At our production facility, we frequently analyze returned hardware to understand why it failed in the field. We know that the shower environment—hot, wet, and soapy—is brutally harsh on metals. You step into the shower, reach for the knob, and suddenly it spins loosely or cuts your hand with peeling chrome. It is a frustrating way to start the day, but identifying the root cause is the first step toward a permanent solution.

The four most common shower knob problems are stripped splines causing the handle to spin, mineral buildup freezing the mechanism, plating failure leading to sharp peeling finishes, and loose set screws causing the knob to fall off. These issues primarily stem from using low-quality zinc materials instead of solid stainless steel.

Let’s examine these failures in detail so you can decide whether to repair the part or upgrade to a better material.

Problem 1: The "Spinner" (Knob Spins but No Water)?

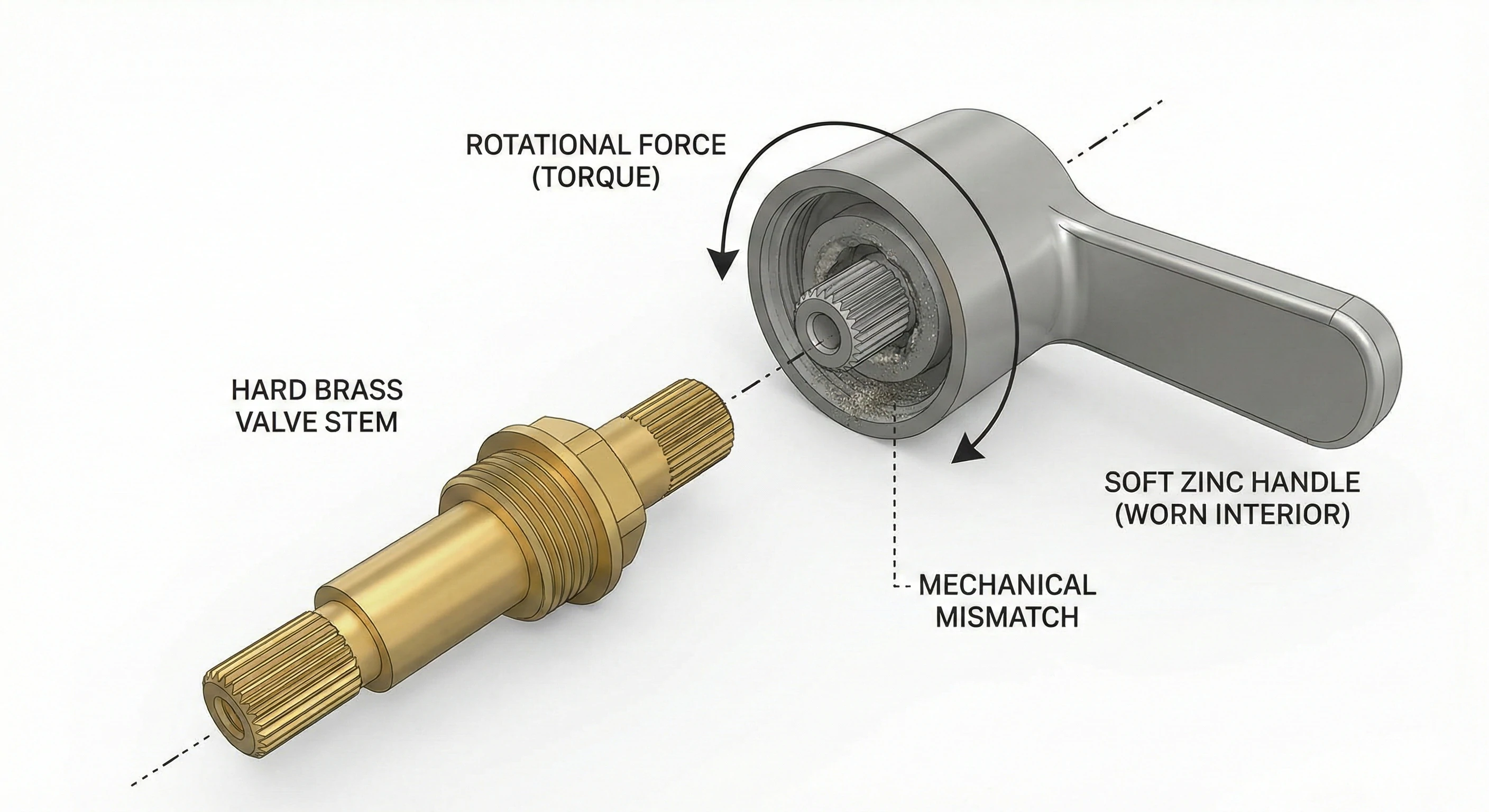

When we design the internal splines for our handles, we calculate the precise torque needed to turn a valve, but cheaper materials often cannot withstand this force. You might turn the handle hoping for a hot shower, but the water doesn't turn on because the handle feels loose and completely disconnected from the wall.

A spinning shower knob typically indicates stripped splines inside the handle. This occurs when soft zinc or plastic teeth wear down against the harder brass valve stem, resulting in a loss of grip. The only permanent solution is replacing the handle with a harder material like solid stainless steel.

The mechanics of this failure are simple but annoying. Inside the knob, there are small teeth, known as , which are designed to grip the valve stem. If the knob is manufactured from soft zinc or plastic, these teeth are significantly softer than the brass valve stem they connect to. Over time, the harder brass wears down the softer zinc until the inside of the handle becomes completely smooth.

Why Soft Metal Fails

We have observed that 90% of failures are due to material quality. Once the teeth are stripped, you cannot repair them. No amount of glue or tightening will restore the grip because the physical structure of the connection is gone.

The Stainless Steel Solution

The upgrade we recommend to our clients is solid stainless steel. Stainless steel is harder than the brass valving, meaning the teeth will never strip. This ensures that when you turn the handle, the valve actually opens.

| Feature | Zinc/Plastic Handle | Solid Stainless Steel Handle |

|---|---|---|

| Material Hardness | Soft, wears down easily | Hard, durable |

| Spline Lifespan | 1-3 Years | Lifetime |

| Failure Mode | Strips and spins | Does not strip |

| Repairable? | No, must replace | N/A (Rarely fails) |

Problem 2: The "Frozen" Handle (Hard to Turn)?

In our testing labs, we simulate years of water exposure to see how mineral deposits affect moving parts. A "frozen" handle is a serious issue because you need two hands and a lot of force just to turn the water on, which risks breaking the plumbing inside the wall.

A frozen shower handle is usually caused by mineral buildup (scale) from hard water or corrosion fusing the metal handle to the valve stem. While soaking the assembly in white vinegar can dissolve calcium deposits, force should never be applied, as it may snap the internal valve stem.

Hard water contains dissolved minerals like calcium and magnesium. As water dries on your fixtures, it leaves these minerals behind. Over time, act like glue, cementing the handle to the valve.

The Corrosion Factor

If the handle is made of cheap metal, it might have actually rusted onto the valve stem. This is different from mineral buildup; it is a chemical bond caused by oxidation.

Safe Removal Techniques

We cannot stress this enough: Don't force it. Applying excessive torque can snap the valve stem, turning a $20 handle replacement into an expensive plumbing bill involving a plumber and open walls.

How to Fix It safely

-

Soak it: Use white vinegar to dissolve the calcium.

-

Wait: Let it sit for at least 15 minutes.

-

Lubricate: If it is stuck, spray (like WD-40) into the set screw hole.

| Symptom | Cause | Solution |

|---|---|---|

| White crusty buildup | Calcium deposits | Vinegar soak |

| Red/Brown rust | Corrosion | Penetrating oil |

| Handle won't budge | Fused metal | Do not force |

Problem 3: The "Razor Blade" (Peeling Finish)?

Our quality control team pays close attention to plating thickness because we know the dangers of a failed finish. The symptom is unmistakable: the chrome coating bubbles up, flakes off, and becomes razor-sharp, capable of cutting your hand during use.

Peeling finishes occur when moisture penetrates the chrome plating on cheap zinc die-cast knobs, causing the underlying metal to corrode and expand. This "white rust" pushes the plating off, creating razor-sharp edges. The solution is switching to polished stainless steel, which has no plating to peel.

Most stock knobs found in big-box stores are Zinc Die Castings plated with Chrome. While they look shiny when new, they are structurally flawed for wet environments.

The Science of Plating Failure

Plating is like a shell. Over time, microscopic cracks allow water to get under the plating. This causes the zinc underneath to corrode, forming "" (zinc oxide). As the rust expands, it pushes the chrome layer outward, causing it to flake off.

The Polished Advantage

When we manufacture high-end hardware, we often use (304 or 316). There is no coating to peel because the shine comes from the metal itself. If it gets scratched, it is still stainless steel underneath, not a corroding base metal.

Material Comparison

| Material | Finish Method | Risk of Peeling |

|---|---|---|

| Zinc Die Cast | High (1-2 years) | |

| Plastic | Painted/Coated | Medium (looks cheap) |

| Stainless Steel | Polished Metal | Zero (No plating) |

Problem 4: The "Phantom" (Knob Falls Off)?

We ensure every unit we ship has properly threaded fasteners, but vibration is a constant enemy in mechanical systems. The symptom here is sudden and loud: the knob comes loose in your hand or simply falls to the floor while you are showering.

When a shower knob falls off, the culprit is almost always a loose or missing set screw (grub screw). Vibrations from daily use or corrosion can cause this fastener to back out. Tightening it with an Allen key and applying blue thread-locking fluid prevents recurrence.

The handle is held onto the valve stem by a tiny grub screw (also called a ) located on the underside of the knob. It is a small part with a big job.

Why It Happens

Daily use creates vibration. Over months of turning the water on and off, this tiny screw can vibrate loose. In some cases, if the screw is not stainless steel, it may rust away entirely.

The Two-Step Fix

Repairing this is simple, but you must do it correctly to prevent it from happening again next week.

-

Tighten: Use an Allen key to tighten the screw. Ensure it is aligned with the flat spot or groove on the valve stem.

-

Secure: We recommend using a drop of "Blue Loctite" (thread locker) on the screw threads. This hardens into a gum-like substance that absorbs vibration and keeps the screw secure.

Troubleshooting the Set Screw

| Issue | Solution |

|---|---|

| Screw spins but won't tighten | Thread is stripped; need new screw |

| Screw is missing | Replace with stainless set screw |

| Screw loosens repeatedly | Apply Blue Loctite |

Why "Universal" Replacement Knobs Are a Bad Idea?

Our engineers often advise against "one-size-fits-all" solutions because precision matters in plumbing. "Universal" kits attempt to solve the problem with complex clamp systems, but in our experience, they rarely fit perfectly and often wobble.

Universal replacement knobs often rely on complex clamp systems or plastic adapters that rarely fit specific valve stems perfectly. This results in a wobbly, unstable handle that feels cheap and wears out quickly. OEM-style investment cast knobs provide a precise, secure fit for long-term reliability.

When you buy a universal kit, you are paying for a bag of plastic adapters, most of which you will throw away. These adapters use a vice-grip style mechanism to grab onto the valve stem.

The Stability Issue

Because universal knobs rely on friction clamps rather than interlocking teeth, they tend to loosen over time. The handle may feel "mushy" or wobble when you turn it. This detracts from the feeling of quality in your bathroom.

The Manufacturing Difference

We utilize to create knobs with precise splines. This manufacturing process allows us to create heavy, solid-feeling handles that lock directly onto the valve stem without adapters. This provides a luxury touch that universal plastic parts simply cannot match.

Universal vs. Dedicated Fit

| Feature | Universal Kit | OEM-Style Investment Cast |

|---|---|---|

| Fitment | Adapters/Clamps | Direct Spline Match |

| Stability | Wobbly/Loose | Solid/Tight |

| Installation | Complex | Simple (1 screw) |

| Feel | Lightweight/Cheap | Heavy/Luxury |

The Material Difference: Zinc vs. Stainless Steel?

We believe that educating our clients on material science is the best way to ensure satisfaction. Our data shows that while is cheaper upfront ($), it fails quickly. Stainless steel ($$$) is an investment that pays off in longevity and performance.

The material difference lies in durability and longevity. Zinc die-cast knobs are lightweight and prone to pitting and peeling within two years. In contrast, investment-cast stainless steel (304/316) is solid, heavy, and naturally corrosion-resistant, making it the ideal choice for hotels and high-end homes.

This is the most critical decision you will make when repairing your shower. The market is flooded with cheap options, but they are designed to be disposable.

Zinc Die Cast: The "Budget" Trap

Zinc is light and easy to mold, which makes it cheap to manufacture. However, it is chemically reactive. Once the plating is breached, the handle is on a countdown to failure. It will peel, corrode, and eventually strip.

Stainless Steel: The "Forever" Fix

Investment cast stainless steel is dense and heavy. When you hold it, you can feel the quality. It never rusts and never peels because there is no plating to fail. For hotels and high-end homes, this is the only logical choice to avoid constant maintenance calls.

Final Material Comparison

| Attribute | Zinc Die Cast | Brass | Stainless Steel (Investment Cast) |

|---|---|---|---|

| Cost | Low ($) | High ($$$) | Premium ($$$) |

| Weight | Light | Heavy | Heavy |

| Corrosion | High Risk | Low Risk | No Risk |

| Best For | Rentals/Flips | Traditional Homes | Modern/High-End Projects |

Conclusion

Most shower knob problems—whether they are spinning, sticking, or peeling—are caused by cheap materials degrading in a wet environment. Don't let a $20 part ruin your morning routine.

By understanding the root causes, you can stop wasting money on temporary fixes. If you are tired of replacing cheap shower handles, consider upgrading to our Series-S Solid Stainless Steel Shower Knobs. They are investment cast for durability and polished to a mirror finish that lasts forever.

Footnotes

1. Explanation of mechanical splines and their role in torque transmission.

2. How hard water minerals create limescale deposits on fixtures.

3. Guide to using low-viscosity oils to loosen rusted parts.

4. Definition of white rust and zinc corrosion processes.

5. Properties and benefits of stainless steel in construction.

6. Common defects and causes in decorative chromium plating.

7. Technical definition and function of set screws in engineering.

8. How anaerobic adhesives prevent fastener loosening from vibration.

9. Overview of the investment casting process and its precision.