When we pour molten stainless steel into our , we are not just making metal shapes. We are creating devices that control the lifeblood of industries. Whether it is a massive oil pipeline or a precise food processing line, selecting the wrong valve can lead to catastrophic leaks, pressure failures, or costly downtime. We often see procurement managers struggle because they focus only on size, ignoring the critical mechanics of how the valve actually operates.

Valves are primarily classified by four main methods: function, mechanical motion, port size, and material. This system helps engineers select the right device to isolate flow, regulate pressure, or prevent backflow, ensuring safety and efficiency across industrial piping systems ranging from oil pipelines to food processing.

To make the right choice for your project, you need to understand the taxonomy of these components. Let's break down the categories exactly how we view them on the production floor.

1. Classification by Function (What do they do?)

Our engineering team often sees clients confused by the sheer variety of options available in the market. If you pick a valve designed for isolation and try to use it for throttling, you will destroy the sealing surface in weeks. It is vital to start with the most basic question: what is the valve supposed to do in your system?

Classification by function divides valves based on their specific job within a pipeline. The three primary categories are isolation valves for stopping flow, regulation valves for throttling volume or pressure, and non-return valves that automatically prevent dangerous backflow to protect upstream equipment.

Understanding function is the first step in the selection process. Here is a deeper look at how these functions differ in an industrial setting.

Isolation (On/Off) Valves

These are the workhorses of the industry. We design isolation valves to be either fully open or fully closed. They are not meant to control the speed of the fluid. When a is left half-open, the high-velocity fluid erodes the metal disc, leading to leaks.

-

Common Types: Ball Valves, Gate Valves.

-

Our Focus: When we cast ball valve bodies, we ensure the internal sphere is perfectly round to provide a tight seal when closed.

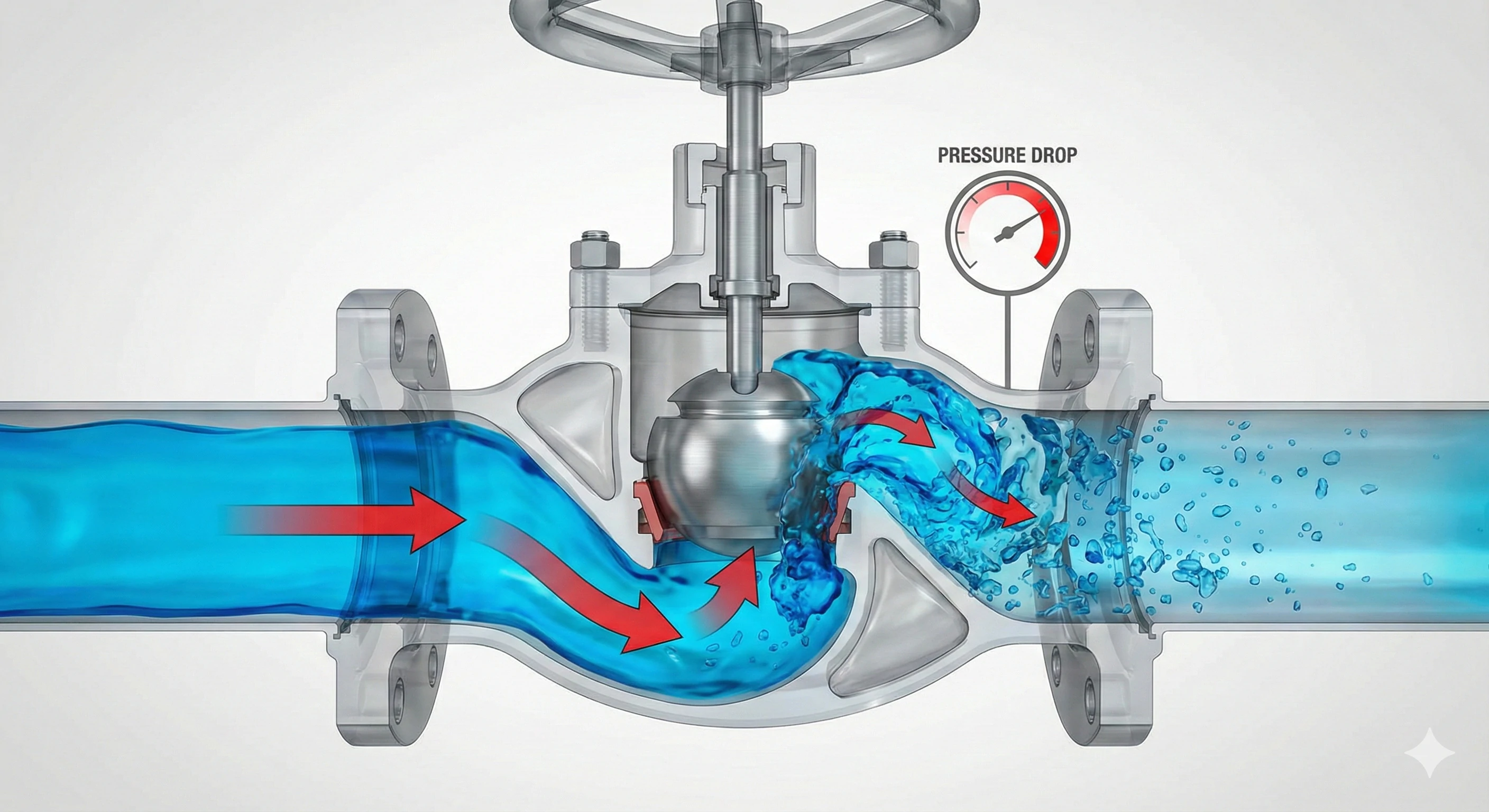

Regulation (Throttling) Valves

Unlike isolation valves, these are built to handle the stress of partial flow. They control the volume or pressure of the liquid or gas. The internal design usually forces the flow to change direction, which consumes energy and drops pressure but allows for precise control.

-

Common Types: Globe Valves, Needle Valves, Butterfly Valves.

-

Engineering Note: are the industry standard here, but they create a high pressure drop.

Non-Return (Protection) Valves

These are the "safety guards" of the piping system. They do not require a handle or an actuator. Instead, they rely on the pressure of the fluid itself to open and close. If the pump fails and flow reverses, gravity or a spring slams the valve shut to prevent backflow.

-

Common Types: (Swing Check, Wafer Check).

Comparison of Valve Functions

| Function Category | Primary Goal | Flow Resistance | Typical Valve Types |

|---|---|---|---|

| Isolation | Stop or start flow completely | Low (when fully open) | Ball, Gate |

| Regulation | Control flow rate or pressure | High | Globe, Needle, Butterfly |

| Non-Return | Prevent reverse flow | Moderate | Swing Check, Lift Check |

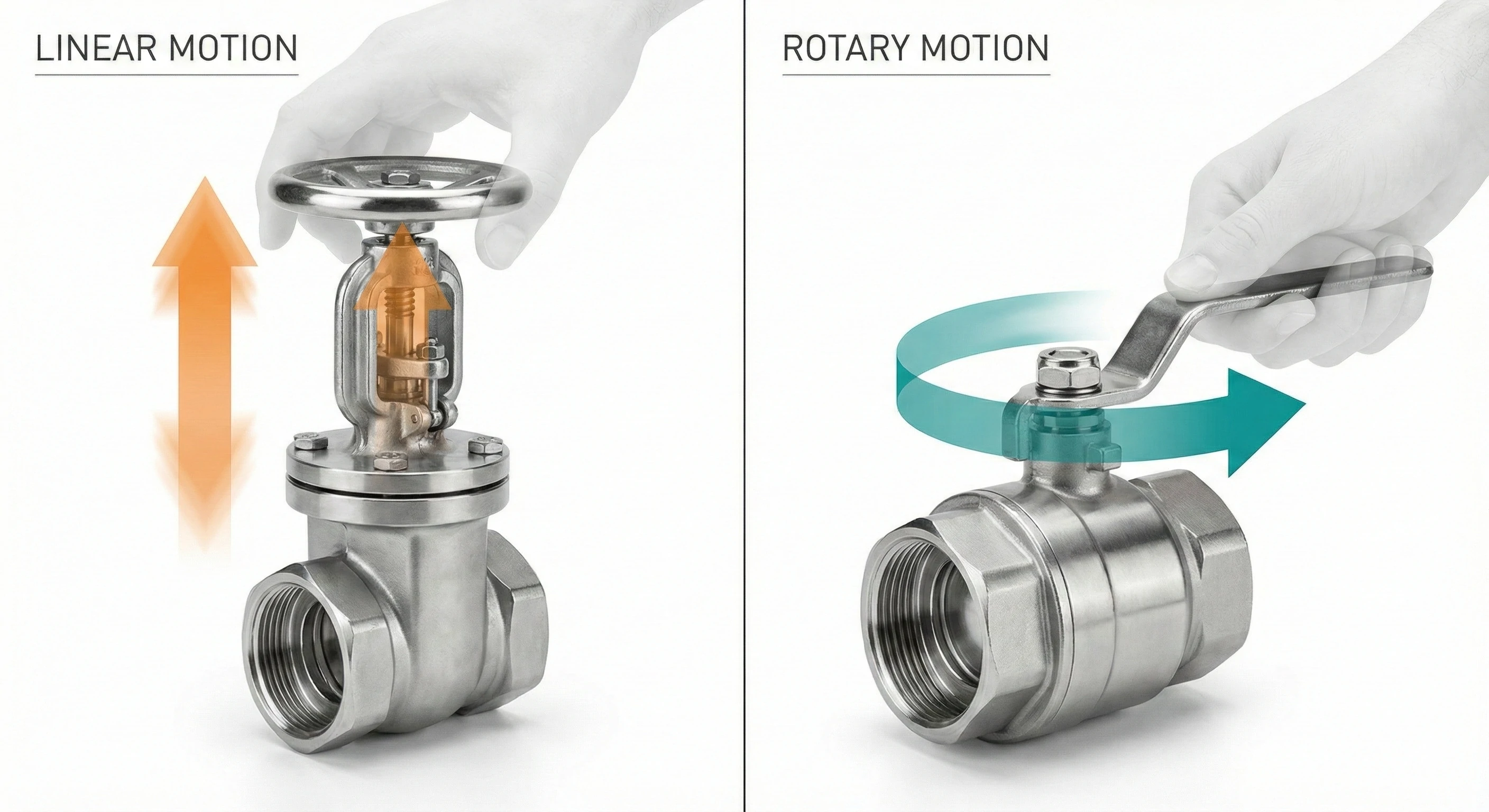

2. Classification by Mechanical Motion (How do they move?)

We design our valve bodies to accommodate specific internal movements. Friction is the enemy of longevity. If a valve requires too much torque to turn, it frustrates the operator and wears out the stem. The way the closure member moves inside the body defines its speed of operation and its sealing capability.

Mechanical motion classification groups valves by how the internal closure member moves to block flow. Linear motion valves, like gate types, use a sliding stem, while rotary motion valves, such as ball and butterfly types, utilize a quick quarter-turn action for rapid opening and closing.

The motion type dictates how much space you need for installation and how quickly you can shut off the line in an emergency.

Linear Motion Valves

In these designs, the stem pushes the closure member (like a gate or a plug) in a straight line—up and down.

-

Gate Valves: Imagine a guillotine. The gate slides down to chop off the flow. It takes many turns of the handle to close, which prevents (a shockwave caused by sudden stopping of fluid).

-

Globe Valves: A plug is pushed down into a seat. This is excellent for throttling but requires significant force to close against high pressure.

Rotary Motion (Quarter Turn) Valves

These are fast. A 90-degree turn of the handle moves the valve from fully open to fully closed.

-

Ball Valves: We machine a hole through a sphere. When the hole aligns with the pipe, flow occurs. When rotated 90 degrees, the solid side blocks the flow.

-

Efficiency: Because they are fast-acting, they are preferred for emergency shut-off applications. However, closing them too fast on high-pressure liquid lines can cause damage.

Motion Types and Maintenance

| Motion Type | Operation Speed | Wear Points | Best Application |

|---|---|---|---|

| Linear | Slow (Multi-turn) | Stem packing, Seat rings | Precise control or high pressure |

| Rotary | Fast (Quarter-turn) | Ball seats, Pivot points | Quick shut-off, automation |

3. Classification by Design (The "Big 4" for Casters?)

In our foundry, we focus heavily on the "Big 4" designs because they cover 90% of industrial needs. Sourcing obscure designs can be a nightmare for maintenance teams. We recommend sticking to these standard designs unless your application has extremely unique requirements.

Classification by design focuses on the physical construction of the valve body and internal mechanism. The most common industrial designs are ball valves for durability, gate valves for straight flow, globe valves for precise throttling, and check valves for automated one-way flow control.

Let's look at why these specific designs dominate the market and how we approach them during the manufacturing process.

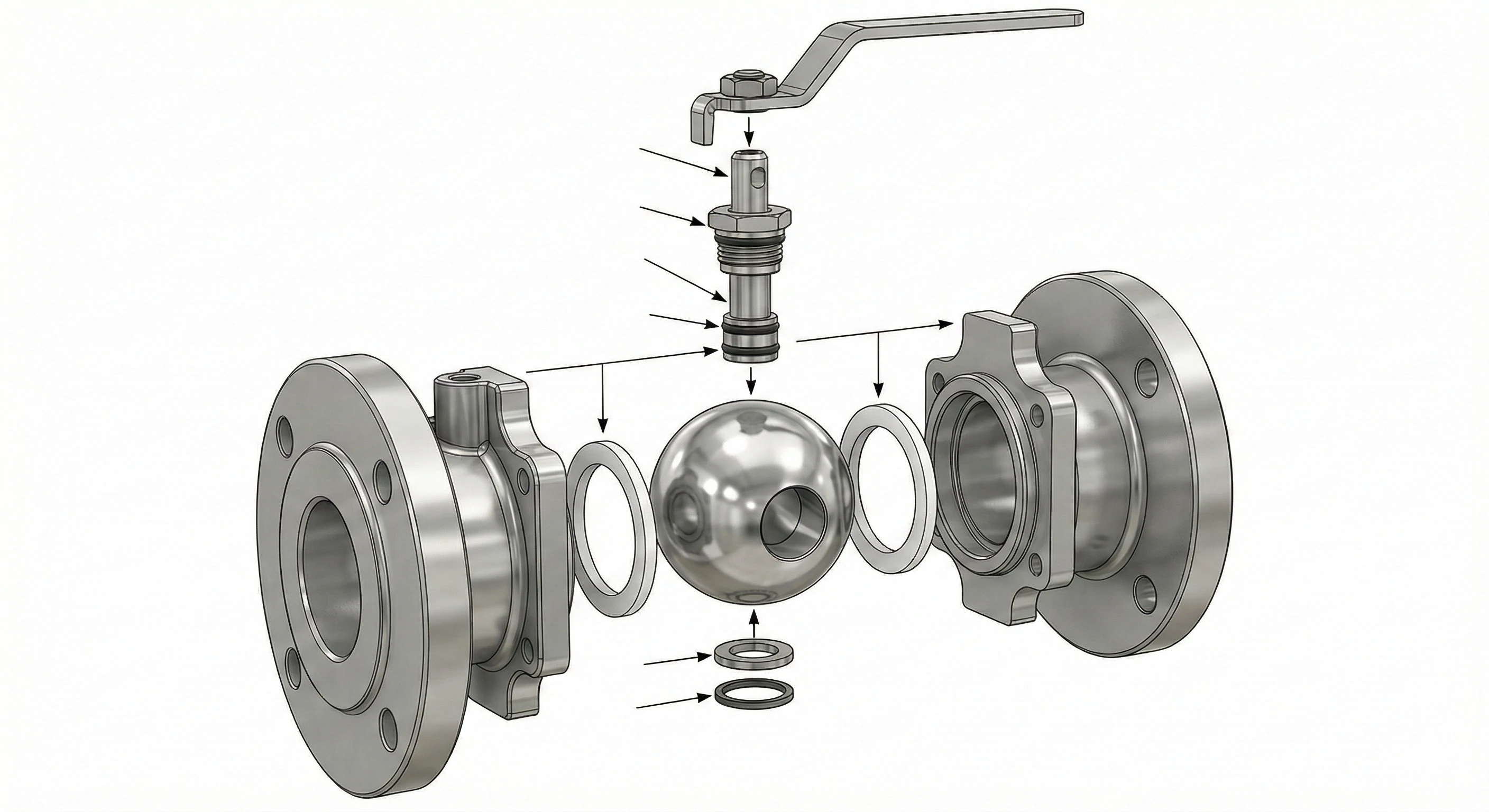

The Ball Valve: Durability King

The ball valve is perhaps the most versatile design. Its strength lies in its simplicity.

-

Casting Insight: Investment casting is essential here. We need to cast the body with strict so the ball "floats" perfectly against the seats. If the casting is rough, the valve leaks.

-

Why choose it: It offers tight sealing with low torque.

The Gate Valve: The Straight Shooter

Designed for straight-line flow with minimum restriction.

-

Mechanism: It lifts a barrier out of the path of the fluid.

-

Limitations: It is strictly for isolation. Never use it to throttle. The vibration from the fluid will destroy the gate against the body.

The Globe Valve: The Flow Controller

The body shape forces flow into a Z-pattern.

-

Why we cast it: The internal chambers are complex. Casting allows us to create smooth curves inside the valve body, reducing turbulence even though the pressure drop is inherent to the design.

The Check Valve: The Silent Guardian

This design is self-acting.

-

Swing Check: A disc swings on a hinge.

-

Wafer Check: A compact design that fits between flanges.

-

Benefit: No human intervention is needed. It works purely on physics.

4. Classification by Material (The Foundry Perspective?)

Material selection is where we see the most critical mistakes. Using the wrong alloy causes corrosion, contamination, and eventual failure. When we receive an order, the first thing we check is the fluid type. A valve body is a pressure vessel; if the material fails, the results can be dangerous.

Valves are classified by material to ensure compatibility with specific fluids and environments. Common options include cast iron for basic water systems, carbon steel for high pressure, and stainless steel, particularly CF8 and CF8M, for superior corrosion resistance in chemical and food processing applications.

From a foundry perspective, the material determines the casting method and the final durability of the product.

Cast Iron

-

Pros: Cheap and easy to cast.

-

Cons: Brittle and rusts easily.

-

Use: General water, steam, and sewage lines where purity isn't a concern.

Carbon Steel (WCB)

-

Pros: Handles high pressure and high temperatures much better than iron.

-

Cons: It will corrode if not painted or coated.

-

Use: Oil and gas industries.

Stainless Steel (CF8/304 & CF8M/316)

This is our specialty.

-

The Standard: Stainless steel is the gold standard for chemical, food, and marine industries.

-

CF8M (316): Contains , which resists pitting corrosion from chlorides (salt water).

-

Investment Casting Advantage: We use investment casting for stainless steel to ensure a smooth surface finish. Rough surfaces trap bacteria, which is unacceptable in food or pharmaceutical plants.

Material Selection Guide

| Material | Common Code | Corrosion Resistance | Cost | Typical Application |

|---|---|---|---|---|

| Cast Iron | GG25 | Poor | Low | Water supply, HVAC |

| Carbon Steel | WCB | Moderate (needs paint) | Medium | Oil, Gas, Steam |

| Stainless Steel | CF8M (316) | Excellent | High | Chemicals, Food, Marine |

5. Classification by End Connection?

Even the perfect valve fails if it leaks at the connection point. Our clients rely on precise threads and flanges to ensure the valve integrates seamlessly into their existing infrastructure. The connection type often dictates the pressure rating and ease of maintenance.

End connection classification defines how a valve attaches to piping systems to prevent leaks. The standard methods include threaded connections for smaller low-pressure lines, flanged ends for easy removal in industrial settings, and socket weld connections for permanent, high-pressure, leak-proof integrity.

The choice of connection depends on whether you need to remove the valve frequently for cleaning or if it needs to stay put forever.

Threaded (NPT/BSP)

This is the "screw-on" method.

-

Usage: Common for small valves (usually under 2 inches).

-

Pros: Cheap and easy to install.

-

Cons: Can leak over time if not sealed properly.

Flanged

The valve has a rim (flange) with holes. You bolt it to a matching on the pipe with a gasket in between.

-

Usage: Industrial standard for pipes above 2 inches.

-

Pros: Very easy to remove the valve from the line for maintenance without cutting the pipe.

Socket Weld

The pipe is inserted into a socket in the valve and welded shut.

-

Usage: High-pressure steam or toxic gas lines.

-

Pros: Zero leakage.

-

Cons: Permanent. You have to cut it out to replace it.

The Role of Investment Casting in Valve Manufacturing?

We use the because machining a valve body from a solid block is inefficient and expensive. You need seamless strength to handle high pressure. When we produce valve bodies, we aim for a "near-net-shape," meaning the cast part is almost identical to the final product.

Investment casting plays a crucial role in valve manufacturing by creating complex, near-net-shape bodies with smooth internal surfaces. This process eliminates joinery seams, reduces machining costs, and prevents bacterial entrapment, making it the superior method for producing high-performance stainless steel valve components.

Complex Geometries and Flow

A valve body is not just a box. It has complex internal chambers that guide fluid. Investment casting allows us to form these internal shapes in a single piece.

-

Monolithic Design: There are no welded seams inside the body that could burst under pressure.

-

Flow Efficiency: The smoother the casting, the less friction the fluid encounters. This increases the energy efficiency of the entire system.

Understanding WOG and Pressure Testing

You might see "1000 WOG" stamped on our valves. This stands for Water, Oil, Gas. It means the valve is rated to handle 1000 PSI of pressure for these fluids at ambient temperature.

-

Testing: Every single valve body we cast undergoes . We pressurize it beyond its rating to ensure there are no microscopic cracks or porosity in the metal.

Why Choose Investment Casting?

-

Precision: We save money on machining threads and sealing surfaces because the casting is already so accurate.

-

Hygiene: In industries like food processing, "entrapment areas" (rough spots where bacteria hide) are a major risk. Investment casting produces a surface smooth enough to prevent this.

Conclusion

Valves are the unsung heroes of industrial infrastructure. Whether you categorize them by function (Isolation vs. Control), motion (Linear vs. Rotary), design, or material, the goal is always safety and efficiency. Understanding these classifications helps you avoid costly mistakes, like using a gate valve for throttling or a carbon steel valve for saltwater.

As a manufacturer, we know that the quality of the valve starts with the casting. A precise, defect-free body is the foundation of a reliable system.

Are you a valve brand looking for a high-quality OEM partner? We manufacture Stainless Steel Valve Bodies and Components using precision investment casting. Contact us for a quote on your valve parts.

Footnotes

1. Manufacturing process for creating high-precision metal components.

2. Valve type primarily used for on/off flow isolation.

3. Valve designed for regulating flow in a pipeline.

4. Valve that allows fluid flow in only one direction.

5. Pressure surge caused by sudden fluid stoppage.

6. Permissible limit of variation in physical dimensions.

7. Element added to steel to increase corrosion resistance.

8. Rim used to connect pipes, valves, and equipment.

9. Method for creating complex metal shapes from wax patterns.