In the world of high-precision metal parts—from aerospace components to the architectural glass hardware we produce daily—standard methods often fall short. We have seen too many projects fail because buyers selected a foundry based solely on price, only to receive fittings that rust or crack under load. At our factory in Rizhao, we emphasize that understanding the manufacturing process is the first step to securing quality. Whether you need glass spigots or complex hinges, knowing what goes into the mold is just as important as the final polish.

Investment casting, also known as lost wax casting, is the gold standard manufacturing process for creating precision stainless steel architectural hardware. This guide explains how the process works, why it is superior for complex geometries compared to other methods, and provides a checklist for evaluating manufacturers to ensure you receive durable, high-quality components.

This article will guide you through the technical details and sourcing strategies you need to succeed.

What is Investment Casting and How Does the "Lost Wax" Process Work?

When we walk clients through our production floor, the first thing they notice is the intricate wax trees before they ever see any metal. From our perspective as producers, the is less about heavy industry and more about precision replication. We spend a significant amount of time ensuring the ceramic slurry perfectly coats these wax patterns because any imperfection here will show up in the final steel. It is a meticulous cycle that we repeat thousands of times to guarantee consistency.

Investment casting is a manufacturing technique where a wax pattern is coated in ceramic slurry to build a hard shell. Once the shell dries, the wax is melted out to create a hollow mold, and molten metal is poured in. This process allows for the production of parts with complex geometries, tight tolerances, and excellent surface finishes.

The term "Investment" doesn't refer to money. It comes from the word "invest," meaning to surround or clothe. In this case, the ceramic slurry surrounds the wax pattern.

The 5-Step Manufacturing Cycle

To help you understand where your lead time goes, here is the breakdown of the process we follow for every batch of glass clamps and spigots.

-

Wax Injection

First, we inject hot wax into a metal die. This creates a replica of the final part. These wax replicas are then attached to a central wax stick, creating a "tree" or cluster.

-

Shell Building (The "Investment")

We dip the entire wax tree into a ceramic slurry and coat it with sand. We repeat this dipping and drying process multiple times until a thick, hard ceramic shell forms around the wax.

-

Dewaxing

This is where the name "Lost Wax" comes from. We place the shell in an autoclave (a high-pressure steam oven). The wax melts and drains away, leaving a perfectly hollow ceramic mold.

-

Pouring

We heat the ceramic mold to prevent it from shattering. Then, we pour molten stainless steel (usually Grade 304, 316, or Duplex 2205 ) into the cavity. The metal fills every tiny detail left by the "lost" wax.

-

Finishing

Once the metal cools, we vibrate or hammer the ceramic shell off. We cut the parts off the tree, grind down the "gates" (where the metal entered), and proceed to sandblasting or polishing.

Process Timeline Overview

| Stage | Estimated Time | Key Quality Check |

|---|---|---|

| Mold Creation | 15-25 Days | Dimension accuracy of the metal die. |

| Wax & Shell | 3-5 Days | Proper drying to prevent shell cracking. |

| Pouring & Cooling | 1 Day | Temperature control to avoid porosity. |

| Finishing | 2-3 Days | Surface smoothness and gate removal. |

Why Use Investment Casting for Architectural Hardware?

We often receive inquiries from buyers wondering if they can use die casting to lower costs. In our engineering meetings, we always come back to one factor: material integrity. While other methods exist, we rely on investment casting for our glass hardware because it is the only way to shape high-strength stainless steel into complex forms without compromising its structure. When you are holding a heavy glass panel on a balcony, you cannot afford the structural risks associated with cheaper casting methods.

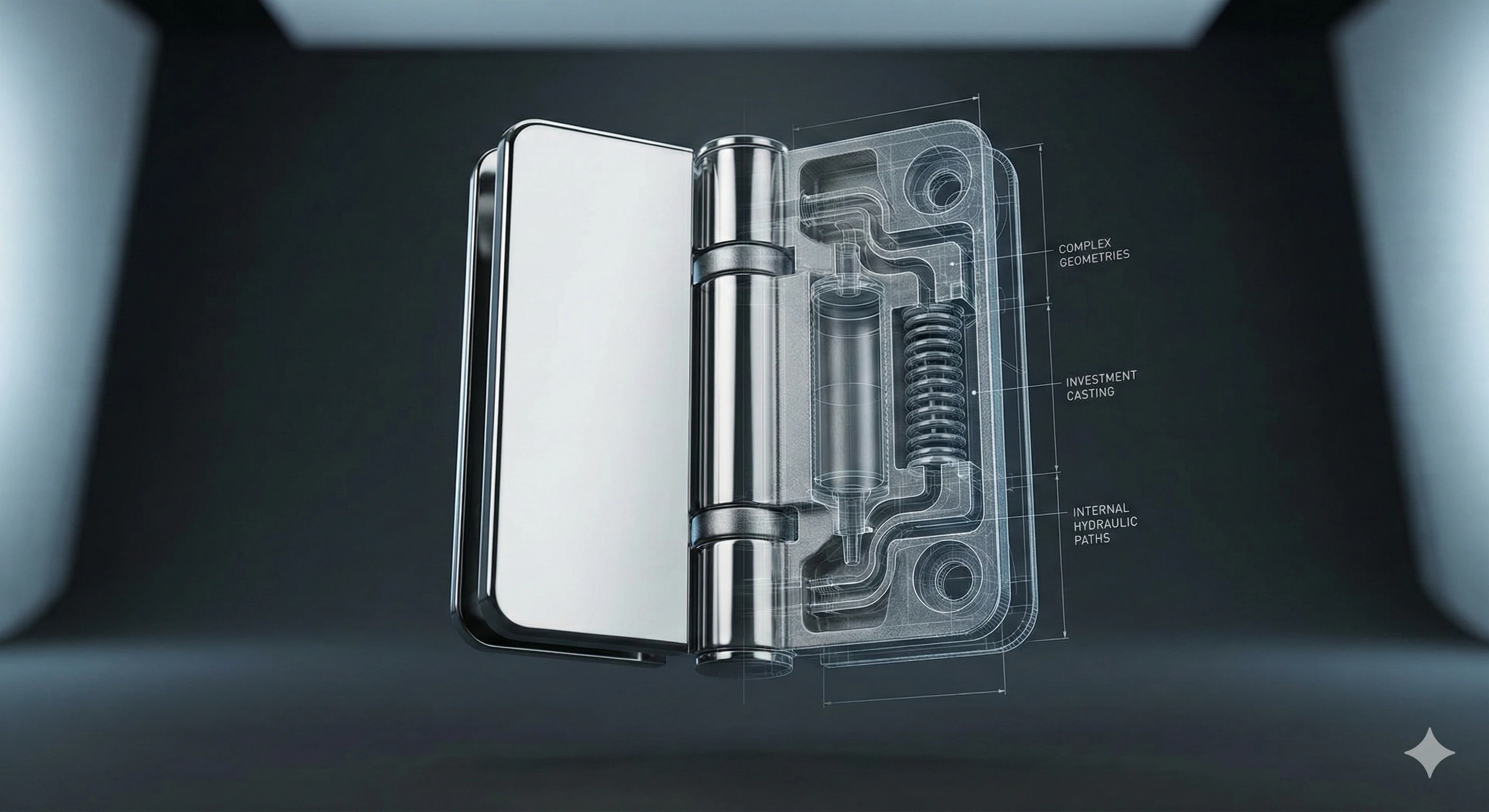

Investment casting is essential for architectural hardware because it supports high-melting-point alloys like Duplex 2205 which cannot be die-cast. It enables the production of complex shapes with undercuts, such as internal hinge mechanisms, while delivering a superior surface finish that minimizes the need for extensive secondary machining and ensures a high-quality final polish.

Handling Complex Geometries

Machining a part from a solid block of steel is expensive and wasteful. Investment casting allows us to create and internal voids that are impossible or too costly to machine.

For example, the internal housing for the spring mechanism in a hydraulic hinge requires precise internal dimensions. With investment casting, we create that internal shape in the wax stage. When the metal is poured, the shape is already there. This "near-net-shape" capability means we only have to machine the mating surfaces, saving you money on raw material and labor.

Superior Surface Finish

For architectural products, looks matter. A glass spigot needs to look flawless.

-

Sand casting leaves a rough texture that looks like sandpaper. Smoothing this out takes hours of grinding, which can alter the dimensions of the part.

-

Investment casting produces a surface that is naturally smooth (typically or better). This makes it much easier to achieve a Mirror Polish or Satin Finish.

Material Versatility and Lead Times

Unlike die casting, which is limited to , investment casting works with almost any alloy.

-

Duplex 2205: This is harder and more corrosion-resistant than SS316. It has a very high melting point. Investment casting is the preferred method for Duplex 2205 because it maintains the material's structural integrity.

-

Lead Times: Generally, it takes 15-25 days to open the metal mold for wax injection, and another 7-10 days for sample production.

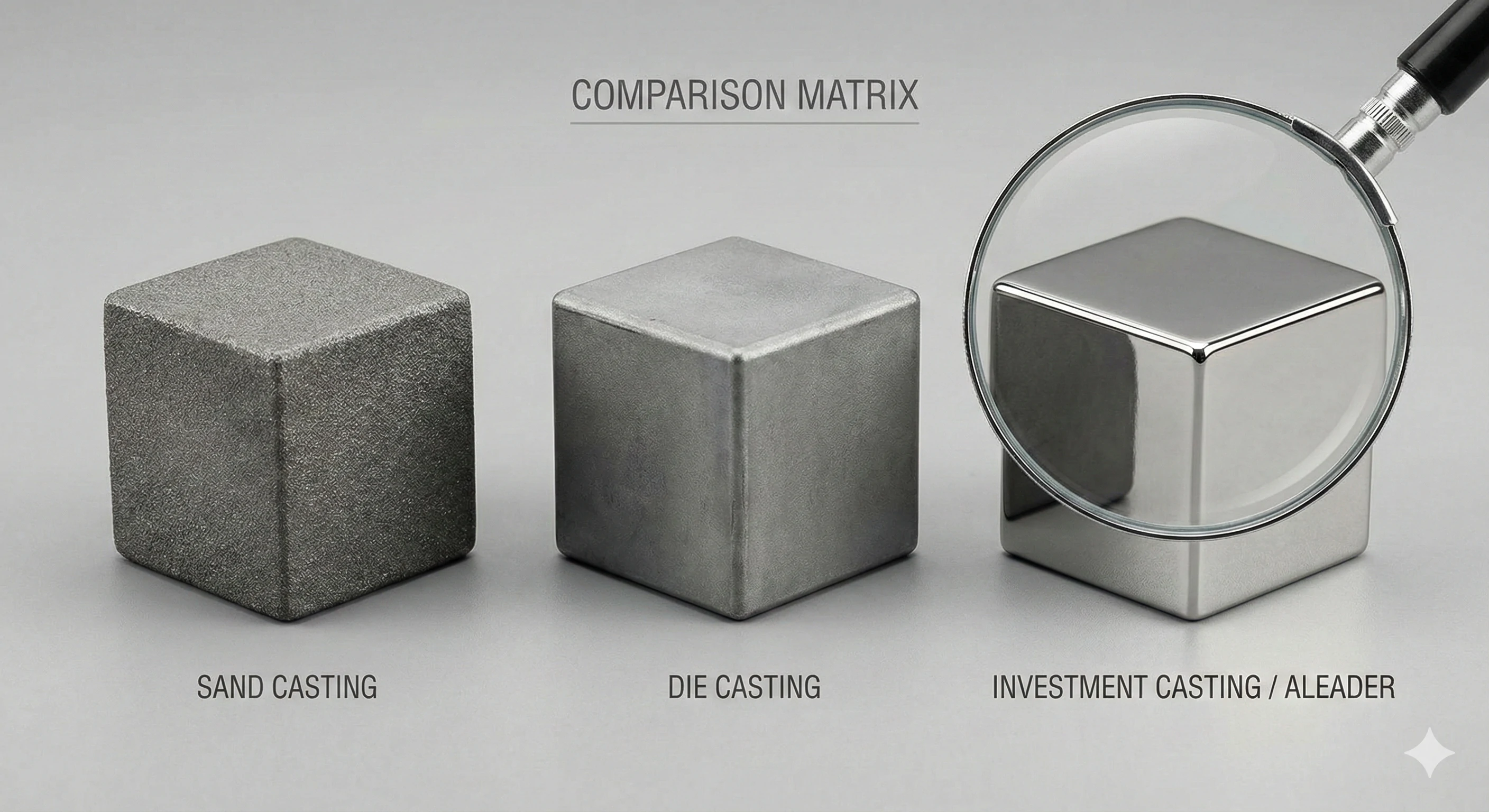

Investment Casting vs. Die Casting vs. Sand Casting: Which is Best?

We frequently have to explain to procurement managers why a competitor's quote might be half the price of ours. Usually, the competitor is using a different process entirely. In our experience exporting to the US market, confusion between casting types is the number one cause of quality disputes. It is vital to compare apples to apples. If you need structural strength and stainless steel, there is really only one option.

While sand casting is suitable for large, rough components and die casting offers speed for soft metals like zinc and aluminum, investment casting is the only viable choice for precision stainless steel hardware. It bridges the gap by offering the high precision of die casting with the material strength and versatility required for structural safety applications.

The Comparison Matrix

To help you make the right decision for your project, we have broken down the three main casting methods below.

| Feature | Investment Casting | Die Casting | Sand Casting |

|---|---|---|---|

| Primary Materials | Stainless Steel (304, 316, 2205) | Aluminum, Zinc, Magnesium | Iron, Bronze, Large Steel |

| Surface Finish | Excellent (Smooth) | Good | Rough (Grainy) |

| Precision | High (+/- 0.1mm) | Very High | Low |

| Tooling Cost | Moderate | High | Low |

| Part Cost | Moderate/High | Low (High Volume) | Low/Moderate |

| Best Application | Glass Spigots, Hinges, Clamps | Door Handles (Zinc), Car Parts | Engine Blocks, Manhole Covers |

Why Not Die Casting?

injects molten metal into a steel mold under high pressure. It is fast and cheap. However, you cannot easily die cast Stainless Steel. The melting point of steel is too high and would destroy the mold. If a supplier offers you a "stainless steel" part at a die-casting price, be very careful—they might be using a with a chrome plating, which will eventually peel and corrode.

Why Not Sand Casting?

Sand casting uses a mold made of packed sand. It is great for giant parts like ship anchors. However, for a small glass clamp, the finish is too rough. To get it smooth enough for a bathroom or balcony, you would have to grind away so much material that you lose precision.

How to Evaluate an Investment Casting Supplier?

When we onboard new vendors for our own supply chain, we do not just look at their website. We look at their testing lab. We know that any foundry can pour metal, but only a few can control the chemistry correctly. In the B2B world, a certificate is only as good as the machine that printed it. You need to ask specific technical questions to separate the traders from the actual manufacturers who care about quality.

To evaluate a reliable investment casting supplier, you must confirm they have an in-house spectrometer to verify chemical composition and prevent material fraud. Additionally, check that they perform rigorous quality control tests, such as salt spray testing for corrosion resistance and load testing for structural safety, and hold ISO 9001 certification.

The B2B Buyer’s Checklist

Use this checklist when interviewing potential suppliers in China.

-

Material Analysis (Spectrometer Testing)

The most critical risk is buying SS316 and receiving SS304 (or worse, 201). The difference is invisible to the naked eye but disastrous for corrosion resistance.

-

The Question: "Do you have an OBLF or similar in-house, and do you provide a material composition report with every shipment?"

-

The Trust Signal: A reliable supplier will invite you to see the test results live via video call.

2. Mold Making Capabilities

-

The Question: "Do you design and make the wax injection molds in-house?"

-

Why it matters: In-house mold making reduces lead time. If they outsource this, making a simple modification to your design could take weeks of back-and-forth communication.

-

Quality Control (QC) Protocols

You need to know if the parts will survive in the real world.

-

Salt Spray Testing: Essential for coastal areas. Ask for a 72-hour or more test report to ensure the works.

-

Load Testing: For glass railings, safety is paramount. The casting must not contain "porosity" (air bubbles) that weakens it.

Common Defects to Watch For

-

Inclusions: Ceramic particles trapped in the metal. This creates weak points.

-

Porosity: Tiny holes caused by .

-

Shrinkage: Deformities caused by the metal cooling unevenly.

Why Partner With Us for Your Casting Needs?

We built our factory in Dongying and expanded to Rizhao with a single focus: creating hardware that lasts. We have spent years refining our technique for casting Duplex 2205 because we know the market demands higher corrosion resistance. When we work with our clients, we don't just take an order; we optimize the design for the casting process to save costs and improve strength.

Partnering with Aleader means accessing deep expertise in casting high-grade stainless steel and Duplex alloys specifically for the glass hardware industry. We offer a complete end-to-end solution, from initial CAD design and 3D printed prototyping to mass production and precision polishing, ensuring your products meet strict international standards.

Our Capabilities

Experience with Difficult Alloys

Many foundries struggle with Duplex 2205 Stainless Steel because it is difficult to control during the cooling phase. We have specialized cooling protocols that ensure the duplex microstructure forms correctly, giving you the perfect balance of strength and corrosion resistance.

End-to-End Service

We handle the entire lifecycle of the product:

-

3D Design (CAD): We review your drawings and suggest improvements.

-

3D Printed Prototype: We can print a plastic model of your part before cutting the metal mold. This helps verify the fit and function cheaply.

-

Mass Production: Our capacity allows us to scale from small trial orders to full containers.

-

Polishing: We do not outsource the critical finishing step. We ensure the Satin or Mirror finish matches your brand's standard.

Industries We Serve

While we focus on Architectural Glass Hardware, our casting capabilities extend to:

-

Marine: Cleats, chocks, and hinges that resist saltwater.

-

Machinery: tough industrial components.

-

Automotive: complex brackets and housings.

Conclusion

Selecting the right investment casting foundry is about balancing cost with quality assurance. A cheap casting that rusts will destroy your brand reputation faster than any marketing campaign can fix. By understanding the lost wax process and knowing what questions to ask—about spectrometers, mold making, and QC—you can find a partner that adds value to your business.

Have a custom design? We provide OEM/ODM investment casting services with strict material reports. Send us your drawings today for a free quote.

Footnotes

1. Overview of the traditional lost wax casting technique. ↩︎

2. Properties and applications of Duplex 2205 stainless steel.

3. Design challenges and solutions for molding undercuts. ↩︎

4. Conversion chart for surface roughness standards. ↩︎

5. Characteristics distinguishing non-ferrous from ferrous metals. ↩︎

6. Detailed explanation of the die casting manufacturing process. ↩︎

7. Material science behind zinc alloys in manufacturing. ↩︎

8. How optical emission spectrometry verifies metal composition. ↩︎

9. Explanation of chemical passivation for stainless steel protection. ↩︎