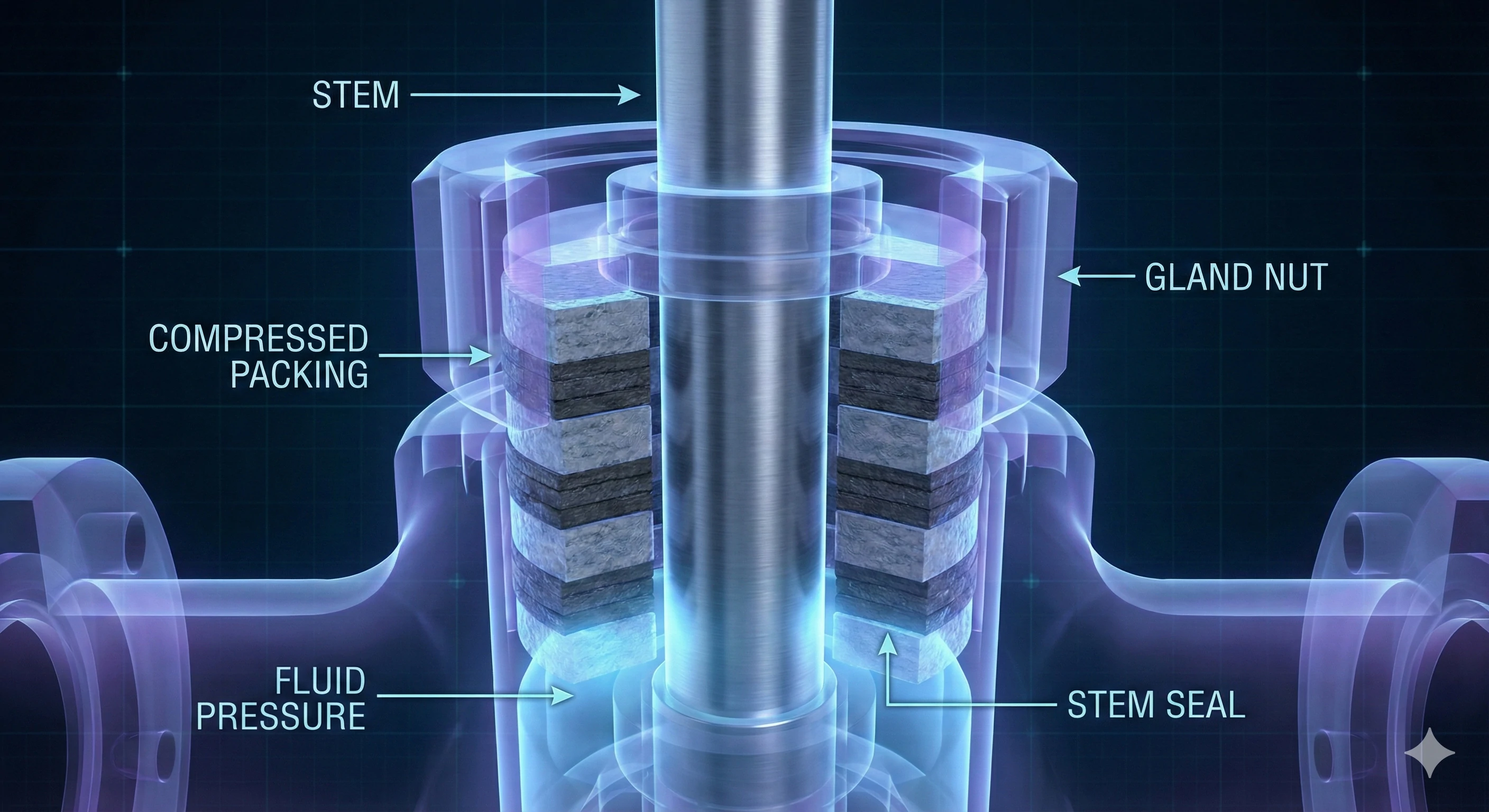

A valve is useless if you cannot operate it, and it is dangerous if it leaks around the handle. We spend a lot of time testing the "stem seal" area because this is the most common leak path in any industrial plant. The actuator provides the muscle, but the packing provides the safety.

The actuator is the mechanism that operates the stem assembly to open or close the valve, while packing is the fibrous material stuffed around the stem to prevent fluid from leaking out. Together, they allow external control without compromising the internal pressure boundary.

The Muscle: Actuators

How do you want to move the valve?

-

Manual (Handwheel/Lever): Simple and reliable. Most of the valves we cast parts for end up with manual handwheels.

-

Pneumatic: Uses air pressure. Fast and good for emergency shutdowns.

-

Electric: Uses a motor. Good for precise flow control in automated factories.

The Seal: Packing & Gaskets

There are two types of static seals you need to know.

Gaskets

The gasket sits between the Body and the Bonnet. It is a static seal—it does not move. It just gets crushed between the bolts to stop leaks.

Packing

The packing is dynamic—it touches the moving stem. We usually install a that you can tighten. This compresses rings of or PTFE around the stem.

-

FAQ: Why do valve stems leak?

Usually, the packing dries out or wears down. Tightening the gland nut often fixes this, but eventually, the packing needs replacement.

Packing Material Options

| Material | Temperature Limit | Friction | Best For |

|---|---|---|---|

| PTFE (Teflon) | Medium (~200°C) | Very Low | Chemicals, Food |

| Graphite | High (~500°C+) | Medium | Steam, High Heat |

| O-Rings | Low | Low | Water, Air |

Which Valve Parts Are Best Suited for Investment Casting?

As a supplier to major valve brands, we do not always build the finished product. Instead, we focus on what we do best: creating the complex metal shapes that others assemble. We have found that the most critical parts of the valve are the ones that are the hardest to machine from scratch. This is where our casting technology shines.

Investment casting is the ideal manufacturing method for the Valve Body, Valve Bonnet, and the Disc/Ball because it allows for complex 3D shapes and high-strength alloys. Casting these components ensures a seamless pressure boundary and reduces the cost of machining from raw metal blocks.

The "Pressure Boundary" Specialist

We specialize in casting the Body and Bonnet. Why?

-

Complex Geometry: A valve body has curved internal chambers to guide fluid. You cannot drill these shapes easily. Casting pours liquid metal into a mold, capturing every curve perfectly.

-

Alloy Versatility: We can melt and pour specialized alloys like or that are very hard to cut but easy to cast.

The Internal Elements

We also cast the Ball or Disc. A cast ball is perfectly spherical right out of the mold. It requires minimal grinding to make it shiny and smooth. If you tried to cut a ball out of a square block of steel, you would waste 50% of the material.

Our Service for OEMs

We deliver these rough or machined castings to Valve Brands ( ). They then:

-

Install their own proprietary seats and packing.

-

Paint the valve.

-

Add their logo.

-

Sell it to the end user.

By sourcing high-quality castings from us, they ensure the structural integrity of their product is sound.

Conclusion

A valve is not just a single piece of equipment; it is a system of parts working in unison. From the robust Body that holds the pressure to the precision Trim that controls the flow, every component plays a vital role.

The reliability of any valve depends heavily on the quality of the casting. If the body has internal flaws, the best seal in the world cannot save it. Whether you are a maintenance manager replacing a worn valve or a manufacturer looking for a casting partner, understanding these parts helps you make better decisions.

Are you a Valve Manufacturer? Secure your supply chain with high-quality OEM Valve Castings. We produce pressure-tested Bodies and Bonnets ready for your assembly line. Request a sample kit today.

Footnotes

1. Process of creating complex metal parts using wax patterns.

2. Standard configurations for connecting valves to piping systems.

3. Sealing material placed between mating surfaces to prevent leaks.

4. Formation of vapor bubbles causing rapid wear in valves.

5. Cobalt-chromium alloy used for wear-resistant hard-facing.

6. Component used to compress packing material around the stem.

7. Heat-resistant material used for high-temperature valve sealing.

8. Stainless steel family with high strength and corrosion resistance.

9. High-alloy steel designed for severe corrosive environments.