As fundamental components in manufacturing, castings are extensively utilized across automotive, mechanical, and aerospace industries. Their production constitutes a comprehensive system engineering process involving design, material selection, casting, quality inspection, environmental protection, and maintenance. Each stage directly impacts casting quality, performance, and cost efficiency. Many manufacturers frequently encounter challenges such as "design flaws causing defects," "material misselection increasing costs," and "poor maintenance reducing service life." This article examines six critical aspects of casting manufacturing from a full lifecycle perspective: structural design, material selection, defect prevention, non-destructive testing, eco-friendly production, and post-production maintenance. By exploring these core elements, we aim to help manufacturers fully grasp the fundamental principles of casting production, thereby enhancing operational efficiency and product competitiveness.

Foundry Structure Design: Ensuring 'Manufacturability' and 'Reliability' from the Source

The structural design of castings serves as the "first checkpoint" in manufacturing. Poor design not only increases casting difficulty and defect rates but also affects subsequent processing and usage. The core principles of design are "easy casting, reasonable stress distribution, and material conservation," with particular attention to four key elements: wall thickness, fillet radius, draft angle, and reinforcing ribs.

Wall thickness design: Reject the myth of "thicker is stronger"

The strength of castings isn't directly proportional to wall thickness. Excessively thick walls cause uneven cooling of molten metal, leading to defects like shrinkage cavities and porosity, which ultimately degrade mechanical properties. For example, a 100mm thick cast iron component exhibits 20% lower tensile strength at the center compared to a 20mm thick casting. Therefore, the design should adhere to the principle of "uniform wall thickness".

- The wall thickness deviation should be controlled within 20%, avoiding sudden thickness changes (e.g., from 5mm to 20mm abruptly).

- A transition zone should be established at the thickened section, using a "gradual wall thickness" approach (e.g., 5-10-15-20mm).

- Determine the reasonable wall thickness range according to the material (8-50mm for gray cast iron, 3-20mm for aluminum alloy).

After an aluminum alloy motor housing manufacturer optimized the wall thickness design from the original "8mm to 20mm" to a gradual wall thickness, the casting qualification rate increased from 60% to 92%, and the scrap rate was greatly reduced.

Chamfer and draft angle: Address the issues of "difficult mold removal and cracking"

The corners and joints of castings are the "hardest hit" areas of stress concentration. The design of right angles is easy to lead to cracking during cooling; while no pull-out mold slope will cause the casting to stick to the mold and scratch the surface when removing the mold. Specific design requirements:

- Rounded corners: All corners should be rounded with a radius ≥ 1/3 of the wall thickness (e.g., R3-R5 for a 10mm wall thickness), which can reduce the cracking rate of cast iron brackets from 30% to 2%.

- Mold pulling slope: the surface in contact with the mold should be set with 1°-3° mold pulling slope, the direction is consistent with the demolding direction. The pull scratch rate of aluminum alloy cover without slope is 80%, and the pull scratch rate is 0 after adding 2° slope.

Reinforcement ribs and weight reduction holes: balance strength and lightweight

Thin-walled castings (≤5mm) are prone to deformation, requiring stiffeners to enhance rigidity. Large castings need not be solid; weight reduction holes can be strategically placed for lightweight design. Design considerations:

- Reinforcement: The rib width should be 0.6-1 times the wall thickness, and the height should be ≤ 5 times the wall thickness. The bending strength of the 2mm thick aluminum alloy UAV frame is increased by 40% after reinforcement, and the weight is only increased by 5%;

- Weight reduction hole: the hole diameter is more than twice the wall thickness, and the hole spacing is more than 1.5 times the hole diameter. After adding the weight reduction hole to the base of the large machine tool, the weight can be reduced by 10%-20%, and it is conducive to internal cooling.

Casting material selection: The matching scenario is more important than "expensive"

The selection of casting materials directly determines their performance and cost. The mechanical properties, corrosion resistance and high temperature resistance of different materials are significantly different, so they need to be accurately matched according to the application scenario (load, environment and cost). Common casting materials can be divided into three categories: cast iron, casting alloy and casting steel.

Cast iron: A cost-effective choice for low-cost, high-rigidity applications

Cast iron has low cost and good processability, and is the most widely used casting material, mainly including:

- Gray cast iron (HT200/HT300): priced at approximately 5 yuan/kg, offering excellent rigidity and vibration damping, though brittle. It is ideal for agricultural machinery frames, machine tool bases (requiring vibration damping), and valve housings (where impact is negligible).

- Pebble iron (QT450/QT600): With three times the toughness of gray iron and steel-like strength, it excels in impact scenarios like automotive crankshafts (repeated torque) and construction machinery connecting rods (impact loads).

- Malleable cast iron (KT300-06): brittle and slightly bendable, suitable for small parts such as pipe joints and wrenches, but the production cycle is long (annealing 72 hours) and the cost is 20% higher than that of gray cast iron.

Casting alloys: suitable for lightweight, high-temperature and corrosion-resistant scenarios

The cast alloy has low density and special properties, which is suitable for high-end or special environmental requirements:

- Aluminum alloy (A356/ZL101): With a density of only 2.7g/cm³ (one-third of steel), it is the preferred lightweight material for automotive wheels and electronic housings. However, its low tensile strength (≤300MPa) makes it unsuitable for heavy-duty applications.

- Copper alloys (tin bronze ZCuSn10Pb1 and brass ZCuZn38) exhibit strong corrosion resistance and excellent thermal conductivity. Tin bronze is wear-resistant for bearing sleeves, while brass is easy to machine for pipe joints. However, their production cost is relatively high, approximately 60 yuan per kilogram.

- High-temperature alloy (GH4169/K418): Maintains strength at 600-1000℃, ideal for aerospace turbine blades and rocket combustion chambers. However, its exorbitant cost (around 1000 yuan/kg) limits its use to high-end applications.

Cast steel: suitable for high strength and heavy load scenarios

Cast steel has high strength and good toughness, suitable for heavy load and impact working conditions:

- Carbon cast steel (ZG230-450): Tensile strength ≥450MPa, suitable for construction machinery buckets and mining machinery gearboxes. However, it has a high shrinkage rate (2%) and is prone to cracking, requiring strict control of cooling speed.

- Stainless steel cast steel (CF8/CF3): Excellent corrosion resistance, ideal for chemical reactors and food machinery components. However, its high cost (approximately 30 yuan/kg) and tendency to form porosity during casting require vacuum casting.

Analysis and Prevention of Common Defects in Castings: From Passive Repair to Active Prevention

Casting defects are the main cause of casting scrap (accounting for more than 60% of the scrap quantity), including shrinkage holes, sand holes, air holes, etc. Mastering the causes of defects and prevention methods can reduce the scrap rate from the source and improve production efficiency.

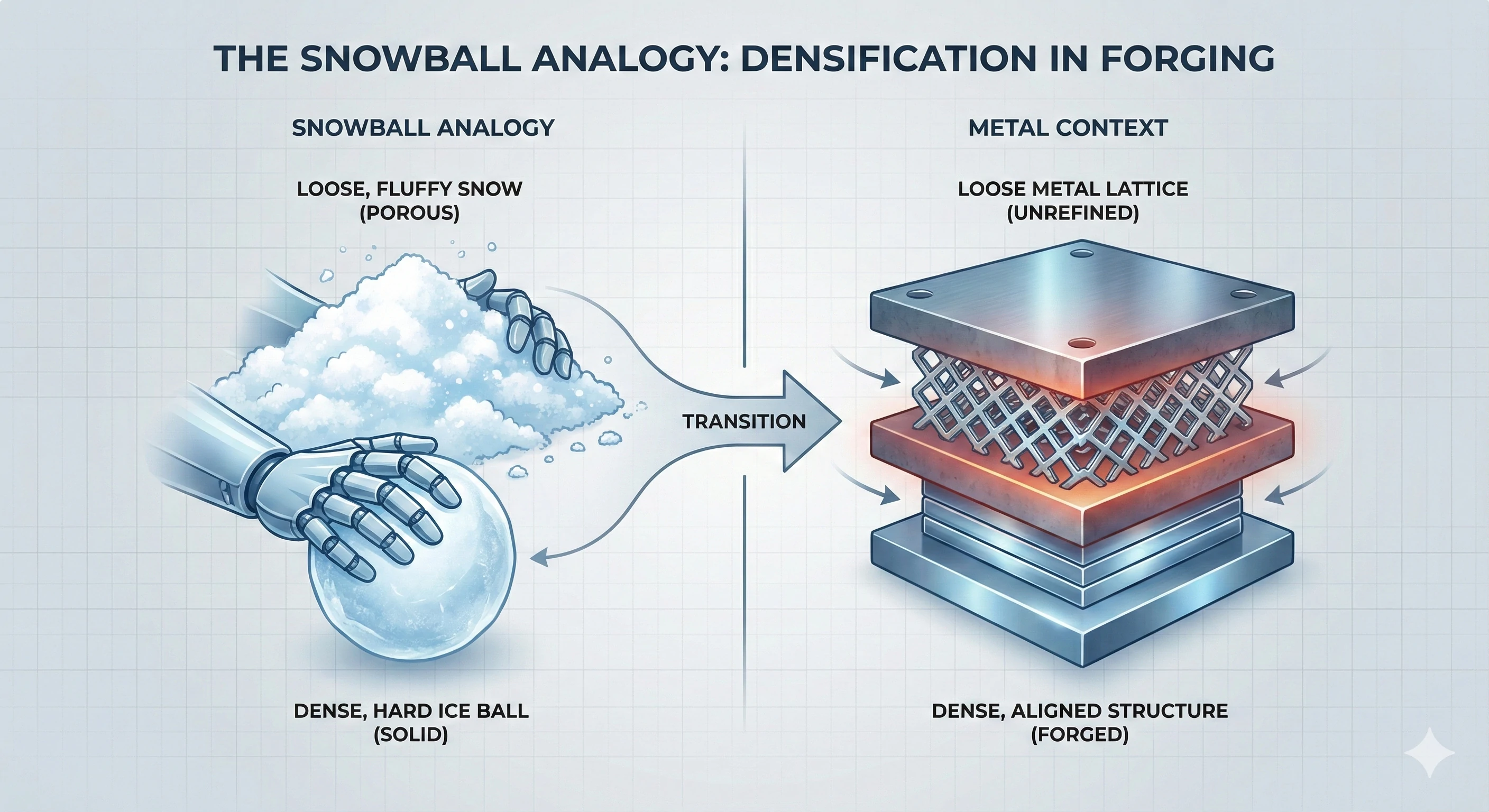

Shrinkage: The "culprit" of internal voids

Characteristics: Shrinkage cavities are large voids with diameters ≥5mm, while shrinkage porosity refers to fine voids ≤2mm, commonly occurring in thick-walled areas near gates. Causes: During the cooling and solidification of molten metal, insufficient replenishment occurs (the outer layer of thick walls solidifies first, leaving the inner layer to contract without proper replenishment). Preventive measures:

- Design reasonable gate, volume is more than 1.5 times the volume of the hot joint of the casting;

- The sequence solidification process is used to cool the casting from thin wall to thick wall;

- Cast iron parts can be added with inoculant (such as ferrosilicon) to refine the grain and reduce shrinkage and looseness.

After adding 2 pouring spouts, the shrinkage rate of a foundry cylinder head manufacturer was reduced from 15% to 3%, and the waste loss was reduced by 1 million yuan.

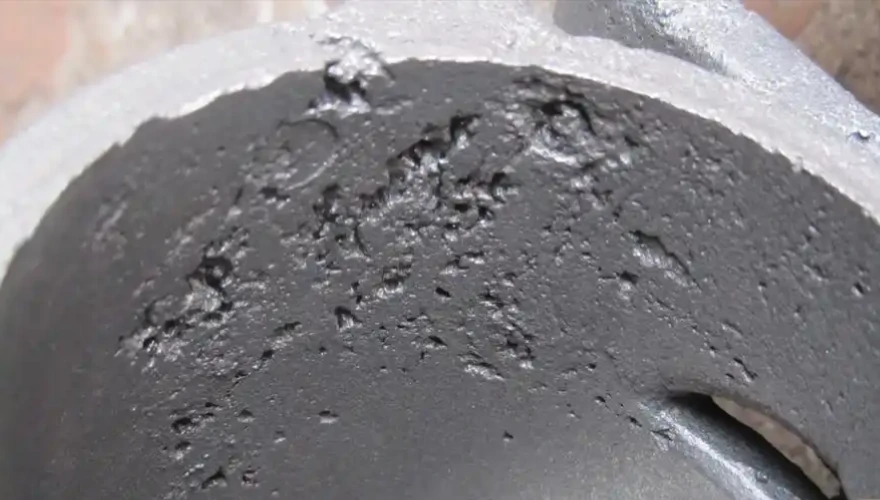

Sand Holes and Sand Trapping: Causes of Surface “Hard Lumps”

Characteristics: Sand holes are small holes containing sand particles on the surface, and sand interlayers are surface stratification (sand interlayers), which are commonly seen in sand casting. Causes: Low strength of sand mold, poor air permeability, sand particles remaining in the cavity. Preventive measures:

- Use high strength sand (quartz sand with 1% bentonite);

- For sand layers, install one Φ2mm vent hole every 100cm²;

- Clean the sand particles in the cavity with compressed air before molding.

After optimization, the sand hole rate of carbon steel bracket decreased from 20% to 2%, and the surface quality was significantly improved.

Blowhole : The source of surface bubbles

Characteristics: Smooth small holes with circular or oval shapes, containing exsudative porosity (gas released from molten metal) and intrusive porosity (gas infiltration from sand mold/coating). Causes: Incomplete degassing of molten metal, high moisture content in sand mold, and un-dried coating. Preventive measures:

- During the smelting of aluminum alloy, nitrogen is introduced to remove gas, reducing hydrogen content to ≤0.1mL/100g.

- Dry the sand to a moisture content of less than 2%, and dry the paint at 120℃ for 2 hours after spraying;

- Control the temperature of molten metal during casting to avoid overheating (e.g., the temperature of molten cast iron should be ≤1450℃).

After optimization, the porosity of aluminum alloy wheel hub manufacturer decreased from 12% to 1%, and the product qualification rate increased significantly.

Non-Destructive Testing (NDT) for Castings: A Non-Invasive Tool for Defect Detection

Non-destructive testing is a key means to ensure the quality of castings. It can detect internal and surface defects without damaging the castings, and is widely used in factory inspection of castings and quality control of key components. Common testing methods include ultrasonic testing, radiographic testing, magnetic powder testing and penetrant testing.

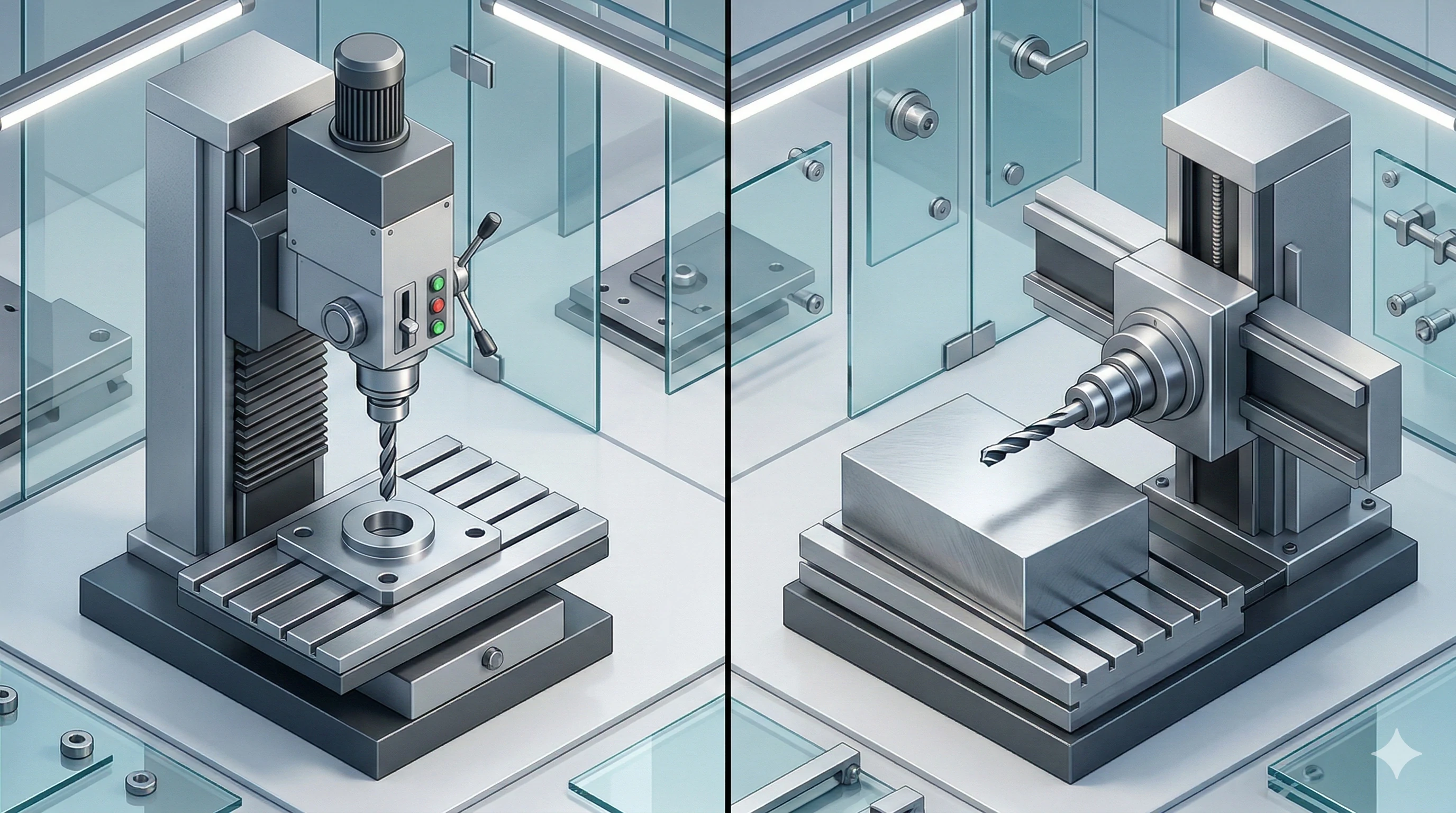

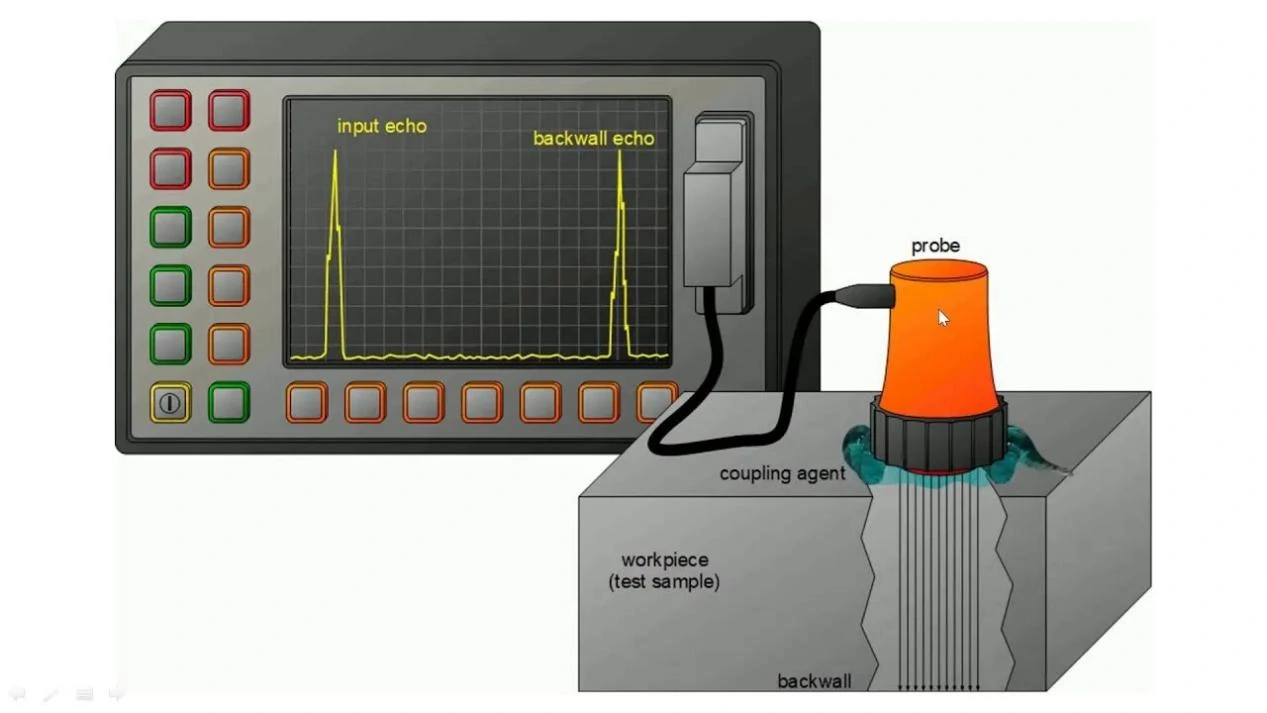

Ultrasonic Testing (UT): The "detector" for internal defects in thick-walled castings

The principle involves using ultrasonic waves to penetrate castings, where the differences in reflected wave signals at defect locations determine their position and size. This method is suitable for cast steel components and ductile iron castings with thickness ≥8mm, capable of detecting internal defects such as shrinkage cavities and inclusions. With a detection depth of up to 1m and positioning accuracy of ≤2mm, it can precisely identify 5mm shrinkage cavities in a 200mm-thick wind turbine flange cast steel component.

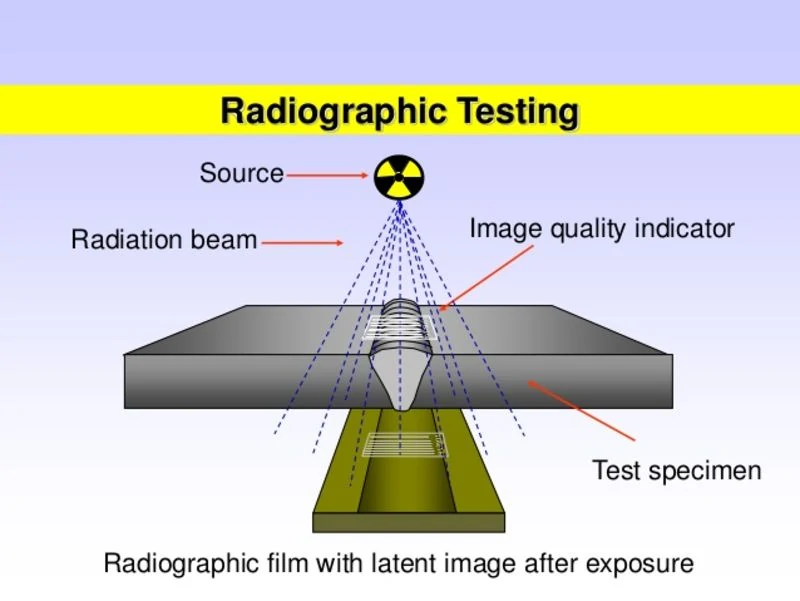

Radiographic Testing (RT): A 'X-ray' for revealing intricate details within complex structures

When castings are exposed to X-rays or γ-rays, the varying attenuation of radiation at defect locations creates distinct black shadows on the film. This method is particularly effective for complex structures like multi-chamber valve bodies and turbine blades, clearly revealing defects such as porosity and sand inclusion. However, due to radiation exposure, it requires professional operation and is primarily used for 100% inspection of critical castings like aviation engine components.

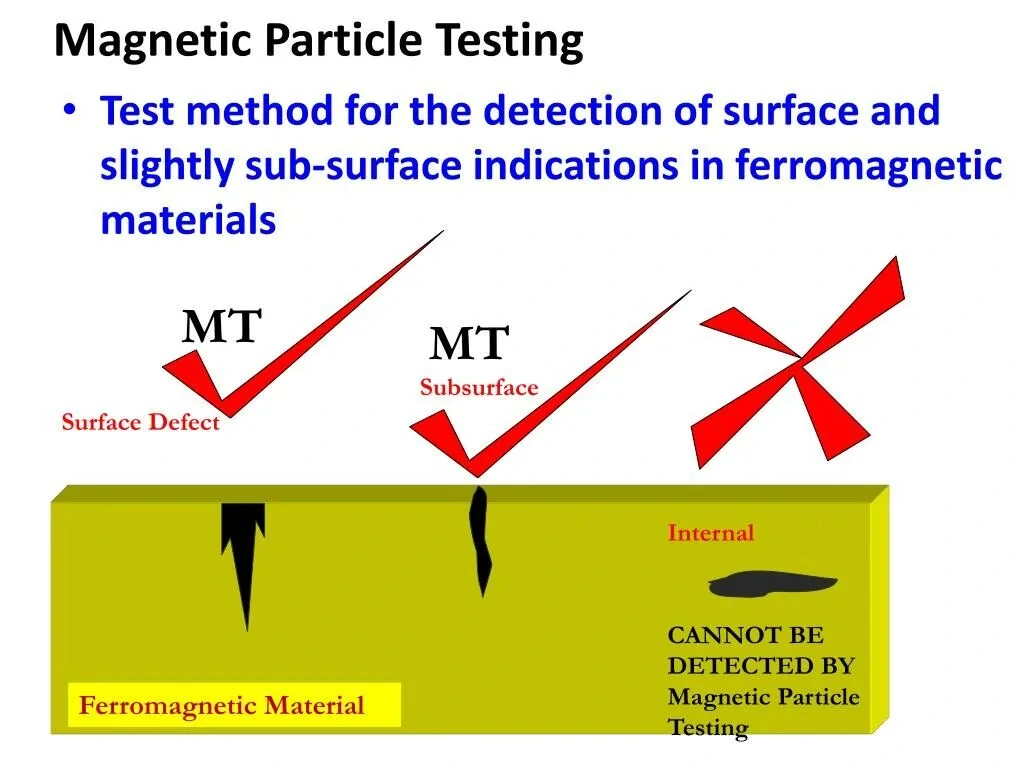

Magnetic particle testing (MT): A surface defect scanner for ferromagnetic castings

Magnetic flux leakage from surface/subsurface defects in castings induces magnetic powder adhesion, forming detectable traces. This method is suitable for ferromagnetic materials like cast iron and steel, detecting surface defects up to 5mm deep including cracks and cold shuts. With rapid inspection (≤5 minutes per piece) and low cost, it's ideal for batch casting quality control (10% sampling rate) of automotive components such as connecting rods.

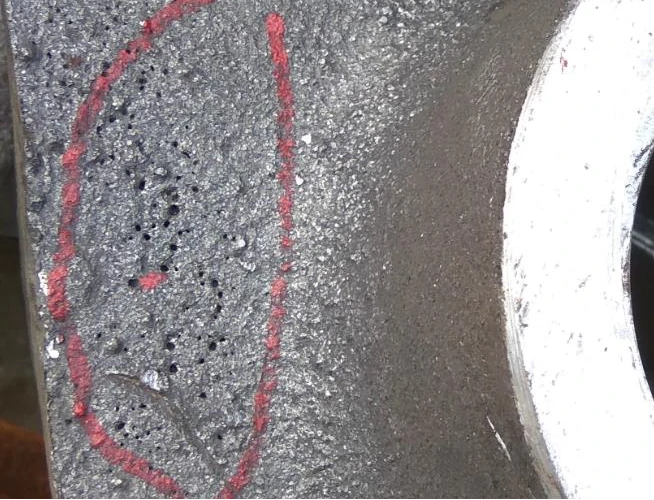

Penetration Testing (PT): A non-magnetic flaw detector for surface-opening defects in castings

Apply the penetrant to the casting surface. After the penetrant penetrates the open defects, clean the surface and apply the developer. Red traces will appear where defects have exuded. Suitable for non-magnetic materials such as aluminum alloys and copper alloys, this method can detect surface cracks, sand holes, and other open defects. The operation is simple, material restrictions are minimal, and it is ideal for inspecting castings with smooth surfaces (Ra≤6.3μm).

Environmental protection and sustainable manufacturing of castings: the inevitable trend of green production

With the increasingly strict environmental protection requirements, the treatment of waste gas, waste water and waste materials in the production of castings has become the key to the sustainable development of enterprises. The realization of green casting can not only meet the environmental protection standards, but also reduce the consumption of resources and costs.

Exhaust gas treatment: Say goodbye to "smoke from smelting, pungent smell from painting"

The smelting process generates dust (PM2.5) and sulfur dioxide, while the painting process produces VOCs. The smelting exhaust is treated using a "baghouse filter + desulfurization tower" system (achieving ≥99% dust removal and ≥90% SO₂ removal), while the painting VOCs are processed through "activated carbon adsorption + catalytic combustion" (removal rate ≥95%). After the renovation of a foundry, the workshop dust concentration dropped from 50mg/m³ to 0.5mg/m³, meeting national standards.

Waste water recycling: Achieve water recycling

The sand washing wastewater is recycled through a "sedimentation + filtration" process for sand treatment (with a reuse rate of ≥80%). The acid washing/phosphating wastewater undergoes treatment via "neutralization + heavy metal capture + reverse osmosis" (achieving a heavy metal removal rate of ≥99%). The treated water can be used for landscaping or irrigation. After the plant's renovation, it saves 100 tons of water daily, reduces annual wastewater discharge by 36,000 tons, and lowers water resource costs by 40%.

Waste reuse: turning waste into treasure

60% of the waste material consists of foundry sand, which can be processed through magnetic separation for iron removal and screening to produce reusable sand (with a recycling rate of ≥50%) or construction bricks (with a strength of ≥MU10). Waste castings and cutting scraps are sorted and recycled through furnace melting (with a recovery rate of ≥95%). A factory processes 10,000 tons of waste sand annually, generating an additional annual revenue of 200,000 yuan from brick sales while reducing solid waste landfill volumes, achieving a win-win outcome for both economic and environmental benefits.

Assembly and Maintenance of Castings: The Final Step from 'Making Well' to 'Using Well'

The assembly quality and later maintenance of castings directly affect their service performance and service life. Correct operation can avoid assembly deformation, leakage and other problems, and prolong the service life of castings.

Cast parts assembly: Avoid damage caused by forced installation

- Clean the mating surfaces: Use sandpaper to remove burrs and oil stains, ensuring the fit gap is ≤0.1mm. Failure to clean the mating surfaces during flange assembly may cause leakage.

- Evenly tighten the bolts: tighten them in diagonal order, and the torque deviation should be less than or equal to 10%. Uneven torque of cast iron pump body bolts may cause cracks in the pump body.

- Protect thin-walled components: For thin-walled castings (≤3mm), use soft gripper fixtures or add washers to prevent surface damage (e.g., aluminum alloy housings require reduced pressure marks when using soft grippers).

Post-maintenance: The key to prolonging the service life of castings

- Anti-rust treatment: cast iron parts outdoors should be coated with anti-rust paint once a year, stainless steel parts should avoid contact with salt water, and coastal environment should be washed with clean water every quarter;

- Impact resistance: avoid violent impact on brittle castings such as gray cast iron. The machine tool base is not allowed to be struck with an iron hammer. Protective sleeves can be added;

- Regular inspection: Key castings (such as car crankshaft) should be checked for surface cracks with magnetic powder every 1000 working hours, and small cracks should be welded in time to avoid fracture and scrap.

Conclusion

Casting manufacturing is a tightly integrated system engineering process. From structural design optimization to precise material matching, and through defect prevention, non-destructive testing, eco-friendly production, and post-maintenance, every stage requires rigorous control and specialized expertise. Mastering these critical aspects not only enhances casting quality and performance while reducing production costs and defect rates, but also drives enterprises toward green and sustainable development. This comprehensive guide aims to provide practical references for casting professionals, helping solve real-world production challenges and elevate the industry's overall manufacturing standards. If you have deeper questions about any specific phase, feel free to share your insights in the comments section!