When we cast valve bodies or machine precision gears in our factory, we aren't just making metal shapes. We are building the muscles that make machines move. Whether it is a heavy industrial crane or a delicate glass door latch, every machine relies on a system to transmit energy. If you are selecting components for a new project, understanding the fundamental differences between is critical. You might struggle to decide between the raw force of hydraulics or the clean speed of pneumatics. Choosing the wrong system often leads to maintenance headaches or poor performance later.

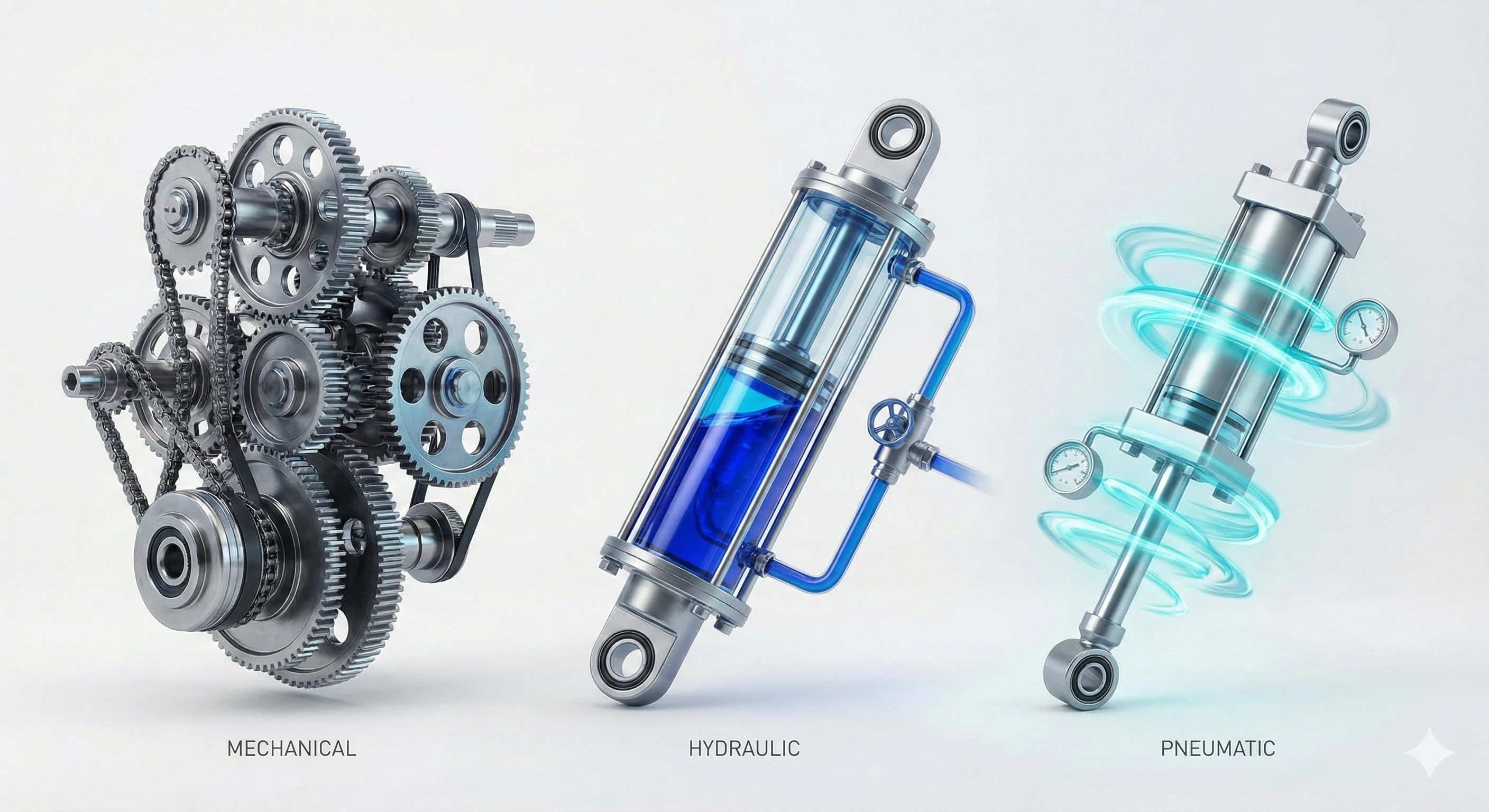

In industrial engineering, power transmission is categorized into three distinct families: Pure Mechanical systems using solid-to-solid contact, Hydraulic systems utilizing pressurized liquids for massive force, and Pneumatic systems leveraging compressed gas for high speed. We explain the differences below to help you choose the right components for your specific project requirements.

To make the right choice, you need to look at how each system handles force, speed, and precision.

1. Pure Mechanical Systems (Direct Drive)?

In our experience designing glass latches and friction spigots, we rely heavily on direct mechanical action. There is no fluid to leak and no air to compress. When you turn a handle, the latch moves. It is immediate. We often recommend mechanical solutions to clients who need absolute reliability without the complexity of hoses or pumps. However, we also know that creates friction, which is the enemy of longevity.

Pure mechanical systems transmit power through direct physical contact using solid components like gears, chains, belts, shafts, and levers. These systems offer high efficiency and precise synchronization without fluid leaks, making them ideal for applications requiring exact timing, though they often require regular lubrication to minimize friction and wear.

Understanding Solid-to-Solid Transmission

Mechanical systems are the oldest and most common form of power transmission. They work on a simple principle: one solid object pushes another. Because there is no fluid to compress, the action is rigid and precise. If you rotate a drive gear by 10 degrees, the driven gear moves exactly according to the ratio. There is no lag.

This precision is why we use mechanical principles in our Glass Latches and Friction Spigots. These products rely on torque and friction to hold heavy glass panels securely in place.

Key Components and Wear

While simple, these systems require high-quality materials.

-

Gears: Must be hardened to resist stripping.

-

Belts and Chains: Subject to stretching over time.

-

Bearings: Critical for reducing friction.

The biggest downside we see in our workshop equipment is maintenance. Mechanical systems generate heat and wear particles. If you don't lubricate them, they fail.

Mechanical Systems at a Glance

Below is a breakdown of where mechanical systems excel compared to fluid power.

| Feature | Performance | Typical Application |

|---|---|---|

| Precision | Very High (No slip) | Watches, CNC Machines, Latches |

| Maintenance | Moderate (Grease/Oil) | Conveyor belts, Gearboxes |

| Force Density | Low to Moderate | Hand tools, Bicycles |

| Cleanliness | Moderate (Grease risk) | Food packaging (requires care) |

2. Hydraulic Systems (Liquid Muscle)?

When we manufacture heavy-duty pump housings or impellers, we are usually dealing with hydraulics. Our engineers know that when you need to lift something truly heavy—like a customized glass gate or an excavator arm—solid gears aren't enough. You need liquid muscle. We also apply this technology in our Hydraulic Soft-Close Hinges, where creates a smooth damping effect that a simple spring cannot achieve.

Hydraulic systems function by transmitting force through pressurized liquids, typically oil, to generate immense power in compact spaces. They are the standard choice for heavy lifting and smooth, high-torque applications, though they operate at slower speeds and require strict maintenance to prevent fluid leakage and contamination.

The Power of Incompressible Fluid

Hydraulics works on . Because you cannot compress liquid oil, any pressure you apply at one end is transmitted instantly to the other. This allows you to multiply force easily. A small pump can drive a massive cylinder.

In our Hydraulic Soft-Close Hinges, we use this principle for control rather than lifting. The oil inside the hinge resists the closing motion. It forces the heavy glass door to close slowly and softly, preventing slamming. A mechanical spring alone would just snap the door shut. This is a perfect example of how hydraulics provide "smoothness" that solids cannot.

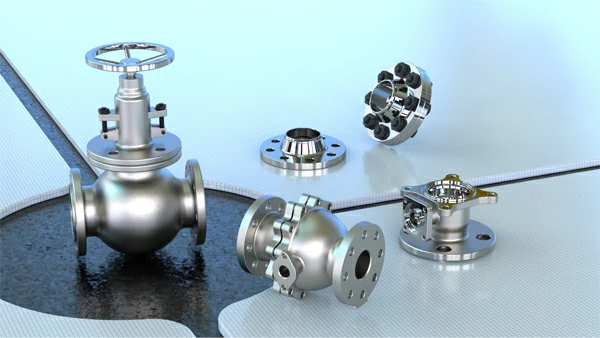

Components We Manufacture

The hardware for these systems must be incredibly strong to withstand high pressure.

-

Pump Housings: We often use for these to ensure no porosity.

-

Valve Bodies: These direct the flow of oil and must be precision-machined.

-

Impellers: Drive the fluid flow.

Pros and Cons of Hydraulics

While powerful, hydraulics can be messy. A leaking seal means oil on your floor.

| Characteristic | Description |

|---|---|

| Force Density | Excellent. The strongest of the three systems. |

| Speed | Slow. It takes time to move fluid. |

| Environment | Dirty. Leaks are a common issue. |

| Temperature | Sensitive. Oil gets thin when hot and thick when cold. |

3. Pneumatic Systems (Air Power)?

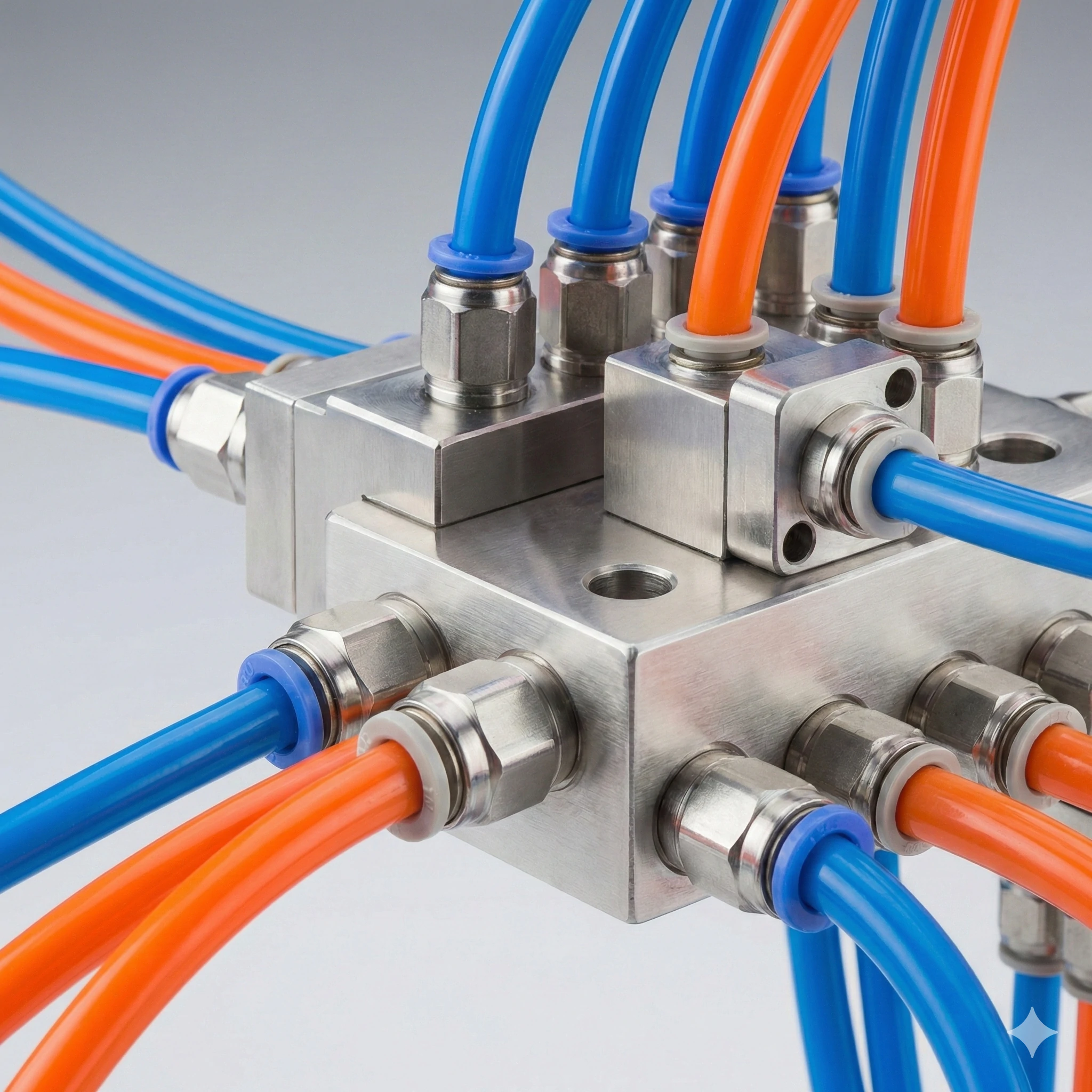

We frequently cast stainless steel manifolds for factory automation lines. In these environments, speed is everything. Our clients use pneumatic systems because they are fast, snappy, and clean. Unlike oil, if an air line leaks, you just lose some air—you don't create a hazardous spill. We recommend pneumatic components for environments where cleanliness is mandatory, such as food processing or pharmaceutical manufacturing.

Pneumatic systems utilize compressed gas, usually air, to transmit power quickly for high-speed, low-impact applications. They are valued for being clean, spark-free, and capable of rapid cycling, although the compressibility of air makes them less precise than hydraulic or mechanical systems for holding specific positions.

Speed vs. Precision

The defining characteristic of pneumatics is the "sponginess" of air. Since gas can be compressed, act like springs. This makes them incredibly fast—perfect for a factory robot arm that needs to "pick and place" items three times a second.

However, this compressibility makes precision difficult. You cannot easily stop a pneumatic cylinder halfway with millimeter accuracy because the air will keep compressing or expanding.

Why Material Matters: The Rust Problem

Compressed air systems have a hidden enemy: water. When you compress air, moisture condenses. If your valve bodies are made of standard carbon steel, they will rust from the inside out.

We manufacture Valve Bodies and Manifolds using Stainless Steel 304 or 316. This ensures that the valves don't jam after a few months of operation. If you are buying pneumatic parts, always ask about the material grade.

Pneumatic Application Matrix

Where does air power win?

| Requirement | Verdict | Why? |

|---|---|---|

| High Speed | Best | Air moves faster than oil. |

| Safety | Best | No spark risk (great for explosive environments). |

| Control | Poor | Air is "bouncy" and hard to hold still. |

| Noise | High | Exhaust air is loud when released. |

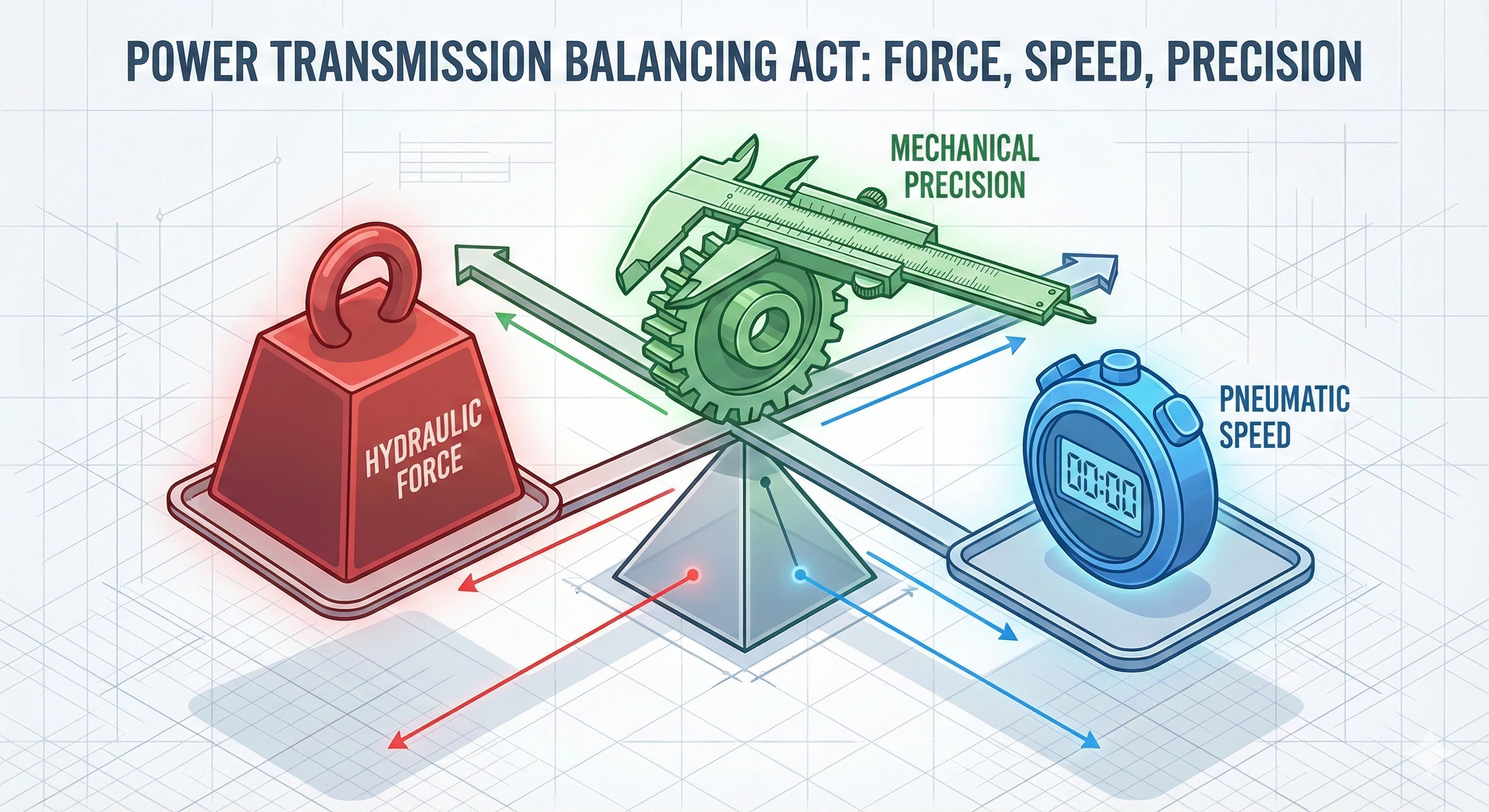

Comparison: Which System Should You Use?

We see many procurement managers struggle to finalize their component lists because the lines between these systems can blur. Sometimes, you need a hybrid approach. From our manufacturing perspective, the choice comes down to three main variables: Force, Speed, and Precision. We have created a simple framework to help you decide which system aligns with your project goals.

To select the correct power system, prioritize your primary constraint: choose Pneumatic for high-speed automation, Hydraulic for massive force and heavy lifting, or Mechanical for high-precision synchronization. Review the specific torque, environmental cleanliness, and maintenance capabilities of your facility before finalizing the design.

The Decision Matrix

Use this table to quickly identify the right system for your machinery.

| Feature | Mechanical | Hydraulic | Pneumatic |

|---|---|---|---|

| Primary Strength | Precision (Timing) | Force (Power) | Speed (Cycle time) |

| Medium | Solids (Gears/Chains) | Liquid (Oil) | Gas (Air) |

| Motion Type | Rotary/Linear | Linear/High Force | Linear/High Speed |

| Cleanliness | Moderate | Low (Messy) | High (Clean) |

| Cost | Low to High | High | Low to Moderate |

The Hybrid Solution: Door Closers

It is important to note that you don't always have to pick just one. Many of the products we analyze are Hybrids.

Take a standard as an example.

-

Mechanical: It uses a steel spring to store energy when you open the door.

-

Hydraulic: It uses an oil-filled cylinder to dampen that energy so the door doesn't slam shut.

By combining the energy storage of a solid spring with the damping control of fluid, you get the best of both worlds.

Manufacturing Components for These Systems

At our foundry, we don't just design systems; we manufacture the critical metal parts that make them work. Regardless of whether you choose mechanical, hydraulic, or pneumatic, they all share one requirement: they need high-precision metal components. A system is only as reliable as its weakest valve or gear.

Manufacturing high-performance power transmission components requires specific processes: hardened CNC machining for mechanical gears, pressure-tight investment casting for hydraulic housings, and corrosion-resistant stainless steel casting for pneumatic valves. We provide a one-stop solution by casting raw shapes and finishing critical surfaces to exact tolerances.

Our Manufacturing Process

We tailor our production method to the system type.

1. For Mechanical Parts

-

Requirement: Hardness and wear resistance.

-

Our Process: We often use CNC Machining on to create gears and shafts that can withstand constant friction without stripping.

2. For Hydraulic Parts

-

Requirement: Pressure containment.

-

Our Process: We use Investment Casting (Lost Wax) with stainless steel. This creates a dense, non-porous structure that can hold high PSI without leaking oil through the metal walls.

3. For Pneumatic Parts

-

Requirement: Corrosion resistance.

-

Our Process: As mentioned earlier, we cast these in Stainless Steel 316. Since air brings moisture, using cheaper metals is a recipe for failure. We machine the sealing surfaces to ensure air-tight operation.

Why Precision Matters

In a hydraulic pump, a gap of just 0.05mm can cause a significant drop in pressure. In a pneumatic valve, rough surfaces tear seals. We use advanced CNC centers to finish our castings, ensuring that the "Raw Muscle" of the metal meets the "Fine Precision" required for modern engineering.

Conclusion

Understanding the three types of mechanical power systems—Mechanical, Hydraulic, and Pneumatic—is the first step in designing reliable machinery. Whether you are building a gearbox, a heavy-duty gate, or a fast-paced assembly line, the reliability of your system depends heavily on the quality of its metal components.

If you are designing a mechanical, hydraulic, or pneumatic system, you need parts that meet strict tolerance and material standards. We provide the high-precision Investment Casting & Machining services you need to build reliable machinery. Contact us today for a component quote and let us help you build your next project.

Footnotes

1. Overview of how energy is moved from source to application.

2. Understanding the resistance force caused by contact mechanics.

3. Properties of fluid resistance essential for hydraulic damping effects.

4. The physics principle behind hydraulic force multiplication and pressure.

5. Manufacturing process for high-precision metal components with no porosity.

6. Devices that convert compressed air into mechanical motion efficiently.

7. Chemical degradation process affecting metal longevity in moist environments.

8. Mechanism combining mechanical springs and hydraulic damping for control.

9. Heat-treated alloys designed for increased wear resistance and strength.