When we discuss production strategies with our clients, we often notice some confusion regarding industry terminology. It is not uncommon for a procurement manager to ask us to explain the distinction between CNC and HMC technology before finalizing an order for pump casings or valve bodies. This is a bit like asking for the difference between a "vehicle" and a "truck." In our factory, we view CNC as the overarching technology that powers the automation, while HMC refers to a specific, high-performance machine configuration designed for heavy-duty tasks.

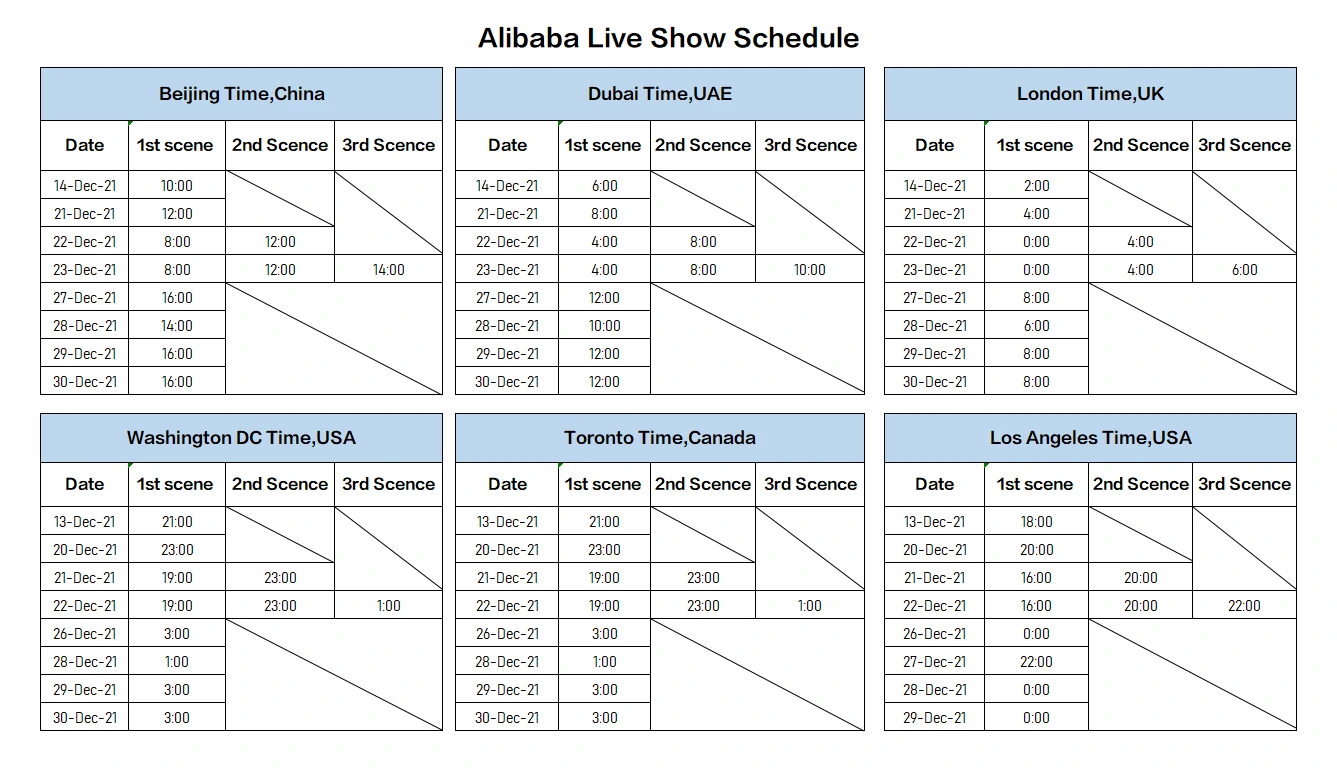

CNC (Computer Numerical Control) is the broad technology or "brain" that uses computer software to control machine tools, whereas HMC (Horizontal Machining Center) is a specific type of CNC machine or the "body." HMC features a horizontal spindle orientation, making it the ideal choice for mass-producing complex, multi-sided parts like pump housings.

To help you make the best decision for your next project, we need to clarify these definitions and explore the real comparison: Vertical (VMC) versus Horizontal (HMC) machining.

What is CNC? (The Umbrella Term)

When we program our equipment for a new production run, we utilize CNC technology across almost every department on the floor. Whether we are cutting raw metal bars or engraving final details, the underlying control system remains consistent. We rely on this automation to remove human error and ensure that every single part meets strict . If the machine uses G-Code to move motors based on a digital design file, it falls under the CNC umbrella.

CNC stands for Computer Numerical Control, which is the automation method used to drive various manufacturing tools. This term acts as an umbrella that covers a wide range of machines, including mills, lathes, routers, lasers, and specifically HMCs, all of which use digital instructions to shape material with precision.

Understanding the "Brain" of Manufacturing

To truly understand our production capabilities, it is helpful to view CNC as the "brain" of the operation. It is not a machine itself, but rather the system that tells the machine what to do. In our facility, CNC systems read code—typically —which contains precise coordinates and speed instructions.

This technology allows us to automate movements that would be impossible or incredibly slow for a human operator to perform manually. Because CNC is the governing technology, asking "What is the difference between CNC and HMC?" is technically a category error. HMC is a CNC machine.

The Scope of CNC Applications

We utilize CNC controls for a vast array of machinery. It is important to recognize that this technology is not limited to just cutting metal.

Types of CNC Machines We Use

| Machine Type | Primary Function | Axis Configuration |

|---|---|---|

| Vertical cutting for flat parts | 3-Axis to 5-Axis | |

| CNC Lathe | Turning cylindrical parts | 2-Axis to Multi-Axis |

| CNC Router | Cutting softer materials/sheets | 3-Axis |

| CNC HMC | Horizontal cutting for blocky parts | 4-Axis (Standard) |

As you can see, CNC is the foundational technology. However, the physical configuration of the machine—how it holds the tool and the part—is what determines efficiency. This brings us to the specialized powerhouse of our factory: the HMC.

What is an HMC? (The Horizontal Specialist)

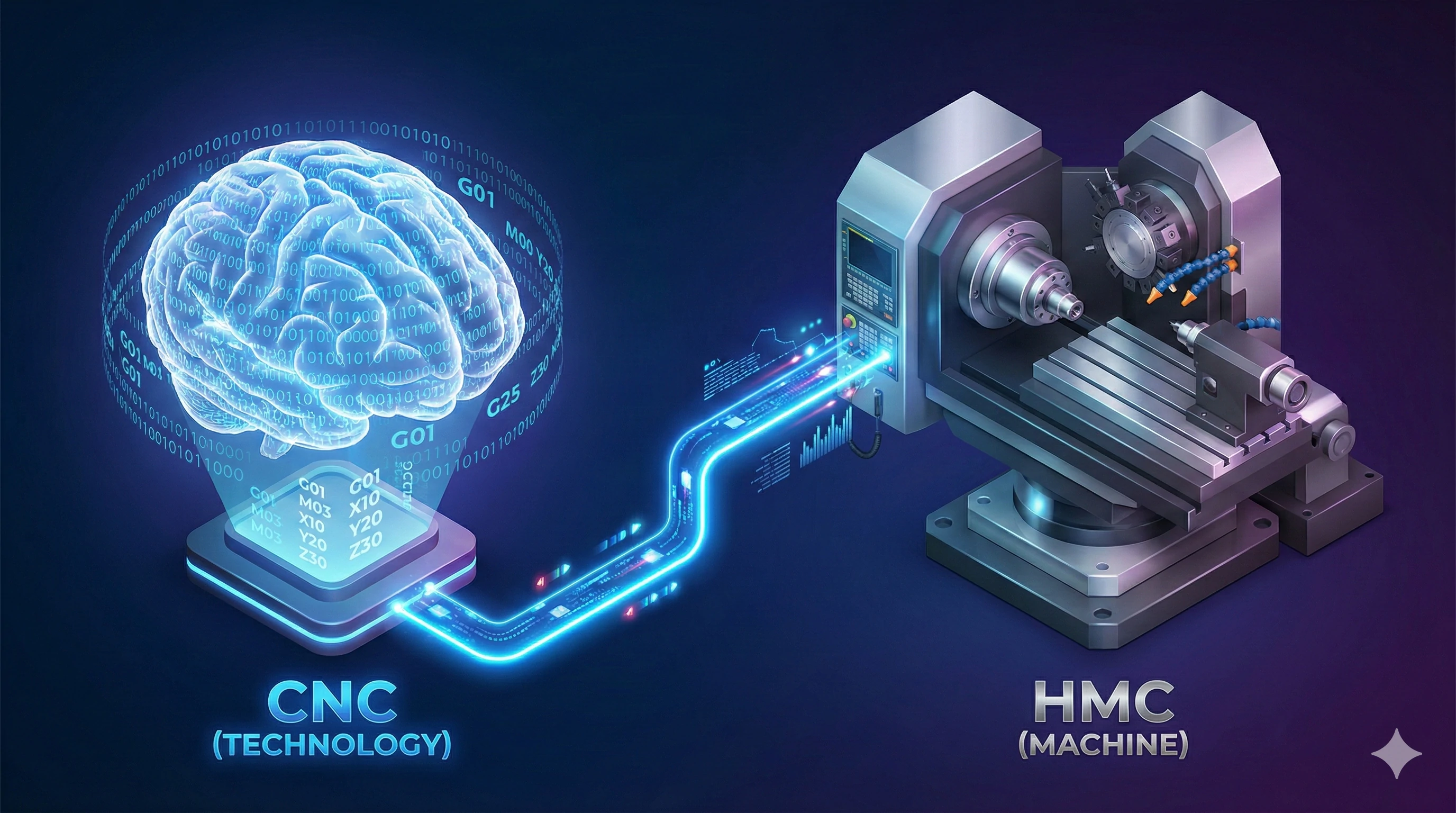

On our factory floor, the HMCs are the true heavy lifters when it comes to volume production. We specifically install these machines to handle complex projects that require access to multiple sides of a workpiece. Unlike standard vertical mills that you might see in a prototype shop, our horizontal centers are designed to run continuously. The key difference we see daily is in the orientation; the spindle is mounted horizontally, parallel to the floor, which fundamentally changes how the engages with the material.

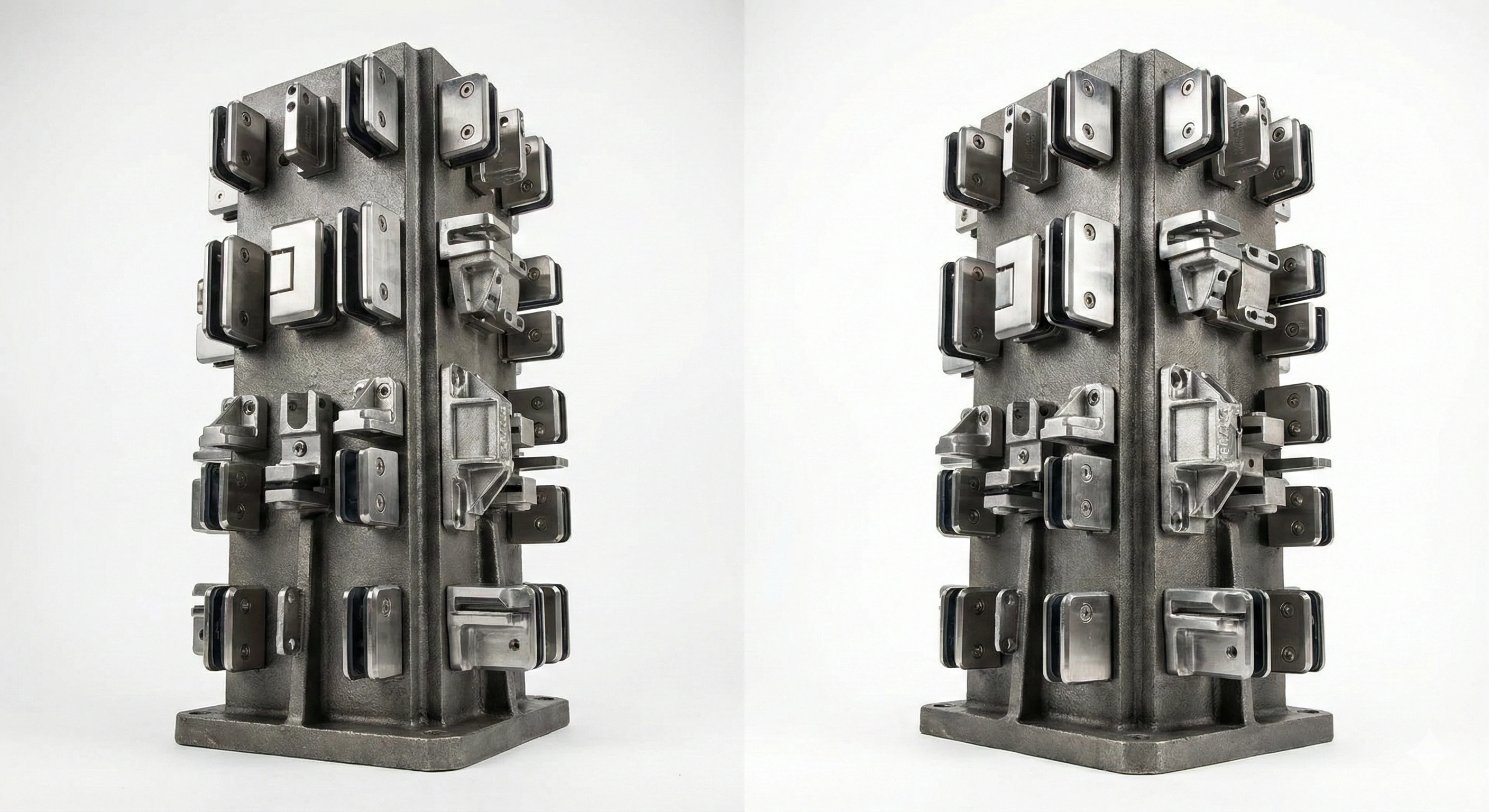

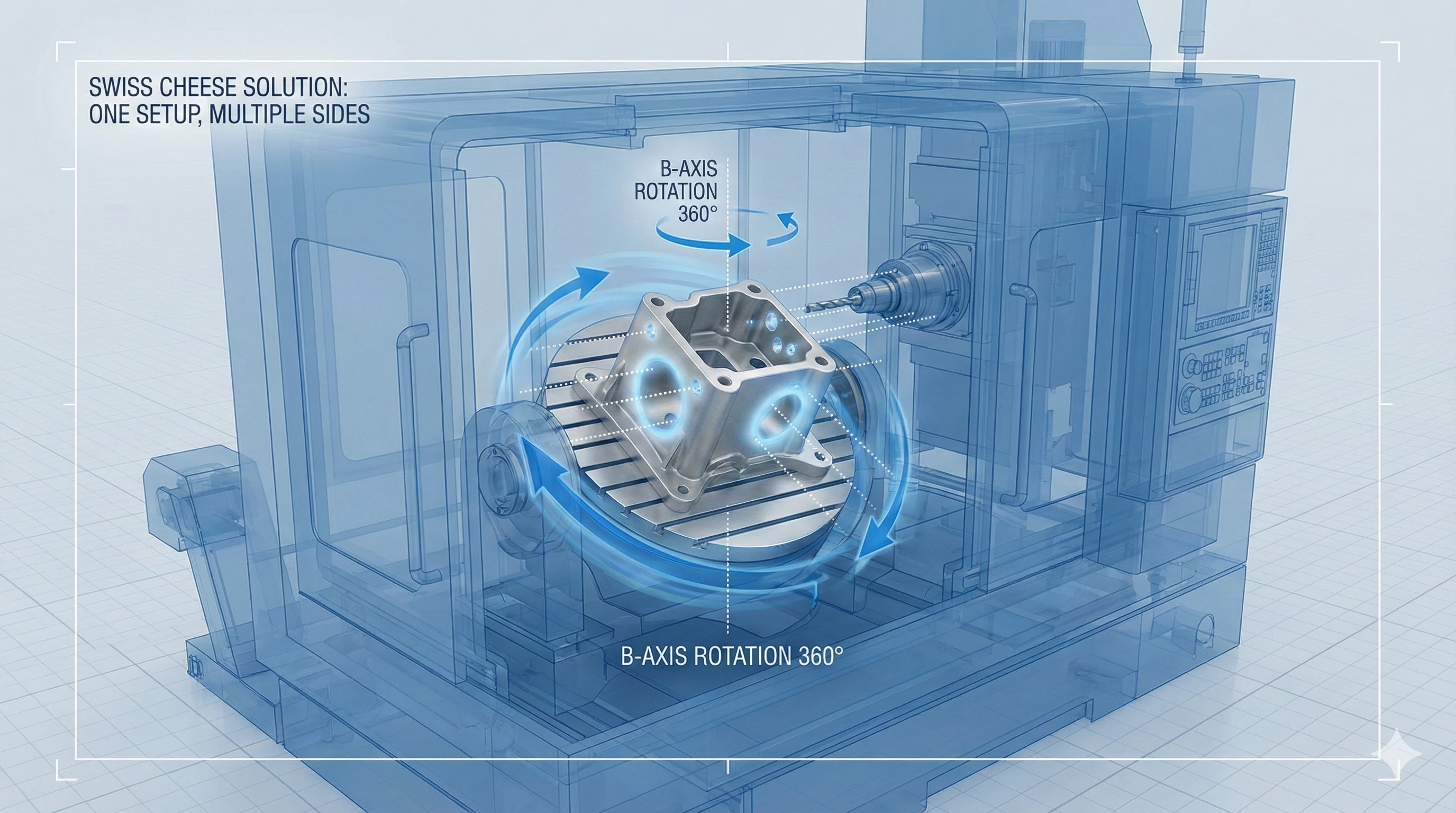

HMC stands for Horizontal Machining Center, a CNC machine where the spindle and cutting tool are oriented horizontally rather than vertically. These machines typically feature a "tombstone" fixture on a rotary table, allowing our engineers to machine four different sides of a part in a single setup for maximum efficiency.

The "Tombstone" Advantage

The magic feature of the HMC is what we call the "Tombstone". Imagine a large, rectangular tower sitting on a rotating table inside the machine. Because the spindle comes in from the side (like a punch, rather than a pencil coming down), we can mount parts on all four faces of this tower.

When we set up a job, we clamp the workpiece onto this tombstone. The machine's can spin the tombstone to present the Front, Left, Right, and Back of the part to the cutter. This capability is revolutionary for efficiency.

Why Orientation Matters

In a standard vertical setup, the tool hangs down. In an HMC, the tool stays horizontal. This might seem like a minor detail, but it solves massive engineering headaches.

-

Rigidity: Horizontal structures are often built heavier and more rigid, allowing us to cut tougher metals faster.

-

Capacity: We can load more parts. If we put 4 parts on each side of a tombstone, and the tombstone has 4 sides, we are machining 16 parts in one cycle.

-

Complexity: It turns a complex multi-setup job into a simple "one-and-done" operation.

The Real Battle: VMC (Vertical) vs. HMC (Horizontal)

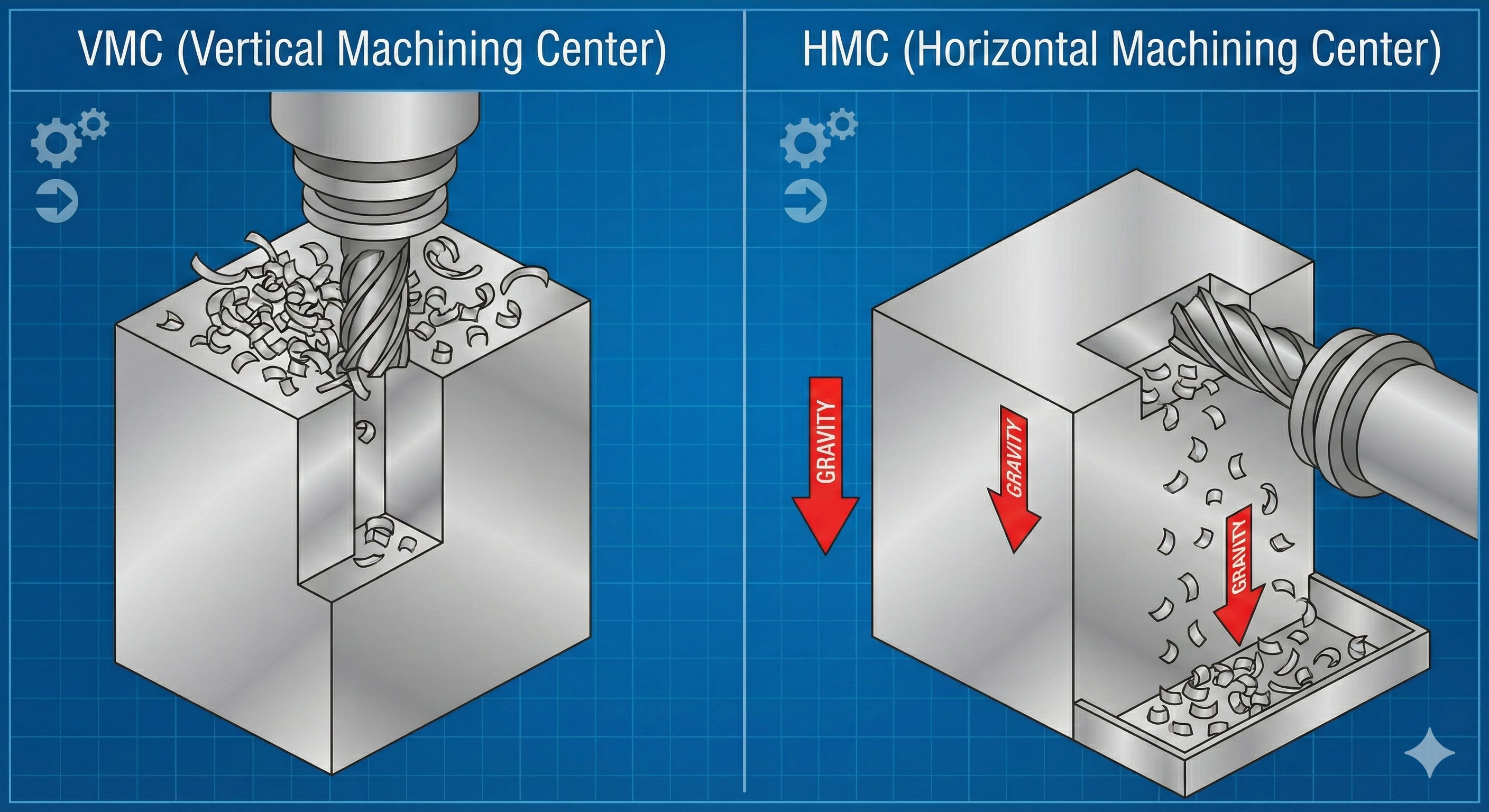

Deciding between a VMC and an HMC is a calculation our production team makes for every new order. While VMCs are excellent for flat plates and simple work, they struggle with the complex geometries of pump bodies or gearboxes. We often explain to clients that while a VMC fights gravity, an HMC uses gravity to its advantage. This fundamental difference in physics affects everything from the of your part to the final cost of the production run.

The main difference lies in chip evacuation and setup efficiency: VMC cutters are vertical, causing metal chips to pile up on the part, whereas HMC cutters are horizontal, allowing gravity to pull chips naturally away. Additionally, HMCs can access four sides of a part without manual turning, while VMCs typically access only one.

1. The Gravity Factor: Chip Evacuation

One of the biggest issues we face in machining is "chips"—the created during cutting.

-

In a VMC: The cutter is on top. As it cuts, the chips fall directly onto the workpiece. If they pile up, the cutter might re-cut them, damaging the surface finish or breaking the tool. We have to blast high-pressure coolant to wash them away.

-

In an HMC: The cutter is on the side. As soon as a chip is cut, gravity pulls it down to the conveyor below, keeping the cutting area clean. This results in better surface finishes and longer tool life for your parts.

2. Efficiency: Number of Sides

Efficiency is where the HMC truly wins.

-

VMC (1 Side): A VMC can usually only reach the top surface. If your part needs holes on the side, an operator must stop the machine, unclamp the part, flip it over, and re-clamp it. This introduces "re-clamping errors," reducing accuracy.

-

HMC (4 Sides): Because of the rotary table, we can machine the Front, Left, Right, and Back without ever unclamping the part. This ensures perfect alignment between features on different sides.

3. Production Volume Capabilities

For small batches or prototypes, we often use VMCs because they are easier to set up. However, HMCs are the kings of mass production. Most of our HMCs are equipped with . This means while the machine is cutting "Pallet A" inside, our operator is loading raw parts onto "Pallet B" outside. When the cycle finishes, they swap in seconds. The spindle never stops turning.

Comparison: VMC vs. HMC

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Spindle Direction | Vertical (Down like a pencil) | Horizontal (Sideways like a punch) |

| Sides Machined | 1 Side (Standard) | 4 Sides (Standard with Tombstone) |

| Chip Evacuation | Poor (Chips pile on part) | Excellent (Chips fall away) |

| Ideal Quantity | Low Volume / Prototypes | High Volume / Mass Production |

| Best For | Flat Plates, Single-face parts | Pump Bodies, Valve Housings, Gearboxes |

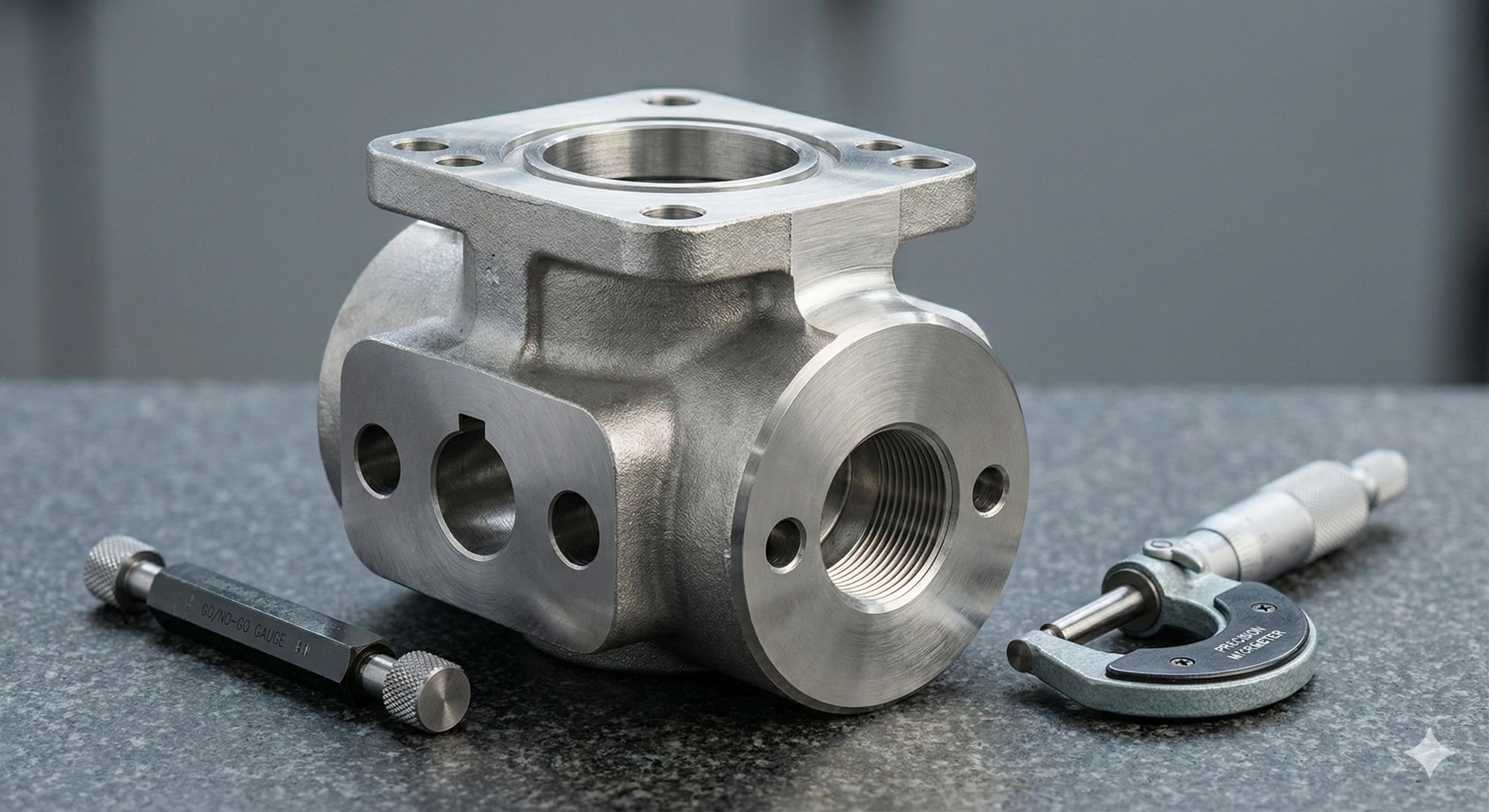

Why We Use HMC for Investment Castings?

When a client sends us a drawing for a complex pump casing or valve body, we almost immediately route the project to our HMC department. These specific products—common in the fluid control industry—usually feature flanges, inlet holes, and outlet holes on multiple faces of the casting. If we were to attempt this on a vertical machine, the error rate would increase significantly due to the constant manual handling required to reach every face.

We use HMCs for investment castings like pump casings because these parts usually require drilling and tapping on multiple sides. By clamping the casting once on a tombstone, the HMC rotates it to machine the inlet, outlet, and flanges in one go, ensuring perfect perpendicularity and significantly faster delivery times.

Solving the "Swiss Cheese" Problem

Parts like valve bodies are essentially blocks of metal that need holes drilled into them from every direction. We call this the "Swiss Cheese" challenge.

If we used a VMC, the process would look like this:

-

Clamp part. Machine Top.

-

Unclamp. Flip 90 degrees. Dial in. Machine Side 1.

-

Unclamp. Flip 90 degrees. Dial in. Machine Side 2.

-

Repeat...

Every time we unclamp, we risk losing the "zero point" (the precise center). This leads to holes that don't line up perfectly.

The HMC Solution for Castings

With an HMC, we clamp the casting once. The machine rotates the part to the tool. This guarantees that the inlet hole is perfectly perpendicular (90 degrees) to the outlet hole because the machine's movement is far more precise than a human hand flipping a part.

Ideal Candidates for HMC Machining

If your project involves any of the following, we strongly recommend HMC production:

-

Pump Housings: Require machining on at least 3-4 faces.

-

Gearboxes: Requires precise bearing bores on opposite sides.

-

Manifolds: Complex channeling requires access from all angles.

-

Engine Blocks: The classic example of multi-sided machining needs.

Cost Comparison: Is HMC Worth It?

We know the upfront tooling costs for HMC fixtures can look intimidating compared to simple VMC vises. However, looking at the sticker price of the machine or the fixture is only half the story. While an HMC is a significant investment for our factory—costing roughly three to four times more than a standard vertical mill—the allow us to lower the per-unit price for you on large orders.

Although an HMC machine costs 3x-4x more than a standard VMC, it is often more cost-effective for high-volume orders. One HMC can do the work of three VMCs due to pallet changers and multi-side access, drastically lowering the "cost per part" for complex OEM components.

Analyzing the Investment

To help you understand where your money goes, we break down the costs into "Machine Rate" and "Cycle Time."

-

Machine Cost: Yes, the hourly rate for an HMC is higher. The machine is more complex and uses more power.

-

Cycle Time: This is where the savings happen. An HMC might finish a part in 10 minutes that takes a VMC 40 minutes (including all the flipping and setting up).

The Volume Break-Even Point

If you need 10 parts, the setup time of an HMC might not be worth it. But if you need 1,000 pump casings, the HMC is the clear winner.

Cost Benefit Matrix

| Factor | Low Volume (1-50 parts) | High Volume (500+ parts) |

|---|---|---|

| VMC Strategy | Cheaper. minimal setup, standard vises. | Expensive. High labor costs for manual loading/flipping. |

| HMC Strategy | Expensive. High setup time for tombstones. | Cheaper. "Lights out" manufacturing, fast cycle times. |

Frequently Asked Questions about HMC Machining?

Our sales team frequently fields specific technical queries from engineers and procurement officers who are vetting our capabilities. We find that clarifying these technical details upfront helps build confidence in our quality control processes. It is essential to distinguish between similar-sounding terms to understand exactly what kind of hardware will be producing your components.

HMC stands for Horizontal Machining Center, a CNC machine with a horizontal spindle designed for multi-side machining. It differs from a lathe, which spins the part itself; an HMC spins the cutting tool while the part remains stationary on a block or tombstone.

Is a Lathe the same as an HMC?

This is the most common confusion we see.

-

Lathe: The part spins securely in a chuck, and the tool is stationary (mostly). This is used for cylindrical shapes like shafts or pins.

-

HMC: The tool spins, and the part is stationary (though it can rotate to face the tool). This is used for blocky shapes like valve bodies.

They are both "horizontal," but they perform opposite tasks.

Why are HMC machines so expensive?

Clients often ask why the hourly rate for HMC work is higher. These machines are built for industrial mass production.

-

Complexity: They feature rotary tables (4th axis) and automatic pallet changers.

-

Build Quality: They have heavier cast iron frames to handle higher cutting forces without vibrating.

-

Longevity: They are designed to run 24/7 without stopping.

Conclusion

To summarize, CNC is the technology that drives the automation, while HMC is the specific machine configuration we use for heavy lifting. While VMCs have their place for simple flat parts, they cannot compete with the efficiency of HMCs when it comes to complex, multi-sided components like pump housings and gearboxes.

If your part has features on multiple sides and requires strict precision, you need a factory equipped with HMCs. At our facility, we leverage this technology to ensure your are machined to perfection, with faster turnaround times and lower unit costs on volume orders.

Need complex multi-sided parts machined to perfection? Our factory is equipped with advanced Horizontal Machining Centers to handle your heavy-duty casting orders. Get a precision quote today.

Footnotes

1. Reference guide for standard CNC machining tolerance standards.

2. Technical overview of G-code programming for milling operations.

3. Explanation of Vertical Machining Centers (VMC) and applications.

4. Definitions and formulas for milling and cutting tools.

5. How rotary tables add axes to machining centers.

6. Understanding surface roughness values and finishing standards.

7. Best practices for managing chips in CNC operations.

8. Benefits of pallet pool systems in manufacturing productivity.

9. Strategic insights on throughput efficiency and cycle times.