In the casting manufacturing chain, surface treatment serves as the "finishing touch" – not only enhancing the appearance and texture of castings, but also directly improving their core performance characteristics like corrosion resistance, wear resistance, and sealing properties. It even determines whether a casting can meet specific application requirements. While many people associate surface treatment with "painting for rust prevention," they often overlook the distinct value of different processes: "What's the difference between sandblasting and shot blasting?" "Is anodizing only suitable for aluminum alloys?" "What challenges can coating treatments address in castings?" Today, we'll focus on six core surface treatment processes for castings, breaking down each technique's purpose, principles, and application scenarios in plain language to help you understand "how to choose the right surface treatment solution for your castings."

1. Sand Blasting: Polishing castings to achieve a uniform rough surface

Sandblasting is the "entry-level process" of casting surface treatment. Its core role is to remove surface oxide scale and burrs, and form a uniform rough surface, laying a foundation for subsequent painting and bonding. It is equivalent to a "fine skin" for casting.

technical principle

By utilizing compressed air to propel abrasive materials (such as quartz sand, diamond sand, or alumina sand) at high velocity onto the casting surface, this surface treatment process achieves its effects through impact and grinding action. When abrasive particles strike the casting surface, they remove oxide scales, burrs, and other protrusions while leaving fine indentations that create a uniform roughness. The surface texture can be precisely controlled by adjusting the abrasive particle size (80 mesh to 320 mesh) and spray pressure (0.3-0.8MPa).

key role

- Eliminate surface defects and enhance visual consistency: Castings often exhibit sand holes, flash, and oxidation stains. Sandblasting effectively removes these imperfections, achieving uniform surface color and texture. For instance, cast iron pipe fittings that previously showed red rust and black spots before sandblasting now feature a uniform grayish-white matte finish, significantly improving their appearance and quality.

- Enhancing surface roughness improves coating adhesion: Excessively smooth cast surfaces hinder coating adhesion. The micro-textured surface created by sandblasting enables mechanical interlocking between the coating and substrate. For example, sandblasted aluminum alloy wheel hubs exhibit 40% better paint adhesion than unblasted counterparts, with reduced risks of paint peeling and blistering.

- Eliminating deep cavities and tackling manual grinding challenges: For castings with deep holes and narrow slots (such as oil passages in engine blocks), where manual grinding can't reach, sandblasting delivers precision. By adjusting nozzle angles, abrasive particles penetrate even the most inaccessible corners, effectively removing residual sand and burrs. For example, hydraulic valve block castings achieve 99% impurity removal in deep holes post-sandblasting, significantly reducing oil passage blockage risks.

applicable scene

Castings with surface oxide scale or burrs (such as carbon steel, cast iron, and stainless steel castings); castings requiring subsequent painting, spraying, or bonding; and castings with complex shapes that are difficult to polish manually.

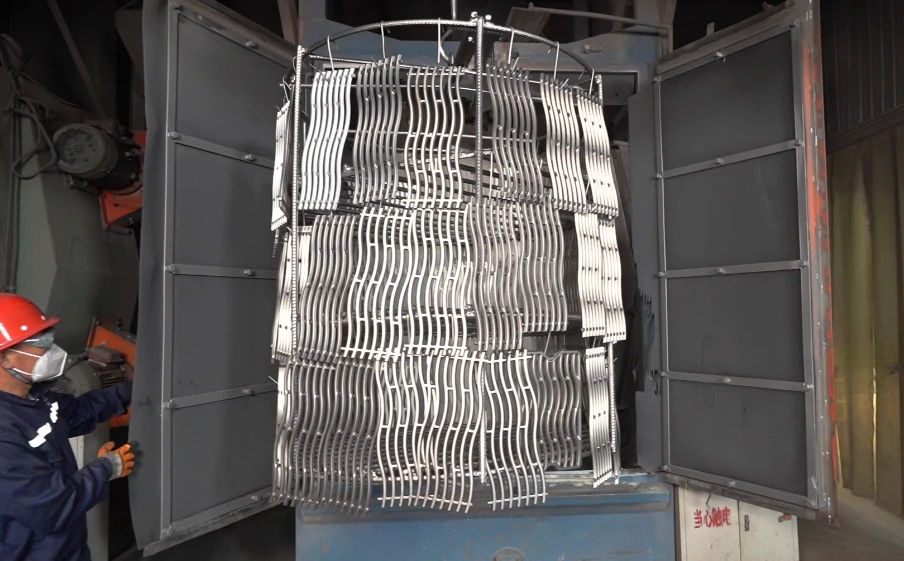

2. Shot Blasting: Enhancing Castings with Dual Benefits of Cleaning and Surface Reinforcement

The principle of shot blasting is similar to that of sandblasting, but it focuses more on the surface cleaning and surface strengthening of mass castings. Through the impact of high-speed steel balls, impurities can be removed and the surface hardness and fatigue strength of castings can be improved, which is equivalent to "strengthening fitness" for castings.

technical principle

The high-speed rotating impeller (1500-3000r/min) of the shot blasting machine is used to throw steel balls (0.2-2mmin diameter) to the surface of the casting. The kinetic energy of the steel balls is converted into impact force to achieve surface treatment. Compared with sand blasting, the impact energy of shot blasting is greater, the treatment efficiency is higher, and the steel balls can be recycled and reused.

key role

- Efficient batch cleaning and reduced production costs: The shot blasting machine can realize automatic continuous operation, and the processing efficiency is 3-5 times that of sand blasting. For example, the shot blasting machine can process 500 parts per hour for the cast spring steel plate of automobile chassis in batch production, while manual sand blasting can only process 100 parts, greatly reducing labor costs.

- Surface Strengthening for Enhanced Fatigue Life: Shot blasting creates a "cold work hardened layer" (depth 0.1-0.3mm) on cast surfaces, increasing surface hardness by 10%-20% while introducing residual compressive stress to suppress fatigue cracks. For example, shot-blasted crawler plate castings for construction machinery extended their fatigue life from 5,000 hours to 8,000 hours, significantly reducing fracture risks.

- Removal of internal stress and stabilization of casting size: The impact of shot blasting can partially release the residual stress in the casting, which is especially suitable for thin-walled castings that are prone to deformation after casting, such as aluminum alloy motor end cover castings. The dimensional stability of shot blasting is improved by 30%, and the dimensional deviation rate of subsequent machining is reduced from 15% to 5%.

applicable scene

Small and medium-sized castings (such as auto parts, agricultural machinery parts) for mass production; force castings (such as springs, gears, track plates) that need surface strengthening; thin-walled castings that need to remove residual stress after casting.

3. Painting/Coating: Giving castings a protective outer layer for enhanced durability and aesthetic appeal

Painting is the most common surface protection process. Its core role is to form an organic coating on the surface of the casting to isolate air, moisture and corrosive media, while beautifying the appearance. Different types of coatings can be selected according to the needs, which is equivalent to "customizing the outer clothing" for the casting.

technical principle

Through methods such as spraying, brushing, or dip coating, coatings (e.g., epoxy resin paint, polyurethane paint, acrylic paint) are evenly applied to the surface of castings. After drying or curing, they form a continuous coating with a thickness of 20-100 μm. Different coatings have distinct curing methods: solvent-based coatings cure through solvent evaporation, water-based coatings through moisture evaporation, while powder coatings require high-temperature baking.

key role

- Long-term rust prevention and adaptation to complex environments: The coating can physically isolate the corrosion medium, and the rust prevention performance of different coatings is quite different. For example, the cast steel structure used outdoors can be coated with polyurethane surface paint, and the salt spray resistance can reach more than 1000 hours. It can be used for more than 10 years without rust in the humid and salty coastal environment.

- Enhance appearance and customize colors: Paint can be mixed in any color according to demand, and different textures such as matte, high gloss and texture can be achieved. For example, household cast iron radiator can be made into white, gray and other colors through electrostatic powder spraying, which is compatible with the home style and gets rid of the "industrial feel" of traditional cast iron.

- Protect the surface and resist physical damage: The coating can form a "buffer layer" on the surface of the casting to reduce the damage of collision and friction to the substrate. For example, the cast iron shell of the tool box will only damage the coating after painting, even if it is slightly impacted, and will not directly cause deformation or corrosion of the substrate.

applicable scene

Outdoor castings (such as street light poles and billboard supports); civil castings with appearance requirements (such as radiators and furniture accessories); castings that need to be anti-rust but do not require high temperature or strong corrosion.

4. Anodizing: Creating Tailored Protective Films for Aluminum Alloy Castings

Anodic oxidation is a special surface treatment process for aluminum alloy castings. Its core role is to form a dense oxide film on the surface, which greatly improves corrosion resistance and hardness, and can achieve color and beauty. It is a "performance and appearance upgrade" solution for aluminum alloy castings.

technical principle

The aluminum alloy casting is used as the anode and immersed in electrolyte solutions such as sulfuric acid or oxalic acid. When a direct current (10-20V) is applied, an Al₂O₃ oxide film forms on the casting surface through electrolysis. During this process, the aluminum alloy at the anode loses electrons to form Al³⁺ ions, which combine with O²⁻ ions from the electrolyte to create the oxide film. The film thickness typically ranges from 5-20 μm and can be adjusted by modifying the electrolysis duration. The porous oxide film can also undergo dyeing treatment for enhanced functionality.

key role

- Addressing the 'oxidation-prone' issue of aluminum alloys: The oxide layer on natural aluminum alloy surfaces tends to loosen and flake off, whereas the oxide layer formed through anodizing is dense and hard, enhancing corrosion resistance by 10-20 times. For example, the aluminum alloy frame of a smartphone, when anodized and stored at room temperature, never develops white spots or blackening, and remains resistant to sweat corrosion, maintaining its appearance even after long-term use.

- Enhanced surface hardness and scratch resistance: The oxide film achieves a hardness of HV300-500, far surpassing aluminum alloy substrates (HV60-120). For example, an anodized aluminum laptop case resists nail scratches and daily wear, maintaining pristine condition for a year, while untreated counterparts develop visible scratches within a month.

- Colorful coloring and rich appearance selection: the porous structure of oxide film can absorb dyes to achieve black, red, blue and other colors. For example, the outdoor aluminum alloy lamp shell can be made into a variety of bright colors through anodized oxide coloring, and the color is resistant to ultraviolet radiation and does not fade for long-term outdoor use.

applicable scene

Aluminum alloy castings (such as electronic equipment shells, lamp accessories, aerospace parts); aluminum alloy products with comprehensive requirements for corrosion resistance, hardness and appearance.

5. Electroplating: Applying a metallic coating to castings to enhance functionality and surface quality

Electroplating is a process of depositing metal coating on the surface of castings through electrolysis. Its core function is to improve the corrosion resistance, conductivity or appearance texture of castings. Common coatings include chromium plating, zinc plating, nickel plating, etc., which is equivalent to wearing a "metal coat" on castings.

technical principle

When casting serves as the cathode and target metals (such as chromium, zinc, or nickel) act as anodes, the assembly is immersed in an electrolyte containing the corresponding metal ions and subjected to direct current. The anode dissolves to form metal ions, which migrate toward the cathode under the electric field's influence, depositing as a coating on the casting surface with a thickness of 5-50 μm. The composition of the electrolyte and process parameters vary depending on the specific coating type.

key role

- Corrosion-resistant coatings for harsh environments: Zinc and nickel plating effectively block corrosive agents. For example, galvanized carbon steel fasteners can withstand salt spray for over 500 hours and remain rust-free for five years in industrial humid conditions. The nickel-plated layer also exhibits excellent resistance to acid and alkali corrosion, making it ideal for chemical equipment components.

- Decorative coatings elevate premium aesthetics: The chrome plating delivers mirror-like sheen, while the copper plating exhibits a reddish-brown hue, enhancing the castings' visual appeal. For instance, bathroom cast iron faucets gain a polished, durable finish with chromium plating, offering both rust resistance and decorative value. Similarly, brass instrument castings achieve a silvery-white finish with nickel plating, showcasing refined texture.

- Functional coatings meet specialized requirements: Silver plating enhances conductivity (ideal for electronic contacts), while gold plating improves corrosion resistance and conductivity (perfect for precision electronics). For example, silver-plated copper cast relay contacts achieve 30% conductivity improvement, ensuring stable signal transmission. Similarly, gold-plated precision castings for aerospace applications maintain performance stability in extreme environments.

applicable scene

Corrosion-resistant carbon steel and cast iron castings (such as fasteners and sanitary fittings); decorative castings with high-end appearance texture; functional coatings (conductive, high-temperature resistant) for electronic and aerospace castings.

6. Laser Surface Treatment: Precision Reinforcement for Castings – Targeted Performance Enhancement

Laser surface treatment is a "high-precision" surface strengthening process. Its core role is to modify the surface of castings locally by the high temperature energy of laser to improve the hardness, wear resistance or corrosion resistance of specific areas. It does not need overall treatment and is suitable for castings with high local performance requirements.

technical principle

High-energy-density laser beams (power density 10⁴-10⁶W/cm²) irradiate casting surfaces, rapidly heating the surface metal to its phase transition or melting temperature within microseconds to milliseconds. The material then solidifies instantly through self-cooling, achieving surface modification. Common laser surface treatments include laser quenching, laser cladding, and laser alloying.

key role

- Laser quenching enhances wear-resistant zones: For castings requiring localized wear resistance (e.g., gear tooth surfaces or machine tool guide rails), laser quenching precisely heats these areas to form a hardened layer (0.2-1mm depth), increasing hardness by 30%-50%. For example, automotive transmission gear castings achieve HRC55 hardness after laser quenching, compared to HRC25, with wear resistance improving 2-3 times while maintaining excellent toughness in the gear core.

- Laser cladding for wear or defect repair: For castings with wear or localized defects, laser cladding can deposit metal powders (e.g., nickel-based or cobalt-based alloys) onto the affected areas, achieving "repair and regeneration". For example, large roll castings can be restored to new part performance through laser cladding after surface wear, saving 80% of the cost compared to replacing new parts.

- Precise control to avoid overall performance impact: Laser treatment only acts on the extremely thin surface area and does not affect the internal structure and properties of the casting. For example, in the case of aluminum alloy blades for aero engines, laser strengthening of the blade edge improves the edge wear resistance, while the lightweight and toughness of the blade body are not affected.

applicable scene

Some castings (such as gears, guide rails, and hammers) need to be wear-resistant and impact-resistant; repair of worn or defective precious castings; aerospace and precision mechanical castings with high performance and precision requirements.

Conclusion

The essence of casting surface treatment lies in selecting the "most suitable" process combination based on material properties, application scenarios, and performance requirements. Sandblasting and shot blasting serve as the "basic pretreatment" to establish foundational preparation for subsequent processes. Coating, electroplating, and anodizing provide "comprehensive protection and aesthetic enhancement," adapting to diverse material types and visual specifications. Laser surface treatment delivers "precision reinforcement and repair," effectively addressing localized performance challenges.

Only by clearly understanding the core value of each casting process can we strike the perfect balance between cost, performance, and appearance, ensuring castings are not just "functional" but also "user-friendly, durable, and visually appealing". If you have questions about "surface treatment combinations for specific material castings" or "process selection for special scenarios", feel free to leave comments below! We'll keep sharing more practical knowledge on casting surface treatment.