When we receive drawings from our Australian clients, the tension is often palpable. Builders and architects are under immense pressure to meet strict safety codes, and one wrong measurement can lead to a failed inspection. At our factory, we have overhauled our production lines to specifically cater to these rigorous demands. We know that navigating the complex web of regulations is frustrating, especially when you just want to finish the project and get paid.

The Australian Standards for glass balustrades are primarily governed by AS 1288 (Glass in Buildings) and AS 1170 (Structural Design Actions). These codes mandate a minimum barrier height of 1000mm for falls over one meter, require the use of laminated safety glass, and strictly enforce the installation of interlinking top rails unless specific engineering-grade glass is used.

You don't need to read the entire to get it right. We have broken down the essential rules you need to know to ensure your hardware and glass specifications pass inspection the first time.

What Is the "Fall Prevention" Height Rule?

When we calibrate our cutting machines for export orders to Sydney or Melbourne, we adhere to a very specific set of dimensions that differ from our American or European projects. We understand that for you, a few millimeters is the difference between a compliant balcony and a costly tear-down. If you are worried about your surveyor pulling out their tape measure, you need to know the baseline numbers.

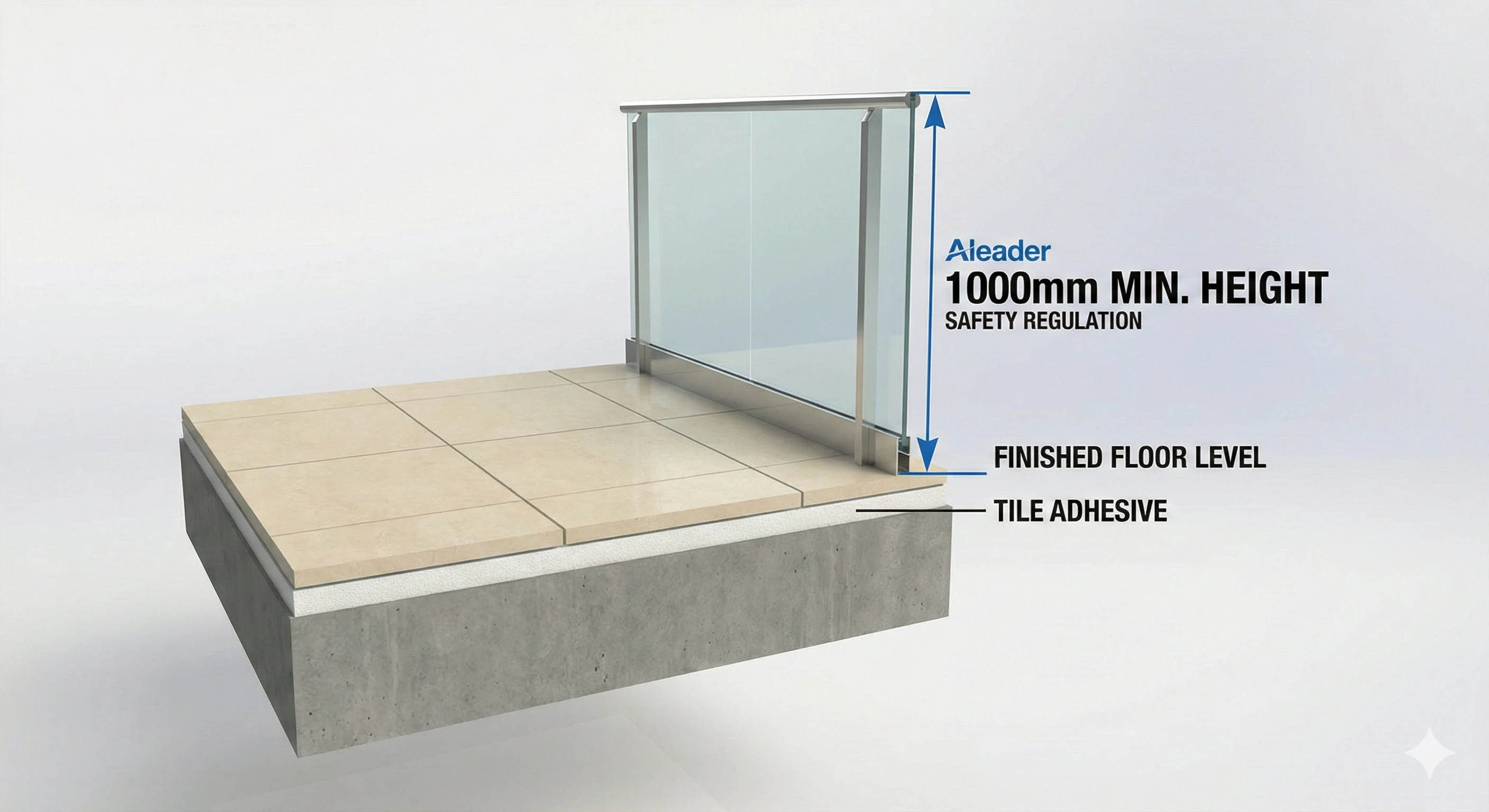

According to the National Construction Code (NCC), any balcony or deck where the floor is more than one meter (1000mm) above the ground requires a compliant barrier. This balustrade must be at least 1000mm high, measured from the finished floor level (FFL) to the top of the handrail.

Understanding the nuances of height requirements is vital for your project's success. The "1-meter rule" is the threshold that triggers the need for a barrier. If your deck is only 800mm off the grass, technically, you might not strictly need a balustrade under this specific code, though we always recommend one for safety.

However, once you cross that 1-meter fall height, the barrier becomes mandatory. The critical measurement here is "Finished Floor Level" (FFL). When we supply spigots or base shoes, we often ask our customers about their tiling or decking thickness. If you measure 1000mm from the concrete slab, but then add 20mm of tiles, your rail height drops to 980mm. This is an instant fail.

Comparing International Heights

It is interesting to note how Australia compares to other regions we supply. The US generally requires 42 inches (approx. 1067mm), while some European countries are lower. Australia sits in the middle for height but is stricter on load testing.

Here is a quick reference guide for height requirements based on location:

| Location Type | Minimum Height Requirement | Key Measurement Note |

|---|---|---|

| General Balcony / Deck | 1000mm (1 Meter) | Measured from Finished Floor Level (FFL). |

| Swimming Pool Fence | 1200mm | Measured from ground level on the outside. |

| Stairways | 865mm | Measured vertically from the stair nosing line. |

| Privacy Screens | 1700mm - 1800mm | Often required to prevent overlooking neighbors. |

When designing your system, always aim for 1020mm or 1050mm. This gives you a safety buffer during installation. It is much easier to shim a glass panel up slightly than to grind down a concrete floor.

Do You Really Need an Interlinking Top Rail?

Shipping containers full of top rails has become a standard part of our logistics since the 2021 updates to . We often hear customers complain that top rails ruin the "frameless" look they promised their clients. We feel your pain, as it complicates the design, but the safety logic behind it is undeniable. Ignoring this requirement is the fastest way to get your project rejected.

Under AS 1288:2021, an interlinking top rail is mandatory for all structural glass balustrades protecting a fall of one meter or more. The rail connects panels to ensure that if one glass pane shatters, the rail acts as a bridge, preventing the barrier from collapsing and maintaining a safety guard.

The concept of the interlinking rail is all about redundancy. In the glass industry, we call this "post-breakage behavior." Standard toughened glass shatters into thousands of tiny cubes when it breaks. Without a rail, that creates an immediate void where a person could fall through. The rail holds the remaining structure together.

The SGP Exception

There is only one way to legally get the "fully frameless" look without a metal rail on top. You must use or an equivalent stiff interlayer. When we manufacture SGP laminated glass, we use a special ionoplast interlayer that is 5 times stronger and 100 times stiffer than the standard PVB interlayer.

If SGP glass breaks, it stays rigid and upright, much like a piece of plywood. Because it does not flop over, it passes the "post-breakage strength test" without needing a rail. However, SGP is significantly more expensive than standard laminated glass.

Choosing Your Hardware

If you choose the rail route to save money on glass, you need the right connectors. We supply several types of joiners to ensure the rail is truly "interlinking":

-

Straight Joiners: Connect two rails in a line.

-

Corner Elbows: Connect rails at 90-degree or adjustable angles.

-

Wall Flanges: Anchor the rail end into the structural wall.

You must connect at least three panels together, or connect the rail to a solid wall. A floating rail on a single panel does not count as "interlinking."

Should You Choose Laminated or Toughened Glass?

We have seen a massive shift in our order volume from monolithic toughened glass to over the last few years. In the past, a single sheet of thick tempered glass was the norm for Australian balconies. Today, relying on that old standard is a risky move that exposes you to liability and compliance failures.

For any barrier protecting a fall of one meter or more, Laminated Safety Glass is effectively mandatory under current revisions of AS 1288. Monolithic toughened glass is rarely permitted because it vacates the opening entirely upon breakage, whereas laminated glass retains the shards and maintains a barrier.

Understanding the composition of the glass is critical. Laminated glass consists of two sheets of glass bonded together by an interlayer (usually PVB or SGP). If one sheet breaks, the other usually holds, and the interlayer keeps the shards from falling onto people below. This is especially important for high-rise buildings or balconies over public areas.

The Hidden Danger: Nickel Sulfide

At our manufacturing facility, we strongly recommend "Heat Soaking" for all balustrade glass. are microscopic impurities that can get trapped in glass during float production. Over time, these inclusions expand and can cause "spontaneous breakage"—where a panel explodes without being touched.

is a process where we bake the glass in an oven after toughening. If a panel has NiS, it will break in our factory, not on your customer's balcony. Using Heat Soaked Laminated Toughened Glass is the gold standard for safety in Australia.

Glass Selection Table

Here is how the different glass types stack up for Australian compliance:

| Glass Type | Description | Compliant for Balconies >1m? | Cost Level |

|---|---|---|---|

| Monolithic Toughened | Single layer of tempered glass. | No (Generally Phased Out) | Low |

| Toughened Laminated (PVB) | Two layers bonded with standard PVB. | Yes (With Top Rail) | Medium |

| Toughened Laminated (SGP) | Two layers bonded with rigid structural interlayer. | Yes (Rail-Free Allowed) | High |

How Does Structural Load Testing Work?

Testing our spigots and standoffs in our laboratory is a daily routine that ensures we sleep well at night. We know that in Australia, the wind loads and "live loads" (people leaning on the glass) are taken very seriously. Using cheap, hollow, or untested hardware is a recipe for disaster when the certifier asks for your engineering reports.

AS 1170.1 mandates that balustrades must withstand specific forces. For residential (Class 1) buildings, the barrier typically needs to resist 0.6kN of force. For commercial or public areas (Class 9), the requirement increases to 1.5kN or even 3.0kN to account for crowd pressure.

When we talk about "kN" (kilonewtons), we are talking about force. 0.6kN is roughly equivalent to 60kg of force applied at the top of the rail. This might not sound like much, but it is applied to the weakest point.

The Role of Hardware

Your glass might be strong enough, but if your spigots bend, the system fails. This is why we cast our spigots from solid . Duplex 2205 is much stronger than standard 316 marine grade stainless steel. It has a higher yield strength, meaning it can take more force before it permanently deforms.

Certification is Key

In Australia, you often need a "Form 15" (Compliance Certificate for Building Design or Specification) or a "Form 12" (Inspection Certificate) depending on your state. To get these signed off, your engineer needs proof.

We provide our clients with accredited test reports or equivalent engineering certifications. If you buy hardware that lacks these reports, you will likely have to pay a local engineer thousands of dollars to site-test the barrier, or worse, rip it out.

Load Requirements Summary

| Building Class | Typical Application | Minimum Live Load (Force) |

|---|---|---|

| Class 1 & 10 | Domestic / Residential Balconies | 0.6 kN |

| Class 2, 3, 4 & 9c | Residential Apartments / Hotels | 0.6 kN - 1.5 kN |

| Class 6 (Retail) | Restaurants / Bars / Shopping Malls | 1.5 kN - 3.0 kN (Crowd Loading) |

What Are the Rules for Swimming Pool Fencing?

orders have distinct specifications compared to our balcony projects, and confusing the two is a common mistake. We constantly remind our distributors that a compliant balcony balustrade is not automatically a compliant pool fence. The stakes are incredibly high here because this standard is specifically designed to save the lives of young children.

Swimming pool fencing is governed by AS 1926.1, which sets the minimum height at 1200mm—higher than a standard balcony. It also strictly defines a Non-Climbable Zone (NCZ) to prevent children from using footholds to scale the fence, and requires self-closing, self-latching gates.

The most critical aspect of is the Non-Climbable Zone (NCZ). This is a 900mm arc measured from the top of the barrier downwards. Within this zone, there can be no horizontal rails, indentations, or objects (like pot plants or BBQs) that a child could use as a step. This is why glass is so popular for pools—it offers a smooth, vertical surface with zero footholds.

The Gate Hardware

The gate is the only moving part of the fence, so it is the most likely point of failure.

-

Latch Height: The release mechanism for the latch must be at least 1500mm above the ground, or located on the inside of the gate with a shield so a child cannot reach through.

-

Self-Closing: The hinges must be hydraulic or spring-loaded. We test our hinges to ensure they close from any open angle, even if the gate is only open an inch.

-

Direction: The gate must open away from the pool area. If the latch fails, the child pushing on the gate will just push it shut, not open.

The Bottom Gap

The gap between the bottom of the glass panel and the finished ground level cannot exceed 100mm. Our standard pool fencing spigots are designed to hold the glass roughly 50mm to 80mm off the ground, which sits perfectly within this safety range. If the gap is too large, a child could crawl under; too small, and debris gets stuck.

Conclusion

Building compliant balustrades in Australia requires strict adherence to AS 1288 and AS 1170. From ensuring your barrier is 1000mm high to installing the mandatory interlinking top rail or paying extra for SGP glass, every detail matters. Using the right materials, like Laminated Safety Glass and Duplex 2205 spigots, is not just about ticking a box—it is about ensuring the long-term safety of the occupants.

We understand these challenges because we solve them for our clients every day. If you need hardware that comes with the right certification and engineering backing, we are here to help you get your project signed off without the headache.

Footnotes

1. Access the official National Construction Code (NCC) for Australia. ↩︎

2. Purchase and view AS 1288:2021 standards for glass in buildings. ↩︎

3. Official product details for SentryGlas™ Plus (SGP) interlayers. ↩︎

4. Technical guide on laminated glass standards from AGWA. ↩︎

5. Understanding the risks of Nickel Sulfide inclusions in glass. ↩︎

6. Explanation of heat soaking processes for glass safety. ↩︎

7. Technical properties of Duplex 2205 stainless steel. ↩︎

8. Verify NATA accreditation and laboratory testing standards. ↩︎

9. NSW Government regulations for swimming pool fencing safety. ↩︎