Investment casting applications in aerospace range from critical hot-section engine components like turbine blades and vanes to structural airframe parts such as landing gear brackets. This "lost wax" process is the industry standard for creating lightweight, near-net-shape parts using superalloys that are too hard or complex to machine using conventional methods.

How exactly does this ancient process power the future of flight? Let's explore the specific areas where investment casting is non-negotiable.

How Critical Are Components in the Jet Engine "Hot Section"?

The heart of any aircraft is the engine, a place where temperatures soar beyond the melting point of most standard metals. From our production experience with high-performance alloys, we understand that creating parts for this environment requires more than just shaping metal; it requires mastering thermodynamics. If a manufacturer cannot control the grain structure of the alloy, the engine will fail catastrophically.

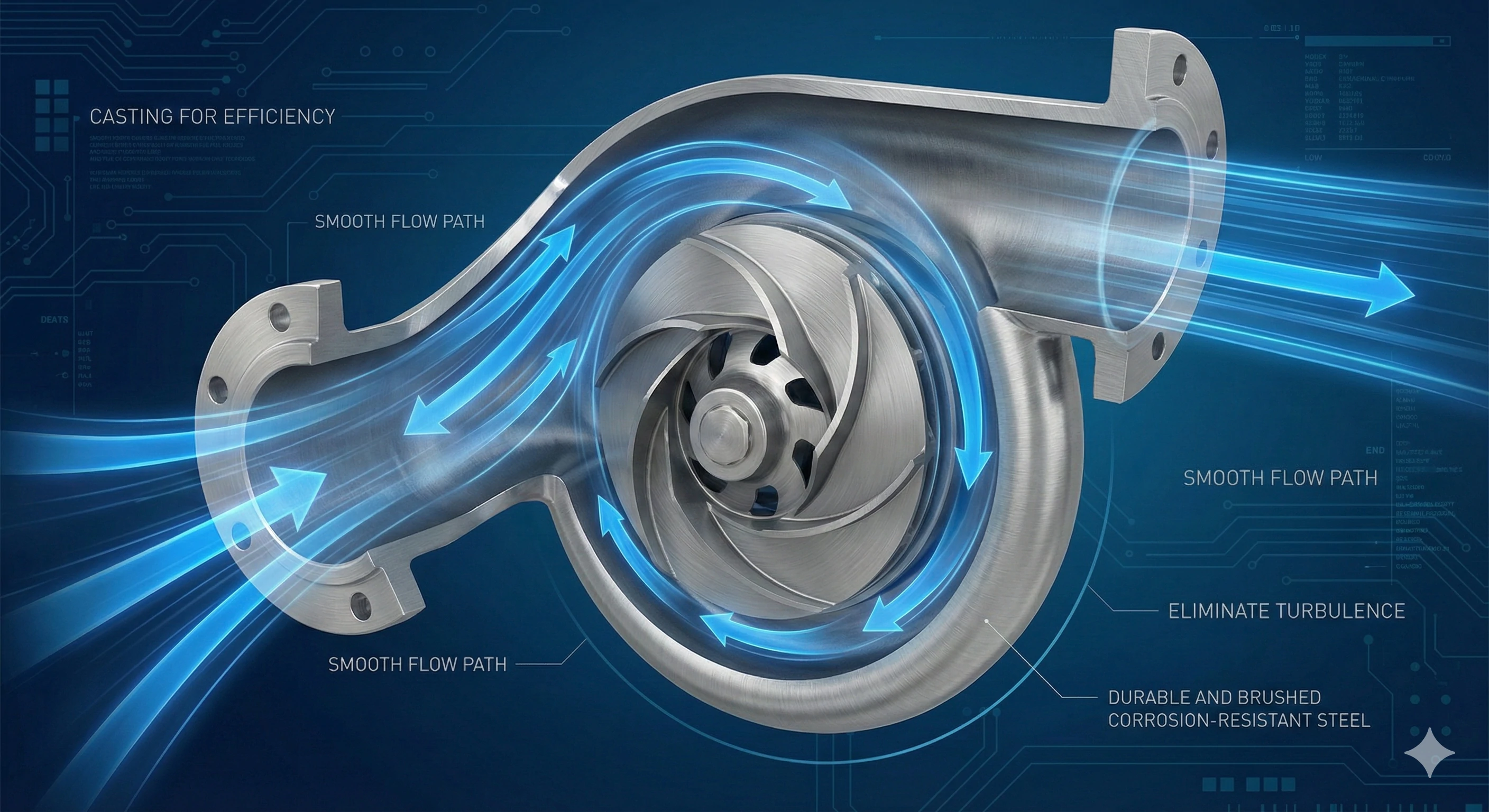

The "hot section" relies entirely on investment casting for turbine blades, vanes, and combustion chambers. These components must withstand temperatures exceeding 1,400°C while spinning at 10,000 RPM. Casting allows engineers to form internal cooling channels within superalloys—a feat physically impossible to achieve with drilling or machining tools.

The "hot section" of a jet engine represents the pinnacle of metallurgical engineering, and it is the primary reason investment casting is indispensable in aerospace. When we look at a turbine blade, we aren't just looking at a piece of metal; we are looking at a component designed to survive inside an inferno.

Turbine Blades and Vanes

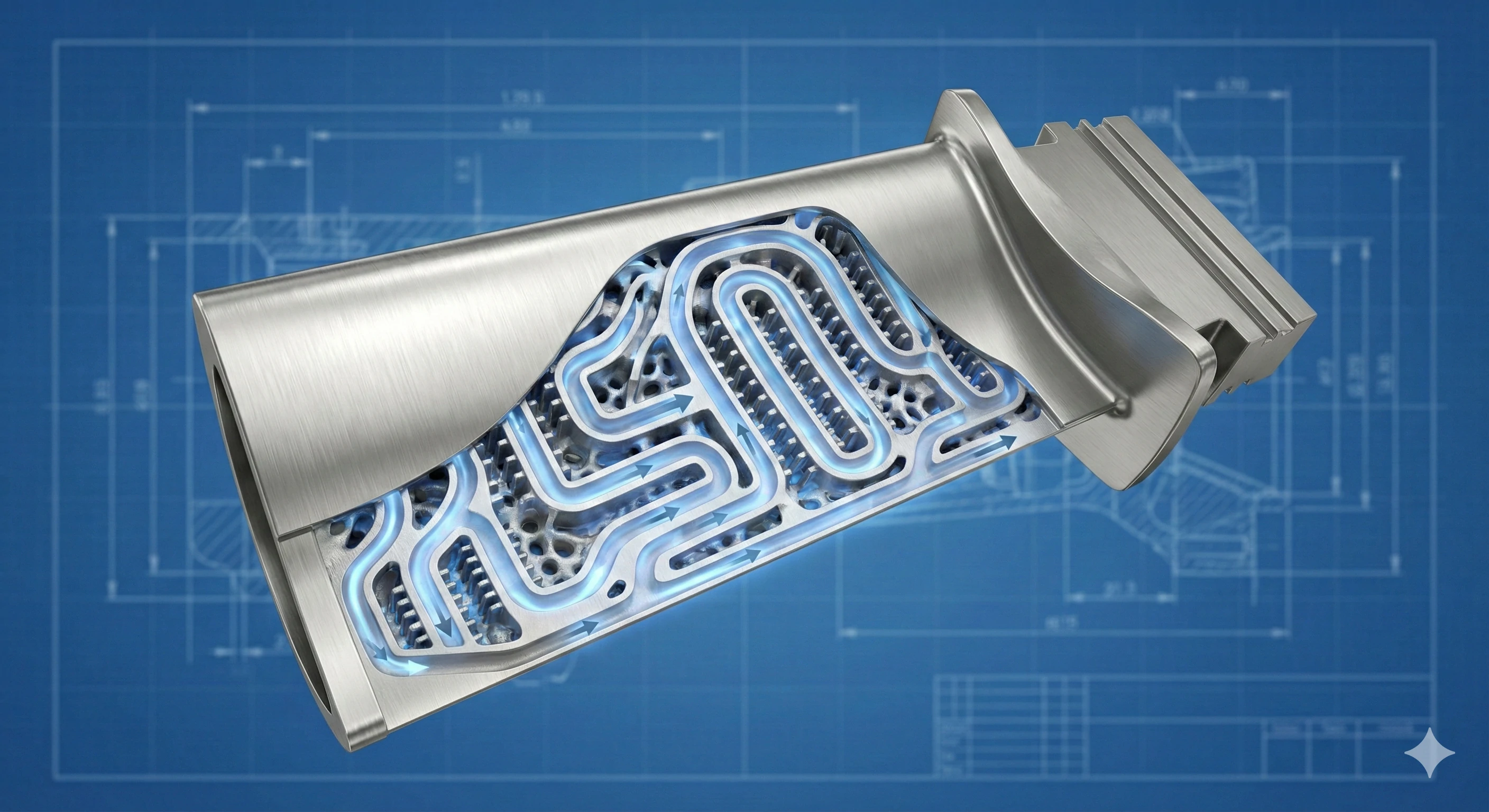

Turbine blades operate in an environment that is often hotter than the melting point of the metal itself. How is this possible? The secret lies in the internal cooling channels. During the wax pattern injection phase of the investment casting process, are placed inside the mold. Once the metal is poured and the ceramic is leached out, it leaves behind a complex maze of hollow passages.

Cool air from the compressor is circulated through these passages, creating a film of cool air on the surface of the blade. In our engineering analysis, we confirm that you simply cannot machine these curved, internal mazes. A drill bit cannot move around corners inside a solid block of metal. Only the fluid nature of molten metal filling a void can achieve this.

Combustion Chambers

Furthermore, the combustion chamber—the ring where the fuel is ignited—requires thin-walled, high-strength structures. These are typically cast from Cobalt-based or Nickel-based superalloys. These materials are chosen for their specific properties:

Key Superalloy Properties in Engine Casting

| Material Type | Primary Characteristic | Typical Application |

|---|---|---|

| High creep resistance at extreme heat | Turbine Blades (High Pressure) | |

| Cobalt-Based Superalloys | Excellent corrosion and thermal fatigue resistance | Static Vanes & Combustion Chambers |

| Single Crystal Alloys | Elimination of grain boundaries | High-Performance Fighter Jet Blades |

By utilizing investment casting, engineers can produce these combustion components as single pieces or large segments, reducing the need for welding. Welds are often stress points, and in the "hot section," every stress point is a potential failure. Therefore, casting provides a seamless, monolithic structure that offers superior safety.

What Role Does Casting Play in Airframe and Structural Integrity?

While the engine provides thrust, the airframe carries the load. In our daily operations handling heavy-duty hardware, we prioritize structural consistency, and this is exactly what aerospace engineers demand for landing gear and wing assemblies. A part that is strong but too heavy burns unnecessary fuel; a part that is light but weak endangers passengers. Balancing this equation is a constant struggle.

Investment casting provides the solution for airframe integrity by enabling "lightweighting" through bionic design. It produces robust landing gear brackets, wing mounts, and heavy-duty struts using Titanium and Aluminum. This process removes excess weight without compromising strength, allowing for organic shapes that distribute heavy loads efficiently during takeoff and landing.

The structural skeleton of an aircraft is a masterclass in efficiency. Every ounce of weight saved on a bracket or mount translates to fuel savings over the lifespan of the airplane. This is where the geometric freedom of investment casting becomes a strategic advantage over machining.

Landing Gear Components

Landing gear creates a massive shock to the system every time a plane touches down. The brackets, struts, and torque links involved must absorb incredible impact forces without cracking. We often see manufacturers turn to Titanium investment castings for these applications. Titanium is notoriously difficult to machine—it is gummy and destroys tools—but it flows excellently into a ceramic mold. By casting these large structural parts, manufacturers avoid the "chips on the floor" waste associated with machining huge blocks of expensive titanium.

Wing Connectors and Flap Tracks

The mechanisms that move the flaps and ailerons are critical for flight control. These connectors are often complex, three-dimensional shapes that need to fit into tight spaces inside the wing. Machining these from a solid block would require multiple setups on a 5-axis CNC machine, increasing time and cost.

The Concept of "Lightweighting"

One of the most profound benefits we observe in casting is the ability to design "bionic" or organic shapes.

-

: Engineers can use software to determine exactly where the stress flows through a part.

-

Material Removal: Metal is only placed where the load path exists.

-

Result: The final cast part looks almost skeletal, resembling a bone structure rather than a blocky machined part.

This approach maximizes the Weight-to-Strength Ratio. In our own product development, we know that removing even 10% of the material cost while maintaining strength is a massive win; in aerospace, that win is multiplied by the fuel cost saved over 20 years of service.

How Do Fluid Systems and Hydraulics Rely on Investment Casting?

An aircraft is a web of fluids: fuel, hydraulic oil, and air management systems. When we test valves for industrial applications, we check for leaks under pressure, but aerospace takes this to a zero-tolerance level. A pinhole leak in a hydraulic manifold at 30,000 feet causes a loss of control surfaces. You cannot rely on multi-piece assemblies bolted together; you need unitary construction.

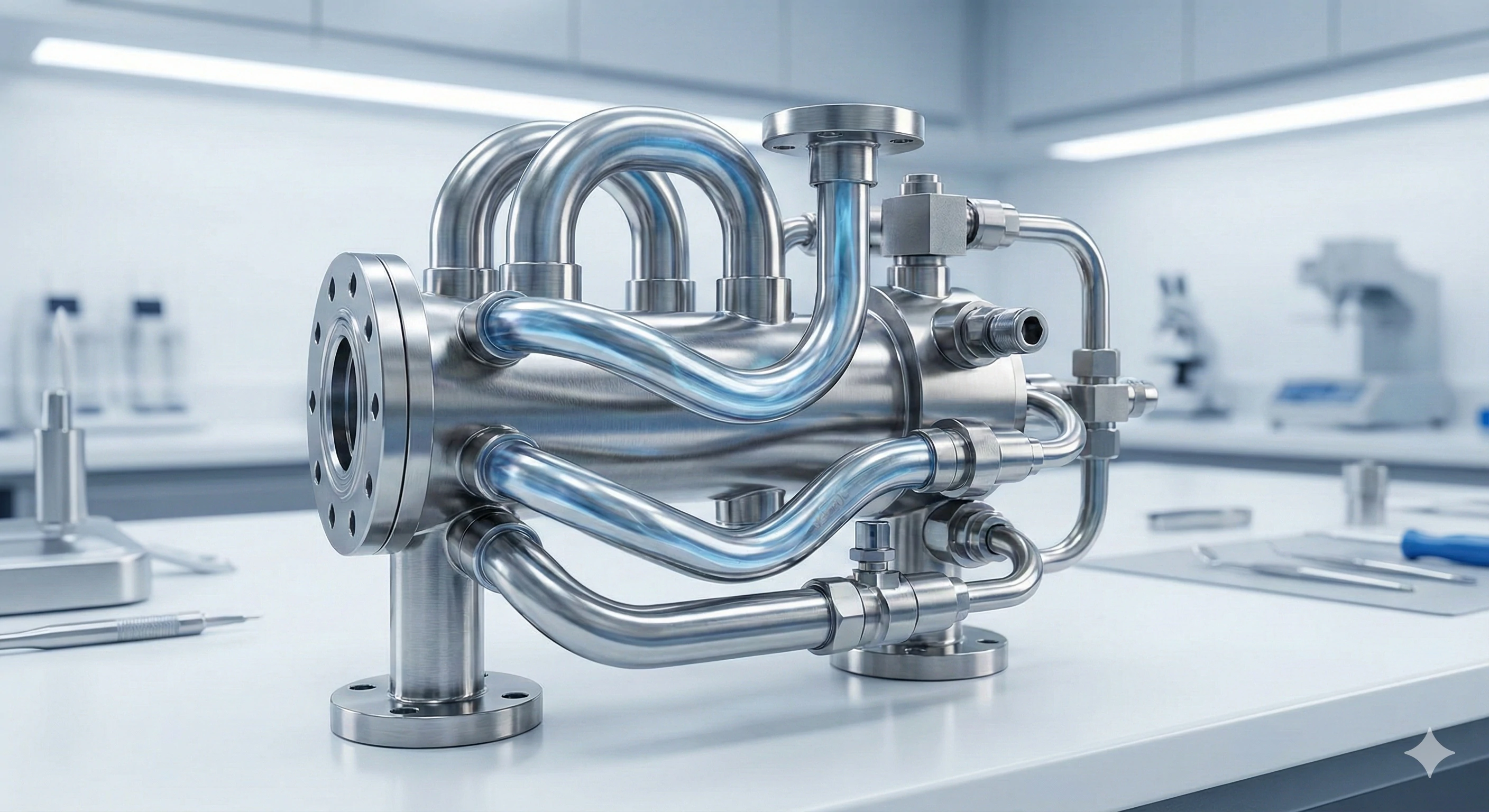

Fluid systems rely on investment casting to produce complex, leak-proof housings for fuel pumps, hydraulic manifolds, and filtration systems. By casting these components as single units in stainless steel or aluminum, engineers eliminate potential leak paths caused by gaskets and joints, ensuring the "nervous system" of the aircraft remains pressurized and functional.

The "nervous system" of an aircraft functions through high-pressure hydraulics. These systems move the rudder, the elevators, and the landing gear. The components governing this flow—manifolds and pumps—are surprisingly complex.

Hydraulic Manifolds

A is essentially a traffic cop for fluid. It directs hydraulic oil to different actuators. Internally, a manifold might have dozens of intersecting channels, ports, and valve seats.

-

Machining Limitations: Drilling deep, intersecting holes in a solid block is risky. If a drill bit wanders even slightly, it breaks into a neighboring channel, scrapping the entire part.

-

Casting Solution: With investment casting (lost wax), the internal channels are formed by the wax pattern. We can create smooth, curved flow paths that reduce turbulence and pressure drop. Fluid flows better around a cast curve than a drilled sharp corner.

Fuel System Components

Fuel pumps and housings face a different challenge: corrosion and chemical resistance. Jet fuel can be harsh, and the environment is subject to rapid temperature changes.

Material Selection: 17-4 PH Stainless Steel

We frequently encounter in these applications. It is a precipitation-hardening steel that offers an excellent balance of high strength and good corrosion resistance.

| Component | Function | Why Cast? |

|---|---|---|

| Fuel Pump Housing | Houses the impeller and directs fuel flow | Complex volute shapes improve pump efficiency. |

| Bleed Air Valves | Manages hot air from the engine | Must handle high thermal shock without warping. |

| Filter Heads | Mounts fuel/oil filters | Consolidates multiple mounting points into one part. |

By casting these fluid management components, we ensure that the internal surfaces are smooth and free of burrs (which are common in machining). In a hydraulic system, a loose metal burr can jam a valve and cause catastrophic failure. Casting provides a cleaner internal finish inherently.

Why Are Interior and Cabin Components Manufactured Using This Process?

While passengers rarely see the engine core, they interact with cast components every time they sit down. In our design discussions, we emphasize that aesthetics and function are not mutually exclusive. The interior of a plane must look premium for business class travelers while withstanding the abuse of thousands of flight cycles. Plastic breaks; machined metal is too heavy.

Interior and cabin components utilize investment casting to combine high aesthetics with durability in seat mechanisms, cargo latches, and galley hardware. This method allows for thin-walled, strong aluminum or steel parts that reduce cabin weight, while also enabling high-quality surface finishes like gold plating or polishing for luxury business class fittings.

The commercial success of an airline often depends on passenger comfort and cargo efficiency. While these parts are not "flight critical" in the same way an engine blade is, they are "business critical." If a cargo latch breaks, freight cannot be loaded. If a first-class seat mechanism jams, the airline loses a high-paying customer.

Seat Mechanisms and Hinges

Modern aircraft seats are marvels of engineering. They must recline, extend leg rests, and support passengers of varying weights, all while being incredibly light to save fuel.

-

The Problem: A machined hinge is heavy and blocky.

-

The Solution: An investment cast hinge can be designed with thin webbing (I-beam construction). It puts strength only where it is needed.

-

Result: A row of seats that saves 50 lbs creates massive fuel savings over a year.

Cargo Systems

Beneath the passenger deck, the cargo hold uses heavy-duty locking systems to secure pallets. These "cargo latches" must restrain thousands of pounds of freight during turbulence. We often see these cast in 17-4 PH steel or high-strength aluminum alloys. They need to be tough, impact-resistant, and cheap enough to manufacture in high volumes. Investment casting is the only process that hits the "sweet spot" of high strength and mid-range volume production costs.

Aesthetic Freedom

For business and first-class cabins, the visual appeal is paramount. Designers want organic curves, ergonomic handles, and sleek trim. Investment casting produces a surface finish (typically 125 RMS or better) that is easy to polish.

We can take a cast aluminum armrest support, polish it, and anodize it to look like a piece of modern art. This "premium feel" is difficult to achieve with stamped sheet metal or plastic.

Material Choices for Interiors

| Application | Material | Reason |

|---|---|---|

| Seat Structure | Aluminum 356 | Lightweight, good strength-to-weight ratio. |

| Cargo Locks | 17-4 PH Steel | High impact resistance, durability. |

| Galley Latches | 300 Series Stainless | Corrosion resistance (food/drink spills), easy to clean. |

Why Do Aerospace Engineers Prefer Investment Casting Over Other Methods?

Choosing a manufacturing process is essentially a risk management decision. Our engineering team knows that switching production methods can introduce variables, but investment casting offers a stability that other methods lack. When dealing with expensive raw materials and strict safety certifications, the cost of error is astronomical.

Aerospace engineers prefer investment casting because it is the only viable method for shaping superalloys and reactive metals like Titanium into complex, near-net-shape forms. This process significantly reduces material waste compared to machining, ensures consistent mechanical properties across production runs, and meets the rigorous AS9100 quality standards required for flight safety.

Why do engineers keep coming back to a process that is thousands of years old? The answer lies in the intersection of material science and economics.

1. Superalloy Compatibility

As we touched upon earlier, aerospace relies on Superalloys ( , Hastelloy, Waspaloy). These materials are designed specifically not to deform or cut easily.

-

Machining Nightmare: If you try to CNC machine Inconel, you will burn through expensive carbide cutters rapidly. The material work-hardens, meaning it gets harder the more you cut it.

-

Casting Ease: In investment casting, we don't need to cut the metal; we melt it. This bypasses the hardness issue entirely.

2. Near-Net-Shape and the "Buy-to-Fly" Ratio

In aerospace, the "Buy-to-Fly" ratio is a critical metric. It compares the weight of the raw material bought versus the weight of the final part that flies.

-

Machining: You might buy a 10kg block of Titanium to machine a 1kg bracket. The Buy-to-Fly ratio is 10:1. You just wasted 90% of expensive titanium as scrap chips.

-

Casting: You pour 1.5kg of Titanium to get a 1kg bracket (accounting for the gate and riser). The ratio is 1.5:1.

This massive reduction in waste makes casting the most improved economic choice for expensive materials. The is a critical metric.

3. Repeatability and Certification

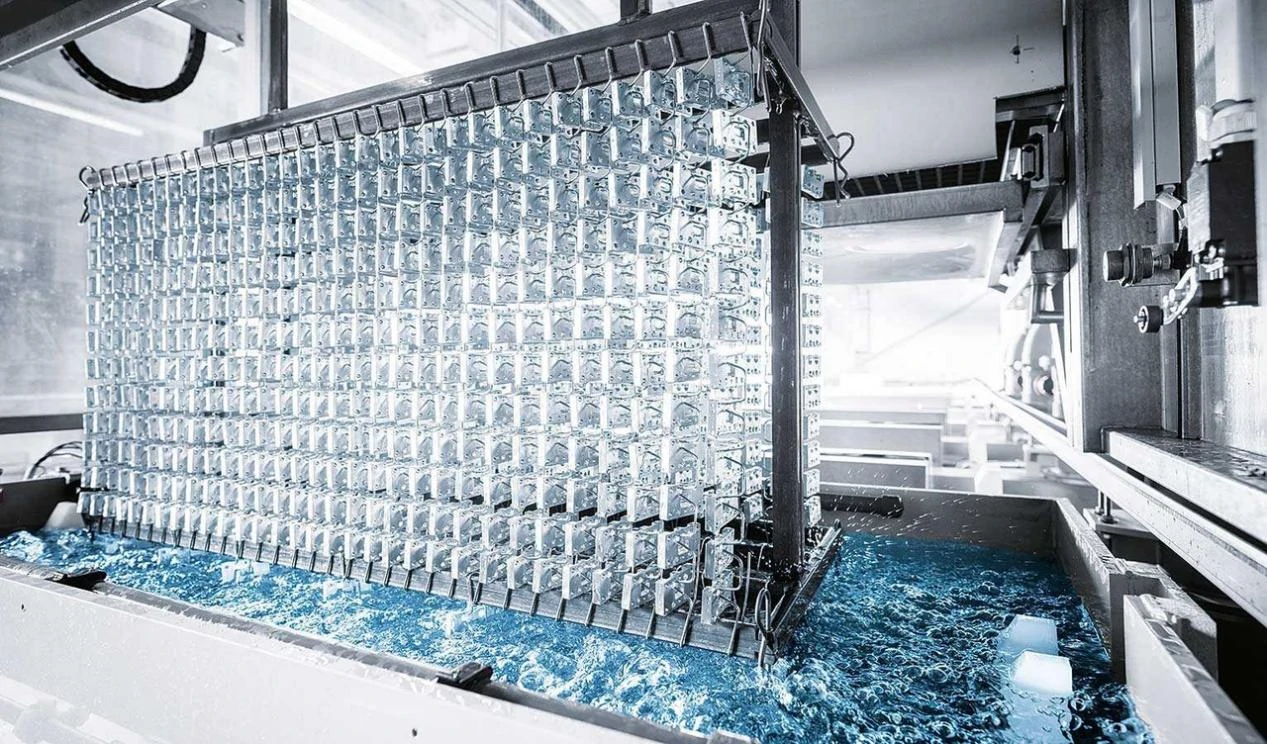

Once a mold is created and qualified (a process known as First Article Inspection), every subsequent part is virtually identical. In our factory, we know that consistency is key. With machining, tool wear changes the dimensions of the part over time. With casting, the ceramic mold is destroyed, but the wax injection die remains constant. This ensures that the 1000th part is dimensionally the same as the 1st part, which is a requirement for .

How Can We Bring Aerospace Precision to Commercial Industries?

The gap between aerospace engineering and commercial hardware is narrowing. We believe that the rigorous standards used to build jet engines should be applied to the products people use every day, like glass railings and shower systems. Why settle for "good enough" when the technology exists to produce "perfect"?

We bring aerospace precision to commercial industries by adopting strict quality control measures such as Non-Destructive Testing (NDT) and material traceability for our glass hardware products. By applying the same logic used for turbine blades—X-ray inspection and exact chemical certification—we ensure that our industrial clients receive durable, safe, and high-performance castings without the aerospace price tag.

At our manufacturing facility, we have adopted a philosophy: "Aerospace Quality for Commercial Application."

While we may be manufacturing glass spigots or hydraulic hinges rather than turbine blades, the physics of failure are the same. A bubble (porosity) inside a casting creates a weak point. If that weak point is in a balcony railing holding glass 20 floors up, the consequences are severe.

Transferring Technology: NDT (Non-Destructive Testing)

In aerospace, every critical casting is X-rayed. We apply this same principle to our heavy-duty commercial hardware.

-

X-Ray Inspection: We can see inside the metal to ensure there are no internal cracks or shrinkage.

-

Dye Penetrant Inspection: We use this to detect microscopic surface cracks that the naked eye cannot see.

Most commercial competitors skip these steps to save money. We include them because durability is our brand signature.

Material Traceability

When Boeing buys a part, they get a "Mill Certificate" proving exactly what chemicals are in the metal. We provide the same transparency. When you buy our stainless steel 316 or hardware, we can trace the raw material back to the furnace.

-

Why this matters: Cheap "stainless steel" often rusts because it lacks Nickel or Molybdenum.

-

Our Promise: Our spectrometer analysis guarantees the chemical composition meets the standard, preventing rust and corrosion even in coastal environments.

The Allwin/Aleader Advantage

We specialize in bridging this gap. We utilize the Lost Wax process to create intricate designs for architects and builders that offer the visual appeal of a luxury cabin interior with the structural strength of an airframe component. Whether you need custom OEM capabilities for a new product line or reliable stock for distribution, we engineer our molds to "Near-Net-Shape" precision, saving you machining costs and ensuring a flawless finish.

Conclusion

Investment casting is the unsung hero of the sky. From the white-hot core of a jet engine to the latch on a cargo door, this process enables planes to fly faster, lighter, and safer. It overcomes the limitations of traditional machining, allowing for the use of superalloys and bionic shapes that define modern aviation.

At our company, we believe you don't have to build a rocket to get aerospace-quality parts. We deliver high-precision investment castings for architectural and industrial applications, bringing flight-grade safety and finish to your projects. If you are ready to elevate your product quality with engineering that stands the test of time, contact our team today for a quote or design consultation.

Footnotes

1. Definition of structural integrity in engineering contexts.

2. Overview of ceramic cores used in investment casting.

3. Properties and applications of nickel-based superalloys.

4. Explanation of topology optimization for lightweight design.

5. Function and design of hydraulic manifolds.

6. Technical data for 17-4 PH precipitation-hardening stainless steel.

7. Guide to working with Inconel and superalloys.

8. Definition and importance of the buy-to-fly ratio.

9. Details on AS9100 aerospace quality management standards.