Capsule houses are generally safe due to their galvanized steel frames and aerodynamic shapes that reduce wind load. However, their overall safety depends entirely on the quality of components like tempered glass, stainless steel locks, and heavy-duty hinges to withstand hurricanes, fire egress requirements, and forced entry attempts.

This guide evaluates the true safety of these structures across four critical areas: weather resistance, fire escape routes, glass durability, and security against break-ins.

1. Weather Safety (Wind & Hurricanes)?

When we engineer components for outdoor modular structures, we have to account for extreme vibration and pressure shifts. A common misconception is that a lightweight-looking pod will blow away like a tent. In reality, the aerodynamic design plays a massive role in stability, but that stability is useless if the connection points fail.

Capsule homes utilize aerodynamic curvature to allow wind to flow around the structure rather than pushing against flat walls. To ensure safety during hurricanes, they must be anchored to a concrete foundation and equipped with marine-grade stainless steel hardware that resists vibration and prevents doors from blowing open.

The Aerodynamic Advantage

Unlike traditional box-shaped tiny homes, which act like sails in strong winds, most capsule houses feature curved exteriors. This shape allows wind to slip around the structure, significantly reducing the or pressure exerted on the frame. Many well-built units are rated for winds up to 120mph (Category 3 Hurricane equivalent).

The Critical Role of Anchoring

However, aerodynamics means nothing if the unit is not grounded. Safety depends heavily on the foundation. We always advise that a capsule must be:

-

Bolted to a reinforced concrete pad.

-

Or secured using deep ground screws.

Hardware: The Weakest Link

The frame might survive the wind, but will the doors stay closed? The weak point in a storm is usually the windows and doors. If a latch fails due to vibration, the door flies open, the internal pressure changes, and the roof can be compromised.

We supply (316) Door Latches and Glass Spigots specifically for this reason. Standard zinc alloy hardware can snap under the repetitive stress of a storm. Using 316-grade stainless steel ensures the hardware holds tight even under heavy vibration.

Wind Load Safety Comparison

| Feature | Standard "Box" Tiny Home | Aerodynamic Capsule House |

|---|---|---|

| Wind Resistance | Low (catch wind like a sail) | High (wind flows around) |

| Drag Coefficient | High | Low |

| Hardware Stress | Moderate | High (requires stronger latches) |

| Hurricane Rating | Varies widely | Often Cat 3+ (with proper anchoring) |

2. Fire Safety (The "Egress" Issue)?

In our discussions with US importers, compliance with local is often the biggest hurdle. The most pressing safety question regarding these compact living spaces is simple: if a fire breaks out in the living room and blocks the front door, how do you get out?

Fire safety in capsule homes relies on accessible emergency egress routes, typically a bedroom window that opens fully. US building codes mandate hardware like heavy-duty 4-bar hinges or casement stays that allow a 90-degree opening, ensuring occupants can escape quickly if the main door is blocked by fire.

Understanding Egress Requirements

A "pod" feels cozy until you realize you are trapped. US Building Code is strict about "Emergency Egress." Every sleeping area must have a secondary way out.

The Friction Hinge Failure

We see many imported capsules arriving with cheap friction hinges on their windows. These hinges are designed to only open the window a few inches for ventilation. In an emergency, you cannot squeeze through a 4-inch gap. This is a major safety failure.

The Hardware Solution

To make a capsule safe, the bedroom window needs specific hardware:

-

Heavy-Duty Casement Stays: These allow the window to be pushed completely open.

-

4-Bar Hinges: These mechanisms allow the window sash to move away from the frame, creating a clear route (90-degree opening) for a person to climb out.

If we are supplying hardware for a unit destined for residential use, we insist on these components. If your capsule does not have this capability, it is not just a code violation; it is a life-safety hazard.

Fire Safety Checklist

| Safety Component | Standard Import Spec | Safe/Code-Compliant Spec |

|---|---|---|

| Bedroom Window | Fixed or tilt-only | Full egress opening (Min 5.7 sq ft) |

| Hinge Type | Standard Friction Hinge | Heavy-Duty 4-Bar Egress Hinge |

| Smoke Detection | Often missing | Hardwired with battery backup |

| Interior Materials | Standard foam/plastic | Fire-retardant insulation |

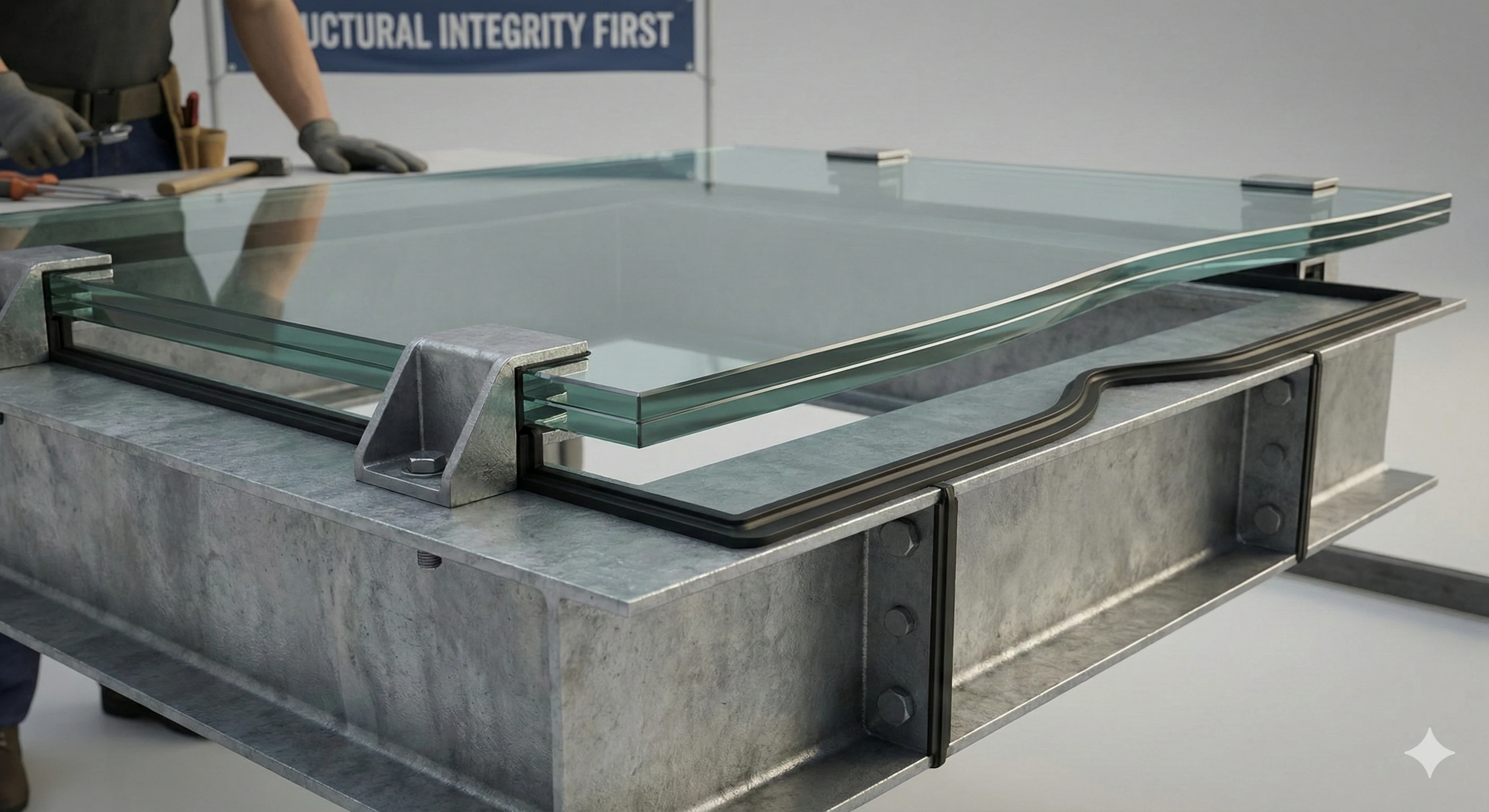

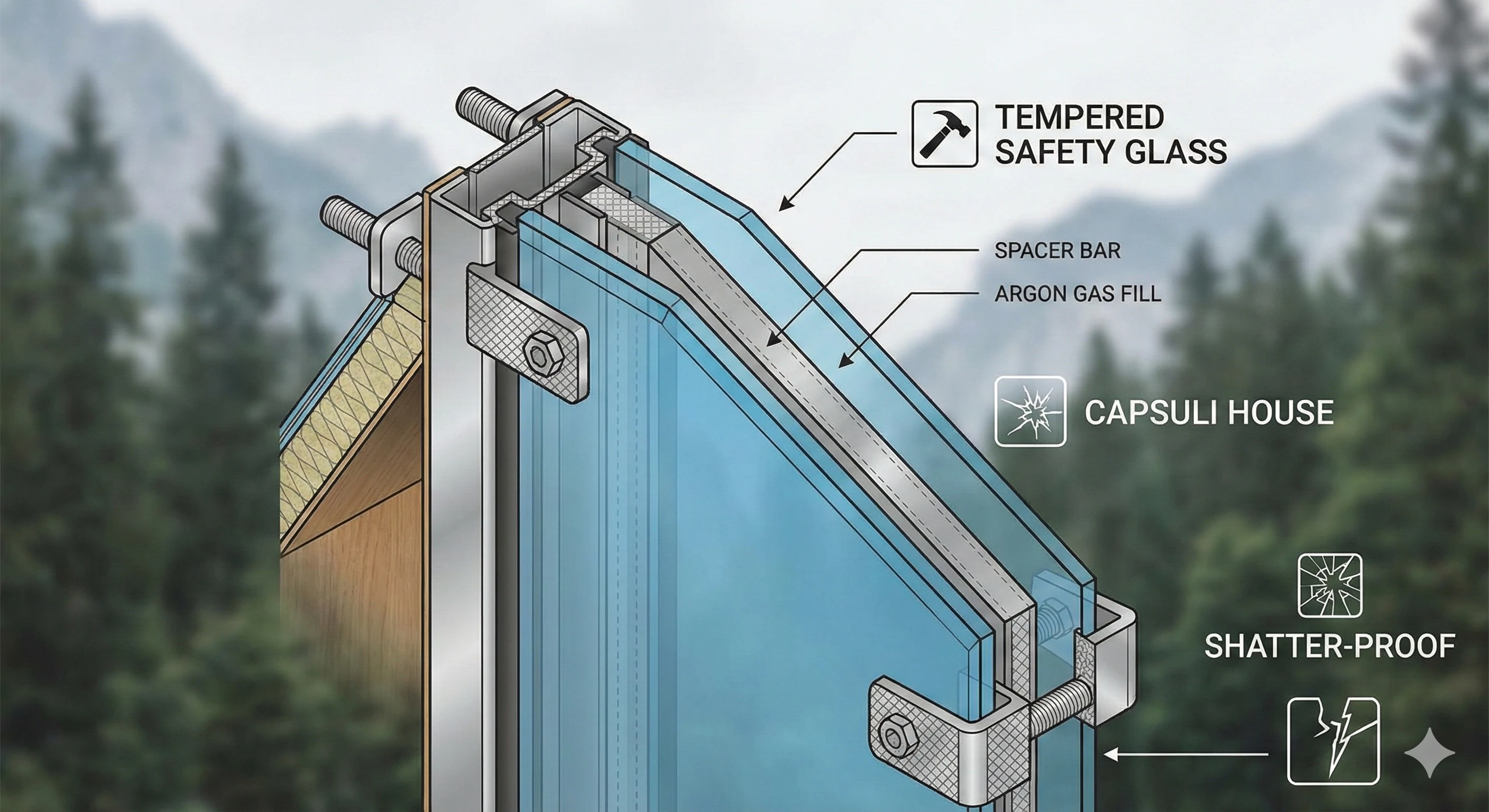

3. "Fishbowl" Safety (Glass Breakage)?

Since we specialize in manufacturing glass fittings, we know that capsule houses are essentially 50% to 80% glass. Clients often worry that living in a "glass house" puts them at risk of severe injury if a window breaks, or that the glass might spontaneously shatter.

Safety depends on using tempered or laminated safety glass held by investment cast stainless steel clamps. Unlike cheap zinc alternatives that crack under thermal expansion, stainless steel clamps maintain high tensile strength, ensuring heavy double-glazed units remain secure and do not shatter into dangerous shards during temperature fluctuations.

Tempered vs. Standard Glass

The material matters immensely. A safe capsule house must use .

-

Tempered Glass: If it breaks, it crumbles into small, dull pebbles rather than jagged, lethal shards.

-

Laminated Glass: Even if it cracks, the plastic interlayer holds the pieces together, keeping the weather out and the occupant safe.

The Hidden Danger: Thermal Expansion

Glass and metal expand at different rates when they get hot. A capsule house sitting in the blazing sun will see its metal frame expand. If the glass is held by cheap clamps, the pressure can cause the glass to explode.

The Role of Investment Cast Clamps

This is why we advocate for Stainless Steel Clamps.

-

Tensile Strength: Steel is strong enough to hold heavy double or triple-glazed units securely for decades.

-

Thermal Stability: It handles temperature swings better than die-cast zinc.

-

Failure Mode: Zinc clamps can become brittle and crack over time. If a clamp breaks, a 200lb sheet of glass can fall. Stainless steel does not suffer from this brittleness.

Glass Safety Standards

| Feature | Unsafe Standard | Safe Standard |

|---|---|---|

| Glass Type | Annealed (Plate) Glass | Tempered or Laminated |

| Breakage Pattern | Sharp, large shards | Small pebbles or held in place |

| Clamp Material | Die-Cast Zinc | Investment Cast Stainless Steel (304/316) |

| Insulation | Single Glazed | Double/Triple Glazed (Argon filled) |

4. Security (Break-In Prevention)?

Security is a top priority for our customers, especially those placing units in remote locations. While the glass walls might seem like a vulnerability, the real entry point for thieves is almost always the door mechanism. We focus heavily on upgrading locking systems to ensure these pods are not easy targets.

While smart locks are standard, true security requires stainless steel mortise locks where the bolt extends deep into the frame. This mechanism prevents forced entry better than surface latches. Additionally, reflective mirror glass coatings provide daytime privacy, making it difficult for outsiders to see valuable contents inside the pod.

The "Kick-In" Risk

Many capsules come with fancy-looking digital keypads. However, if that keypad operates a simple tubular latch (like a bedroom door knob), it offers zero security. A strong kick can split the frame or bend the latch.

The Mortise Lock Upgrade

For genuine security, we recommend .

-

Deep Bolt: The deadbolt extends significantly deeper into the steel frame of the capsule.

-

Box Strike: The bolt slides into a reinforced metal box, not just a hole in the trim.

-

Resistance: This setup is extremely difficult to force open without heavy tools.

Visual Security

Privacy is a form of security. If thieves can't see what is inside, they are less likely to break in.

-

Mirror Glass: Reflective coatings prevent outsiders from seeing in during the day.

-

Curtains/Blinds: Essential for nighttime privacy when the interior lights make the glass transparent from the outside.

The Hidden Danger: "Galvanic Corrosion"?

In our experience supplying hardware for coastal resorts, we have seen structures fail not because of weak design, but because of chemistry. This is an invisible killer of safety that many buyers completely overlook until it is too late.

Galvanic corrosion occurs when dissimilar metals, such as an aluminum shell and steel bolts, interact in wet environments, leading to structural failure. To prevent this, builders must use passivated stainless steel (316) fittings with rubber gaskets to create a neutral barrier and stop the structure from rotting apart.

The Chemical Reaction

Capsule houses are a mix of materials: an Aluminum shell, a Steel frame, and Glass windows. When you bolt aluminum and steel together and add salt water (or just rain), they create a battery. The metals eat each other. This is called .

A Corroded Bolt is a Safety Failure

Imagine the bolts holding your glass railing or your main door hinges dissolving from the inside out. The structure looks fine, but the strength is gone.

The Fix: Isolation

We prevent this by using:

-

Passivated Stainless Steel (316): This material is treated to be less reactive.

-

Isolation Gaskets: We use rubber or plastic washers to ensure the steel bolt never physically touches the aluminum panel. This breaks the electrical connection and prevents corrosion.

Advice for Buyers & Developers?

We always tell our clients that the cheapest option is usually the most expensive in the long run. If you are importing or buying a capsule house, you need to look past the shiny exterior and inspect the "bones" of the unit.

Buyers should prioritize capsule weight, as heavier units indicate a thick steel frame and real glass. Inspect hinges for rust or flimsiness; if the hardware is cheap, the structure likely is too. Always demand ANSI-standard hardware or plan to retrofit high-strength components immediately upon delivery for safety.

Check the Weight

A safe capsule is a heavy capsule. Lightness implies thin walls, plastic windows, and a weak frame. A heavy unit means thick galvanized steel and double-glazed tempered glass.

Inspect the Hinges

Look closely at the door and window hinges.

-

Do they look rusty already?

-

Do they feel flimsy when you move the door?

If the manufacturer cut costs on the hinges (which you can see), they likely cut costs on the internal welding (which you can't see).

Retrofitting is an Option

If you have already purchased a unit with questionable hardware, all is not lost. We often help developers retrofit existing pods with Hardware. Swapping out weak latches for high-strength stainless steel components is a cost-effective way to drastically improve the safety profile of the home.

Conclusion

Capsule homes can be safer than traditional wood-framed houses due to their tough steel skeletons and aerodynamic shapes. However, a chain is only as strong as its weakest link. In a capsule house, those links are the hinges, locks, and glass clamps.

If you ensure these fittings are up to the task, these futuristic pods offer incredible protection against the elements. Don't compromise on the details.

Manufacturing or Importing Capsule Homes?

We manufacture High-Strength Stainless Steel Components specifically for the modular housing industry. Ensure your pods are secure with Allwin Hardware.

Footnotes

1. Benefits of galvanization for structural steel longevity.

2. Understanding wind pressure on building envelopes.

3. Properties of 316-grade stainless steel in marine environments.

4. Overview of International Building Codes for safety.

5. Egress window requirements for residential sleeping areas.

6. Safety standards and breakage patterns of tempered glass.

7. Manufacturing process for high-precision metal components.

8. BHMA standards for high-security door hardware.

9. Electrochemical reactions between dissimilar metals in construction.