Among the hardware accessories of doors, Door Latches are the "invisible guardians" that ensure the stability and safety of doors after closing. Unlike door locks with complex anti-theft structures, they achieve door locking through a simple and direct "plug-in engagement" method, preventing accidental shaking and opening of doors. They are widely used in indoor doors, cabinet doors, warehouse doors, industrial equipment doors and other scenarios. Door latches manufactured by casting technology, with advantages such as solid material, stable structure and wear resistance, have become the preferred choice for many scenarios. Today, we will popularize the practical value of casting door latches from four dimensions: core functions, advantages of casting materials, common types, and selection & installation, and show you the important role of this "small accessory".

Core Functions of Casting Door Latches: More Than "Locking", But Also "Guardians" of Door Stability

The essence of a door latch is to realize door locking through the "engagement between the movable plunger and the fixed lock catch", but its role is far more than "preventing the door from opening". Specifically, it can be decomposed into three core functions to meet the needs of different scenarios:

- Prevent accidental opening and ensure space safety: This is the most basic function of door latches. In indoor scenarios (such as bedroom doors and bathroom doors), inserting the latch after closing can prevent accidental opening caused by children pushing or pets, protecting indoor privacy and safety; in industrial scenarios (such as warehouse doors and equipment maintenance doors), latches can lock the door, avoiding door shaking or sudden opening due to air flow and equipment vibration, and preventing personnel from entering dangerous areas by mistake.

- Auxiliary sealing to improve door closing effect: For doors that require a certain degree of sealing (such as kitchen doors and storage room doors), door latches can tightly press the door panel against the door frame to reduce gaps. For example, after installing a latch on the kitchen door, it can prevent oil fumes from spreading to other areas through the door gap; the storage room door is locked by the latch, which can reduce the entry of humid air and protect the internal items from moisture.

- Share the pressure of door locks and extend the overall service life: On doors that are opened and closed frequently (such as store back doors and factory workshop doors), door locks are easily damaged due to long-term impact of opening and closing. After installing the door latch, you can insert the latch first when closing, then lock the door lock. This allows the latch to share part of the door weight and impact force, reducing the loss of the door lock and extending the overall service life of the door lock and door.

Why Choose Casting Door Latches? 4 Advantages Endowed by Casting Technology

There are many manufacturing processes for door latches, and casting technology (such as cast iron, cast steel, cast aluminum) enables door latches to have advantages that ordinary stamping and forging parts are difficult to match. This is also the reason why they are widely used in medium and heavy door scenarios:

- High material density, strong load-bearing and wear resistance: Castings are formed by pouring molten metal, with a dense internal structure and no obvious pores or gaps. Their load-bearing capacity is far higher than that of stamping parts. For example, the tensile strength of cast iron latches can reach 250-350MPa, which can withstand the long-term extrusion and pulling of the door without deformation; after surface polishing or electroplating, the wear resistance is improved, and it is not easy to get stuck when inserting and sliding. The service life can reach 10-15 years, which is 3-5 times that of ordinary iron sheet latches.

- Flexible structural design, suitable for complex scenarios: Casting technology can realize complex integrated structures, such as latch bases with reinforcing ribs, multi-position adjustable plungers, anti-drop buckles, etc. These structures can make door latches suitable for doors of different thicknesses (such as wooden doors and metal doors with a thickness of 30-80mm), or meet special needs (such as top-bottom latches that can be inserted in both directions, anti-theft latches with lock holes). However, stamping parts are limited by the process and it is difficult to realize complex structures.

- Good impact resistance, suitable for harsh environments: In industrial plants, warehouses and other scenarios, doors may be hit by handling equipment and goods. Casting door latches can resist impact with their solid materials. For example, when a cast steel latch is subjected to an impact force of 50N, the plunger will only have slight deformation, not break or get stuck; while plastic or thin iron sheet latches are easily damaged under the same impact, resulting in the door being unable to be locked.

- Controllable corrosion resistance, suitable for multiple environments: Choosing different casting materials according to the use scenario can achieve excellent corrosion resistance. For example, cast aluminum or galvanized cast iron latches are used in humid environments (such as bathroom doors and basement doors) to resist water vapor corrosion; stainless steel casting latches are used in outdoor scenarios (such as courtyard doors and fence doors) to resist rainwater and ultraviolet erosion, and will not rust after long-term use.

Common Types of Casting Door Latches: Choose the Right "Locking Scheme" According to Installation Method and Function

According to door type, installation position and functional requirements, casting door latches are mainly divided into the following common types, each with different applicable scenarios:

1.Ordinary Surface-mounted Latches: Easy to Install, Intuitive and Durable

Ordinary surface-mounted latches are the most traditional type. The overall structure is exposed and installed on the side of the door, consisting of a plunger, a base and a handle. Insertion and unlocking are realized by manually pushing and pulling the handle. The base of the casting surface-mounted latch is usually designed to be thickened, and is directly fixed on the door with screws. Installation does not require slotting on the door, and the operation is simple.

Applicable Scenarios: Doors with moderate thickness such as wooden doors, metal doors and warehouse doors; scenarios that require high installation convenience and do not pursue concealment (such as store back doors and workshop partition doors).

2.Top-bottom Latches: Upper and Lower Linkage, More Stable Locking

Top-bottom latches are composed of a main plunger and two upper and lower auxiliary plungers. They are installed inside the door (need to slot the edge of the door). By turning the handle or pressing the button, the upper and lower auxiliary plungers are driven to insert into the lock catches on the top and bottom of the door frame at the same time, realizing "upper and lower two-way locking". The linkage structure of casting top-bottom latches is mostly gear or connecting rod transmission, and the stable performance of casting materials can ensure smooth linkage and not easy to get stuck.

Applicable Scenarios: Tall and heavy doors (such as factory doors and courtyard gates with a height ≥2.5m); scenarios that require high locking stability to prevent the door from shaking up and down.

3.Concealed Latches: Concealed and Beautiful, Without Damaging the Door Appearance

Concealed latches are integrally embedded inside the door, only exposing the handle or button. The latch structure cannot be seen from the appearance, which can keep the door neat and beautiful. The shell and plunger of casting concealed latches are integrally formed, and it is necessary to slot and reserve installation space in advance when making the door. The installation accuracy is relatively high, but the locking effect is equivalent to that of surface-mounted latches.

Applicable Scenarios: Indoor decorative doors (such as bedroom doors and study doors); scenarios that pursue a neat and unified door appearance and do not want hardware accessories to be exposed.

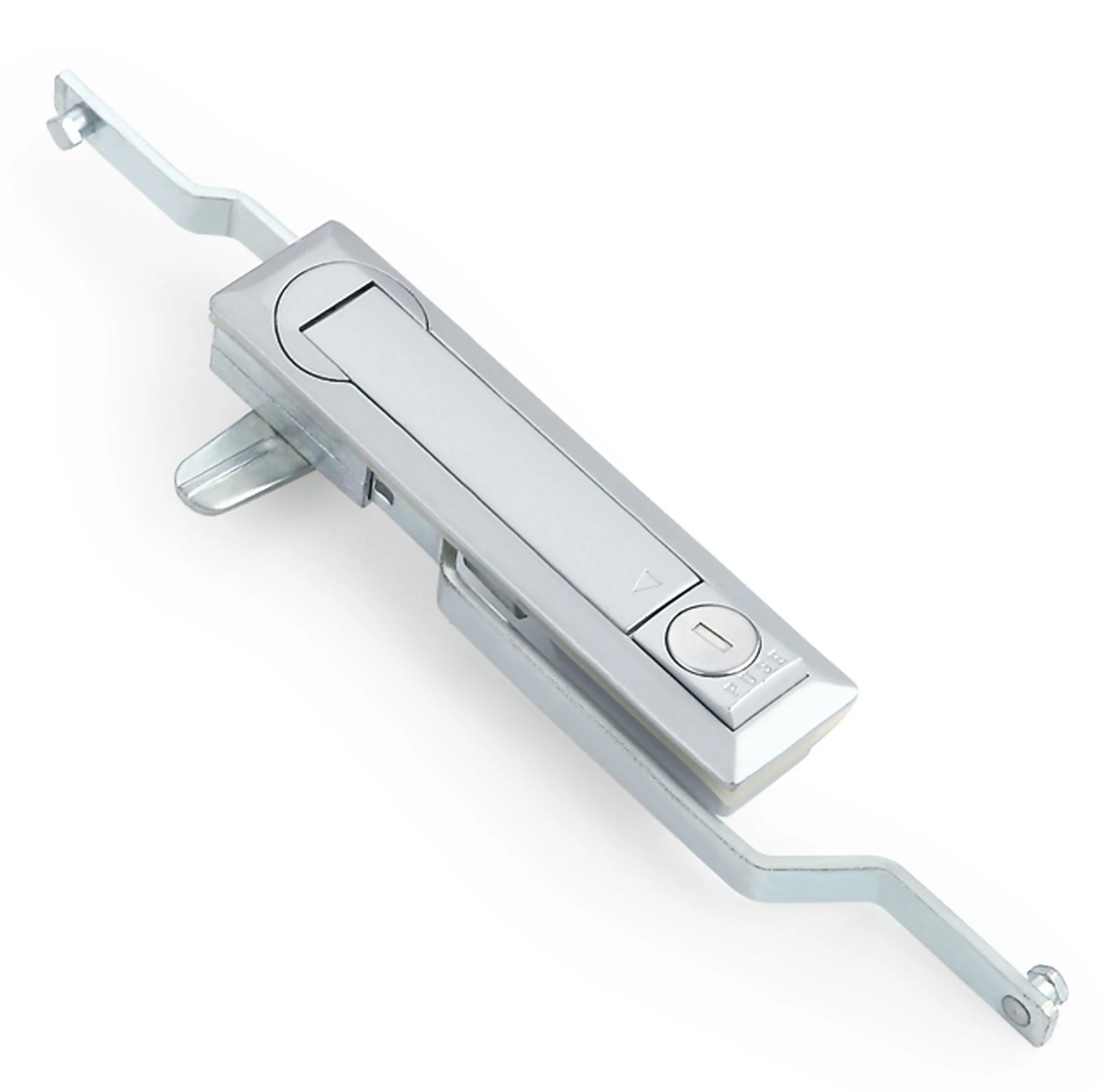

4.Latches with Locks: Dual-purpose, Both Locking and Anti-theft

Latches with locks add a lock cylinder structure on the basis of ordinary latches. After inserting the plunger, the position of the plunger can be locked with a key to prevent others from opening from the outside, which has both the stable function of latches and the anti-theft function of door locks. The connection between the lock cylinder and the plunger of the casting latch with lock adopts a thickened casting structure, which can resist violent prying and has higher safety.

Applicable Scenarios: Doors that require certain anti-theft performance (such as warehouse doors, garage doors, and store side doors); scenarios where the door needs to be locked when no one is watching to prevent items from being lost.

5.Industrial Heavy-duty Latches: Super Strong Load-bearing, Suitable for Large Doors

Industrial heavy-duty latches are made of cast steel or thick-walled cast iron. The diameter of the plunger can reach 10-20mm, and the base is a reinforcing rib structure. The load-bearing capacity of a single latch can reach 50-100kg, which can be suitable for super heavy doors such as large industrial doors, container doors and cold storage doors. Some heavy-duty latches are also equipped with manual or electric drive devices for easy opening and closing.

Applicable Scenarios: Super heavy doors such as industrial plant doors, large warehouse doors, cold storage doors, and container doors at ports and docks; special industrial scenarios that need to withstand large impact forces and gravity.

Selection and Installation of Casting Door Latches: 3 Key Points to Ensure Good Use and Durability

Choosing and installing casting door latches correctly can give full play to their role and avoid problems such as "latch loosening and inability to lock". The following three key points should be focused on:

1. Selection: Choose Materials and Determine Specifications According to Door Weight and Scenario

- Material matches the scenario: Cast iron or cast aluminum latches (cost-effective) can be selected for indoor dry scenarios; galvanized cast iron and stainless steel casting latches (corrosion and rust resistance) are selected for humid or outdoor scenarios; cast steel latches (super strong load-bearing) are selected for industrial heavy-duty doors.

- Specifications match door thickness: The length of the latch plunger should be 5-10mm longer than the door thickness to ensure that it can fully engage the lock catch after insertion. For example, for a wooden door with a thickness of 30mm, choose a latch with a plunger length of 35-40mm; for a metal door with a thickness of 80mm, choose a latch with a plunger length of 85-90mm.

- Structure pays attention to details: Check whether the plunger has an anti-drop design (such as an end buckle) to avoid the plunger falling off during use; whether the base has reinforcing ribs to improve load-bearing stability; whether the moving parts slide smoothly without jamming.

2. Installation: Accurate Positioning is the Key to Avoid "Misalignment and Inability to Insert"

- Surface-mounted latches: First determine the installation height (usually 1.2-1.5m from the ground, or adjust according to usage habits), mark the base position, fix the base with expansion screws or self-tapping screws (self-tapping screws for wooden doors, expansion screws for metal doors), then install the plunger and handle, and finally adjust the position of the lock catch on the door frame to ensure that the plunger can be inserted smoothly.

- Concealed/top-bottom latches: It is necessary to slot the door according to the size of the latch when making the door. The slot depth and width should match the latch shell. After installation, ensure that the latch is flush with the door surface without凸起 or凹陷; for top-bottom latches, it is necessary to specially calibrate the alignment between the upper and lower auxiliary plungers and the door frame lock catch to avoid the situation that "one side can be inserted and the other side cannot be inserted".

- Industrial heavy-duty latches: During installation, high-strength bolts should be used to fix the base to ensure that the base is closely attached to the door and door frame; if the door weight exceeds 50kg, it is recommended to match the door hinge to share the load, avoiding the latch from being deformed due to excessive force alone.

3. Daily Maintenance: Simple Maintenance to Extend Service Life

- Regularly wipe the dust and dirt on the latch surface with a dry cloth to avoid rust caused by oil and water vapor accumulation; in humid environments, a small amount of anti-rust oil (such as petroleum jelly) can be applied regularly to improve corrosion resistance.

- Check the engagement between the plunger and the lock catch. If there is jamming, drop 1-2 drops of lubricating oil (such as sewing machine oil) on the sliding part of the plunger to keep it sliding smoothly; if the engagement gap is too large, adjust the position of the lock catch in time to avoid the plunger loosening.

- When finding that the base screws of the latch are loose, they should be tightened in time to prevent the base from falling off and the door from being unable to be locked; for latches with locks, regularly check whether the lock cylinder rotates smoothly, and a small amount of graphite powder (instead of lubricating oil to avoid oil sticking to dust) can be injected to lubricate the lock cylinder.

Conclusion

Although casting door latches are not the most "eye-catching" accessories in doors, they have become an important part of ensuring door safety and stability due to their strong durability and flexible structure. Whether it is the privacy protection of indoor doors or the safety locking of industrial plant doors, choosing a suitable casting door latch can bring long-term convenience and peace of mind. When purchasing, there is no need to blindly pursue "high-end", just match the appropriate material and specification according to the door type, use scenario and functional requirements, and then cooperate with accurate installation and simple maintenance, so that this "small accessory" can play a big role.

If you encounter problems when purchasing or installing casting door latches (such as confusion in material selection, installation misalignment, etc.), please leave a message in the comment area, and we will provide you with targeted solutions!