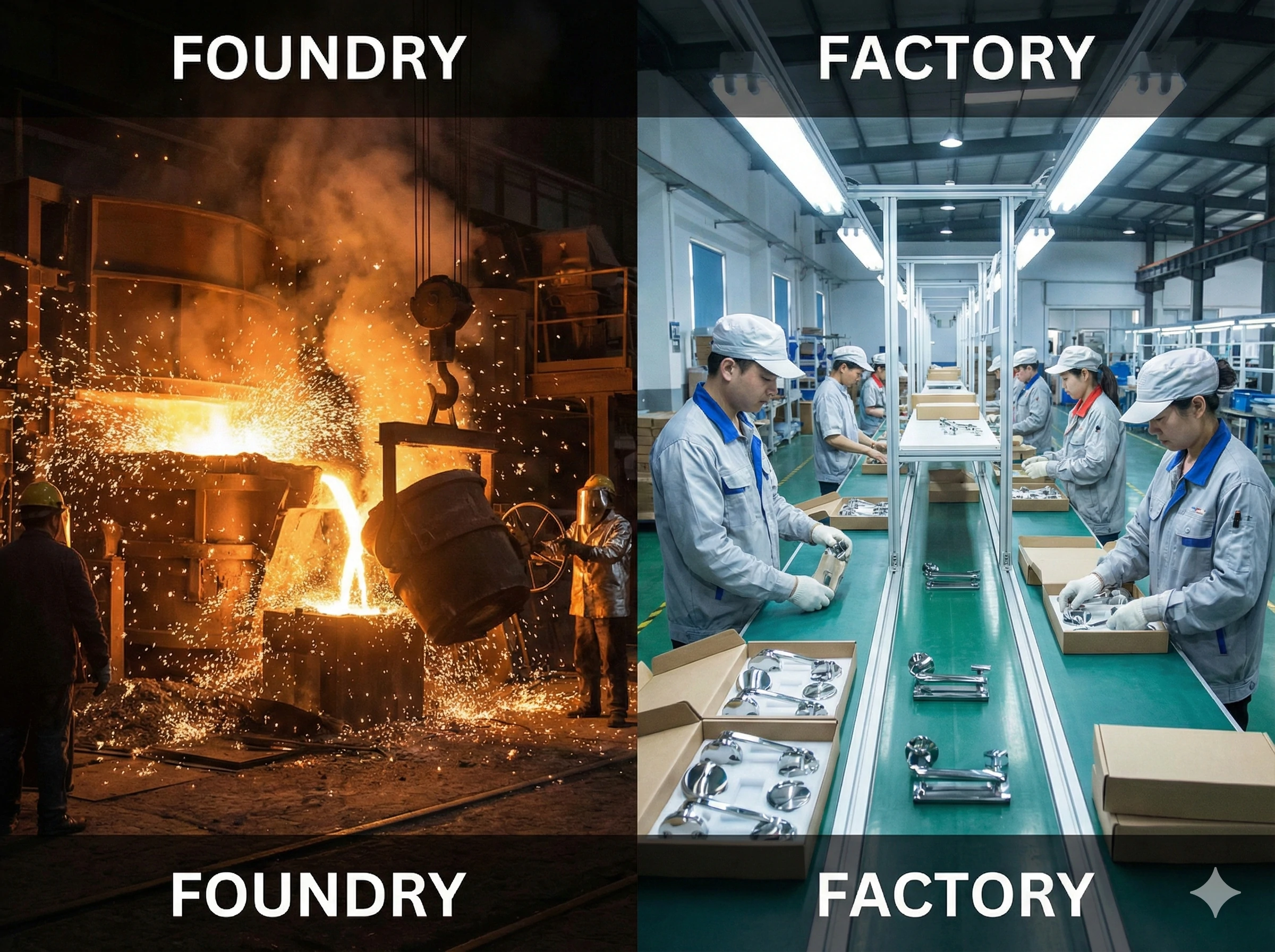

In our years of producing architectural hardware, we often notice a specific confusion among our clients. You might tell us you are planning to visit the "factory," but when you arrive, you are surprised to see molten metal and heavy furnaces. Or, you might be sourcing from a "foundry" expecting them to have advanced packaging capabilities, only to find they focus solely on raw casting. This confusion is common because the terms are frequently used interchangeably in the . However, distinguishing between the two is vital for understanding where your product comes from and who is responsible for its quality.

A factory is a broad term for any facility where goods are manufactured or assembled. A foundry is a specialized type of factory dedicated to melting metal and pouring it into molds to create castings. While all foundries are factories, not all factories are foundries.

Let's break down the specific processes, equipment, and outputs of each facility so you can source with confidence.

What is a Foundry? (The "Liquid" Phase)?

When we walk through our casting workshop, the heat is the first thing we notice. This is the heart of the metal transformation process, and it looks very different from a standard assembly line. In our experience, clients who have never seen this stage of production are often surprised by the intensity of the environment. It is here that we determine the fundamental chemical integrity of the steel before it ever looks like a product.

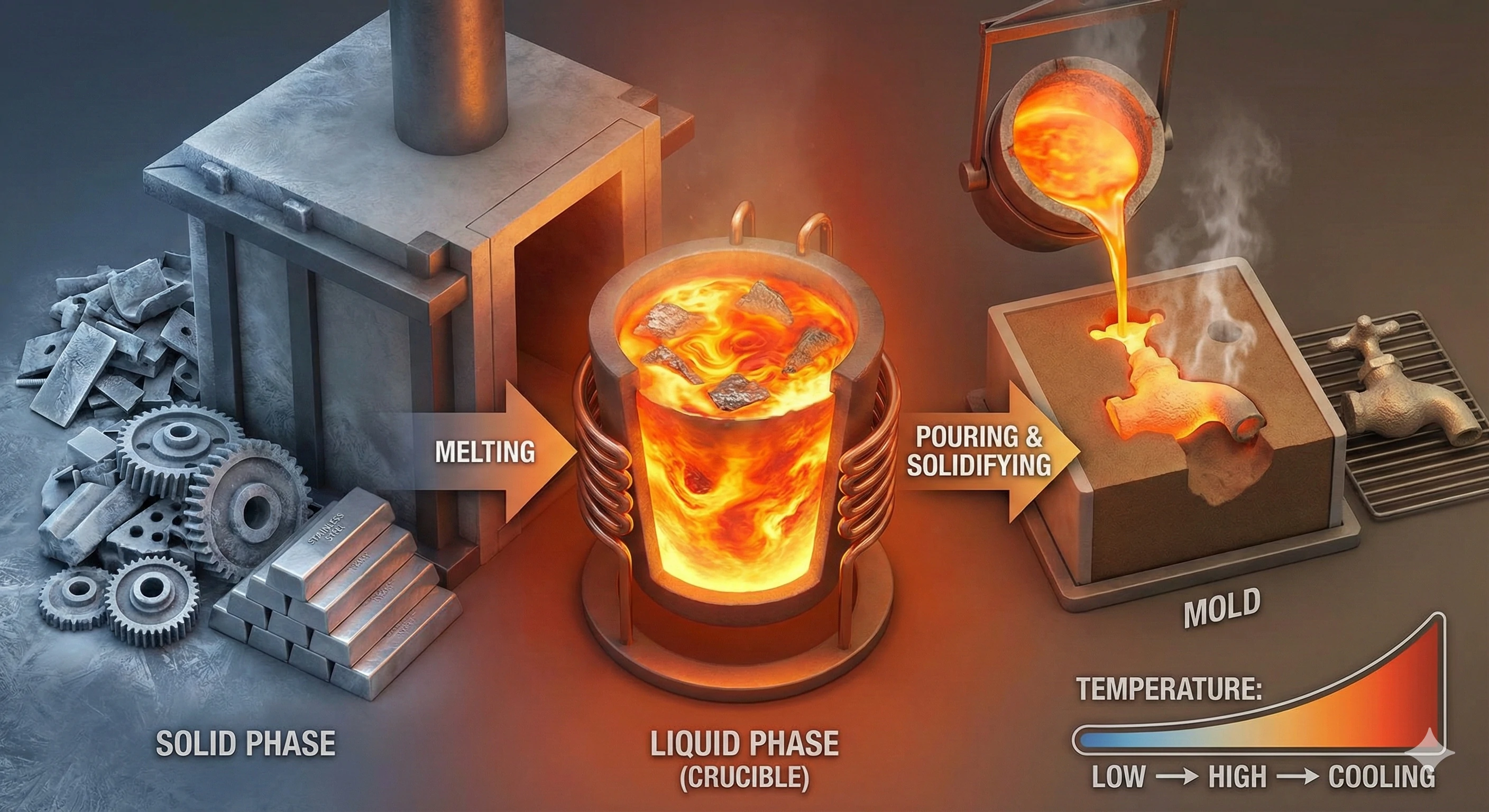

A foundry is a specialized manufacturing facility focused on melting metal and pouring it into molds to solidify into specific shapes. The core process involves a phase change from solid to liquid and back to solid, using furnaces and crucibles to create raw metal castings.

To truly understand a foundry, you have to think about phase changes. In our facility, we are not just cutting material; we are transforming its state. We take solid scrap metal or ingots, melt them down until they are liquid, and then pour them into a void to create a new shape. This is the "Liquid Phase" of manufacturing.

The Core Processes and Equipment

The environment here is defined by extreme heat. We utilize or electric arc furnaces that reach temperatures exceeding 1600°C to melt stainless steel. The process follows a strict rhythm:

-

Pattern Making: We create a wax or sand model of the desired object.

-

Melting: The raw metal is turned into liquid soup in the furnace.

-

Pouring: We carefully pour this liquid into the mold.

-

Solidification: The metal cools and hardens into the shape of the mold.

We often use the analogy of a bakery to explain this to our clients. A bakery deals with dough (raw material), ovens (heat), and molds (pans). A foundry is simply a heavy-industrial bakery. Instead of flour, we use silica sand; instead of dough, we use molten ; and instead of bread, we produce "castings."

Common Misconceptions

One frequent question we get is, "Is a steel mill a foundry?" The answer is no. A steel mill produces semi-finished shapes like beams and sheets from . We, as a foundry, take those materials (or scrap), remelt them, and give them a specific, complex shape—like the body of a glass spigot.

Foundry Output Characteristics

The output of a foundry is a "casting." It is crucial to note that a raw casting is usually rough. It may have burrs, gates (where the metal entered), and a matte surface finish. It is generally not ready for the end consumer immediately.

Table: Typical Foundry Equipment

| Equipment | Function | Temperature/State |

|---|---|---|

| Induction Furnace | Melts solid metal into liquid form | >1600°C (Liquid) |

| Crucible | Holds and transports molten metal | Extreme Heat |

| Shell/Sand Mold | Defines the shape of the final product | Solid |

| Spectrometer | Analyzes chemical composition | Analytical |

What is a Factory? (The "Solid" Phase)?

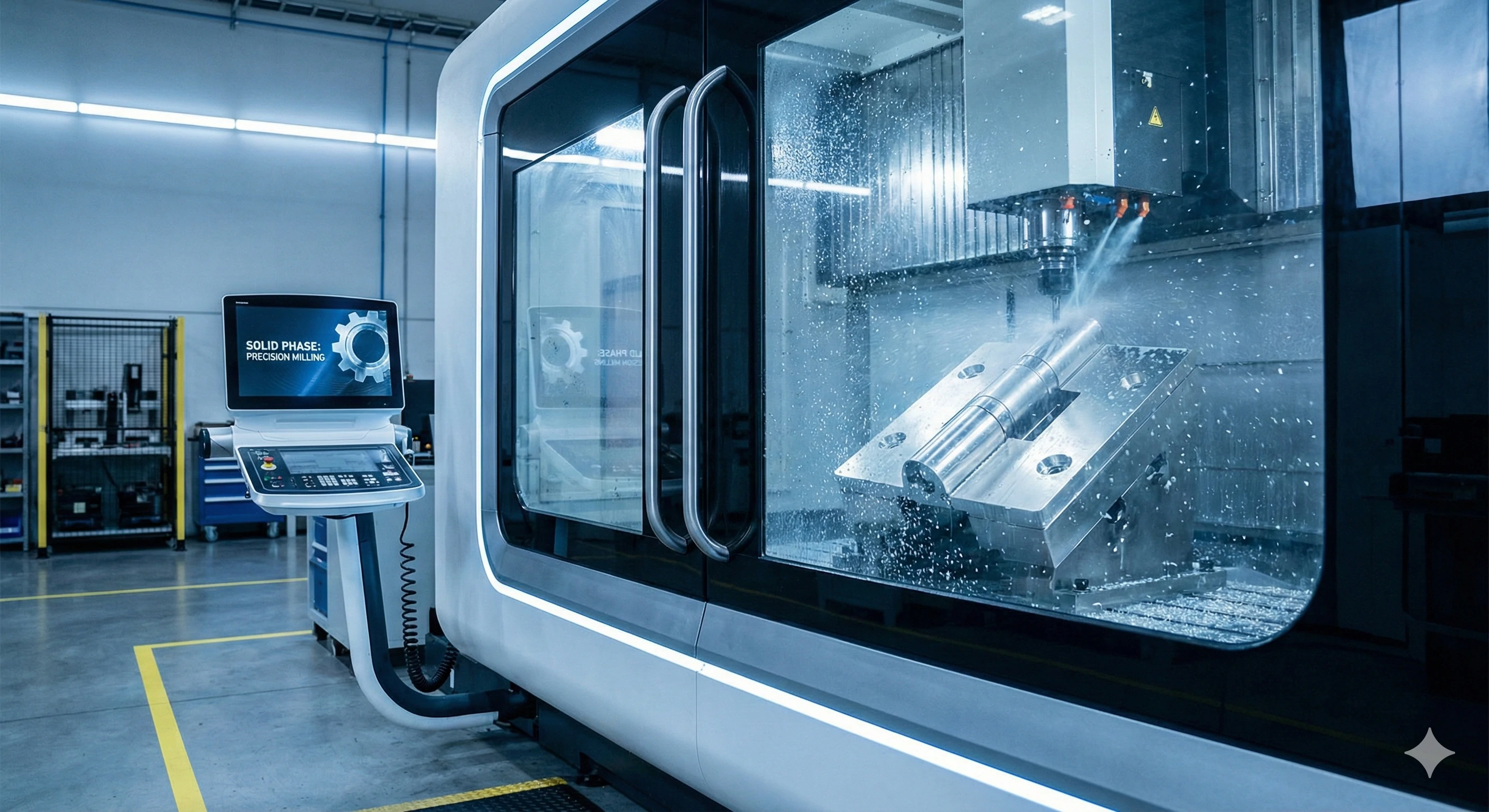

Once the metal has cooled and the heavy lifting of the foundry is complete, the nature of the work changes. When we move parts to our finishing floors, the environment becomes cleaner, quieter, and more controlled. This is where most people feel comfortable because it resembles the standard image of "manufacturing." Here, we are no longer dealing with chemistry and phase changes; we are dealing with physics and mechanics.

A factory is a general term for an industrial site where goods are fabricated, processed, or assembled. Unlike foundries that deal with molten metal, general factories focus on cutting, machining, and joining solid materials to produce finished consumer goods ready for distribution.

If the foundry is the "Liquid Phase," the factory operates in the "Solid Phase." In this stage, the material stays solid throughout the process. We are simply changing its form or combining it with other parts. This distinction is critical because the risks and the required machinery are entirely different.

Fabrication and Machining

In the factory wing of our business, the primary actions are cutting, bending, and drilling. We use:

-

Fabrication: This involves taking sheet metal and bending it on a or cutting it with a laser.

-

Machining: We use machines to mill precise holes or turn threads into the metal.

-

Surface Finishing: This includes polishing, brushing, or powder coating the surface to make it look attractive.

The Role of Assembly

A factory is also where components come together. For example, a glass spigot isn't just a piece of steel. It needs rubber gaskets, a pressure plate, and screws. The factory environment is where we assemble these diverse components into a single, sellable unit.

Table: Factory Processes vs. Foundry Processes

| Feature | Foundry Process | Factory Process |

|---|---|---|

| State of Matter | Liquid to Solid (Phase Change) | Solid (Form Change) |

| Primary Action | Melting & Pouring | Cutting, Joining, Assembling |

| Key Risk | Chemical Composition, Porosity | Dimensional Tolerance, Assembly Errors |

| Temperature | Extreme Heat | Room Temperature / Controlled |

Why This Definitions Matters

If you tell a supplier you need a "factory," you might end up with a company that only does assembly and outsources the casting. If you find a "foundry," they might hand you a rough, unpolished part. Understanding that a factory typically handles cold processing helps you define your procurement scope.

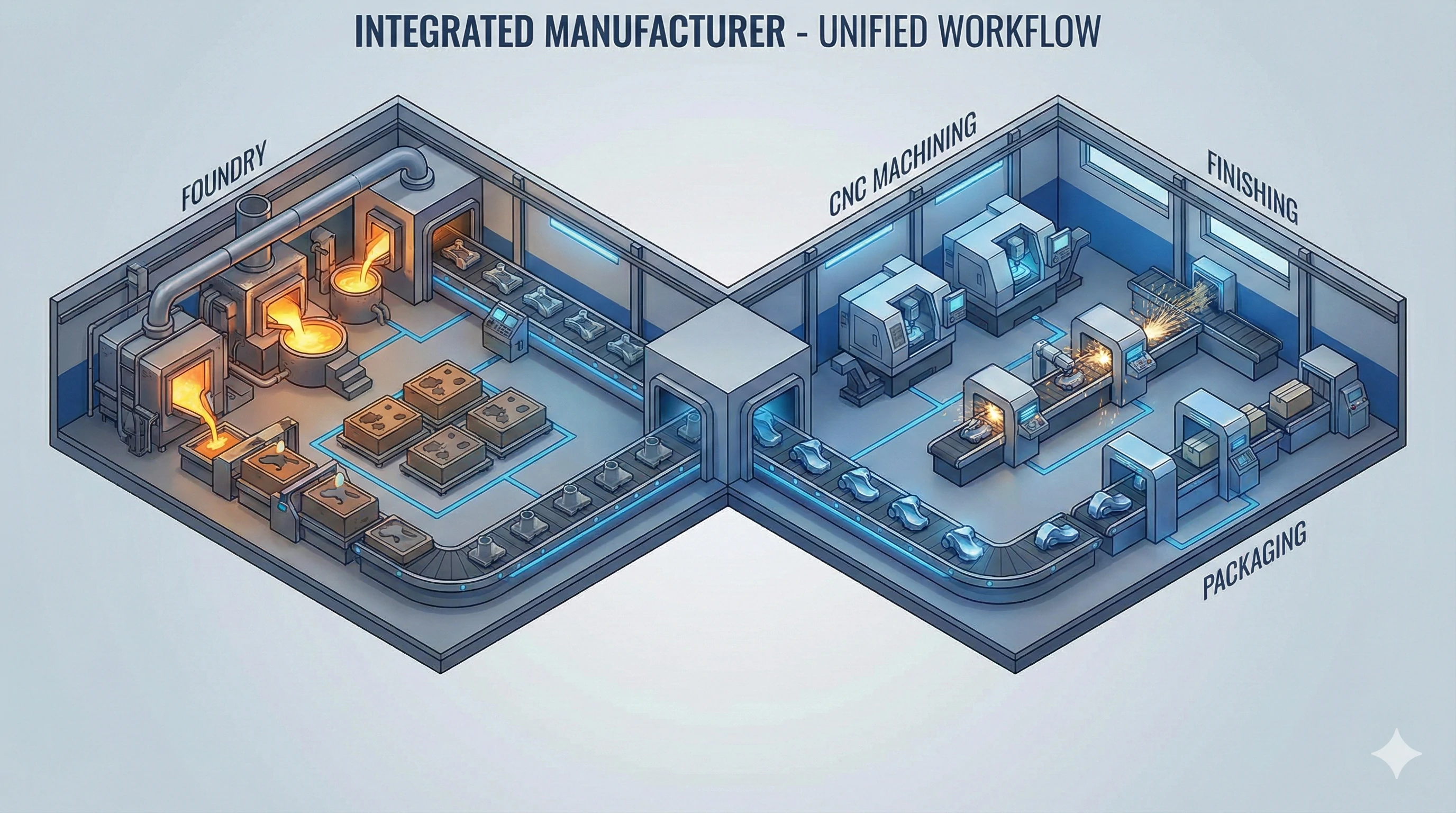

The Intersection: The "Integrated Manufacturer"?

Many of our clients prefer not to manage two separate suppliers—one for casting and one for finishing. That is why we integrated our operations. We realized early on that controlling the quality of the metal was just as important as the shine on the final product. By combining these roles, we eliminate the finger-pointing that often happens when a product fails.

An integrated manufacturer combines the capabilities of both a foundry and a finishing factory under one roof. This model allows for total quality control, taking products from raw molten metal through CNC machining and polishing to the final assembly without outsourcing critical steps.

This is the "Sweet Spot" for modern manufacturing, especially in the architectural hardware industry. Being an integrated manufacturer means we operate two distinct wings that function as one organism.

The Integrated Workflow

-

Foundry Wing: We start by casting the raw stainless steel bodies using the . We ensure the chemical composition (like the Nickel and Chromium content in stainless steel) is perfect.

-

Transition: The rough castings are moved internally—no shipping delays, no third-party handling.

-

Factory Wing: We take those raw castings and load them into our CNC centers. We drill the holes, polish the surface to a mirror finish, and install the rubber gaskets.

The Risk of Non-Integrated Suppliers

If you buy from a factory that isn't a foundry, they are essentially a "middleman" for the raw material. They cannot guarantee what is inside the metal because they didn't melt it. Conversely, if you buy from a foundry that isn't a factory, you will likely receive a product that functions but looks unfinished.

The Buyer's Advantage

For a procurement manager, working with an integrated partner reduces lead times and centralizes accountability. If there is a bubble in the metal (porosity), we catch it before it ever reaches the polishing wheel. We don't have to wait for a supplier to send a replacement; we just melt it down and cast it again.

Why the Distinction Matters for Quality Control?

We advise our procurement partners to ask specific questions during audits. Knowing the difference helps you identify where defects originate and how to fix them. When we troubleshoot a product issue, the first thing we ask is: "Is this a casting error or a machining error?" The answer tells us exactly which part of the facility needs adjustment.

The distinction is crucial for quality control because defects differ by facility type. Foundry defects include porosity and chemical inconsistencies, requiring spectrometer testing. Factory defects involve dimensional errors or poor finishing, requiring calipers and visual inspection. identifying the source ensures the correct fix.

Understanding the source of defects is the most practical skill you can have when importing hardware. The tools and methods we use to check quality in the foundry are completely different from those we use in the factory.

Foundry Defects: The Invisible Threats

Defects from the foundry are often internal.

-

Porosity: Tiny air bubbles trapped inside the metal. You might not see them until the part breaks.

-

Shrinkage: As metal cools, it shrinks. If not calculated correctly, the part will be deformed.

-

Chemical Composition: If the mixture in the furnace wasn't right, the steel might rust, even if it looks shiny.

To catch these, we use to read the chemical makeup and purely mechanical stress tests.

Factory Defects: The Visible Issues

Defects from the factory side are usually external and dimensional.

-

Tolerances: The hole was drilled 1mm too far to the left.

-

Surface Finish: There are scratches from the polishing wheel.

-

Assembly: The screw is loose or the gasket is missing.

To catch these, we use Calipers, , and strict visual inspection protocols.

Table: Defect Origins and Solutions

| Defect Type | Origin | Detection Tool | Solution |

|---|---|---|---|

| Internal Void/Porosity | Foundry (Melting) | X-Ray / Destructive Test | Adjust pouring temperature/venting |

| Rust / Corrosion | Foundry (Chemistry) | Spectrometer | Adjust alloy mix in furnace |

| Wrong Dimensions | Factory (Machining) | Calipers / CMM | Re-calibrate CNC machine |

| Surface Scratches | Factory (Finishing) | Visual Inspection | Improve polishing process |

Summary Comparison Table?

To wrap this up, let's look at the big picture. We believe transparency is the key to a good supplier relationship. By laying out these differences clearly, we hope to help you make better sourcing decisions. Whether you are looking for raw castings or shelf-ready products, knowing the terminology gives you the upper hand in .

To summarize the key differences, foundries process raw inputs like scrap metal using extreme heat to create shapes. General factories process semi-finished materials using mechanical force to create final products. Understanding this helps streamline your supply chain and quality expectations.

Below is the master comparison table. This is a quick reference guide you can use when evaluating potential suppliers in China or elsewhere.

Detailed Comparison Guide

We have found that keeping this distinction clear prevents "square peg in a round hole" situations. You wouldn't ask a bakery to butcher a cow, and you shouldn't ask a pure assembly factory to cast metal.

Table: The Master Comparison

| Feature | Foundry | Factory |

|---|---|---|

| Primary Input | Scrap Metal, Ingots, Alloys | Raw Material Sheets, Bars, Parts |

| Core Transformation | Phase Change (Solid $\rightarrow$ Liquid $\rightarrow$ Solid) | Form Change (Cutting, Bending) |

| Key Equipment | Furnaces, Ladles, Molds | CNC Machines, Lasers, Assembly Lines |

| Working Environment | Hot, Industrial, "Dirty" | Controlled, precise, "Clean" |

| Typical Output | Rough Castings (Semi-finished) | Finished Consumer Goods |

| Quality Focus | Chemistry & Internal Structure | Dimensions & Aesthetics |

| Safety Risks | Molten Metal Burns, Heat Stress | Mechanical Cuts, Crush Injuries |

Making the Right Choice

If your product requires a custom shape made from a specific alloy (like a stainless steel faucet or a glass railing spigot), you need a Foundry. However, if you need that product to be polished, threaded, and packaged in a nice box, you need a Factory.

Ideally, you need a partner who is both.

Conclusion

In the world of manufacturing, terms matter. While all foundries fall under the umbrella of factories, not all factories have the specialized capability to operate as foundries. For products like architectural hardware, quality starts in the foundry with the metal itself and is perfected in the factory with the finish.

We hope this guide clarifies the landscape of our industry. When you are sourcing your next batch of products, ensure your hardware is built right from the melt to the mirror finish. Partner with a supplier that understands the science of the foundry and the precision of the factory.

Footnotes

1. Definition and detailed components of a supply chain network.

2. Technical overview of induction furnace operation and applications.

3. Material properties and applications of Duplex 2205 stainless steel.

4. USGS statistics and information on iron ore production.

5. Introduction to press brake machinery for metal fabrication.

6. Guide to understanding Computer Numerical Control (CNC) machining.

7. Historical and technical explanation of the lost-wax casting process.

8. Principles of optical emission spectrometry for chemical analysis.

9. Best practices for using Go/No-Go gauges in inspection.