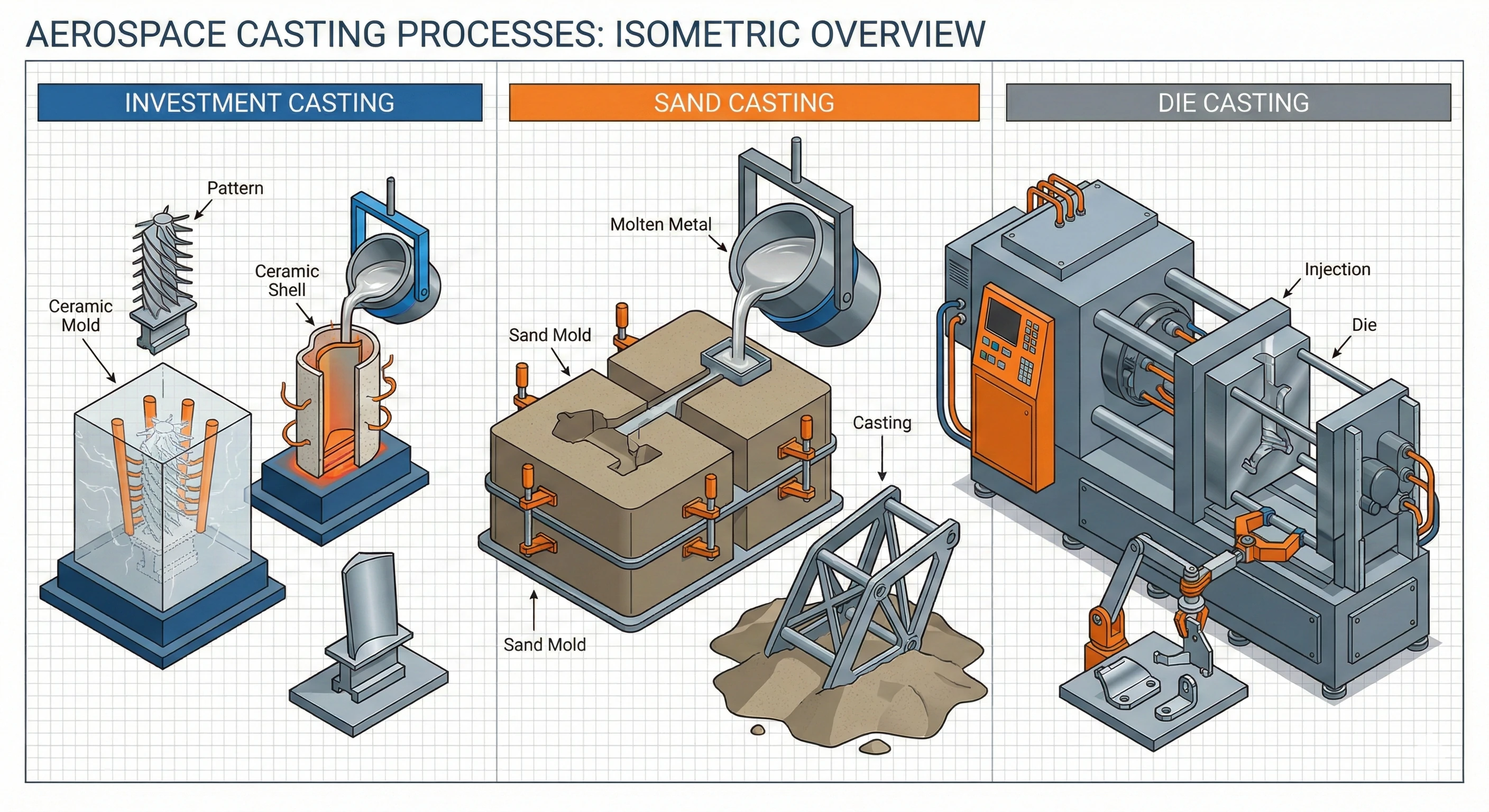

The aerospace industry primarily relies on three distinct casting processes: Investment Casting for critical engine components, Sand Casting for large structural frames, and Die Casting for interior fittings. Manufacturers utilize advanced techniques like Vacuum Investment Casting and Single Crystal solidification to ensure zero-defect quality and superior material integrity.

To understand how these high-performance parts are created, we must look deeper into the specific methods and the rigorous science behind them.

Why Is Investment Casting Considered the King of Aerospace?

When we receive specifications for complex engine parts, standard molding methods simply cannot achieve the necessary geometry. We rely on the precision of the to navigate these engineering challenges.

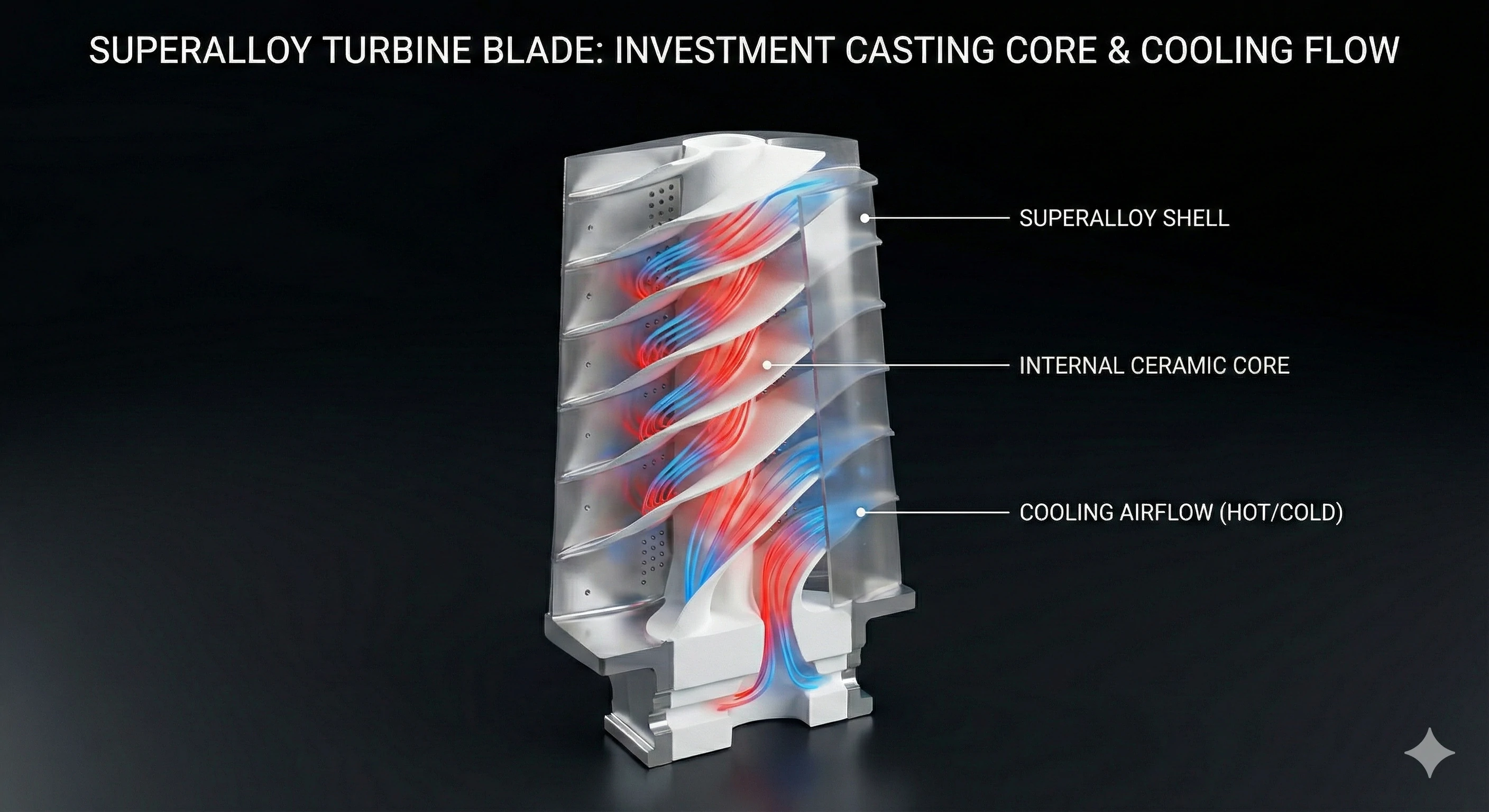

Investment casting is the dominant method in aerospace because it is the only process capable of casting Superalloys into thin-walled, complex shapes with tight tolerances of +/- 0.1mm. It allows engineers to create intricate cooling channels within turbine blades that would be impossible to machine.

The Precision of the "Lost Wax" Technique

Investment casting, historically known as the lost-wax process, is the backbone of modern aerospace propulsion. In our experience, the ability to hold tight tolerances is what sets this method apart. When we cast a turbine blade, we are not just pouring metal into a hole; we are engineering a thermal system.

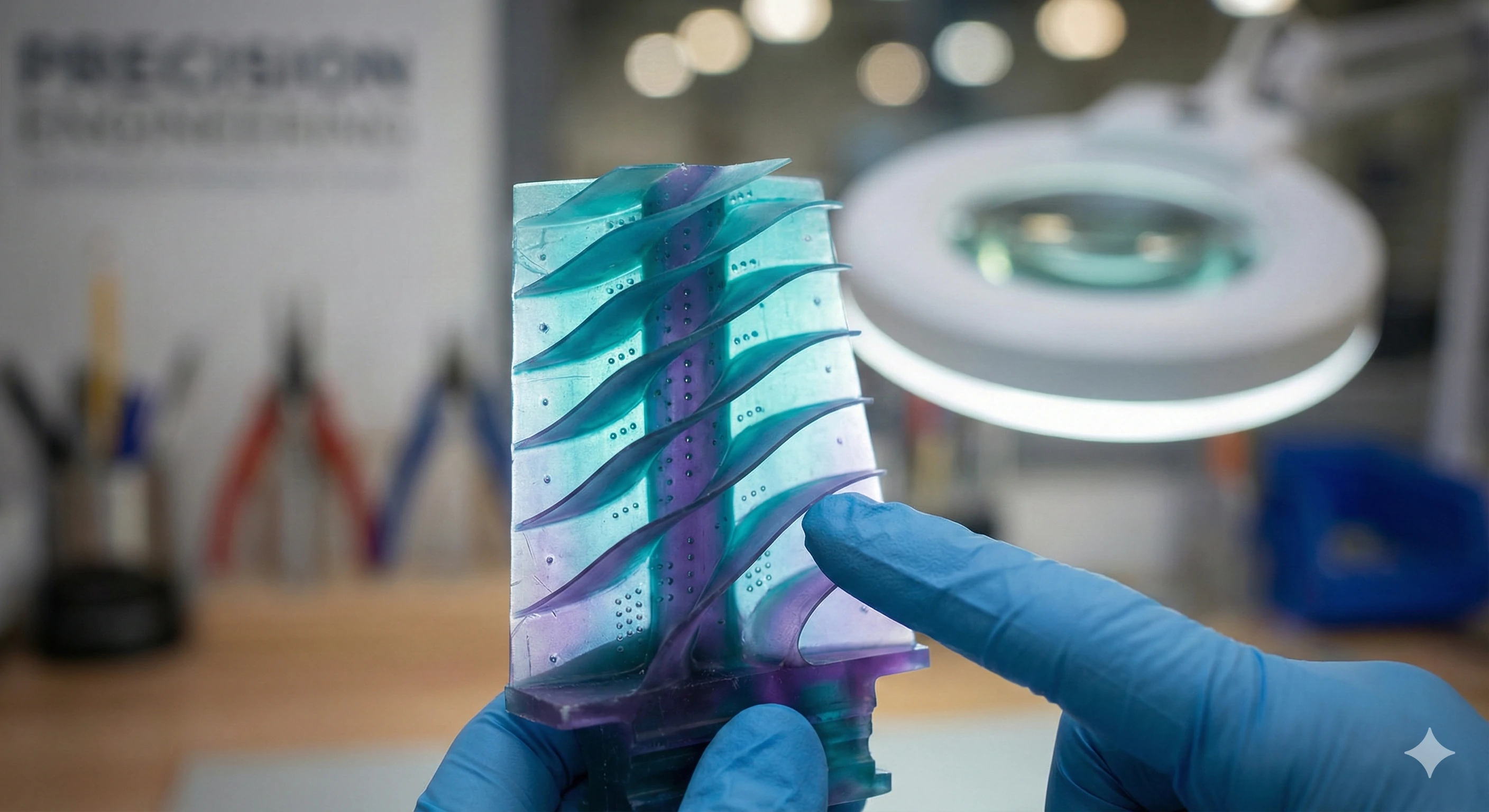

The process begins with the creation of a precise wax pattern. For hollow components, such as , we utilize a "Ceramic Core" technology. A pre-formed ceramic core is placed inside the wax mold before injection. This is a critical step that many standard foundries do not handle. Once the metal solidifies, this ceramic core is chemically dissolved, leaving behind intricate internal cooling channels. Without these channels, jet engines would melt under their own operating temperatures.

Furthermore, the ceramic shell used in this process allows us to pour high-melting-point alloys—specifically —that would destroy standard metal molds. The surface finish achieved is smooth enough to minimize aerodynamic drag without extensive machining, which saves both time and expensive raw material.

Comparison of Casting Methods

To help you understand where investment casting fits, we have compared it with other common industrial methods below:

| Feature | Investment Casting | Sand Casting | Die Casting |

|---|---|---|---|

| Precision | Extremely High (+/- 0.1mm) | Low to Medium | High |

| Surface Finish | Excellent (Smooth) | Rough | Good |

| Material Capability | Superalloys, Titanium, Steel | Aluminum, Magnesium, Iron | Aluminum, Zinc (Low Melt) |

| Typical Part | Turbine Blades, Vanes | Gearbox Housings | Seat Latches, Handles |

| Cost | High (Tooling & Labor) | Low (Pattern cost) | Low (High Volume) |

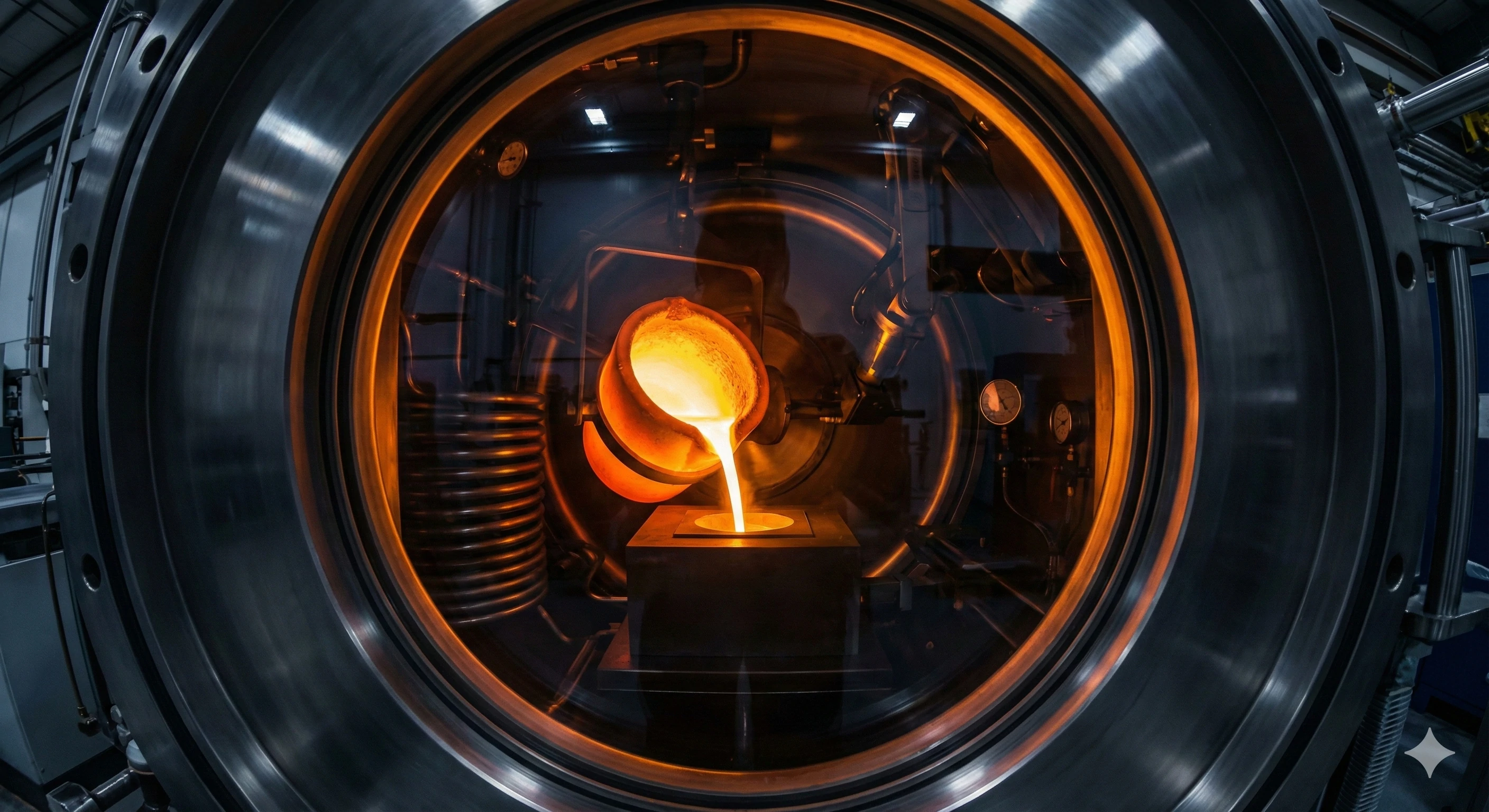

Why Is Vacuum Investment Casting (VIM) Essential?

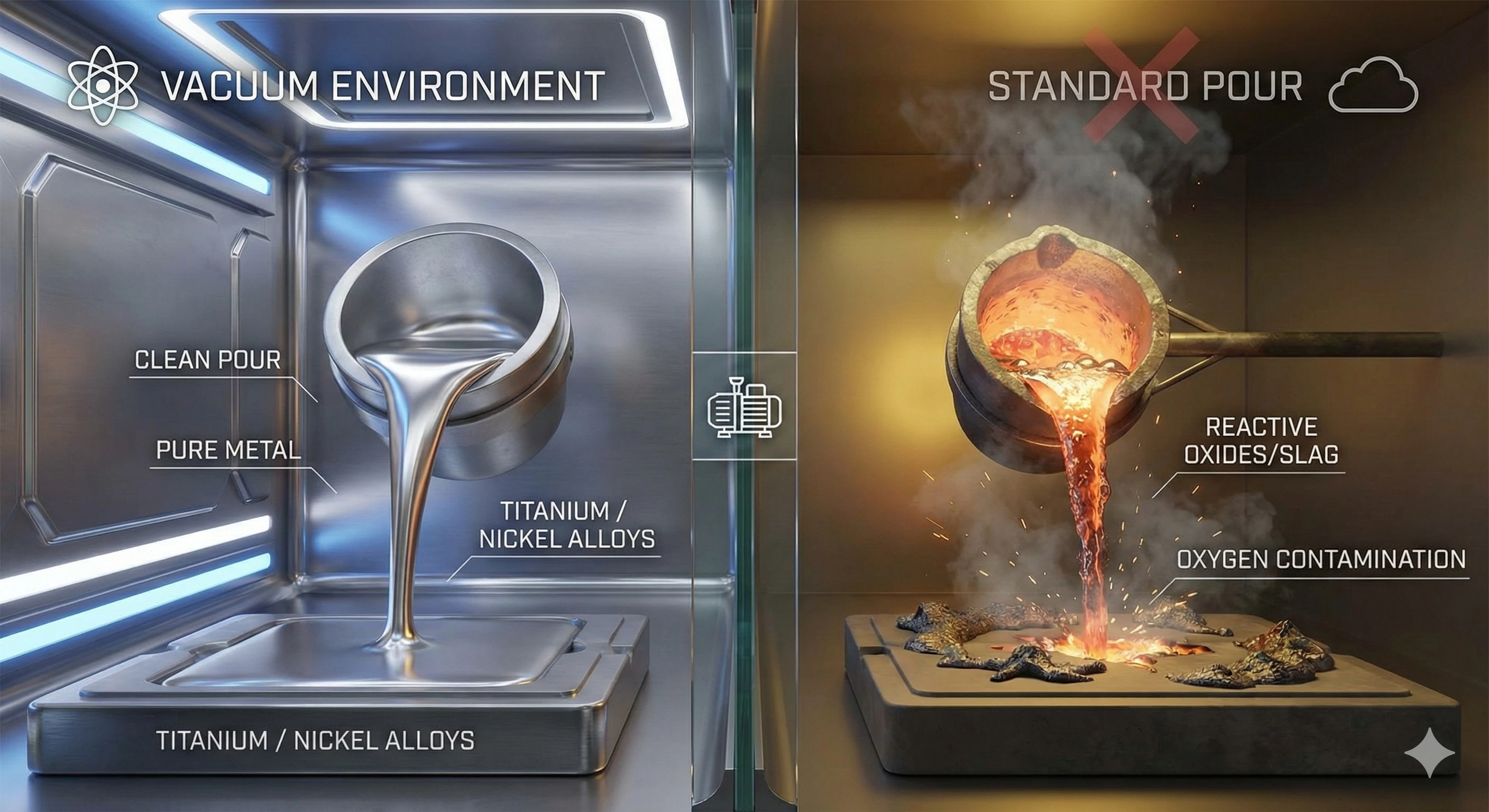

We often face the challenge of working with reactive metals that behave unpredictably in the open atmosphere. Dealing with these materials requires a controlled environment that eliminates atmospheric contamination entirely.

Vacuum Investment Casting (VIM) is essential because molten Superalloys and Titanium react instantly with oxygen and nitrogen in the air to form brittle oxides. By melting and pouring the metal inside a vacuum chamber, manufacturers ensure a pure metallurgical structure free from slag and gas porosity.

Eliminating the Oxygen Threat

In standard foundry practice, we might use slag filters or special gating systems to keep impurities out of the mold. However, for aerospace-grade Titanium or Nickel Superalloys, this is not enough. These metals have a high affinity for oxygen. If we were to pour molten Titanium in a regular room, it would essentially catch fire or, at the very least, instantly form a thick skin of oxides (slag) that creates weak points in the metal.

The solution is the furnace. We place the raw metal stock and the ceramic mold inside a sealed chamber and pump out all the air. The melting, alloying, and pouring all happen in this void. This ensures that the liquid metal never touches oxygen until it has solidified.

For our clients requiring high-grade Stainless Steel for marine or industrial valves, we apply similar "clean pour" principles. While we may not always need a full aerospace vacuum for every industrial valve, understanding VIM helps us control gas porosity in our commercial lines. If gas bubbles get trapped in the metal, they create voids that can lead to leaks or cracks under pressure. Vacuum casting guarantees a density and purity that standard atmospheric pouring cannot match.

Reactive vs. Non-Reactive Metals

Understanding which metals require this expensive process is key to procurement:

| Metal Category | Examples | Reaction to Air | Casting Method Required |

|---|---|---|---|

| Reactive | Titanium, Zirconium | High (Explosive/Oxidizing) | Vacuum (VIM) |

| Superalloys | Inconel 718, René 80 | Medium to High | Vacuum (VIM) |

| Stable | Aluminum, Bronze | Low (Surface Oxide only) | Air Melt (Standard) |

| Iron-Based | Carbon Steel, Cast Iron | Low | Air Melt (Standard) |

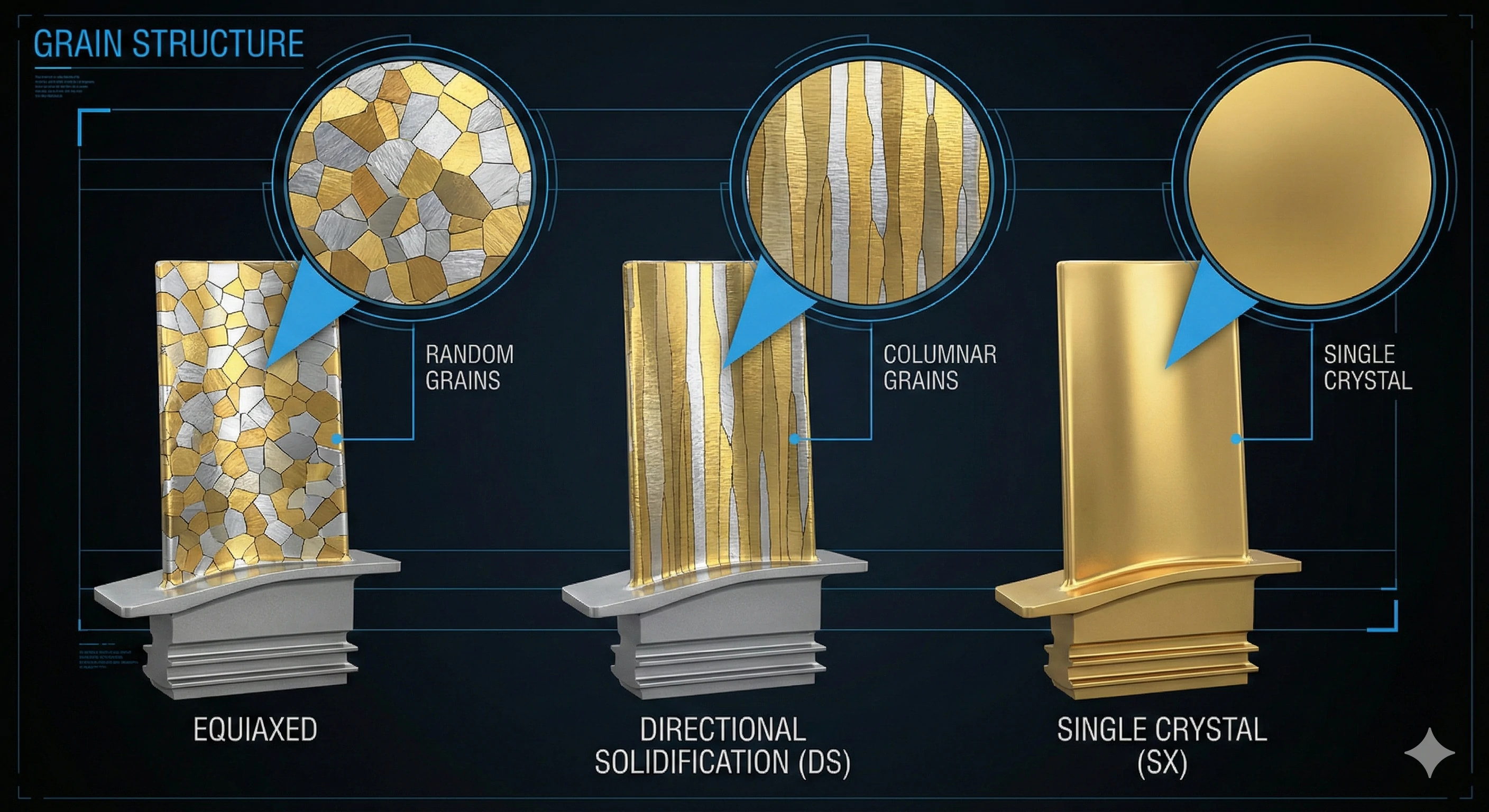

How Do Advanced Solidification Techniques Work?

Controlling the internal grain structure of a metal part is perhaps the most technically demanding aspect of our work. It is not enough to just shape the metal; we must engineer its molecular growth.

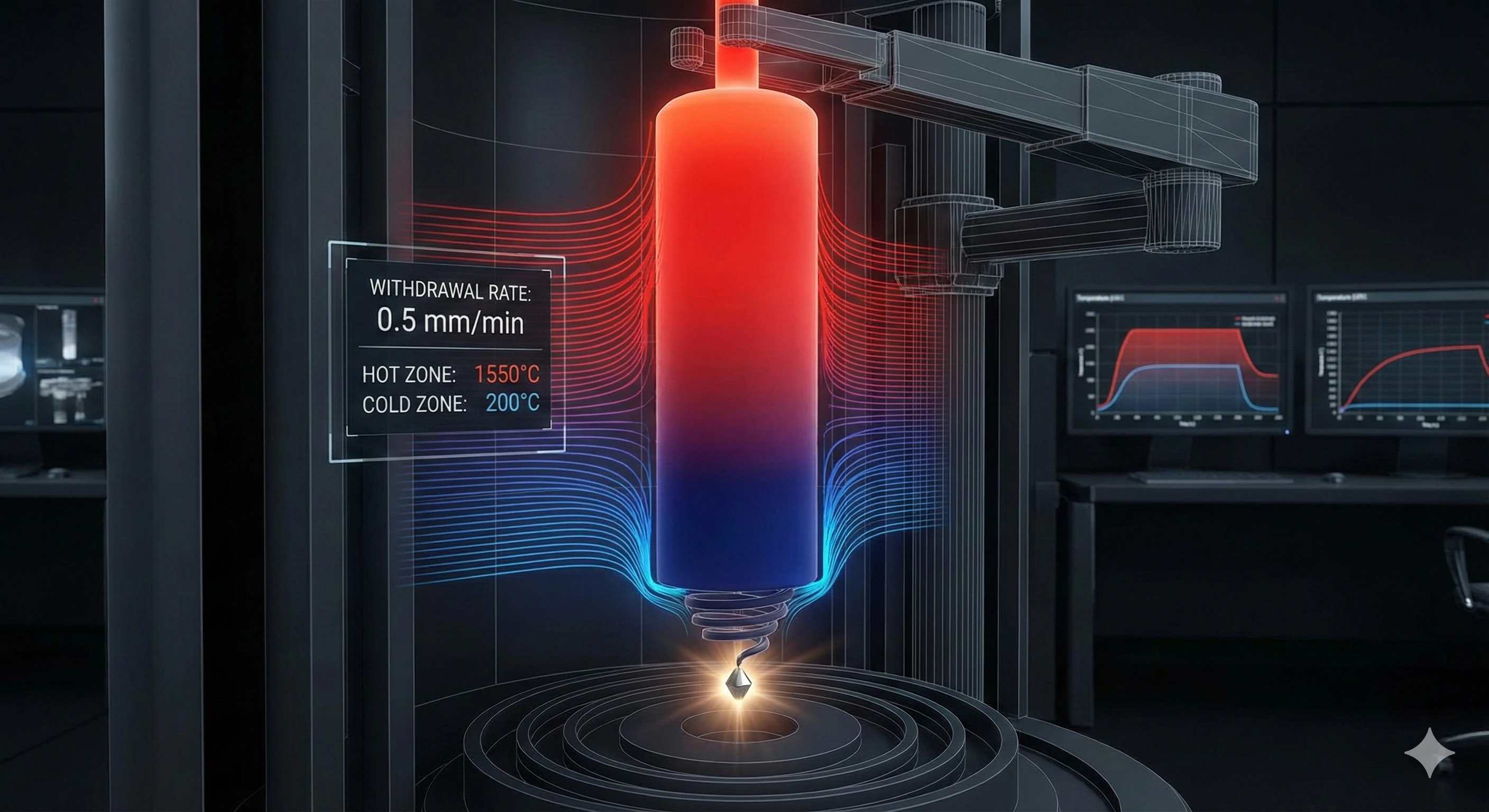

Advanced solidification techniques like Directional Solidification (DS) and Single Crystal (SX) control the cooling process to eliminate grain boundaries. This prevents thermal fatigue and creep, which is critical for turbine blades operating at temperatures exceeding 1,500°C.

From Equiaxed to Single Crystal

When molten metal cools naturally, it forms grains that grow from the outside in, meeting in the middle like random puzzle pieces. This is called Equiaxed (EQ) casting. For 90% of industrial applications, including the valves and fittings we manufacture, this is perfectly strong. However, in a jet engine, the boundaries between these "puzzle pieces" are weak spots. Under high heat and centrifugal force, the metal can tear apart at these boundaries.

To solve this, aerospace engineers developed Directional Solidification (DS). In this process, we withdraw the mold slowly from the furnace, forcing the grains to grow in long, vertical columns—like a bundle of straws. This eliminates the horizontal that are most prone to cracking during rotation.

The ultimate level of control is Single Crystal (SX). Here, we use a "grain selector"—a corkscrew-shaped passage at the bottom of the mold. As the metal solidifies, only one single crystal can navigate through this pigtail shape. That one crystal then grows to fill the entire mold. The resulting turbine blade is effectively one giant molecule. It has zero grain boundaries, offering maximum resistance to "creep" (stretching over time). While this process is incredibly expensive, it is the only way to keep engines running at modern efficiency levels.

Grain Structure Characteristics

| Structure Type | Grain Description | Weakness | Primary Application |

|---|---|---|---|

| Equiaxed (EQ) | Random, multi-directional grains | Grain boundaries fail at high heat | Static parts, Low-pressure turbine |

| Directional (DS) | Long vertical columns | Transverse strength is lower | High-pressure turbine blades |

| Single Crystal (SX) | No grains (One continuous lattice) | Extremely high cost | Hottest engine sections |

When Is Sand Casting Used in Aerospace?

While we often associate aerospace with shiny, precise metal parts, there is still a massive role for the oldest casting method. Size limitations in investment casting often force us to utilize sand casting for larger components.

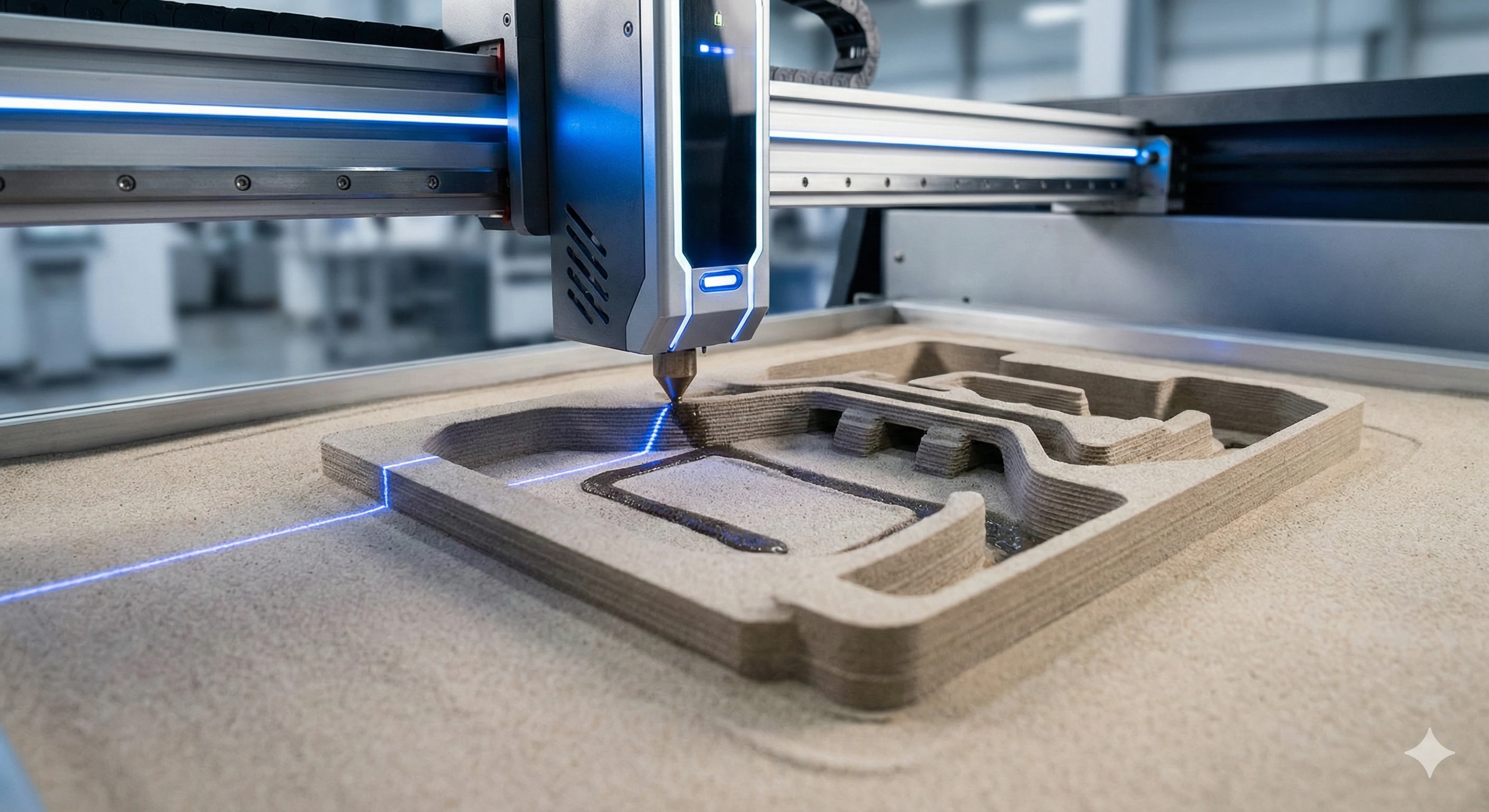

Sand casting is utilized in aerospace for large structural components, such as engine gearbox casings and frame connectors, which are too big for investment molds. Modern aerospace sand casting uses chemically bonded sand and 3D-printed molds to achieve higher precision than standard foundry work.

Refining an Ancient Process

We typically use sand casting for materials like Aluminum and Magnesium alloys. The primary driver here is size. Investment casting relies on a ceramic shell that becomes fragile and difficult to handle when the part exceeds a certain diameter (usually around 1 meter). For a massive gearbox housing or a structural ring frame of a helicopter, sand casting is the practical choice.

However, the "sand casting" used in aerospace is vastly different from the rough iron casting used for manhole covers. We use (no-bake sand) which mixes a resin with the sand to create a mold that is hard, rigid, and dimensionally accurate.

Recently, we have seen a shift toward . Instead of making a wooden pattern to press into the sand, a 3D printer lays down layers of sand and binder to build the mold directly from a CAD file. This allows us to create complex geometries and undercuts that were previously impossible with traditional pattern-making. It bridges the gap between the flexibility of investment casting and the size capabilities of sand casting.

Why Is NDT the Standard for Quality Control?

We operate under the rule that you cannot simply "look" at an aerospace part to determine its quality. Visual inspection is insufficient when internal voids or microscopic cracks can lead to failure.

Non-Destructive Testing (NDT) is the industry standard because it allows quality engineers to inspect the internal integrity of a part without damaging it. Techniques like X-ray radiography and Fluorescent Penetrant Inspection (FPI) reveal hidden voids, cracks, and density changes that are invisible to the naked eye.

Looking Through the Metal

In our facility, Quality Control is not an afterthought; it is a parallel process to manufacturing. The aerospace sector mandates that critical parts undergo 100% inspection using NDT methods. This is a trust signal that we also apply to our high-pressure marine and industrial valves.

Radiography (X-Ray) is the first line of defense. Just as a doctor looks for broken bones, we bombard the casting with X-rays to find internal shrinkage or gas porosity. If there is a bubble inside the metal wall, it shows up as a dark spot on the film.

Fluorescent Penetrant Inspection (FPI) is used to detect surface defects. We coat the part in a special , wash it off, and then apply a developer. Under UV light, even a crack that is narrower than a human hair will glow strictly bright green.

Ultrasonic Testing uses sound waves to detect inconsistencies in density. It is particularly useful for thick sections where X-rays might struggle to penetrate. By adhering to these aerospace-level NDT standards, we ensure that the components we deliver—whether for a jet or an oil rig—are structurally sound and ready for service.

Conclusion

The casting process in the aerospace industry is defined not just by the shape of the metal, but by the rigorous control of every variable. From the vacuum furnaces that prevent oxidation to the single-crystal growth that defies nature, these methods push the boundaries of materials science.

At our facility, we believe that the lessons learned from aerospace precision should be applied across the manufacturing spectrum. Whether it is ensuring the purity of the alloy via vacuum processing or verifying structural integrity through NDT, process control is what separates a good part from a perfect one.

If you require the precision of investment casting for your industrial projects, we can bring this aerospace-level quality control to your commercial components. We invite you to contact us to discuss how we can meet your critical specifications with our rigorous material certification and testing protocols.

Footnotes

1. Definition of a facility producing metal castings.

2. Overview of stress factors in engineering materials.

3. Historical and technical overview of the casting method.

4. Function and design of critical engine components.

5. High-performance alloys for extreme heat resistance.

6. Process for melting metal under vacuum conditions.

7. Explanation of microscopic defects in crystal structures.

8. How resin binders create rigid sand molds.

9. Additive manufacturing techniques for casting molds.