Pumps are the second most common machine in the world, yet we often see confusion regarding which type suits a specific industrial application. In our daily operations at the foundry, we analyze hundreds of technical drawings for casings and impellers, giving us a front-row seat to the engineering behind these devices. We have noticed that selecting the wrong pump category often leads to premature component failure and efficiency losses, which is why understanding the core mechanisms is so vital before ordering parts.

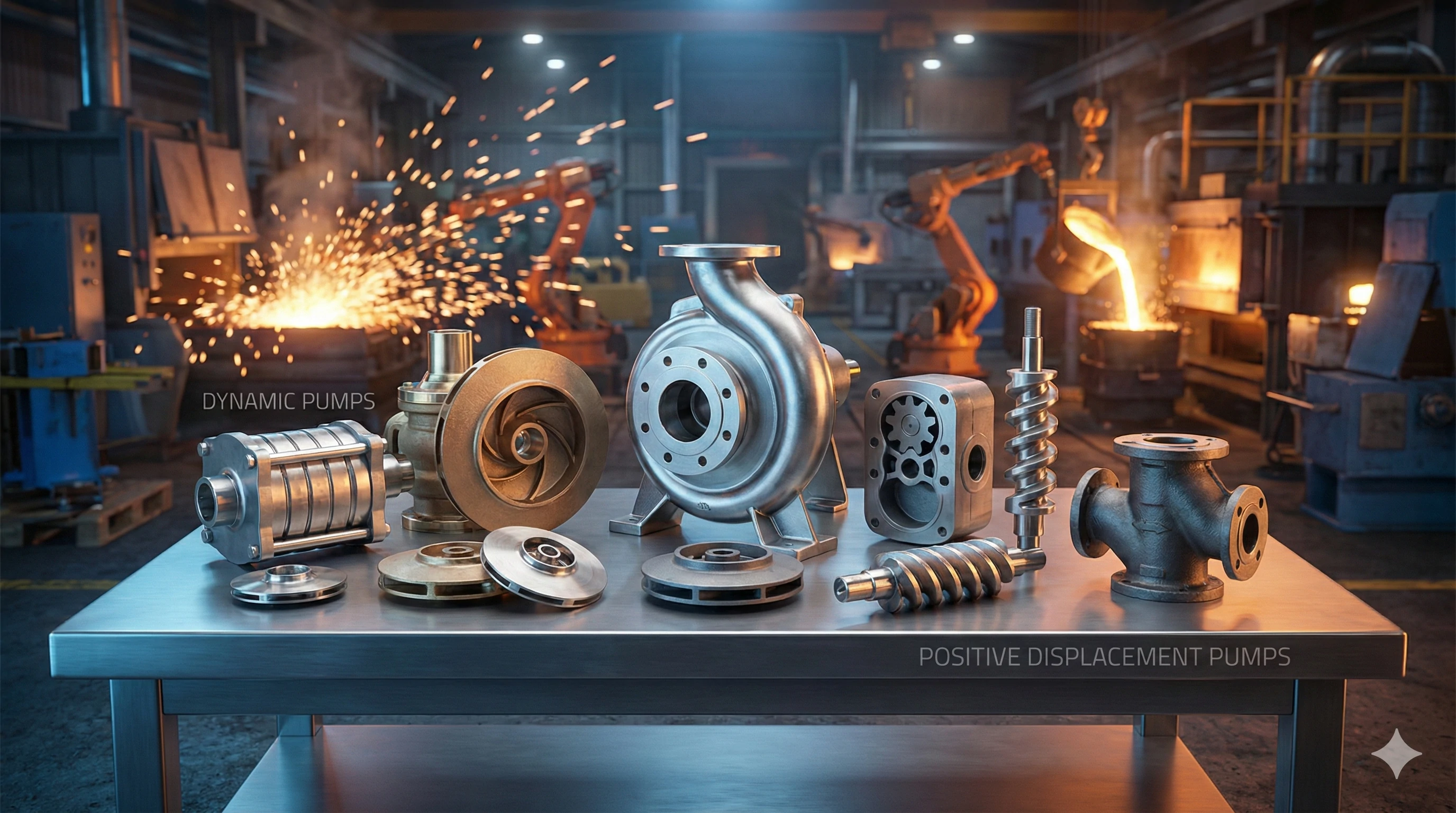

The four main types of pumps used in industry are Centrifugal, Reciprocating, Rotary, and Submersible. While Centrifugal pumps dominate general flow applications, the others serve specialized needs like high-pressure dosing or moving viscous fluids. Broadly, they fall into two engineering families: Dynamic (Kinetic) and Positive Displacement (PD).

Let’s break down these categories to help you understand the engineering logic behind them.

1. Centrifugal Pumps?

When we cast components for water treatment plants or large-scale irrigation, the designs are almost exclusively for . Our engineers frequently work with the complex curves of volutes and impellers, which are designed to optimize . If you need to move thin liquids quickly, this is the standard choice.

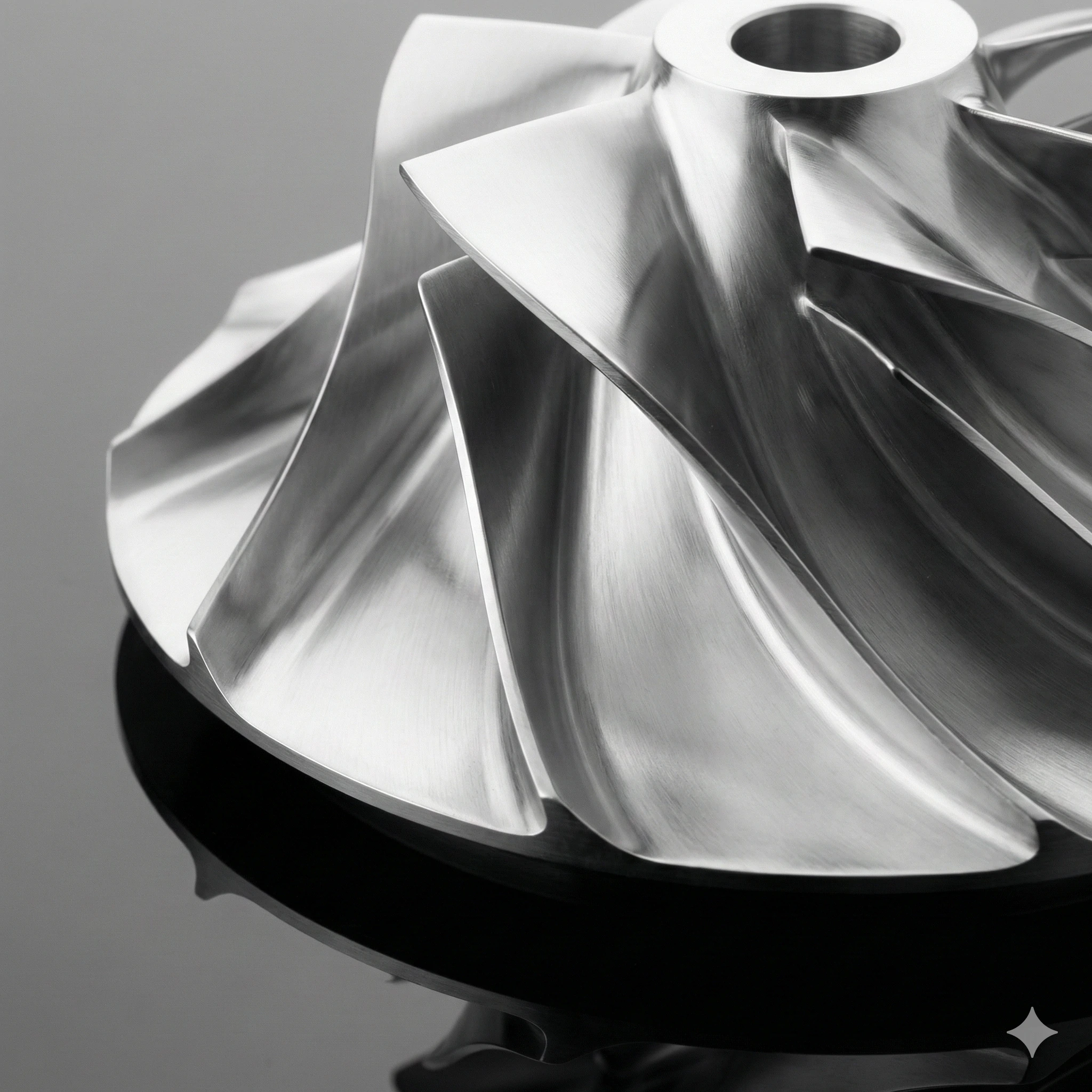

A centrifugal pump uses a rotating impeller to create a vacuum and centrifugal force, flinging fluid outwards to generate pressure. It is best suited for high flow rates and low viscosity fluids like water or thin chemicals. Its simplicity and efficiency make it the most common pump type globally.

How the "Flow Master" Works

The centrifugal pump is often called the "Flow Master" because it handles volume better than any other type. The magic happens inside the casing. A motor spins an impeller—a component we frequently cast from stainless steel—at high speeds. This rotation adds kinetic energy to the fluid.

As the fluid spins, it is pushed outward by centrifugal force. It enters the volute (the spiral casing), where the velocity slows down and converts into pressure. This pressure pushes the liquid out of the discharge point.

Key Components We Manufacture

We focus heavily on two critical parts for these pumps:

-

The Impeller: This is the heart of the pump. We cast these in Open, Semi-Open, or Closed configurations depending on how many solids are in the water.

-

The Volute (Casing): This spiral housing acts as a funnel. Because the internal channels are curved and hollow, they are nearly impossible to machine from a solid block. Investment casting is the only way to produce the smooth internal surfaces required for efficiency.

Pros and Cons of Centrifugal Systems

To help you decide if this fits your project, here is a breakdown of the operational characteristics:

| Feature | Advantage | Disadvantage |

|---|---|---|

| Flow Rate | Extremely high volume capacity. | Efficiency drops with high viscosity. |

| Maintenance | Few moving parts, easy to repair. | Can be damaged by cavitation/bubbles. |

| Cost | Generally lower initial cost. | Performance is sensitive to . |

This type handles about 70% of industrial tasks. However, if you are pumping thick oil or need extreme pressure, the centrifugal design will fail. That brings us to the next category.

2. Reciprocating Pumps?

We often receive requests to cast heavy-duty valve bodies for industries like oil and gas, where pressure is far more important than speed. In these scenarios, our team knows that the client is likely building a . These units are built like tanks because they must withstand immense internal forces without cracking.

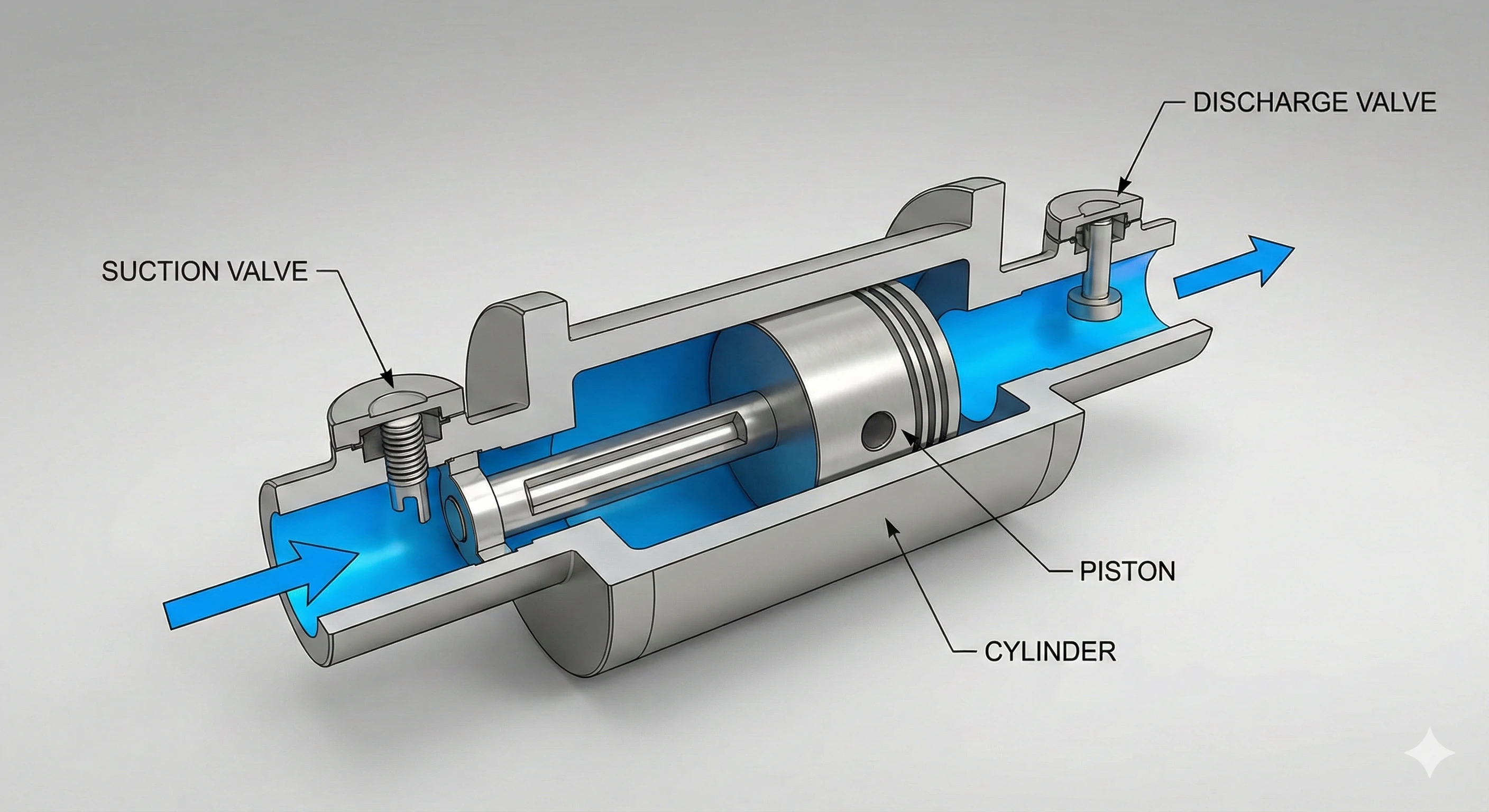

Reciprocating pumps differ by using a piston, plunger, or diaphragm to physically push a trapped volume of fluid. They function similarly to a bicycle pump or syringe, making them ideal for high-pressure applications, low flow rates, and precise dosing requirements.

The "Pressure King" Mechanics

If the centrifugal pump is a fan blowing air, the reciprocating pump is a piston engine. It belongs to the Positive Displacement (PD) family. This means for every cycle of the machine, a specific amount of fluid is moved, regardless of the pressure against it.

The mechanism is cyclical:

-

Suction Stroke: The piston pulls back, opening an inlet valve and drawing fluid into the chamber.

-

Discharge Stroke: The piston pushes forward, closing the inlet and forcing the fluid out through the outlet valve.

Critical Castings for High Pressure

Manufacturing parts for these pumps requires strict quality control. The internal pressure can be massive.

-

Valve Bodies: We cast these from heavy-duty stainless steel or . If there is even a microscopic pore in the casting, the high pressure will cause a leak or a rupture.

-

Connecting Rods: These structural parts drive the piston. They must be rigid and durable to handle the constant push-pull stress.

When to Choose Reciprocating

These pumps are not for moving a swimming pool of water quickly. They are for precision and power.

| Application | Why Reciprocating Works |

|---|---|

| Car Washes | Needs high pressure to blast dirt away. |

| Chemical Dosing | Needs exact measurements (e.g., 10ml per stroke). |

| Hydraulic Systems | Requires force to lift heavy machinery. |

3. Rotary Pumps?

When we collaborate with clients in the food processing or petrochemical sectors, the conversation shifts from water to things like honey, paste, or crude oil. We have found that standard impellers just spin inside these thick fluids without moving them. This is where we recommend , which use mechanical gears to force the product through.

Rotary pumps use rotating gears, lobes, or screws to trap fluid in "pockets" and move it from the inlet to the outlet. They are the superior choice for thick, viscous fluids like oil, sludge, and food pastes, ensuring a steady flow without pulsation.

Handling Viscosity with Precision

Rotary pumps are also Positive Displacement pumps, but instead of a piston moving back and forth, they use rotation. Imagine two gears meshing together. As they turn, they trap liquid in the gaps between the gear teeth and the outer casing.

This trapping action creates a seal. It forces the fluid to move from the suction side to the discharge side. It is incredibly effective for because the thick fluid actually helps seal the gaps between the moving parts, improving efficiency.

Manufacturing Complex Geometries

For us as a foundry, rotary pumps present a unique challenge: Tolerances.

-

Rotors & Lobes: The geometry of a lobe rotor is complex. It must be cast with precision and then machined to very tight clearances. If the gap is too wide, the fluid slips back; if it's too tight, the pump seizes.

-

Gear Housings: The housing must be perfectly flat and rigid. We use advanced casting techniques to ensure the metal doesn't warp during cooling, ensuring the internal gears align perfectly.

Viscosity Comparison Guide

To understand why you would switch from Centrifugal to Rotary, look at the viscosity capability:

| Fluid Type | Viscosity (cPs) | Recommended Pump |

|---|---|---|

| Water | 1 | Centrifugal |

| Olive Oil | 80 | Centrifugal or Rotary |

| Motor Oil | 500 | Rotary (Gear) |

| Honey/Molasses | 10,000 | Rotary (Lobe) |

| Peanut Butter | 250,000 | Rotary (Screw) |

4. Submersible Pumps?

We frequently supply components for municipal water projects and . In these environments, the equipment isn't sitting on dry land; it is completely underwater. Our production line uses specific for these parts because we know that once the pump is submerged, maintenance becomes difficult and expensive.

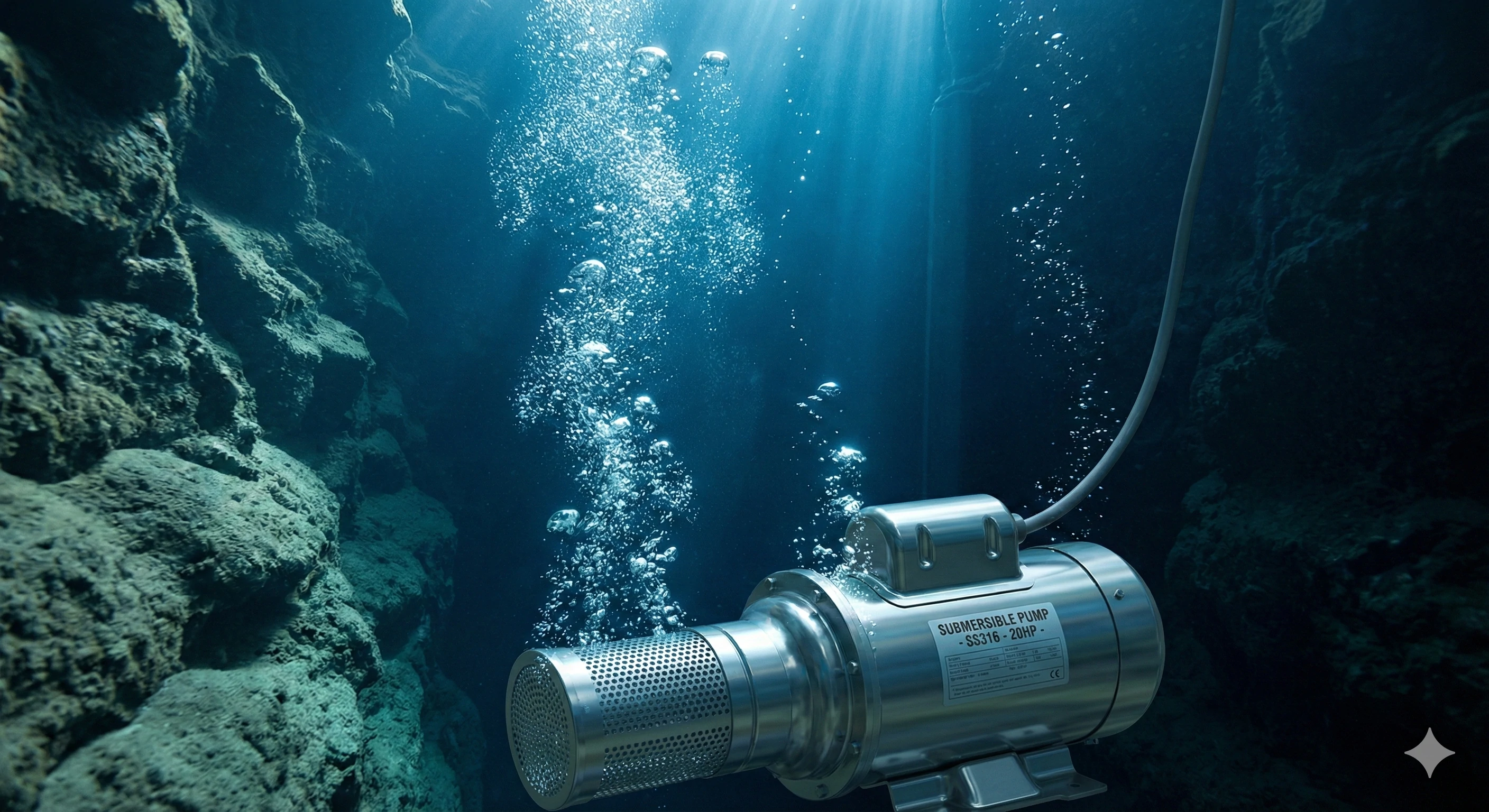

Submersible pumps are usually centrifugal units defined by their environment, where the motor is hermetically sealed and close-coupled to the pump body. The entire unit operates underwater, making it essential for sewage lift stations, deep wells, and drainage systems.

The Underwater Specialist

The defining feature here isn't the pumping mechanism (which is usually a standard centrifugal impeller) but the packaging. The motor and pump are a single unit.

The design relies on the surrounding fluid to cool the motor. This is efficient but risky. If the seal fails, water enters the motor, and the unit is destroyed.

Material Science for Submersion

Because these pumps live in difficult environments, standard cast iron often isn't enough, especially for salt water or corrosive sewage.

-

Motor Housing: We cast these to be watertight.

-

Intake Screens: These filter out large rocks that could smash the impeller.

-

The Material Upgrade: For many clients, we upgrade the specification from Cast Iron to Stainless Steel 316. This prevents rust. A rusted pump in a deep well is a nightmare to replace, so the upfront investment in better casting material pays off in longevity.

Engineering Choice: Cast Iron vs. Stainless Steel

We often guide clients through the "Material Upgrade" pitch.

-

Cast Iron: Cheap and good for vibration damping. It works fine for oil or non-corrosive water.

-

Stainless Steel (Investment Cast): This is the superior choice. The investment casting process creates a smoother surface than sand-cast iron. A smoother surface means less friction for the water. Less friction means the pump uses less electricity to do the same work.

Conclusion

Selecting the right pump is a matter of matching physics to application. If you are moving water, the Centrifugal pump is your workhorse. If you need high pressure, choose Reciprocating. For thick oil, go with Rotary. And for deep wells, rely on Submersible units.

However, a pump is only as good as its parts. As a foundry, we know that the manufacturing method—specifically —determines the efficiency and durability of the impellers and casings. Whether you are a pump manufacturer or a maintenance manager, ensuring your components are cast from the right alloys like SS316 or Duplex 2205 is critical for long-term success.

Does your current project require high-precision metal components? We specialize in casting complex geometries for the pump industry. Contact us to discuss how we can manufacture your impellers and casings with OEM precision.

Footnotes

1. Overview of centrifugal pump components and operation.

2. Scientific principles of fluid behavior in motion.

3. Understanding vertical lift and resistance in pumping.

4. Engineering mechanics of reciprocating positive displacement pumps.

5. Properties and applications of Duplex 2205 stainless steel.

6. Guide to rotary pump types and viscous fluid handling.

7. Technical definition of fluid viscosity and flow resistance.

8. USGS explanation of groundwater wells and pumping.

9. Definition and benefits of alloys that resist corrosion.