Precision Casting & Investment casting

Our company has excellent casting capabilities to provide our customers with high quality cast products covering a wide range of applications. The following is a detailed description of our casting capabilities.

-

How can we help you?

- Analyze your drawings or samples

- Customize manufacturing solutions

- Mold design and process planning

- Material melting and composition control

- Pouring molding and process control

- Mold release and post-treatment processing

- Quality Inspection and Delivery Assurance

- 3D Printing Services

What is investment casting?

Investment casting, also known as lost-wax casting, is one of humanity’s oldest and most sophisticated metalworking techniques. It's a precision casting process that centers on creating a mold made of fusible material, wrapping it in a refractory material to form a shell, removing the mold by heating, and injecting molten metal into the mold, resulting in a casting with high precision and a complex shape. From intricate Bronze Age jewelry to cutting-edge jet engine components, this process has shaped civilizations while evolving into a cornerstone of modern manufacturing. Let’s explore how molten metal meets artistry and engineering in this fascinating process.

Casting Process

Wax Pattern injection

Wax Tree Assembly

Shell Building

Dewax / Burnout

Metal Pouring

Shell Knock Off

Cut- Off

Individual Castings

Our Casting Capability

-

Applications

Our casting products play an important role in a variety of applications, including but not limited to:

- Construction industry

- Chemical machinery

- Shipbuilding equipment

- Medical industry

- Food machinery

- Water and sewage industry

-

Key products

Our casting capabilities cover a wide range of product areas, including but not limited to:

- Architectural hardware

- Automotive parts

- Pump and valve parts

- Impellers

- Marine hardware

- Some other mechanical parts

-

Casting Capability

- Weight range: 0.005kg~100kg

- Maximum contour size: 400mm×500mm×500mm (one side≤700mm)

- Minimum wall thickness: 1mm

- Minimum fillet radius: R0.3

- Through hole: minimum diameter 2mm, maximum depth 4mm

- Blind hole: minimum diameter 2mm, maximum depth 2mm

- Surface roughness: Ra3.2~6.3

- Casting tolerance: conventional CT6 level, up to CT4 level (based on standard GB/T 6414-2017)

-

Main Materials

We can cast using a wide range of materials to meet the specific needs of our customers. Key materials include:

- Stainless steel

- Carbon steel

- Alloy steel

- Brass, etc.

-

Typical Delivery Time

We are committed to providing timely deliveries to meet our customers' needs. Typical lead times include:

- Mold lead time: 2 to 4 weeks

- Cast lead time: less than 20 days

- Average lead time: less than 7 weeks

The Quality Services We Provide

We specialize in full process solutions for precision investment casting, covering the complete chain from design optimization to delivery of finished products, ensuring efficient production and zero-defect delivery of complex parts. The following are our core service steps:

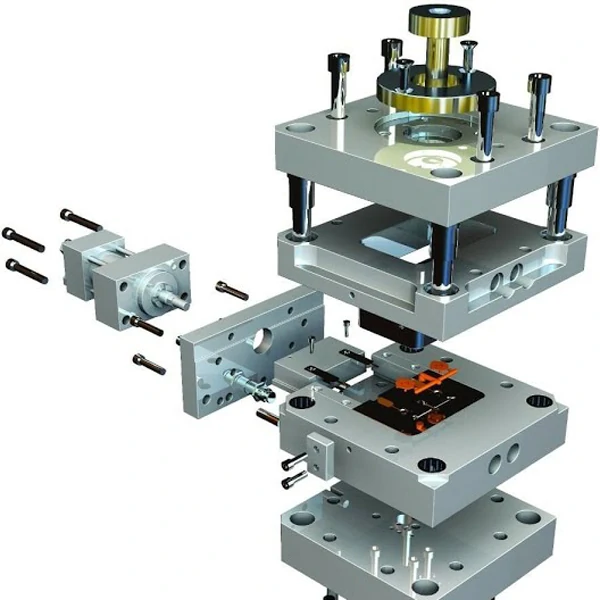

1. Mold design and process planning

- Customer demand matching: According to your part drawings or samples, analyze the structural complexity, material properties and performance requirements.

- Customized mold development: Design high-precision molds using CAD/CAM software, supporting sand and metal casting and 3D Printing Modeling.

- Optimization of process parameters: Predict defects such as shrinkage holes and cracks through computer simulation (e.g. ProCAST), and adjust the pouring system and riser layout.

2. Material melting and composition control

- Melting process monitoring: using medium frequency furnace / induction furnace melting, real-time detection of temperature (such as cast aluminum: 680-750 ℃) and composition (spectrometer analysis).

- Purity Assurance: Reduce oxides and bubbles through degassing and slag removal process to ensure the liquid metal flow is up to standard.

3.Pouring molding and process control

- Customized pouring process: Match the pouring speed and temperature gradient according to the part size (max. 400mm x 500mm x 500mm) to avoid cold segregation and porosity.

- Cooling strategy: natural cooling (small parts) or forced water cooling (large parts) to control grain refinement and residual stress.

- Real-time defects early warning: Infrared temperature and pressure sensors to monitor the cavity filling status, timely adjustment of process parameters.

4. Mold release and post-treatment processing

- Non-destructive demolding technology: use vibrating sand dropping machine and special demolding agent to protect the surface finish of parts (Ra3.2-6.3).

- Precision post-processing

- Cutting and grinding: removal of sprue, laser cutting of ultra-thin walled (1mm) parts.

- Heat treatment strengthening: annealing/hardening process to optimize mechanical properties.

- Surface treatment: support electroplating, sandblasting, passivation and other processes to enhance corrosion resistance.

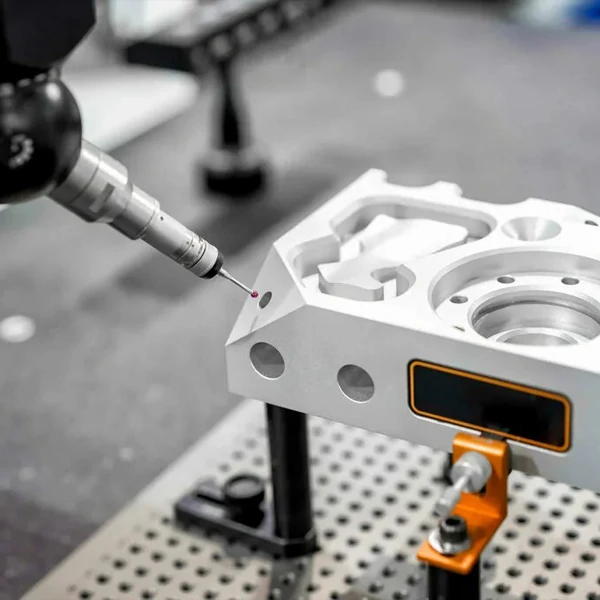

5. Quality Inspection and Delivery Assurance

- Dimensional inspection: CMM to control the tolerance (regular CT6 level, highest CT4 level).

- Non-destructive testing: X-ray detection of internal defects, ultrasonic verification of mechanical properties.

- Packaging and logistics: anti-oxidation vacuum packaging, support global DDP/DAP transportation, ensure delivery cycle is shortened by 30%.

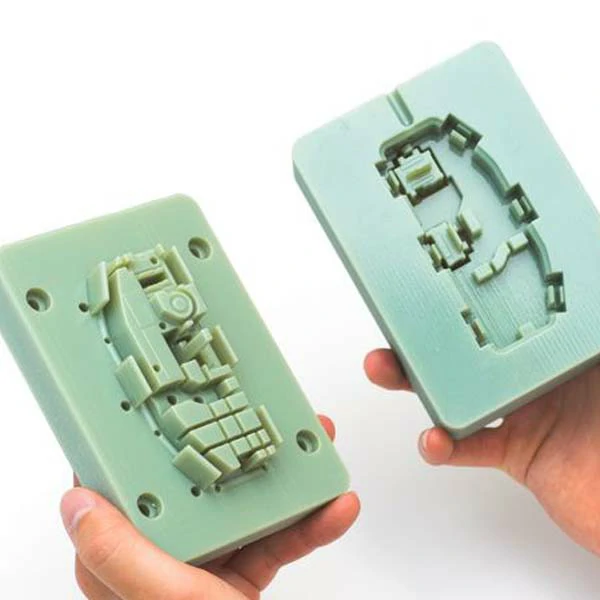

6.3D Printing Services

- We provide professional 3D printing solutions with additive manufacturing technology as the core, supporting the whole process from design to finished product. By stacking materials layer by layer, we can quickly realize complex geometries, customization and high-precision prototyping to meet the needs of multiple industries.

Technical Advantage

Rapid prototyping: from digital models to physical prototypes in a matter of hours, shortening the R&D cycle;

Controllable cost: on-demand production reduces material waste, and the economy of small-lot orders is remarkable;

Complex process breakthroughs: support for internal runners, porous structures and other innovative designs that are difficult to achieve with traditional processing;

Material diversity: covers 50+ materials such as PLA, PETG, titanium alloy, etc., suitable for industrial strength, high temperature resistance and other scenarios.

Our Core Advantages

Rapid prototyping: from digital models to physical prototypes in a matter of hours, shortening the R&D cycle;

Controllable cost: on-demand production reduces material waste, and the economy of small-lot orders is remarkable;

Complex process breakthroughs: support for internal runners, porous structures and other innovative designs that are difficult to achieve with traditional processing;