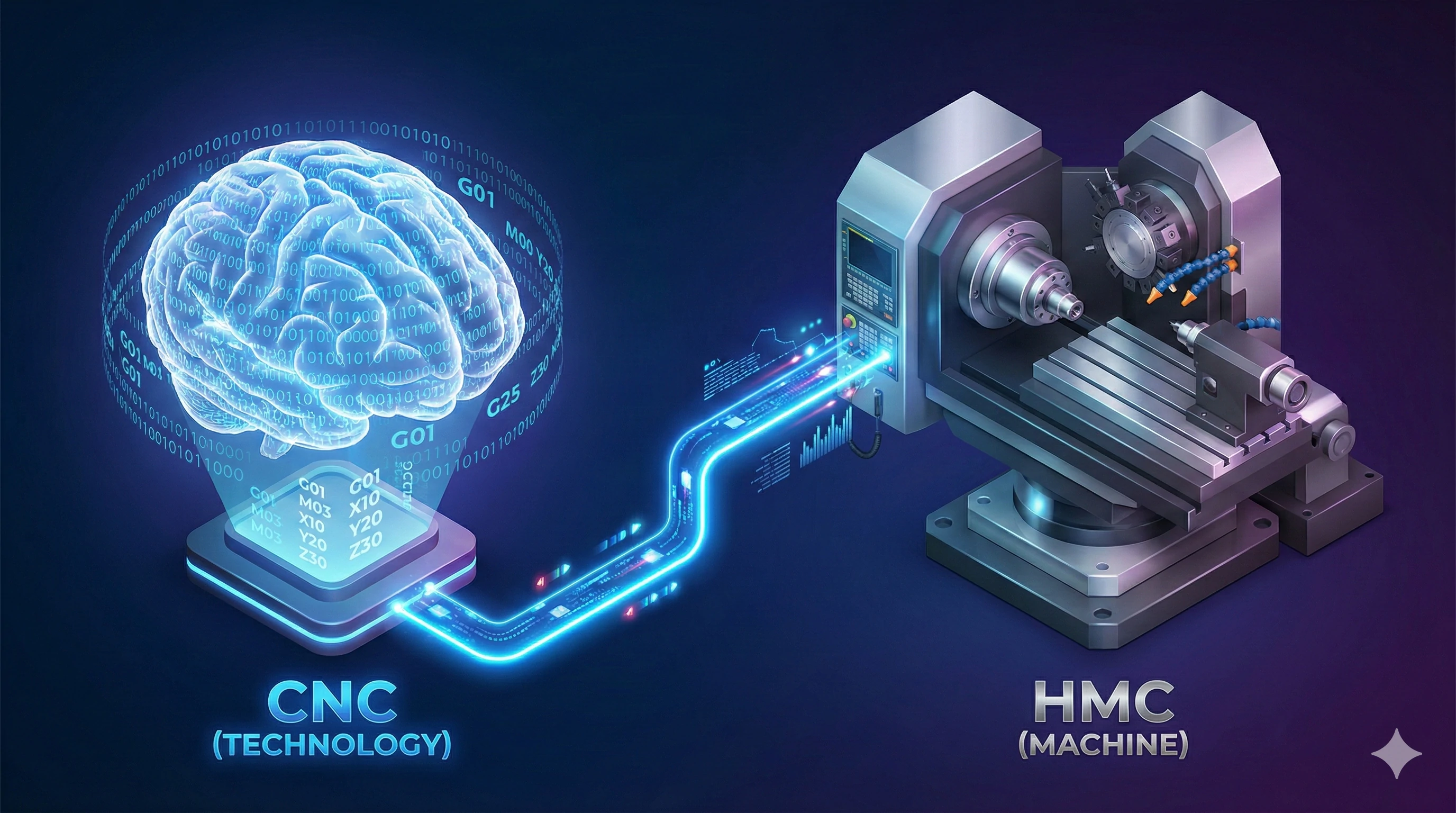

In our machining workshops, we often describe the as the "body" and the computer control as the "brain." However, even the most powerful body and sharpest brain need effective "hands" to perform actual work. From our perspective on the factory floor, a million-dollar machine equipped with cheap clamps or unbalanced holders is essentially useless because it cannot produce precision parts. We rely on these essential components to bridge the gap between raw power and finished quality.

Machine tool accessories are auxiliary devices defined as the essential components used to securely hold the workpiece, grip the cutting tool, or significantly enhance the machine's overall functionality. These devices determine the stability, rigidity, and final precision of every cut, making them the unsung heroes of the manufacturing process.

To help you understand where to invest for better machining results, let's break down the four main categories of accessories we use daily.

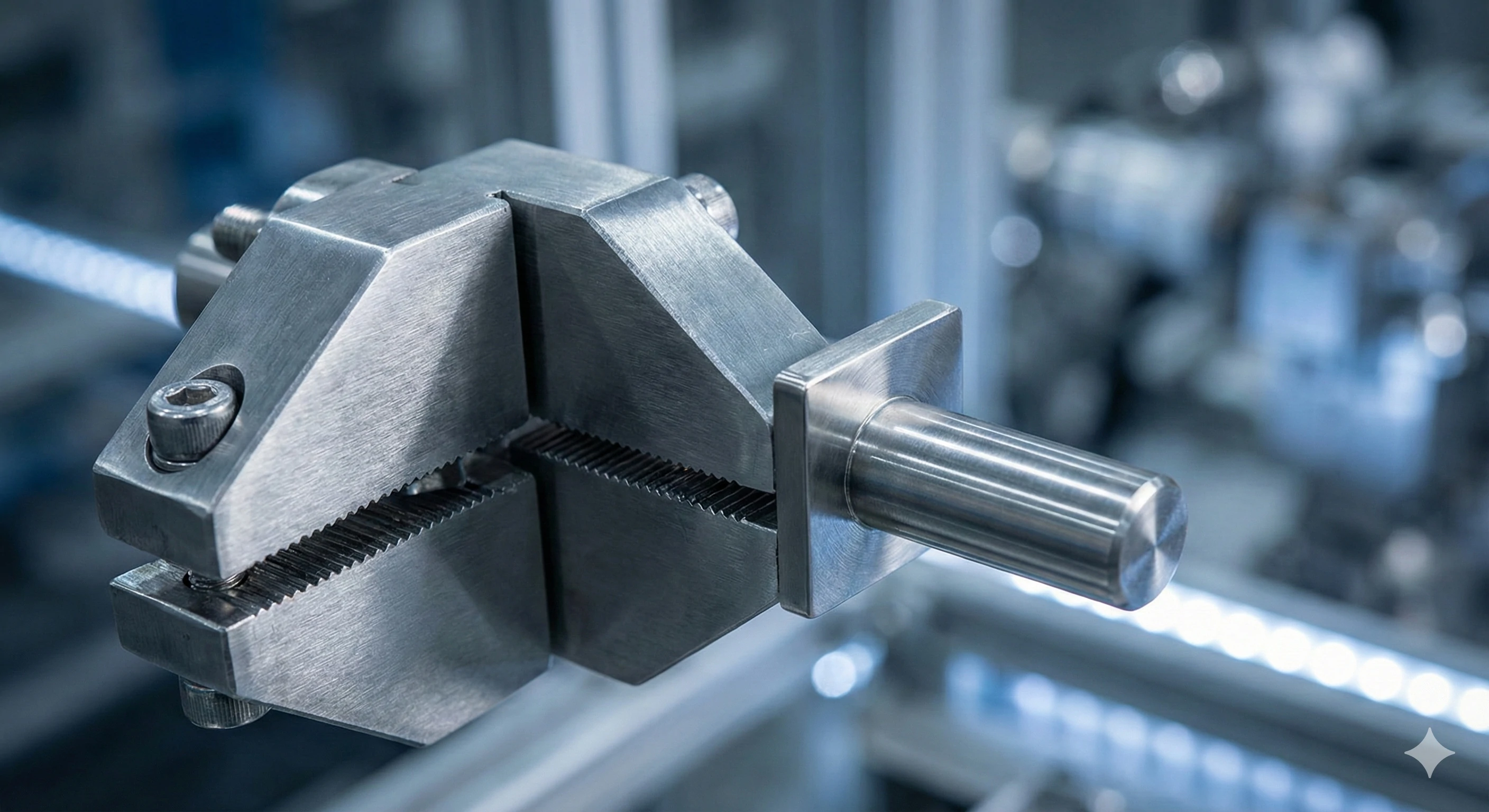

Category 1: Workholding Devices (Holding the Part)?

When we process raw castings like pump housings, we rarely deal with perfectly square blocks. Our engineers constantly face the challenge of securing irregular shapes under massive cutting forces. If the part moves even a fraction of a millimeter during operation, the entire batch is ruined. This experience has taught us that the grip on the material is just as important as the cutter itself.

Workholding devices are specialized tools designed to secure raw material firmly in place, ensuring it does not shift or vibrate under the intense pressure of high-speed cutting. These range from standard vises for square stock to complex custom fixtures for holding irregular, curved castings.

is the foundation of machining. Without a rigid setup, you cannot achieve tight tolerances. We categorize workholding based on the shape of the part and the machine being used.

The Challenge of Irregular Shapes

Standard tools are great, but they have limits. In our production line, we often encounter the "Casting Challenge." Raw castings have curved, uneven surfaces that cannot be gripped by a flat vise without damaging the part or losing grip. To solve this, we utilize Soft Jaws.

What Are Soft Jaws?

Soft jaws are custom-machined clamps, typically made from aluminum or mild steel. We cut them to the exact negative shape of the specific part we are machining. This allows us to grip a curved casting securely without marking the surface, distributing the clamping force evenly.

Below is a comparison of the common workholding types we employ:

| Workholding Type | Best Used For | Key Characteristic |

|---|---|---|

| Machine Vises | Square or rectangular blocks | The standard standard for most milling operations. |

| Chucks (3-Jaw/4-Jaw) | Round parts (Lathes) | 3-Jaw is self-centering; 4-Jaw allows off-center holding. |

| Clamps & T-Nuts | Large or irregular shapes | Versatile but takes longer to set up manually. |

| Soft Jaws | Complex/Curved Castings | Custom-cut to match the specific part geometry. |

Choosing the right device prevents the dangerous and expensive scenario of a part flying out of the machine.

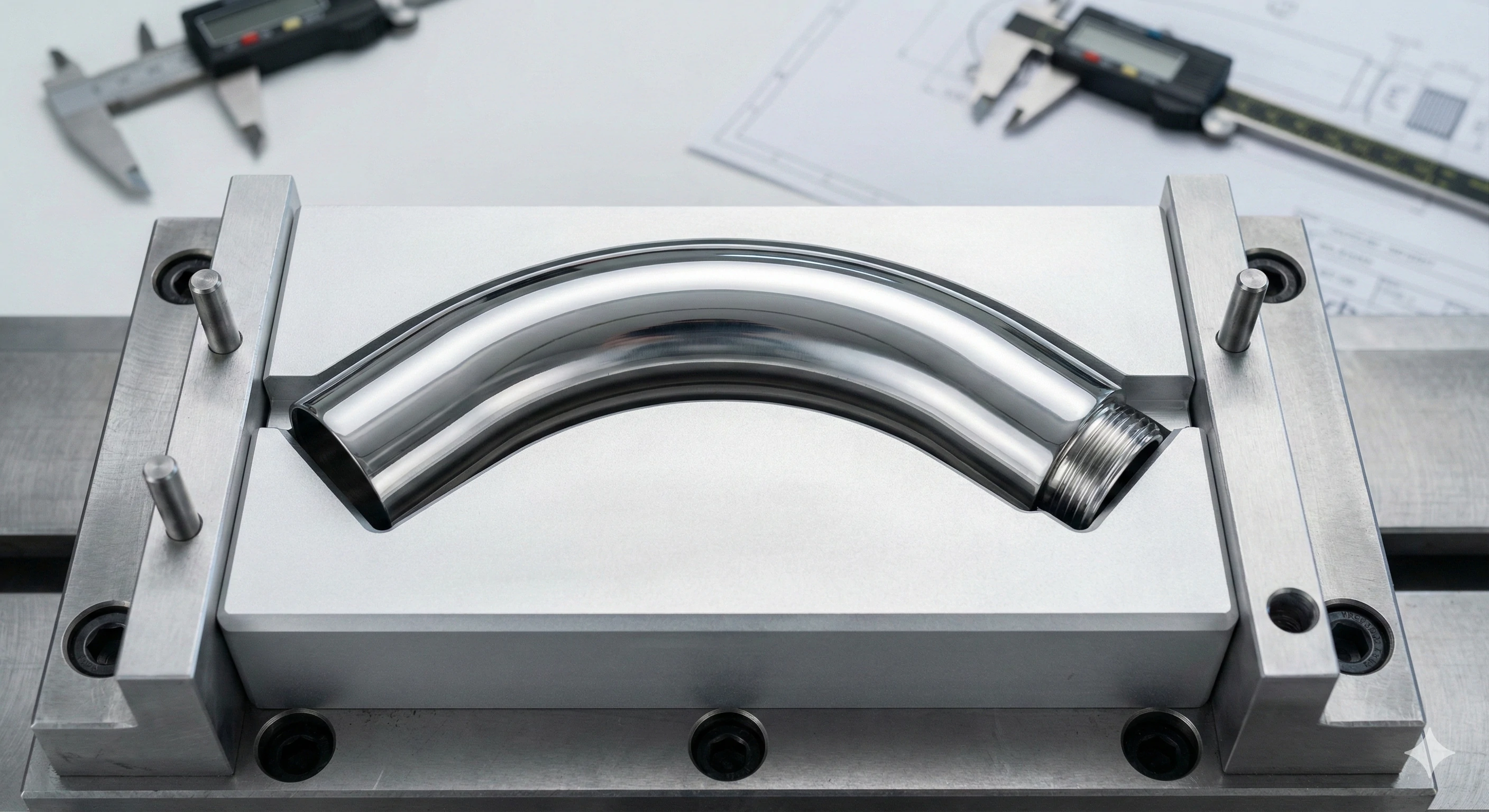

Category 2: Toolholding Devices (Holding the Cutter)?

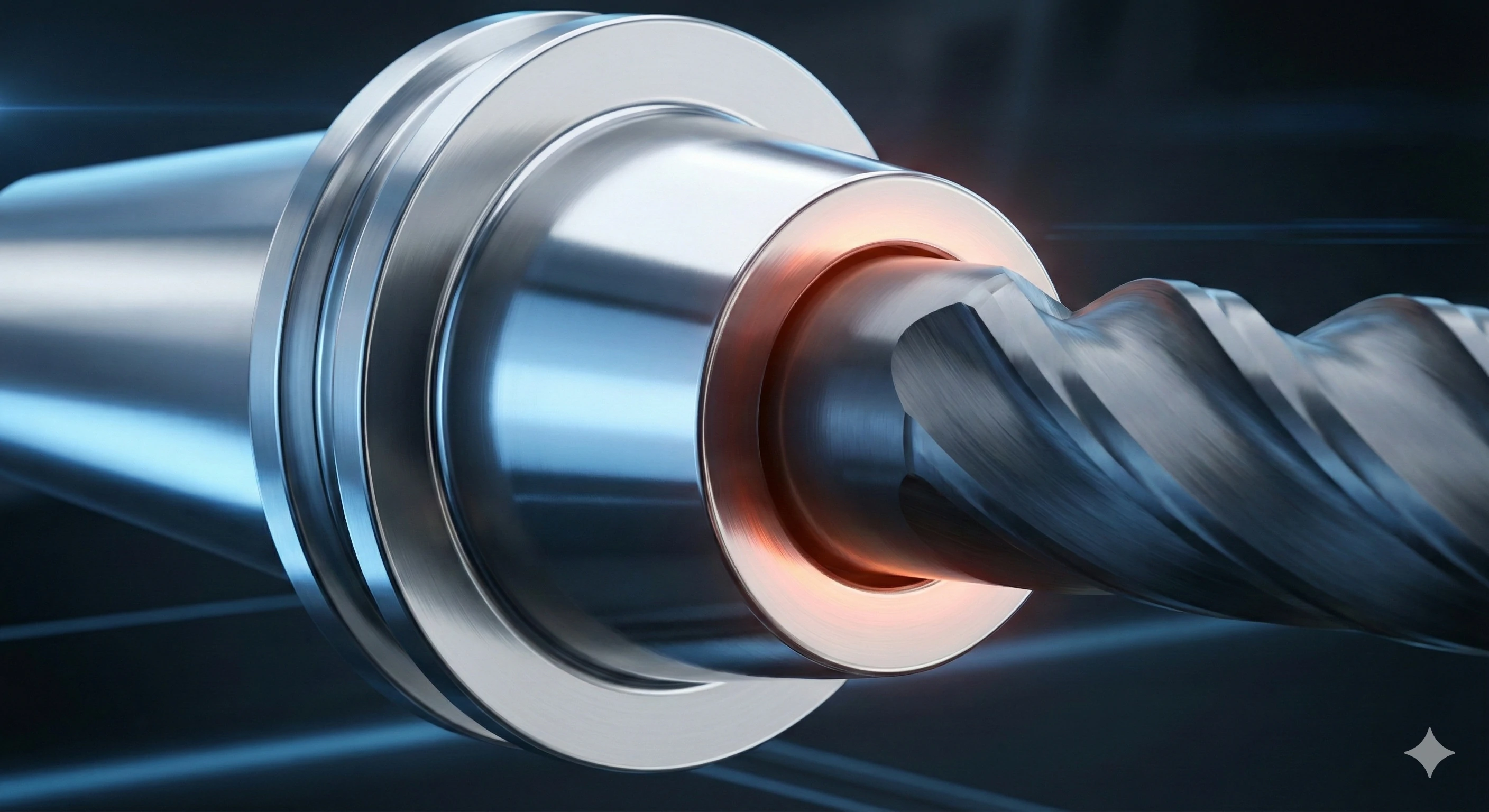

Our production team knows that runout—the wobble of a tool—is the enemy of precision. When we select , we are looking for the perfect interface between the machine's high-speed spindle and the cutting tool. If the connection isn't perfectly concentric, the holes we drill will be oval instead of round, and our tool life will decrease significantly.

Toolholding devices act as the critical interface between the machine spindle and the cutting tool, such as a drill bit or end mill. Quality holders minimize runout and vibration, ensuring that the tool rotates perfectly on its center axis for precise, high-speed machining.

The tool holder must grip the cutter with immense strength to prevent it from being pulled out during heavy cuts. We use different systems depending on the required precision and the type of cutting we are doing.

Common Toolholding Systems

The most versatile holder we see in shops is the Collet Chuck, specifically the . It uses a slotted sleeve to grip the tool. However, for our high-precision work, we often turn to Shrink Fit Holders. These use heat to expand the metal holder; we insert the tool, and as it cools, the metal shrinks around the tool. This provides maximum concentricity and balance.

The Pull Stud

Often overlooked, the pull stud is the knob at the top of the holder that the machine's drawbar grabs to pull the tool into the spindle. It is a small part, but if it fails, the tool falls out.

Comparison of Tool Holding Technologies

| Feature | ER Collet Chuck | Shrink Fit Holder |

|---|---|---|

| Grip Method | Mechanical compression via nut | Thermal contraction (Heating/Cooling) |

| Flexibility | High (Change collet sizes) | Low (Fits only one shank diameter) |

| Runout (Precision) | Good | Excellent (Very low wobble) |

| Setup Time | Fast | Requires heating unit |

| Cost | Moderate | High |

Investments in high-quality shrink fit holders pay off by extending the life of expensive carbide end mills.

Category 3: Auxiliary Attachments (Expanding Function)?

To remain competitive, we cannot afford to have machines sitting idle while operators load parts. We equip our machining centers with that expand their capabilities beyond simple cutting. By adding these devices, we transform a standard machine into a high-production cell capable of handling complex geometries like impeller blades.

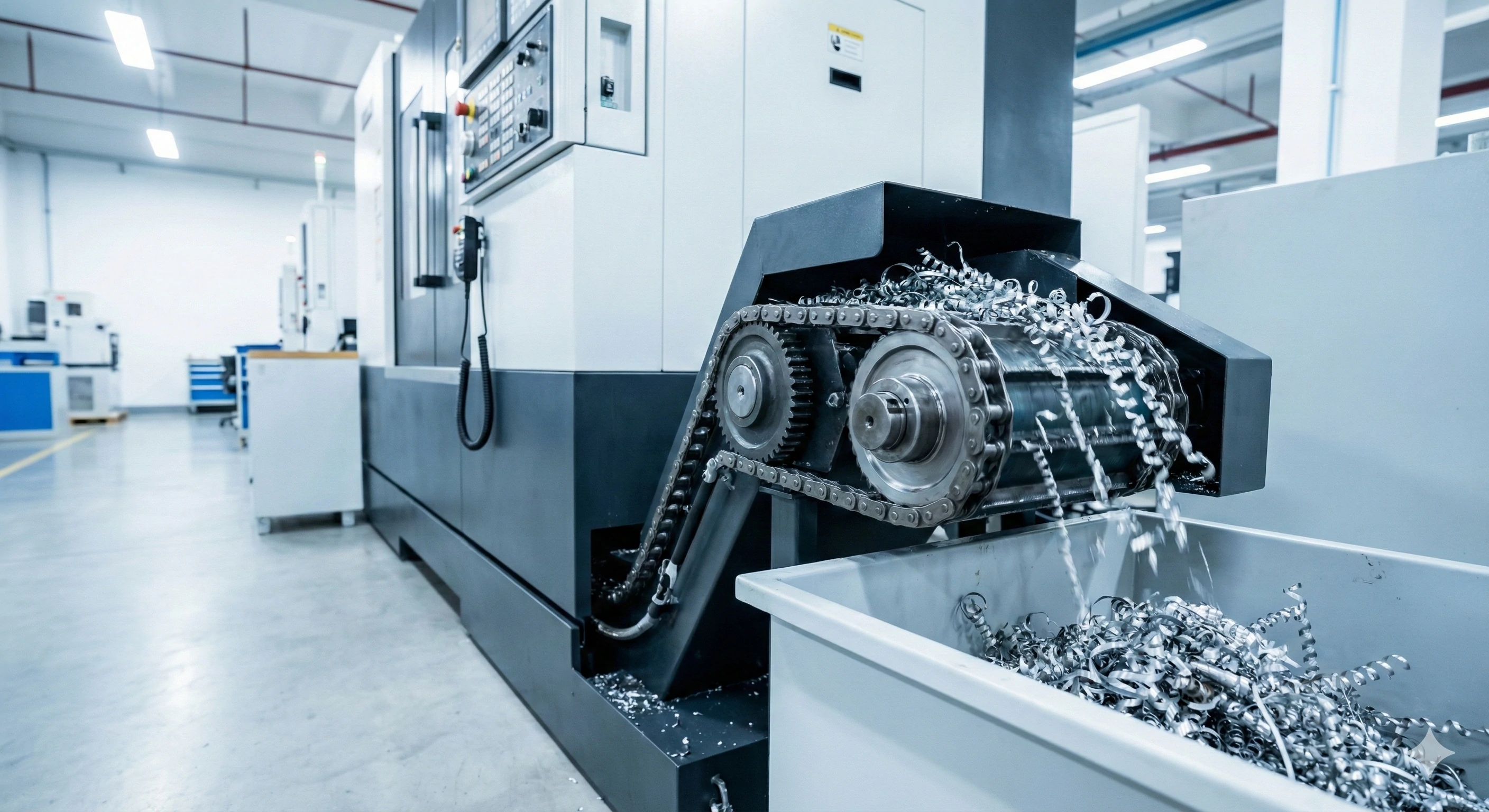

Auxiliary attachments are advanced upgrades like rotary tables, pallet changers, and chip conveyors that expand a standard machine's capabilities. They allow for multi-axis machining of complex curves, automate waste removal, and enable continuous production by reducing downtime.

These accessories are what separate a hobby garage from a professional manufacturing facility. They focus on efficiency and geometry.

Rotary Tables (The 4th Axis)

A standard mill moves in three axes: X, Y, and Z. A Rotary Table adds a , spinning the part while the cutter works.

-

Why we use it: It allows us to reach the sides of a part without stopping the machine to manually flip the workpiece.

-

Application: Essential for machining helical shapes like impeller blades.

Automation Aids

-

Pallet Changers: These allow our operators to load "Part B" on a fixture outside the machine while "Part A" is currently being cut inside. This eliminates the downtime usually required for loading.

-

Chip Conveyors: Machining creates a massive volume of waste metal. A conveyor automatically so the machine doesn't jam, allowing us to run lights-out manufacturing.

Category 4: Probing & Feedback Systems (The "Eyes")?

In the past, our setup technicians used and paper shims to locate the part, which was slow and prone to human error. Now, we rely on probing systems to act as the "eyes" of the machine. By touching the part automatically, we eliminate the guesswork and ensure that the machine knows exactly where the material is located before it takes the first cut.

Probing and feedback systems are electronic sensors that automatically measure the position of the workpiece and the length of the cutting tools. They eliminate human setup errors, reduce downtime, and ensure the machine detects part location with micron-level accuracy.

We typically use technology from brands like to streamline our setup process. There are two main types of "eyes" we install inside the machine.

Tool Setters vs. Part Probes

-

Tool Setters: These are sensors mounted on the machine table. The machine lowers the drill bit onto the sensor to automatically measure the tool's length and diameter. This ensures the machine knows exactly where the tip of the tool is.

-

Part Probes: These are mounted in the spindle like a tool. They touch the casting to find the "Zero" point automatically.

The Impact on Quality

Using probes changes the workflow entirely. Instead of spending 20 minutes manually dialing in a part, the probe does it in 30 seconds.

| Setup Method | Accuracy | Time Required | Risk of Error |

|---|---|---|---|

| Manual Edge Finder | Depends on operator skill | 10-20 Minutes | High (Human error) |

| Automated Probe | Micron-level precision | < 1 Minute | Near Zero |

Why "Custom Fixtures" Are the Most Important Accessory for Foundries?

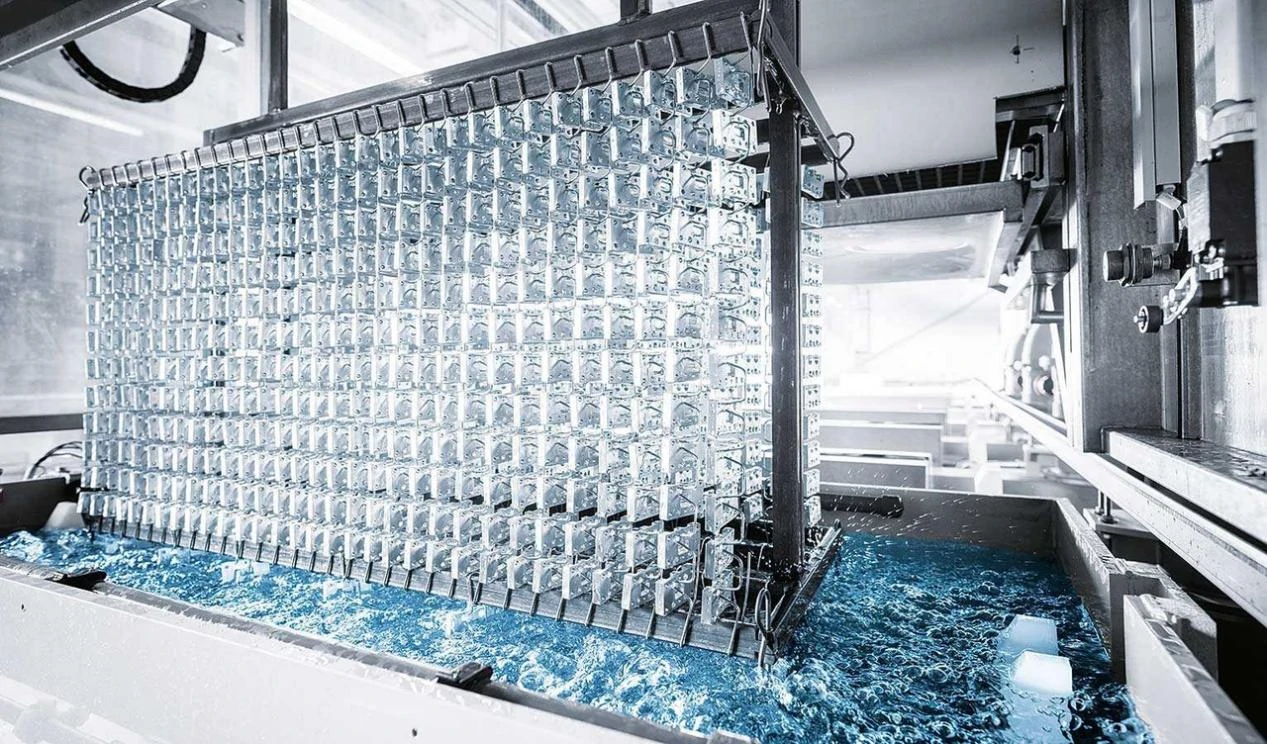

We have found that a standard CNC machine is designed primarily to hold square blocks, but the products we manufacture, such as Glass Spigots or Manifolds, are rarely square. This mismatch creates a bottleneck. To solve this, our in-house tooling team builds custom fixtures that allow us to mass-produce these difficult shapes with speed and precision.

Custom fixtures are specialized workholding solutions engineered to grip specific, non-square parts like manifolds or spigots. Unlike standard vises, they can hold multiple parts simultaneously for simultaneous drilling, significantly reducing cycle times and production costs.

This is where the real engineering value lies. While you can buy a vise off the shelf, you cannot buy a fixture for a unique casting off the shelf.

Jig vs. Fixture: What’s the Difference?

A common question we get is the .

-

A Fixture holds the workpiece in place—it is strictly a workholding device.

-

A Jig holds the workpiece and guides the tool (like a drilling template).

In modern CNC machining, we mostly use fixtures because the computer guides the tool path, making physical guides unnecessary.

Our Approach to Custom Tooling

We design specific accessories to grip the curved surfaces of castings without crushing them. For example, we recently built a fixture that holds 10 glass spigots at once. This allows the machine to drill all 10 parts in a single run, rather than opening and closing the door 10 times. The result is a drastic reduction in cycle times and lower prices for our clients.

Conclusion

Ultimately, the machine provides the power, but the accessories provide the control. Whether it is the rigidity of the workholding or the balance of the tool holder, these components make the difference between a scrap part and a precision component.

If you have a complex part that other shops struggle to hold, we can help. We design and build Custom CNC Fixtures in-house to ensure even the most difficult castings are machined to perfection. Send us your drawing for a manufacturing review.

Footnotes

1. Overview of numerical control history and technology.

2. Comprehensive guide to workholding types and applications.

3. Catalog and data on precision tool holding systems.

4. Technical explanation of collet mechanics and uses.

5. Insights into accessories that boost machine productivity.

6. Benefits of adding rotary axes to standard mills.

7. Solutions for automated chip management and removal.

8. Comparison of manual edge finders versus automated probes.

9. Leading manufacturer of industrial metrology equipment.