In precision casting manufacturing, "wax die pressing" serves as a critical preparatory process for achieving complex structures and high-precision components —— By molding molten wax into wax patterns matching the final casting, engineers can create investment molds and ultimately produce precision castings. From intricate aerospace turbine blades to medical device components, the "precise replication" capability of wax die pressing is indispensable. However, industry practitioners often raise questions: "How does wax die pressing differ from conventional casting?" "What ensures dimensional accuracy of wax patterns?" "Are there variations in wax die pressing techniques for different material types?" Today, we will explore the technical essentials of casting wax die pressing through four dimensions: process principles, core procedures, quality control, and application scenarios, while elucidating its fundamental value in precision casting.

The core logic of wax die die casting is to replicate precision with a "wax model" and achieve "near net forming" of castings

Wax die compression casting (also known as "wax mold pressing") serves as the first critical process in precision casting (such as lost-wax casting), fundamentally employing a "wax-for-steel" replication technique ——. The process involves molding wax material into a wax pattern that perfectly matches the final casting through mold operation. Subsequent procedures including shell coating, dewaxing, baking, and pouring enable molten metal to precisely fill the cavity left by the wax pattern, ultimately producing castings with high dimensional accuracy and superior surface quality. The greatest advantage of this technique lies in its "near-net forming" capability – requiring minimal machining after casting, needing only minor finishing touches to meet specifications, thereby significantly reducing material waste and processing costs.

Compared with traditional sand casting, the core difference of wax die casting lies in "mold and medium":

- Traditional sand casting mold is used as a cavity, with low precision (dimensional tolerance IT12-IT14), rough surface (Ra50-12.5μm);

- The wax-cast die uses metal molds to press wax models, with wax model precision reaching IT8-IT10 grades and surface roughness Ra1.6-3.2μm. Based on this, the castings produced can maintain stable accuracy at IT9-IT11 grades and surface roughness Ra3.2-6.3μm, making it particularly suitable for manufacturing complex structures (such as multi-cavity holes, thin walls, and irregular curved surfaces).

The core process of die casting: from wax preparation to wax mold formation, each step affects the quality of casting

Wax die die casting seems simple, but it actually contains "wax material formula, mold preheating, pressing parameter control, wax model trimming" and other key links. The operation details of each link directly determine the quality of wax model, and then affect the precision and qualified rate of the final casting.

1. Wax preparation: Selecting the right wax material is the basis of wax mold quality

The performance of wax material (such as melting point, hardness, shrinkage rate) is the core factor affecting the die casting of wax parts. The appropriate wax material formula should be selected according to the material and precision requirements of the castings. At present, there are two main types of wax materials used in industry:

- Wax base wax material: mixed with paraffin (accounting for 60%-80%) and stearic acid (20%-40%), with low melting point (50-60℃), good fluidity, easy to press complex wax mold, low cost, suitable for aluminum alloy, copper alloy and other medium-low temperature casting parts;

- Rosin-based wax material: A mixture of rosin (30%-50% by weight), paraffin wax, and mineral wax with a high melting point (70-85℃°C), high hardness (Shore hardness ≥25), and low shrinkage rate (linear shrinkage 0.8%-1.2%). It is suitable for casting high-temperature components such as stainless steel and high-temperature alloys, effectively preventing mold deformation during subsequent processes like shell coating and baking.

When preparing wax materials, strict control of temperature and stirring speed is essential: Heat the wax material to a molten state (temperature 10-15℃ above the melting point, e.g., paraffin-based wax heated to 60-75℃), maintaining a stirring speed of 30-50 rpm to ensure uniform distribution of components and eliminate air bubbles. —— If air bubbles are introduced into the wax material, the molded wax parts will develop pores, which may lead to sand holes in subsequent castings.

2. Mold preheating and spraying mold release agent: ensure the smooth demolding of wax mold and avoid surface damage

Wax die die casting mold is mostly made of metal (such as 45# steel, Cr12MoV), two key preparations are required before pressing:

- Mold preheating: Heat the mold to a temperature close to the wax material's melting point (e.g., 45-55℃ for paraffin-based wax materials, 55-65℃ for rosin-based wax materials). If the mold temperature is too low, the wax material will rapidly solidify upon contact, reducing its fluidity and failing to fill the mold cavity's intricate details. Conversely, excessive temperatures may cause the wax to stick to the mold surface, resulting in surface scratches during demolding.

- Spray mold release agent: Apply a thin layer of release agent (e.g., silicone-based or soap-based types) uniformly across the mold cavity surface to create a lubricating layer that ensures smooth wax pattern demolding. Strictly control the amount of release agent used ——: Insufficient application may cause the wax pattern to stick to the mold, while excessive application leaves residual release agent on the surface. This residue weakens the adhesion between the coating and wax pattern during subsequent shell application, resulting in pitted surfaces on castings.

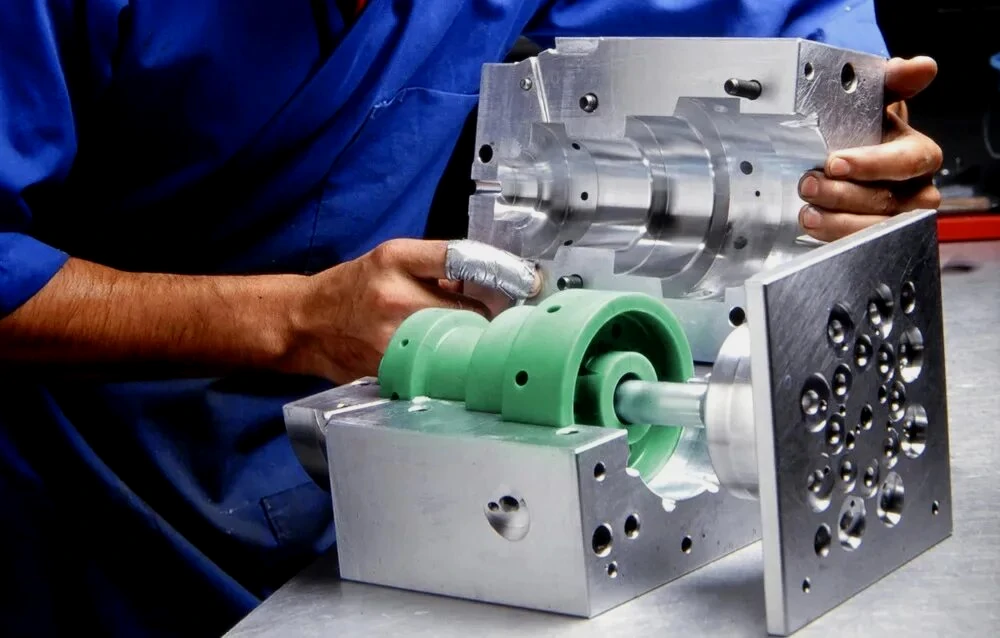

3. Wax model pressing: control "pressure, temperature and time" to accurately reproduce the cavity

Wax molding is the core process. The molten wax material is pressed into the mold cavity by die casting machine. The key parameters should be adjusted according to the type of wax material and structure of castings:

- Mold pressure should generally be maintained between 0.5-5 MPa. For simple wax patterns (e.g., flat plates), the pressure can be set at 0.5-1.5MPa. However, for complex structures like multi-cavity molds or thin-walled components, the pressure must be increased to 2-5MPa to ensure complete filling of every cavity detail. Excessive pressure may cause mold deformation, while insufficient pressure results in inadequate wax density, leading to porosity issues.

- Pressure holding time: that is, the time to maintain pressure after the wax material fills the cavity, usually 5-20 seconds. If the pressure holding time is insufficient, the pressure will be released before the wax material is completely solidified, which is easy to shrink and deform the wax mold; if the time is too long, it will increase the production cycle and reduce the efficiency.

- Demolding Time: The duration required to open the mold and remove the wax pattern after pressure retention ends. The demolding process should be performed when the wax material is fully solidified yet retains sufficient flexibility (typically 3-10 seconds post-pressure retention). Premature demolding may result in insufficient strength and brittleness of the wax pattern, while delayed demolding could lead to excessive cooling shrinkage and increased dimensional deviations.

4. Wax model trimming: Remove defects and ensure that the precision meets the standard

The pressed wax mold needs to be manually or mechanically trimmed to remove two types of defects:

- Process allowance: such as the sprue of the wax mold, flash, burr, these are the inevitable excess parts in the die casting process, which need to be trimmed with special tools (such as craft knife, sandpaper) to ensure that the shape of the wax mold is consistent with the design of the casting.

- Surface Defects: Inspect the wax model surface for defects such as bubbles, material deficiency, or scratches. For minor bubbles (≤0.5mm in diameter), repair by welding the wax material and polishing it smooth. For severe defects like material deficiency or scratches, assess their repairability. Defective wax models must be scrapped and remade to prevent quality issues in subsequent casting processes.

Quality control of wax part die casting: from size to surface, guarding the "first line of defense" of precision casting

The quality of wax mold directly determines the quality of casting, so it is necessary to establish a whole process quality control system, focusing on three core indicators: dimensional accuracy, surface quality and density uniformity.

1. Dimensional precision control: from mold to process, multiple guarantees

Wax mold size accuracy is the basis of casting size accuracy, which needs to be controlled by three measures:

- Mold accuracy calibration: the cavity size precision (tolerance ±0.02-0.05mm) should be guaranteed during mold processing, and the mold size should be calibrated regularly (every 1000 pieces of wax model produced) with a three-coordinate measuring instrument to avoid the wax model size deviation caused by mold wear.

- Wax material shrinkage compensation: Wax material contracts after cooling, requiring size compensation during mold design based on the wax material's shrinkage rate (e.g., 1.0%-1.5% for paraffin-based wax). For example, if the casting design size is 100mm, the mold cavity should be set to 101-101.5mm to ensure the wax model meets the required dimensions after cooling and shrinkage.

- Batch sampling: 5%-10% of each batch of wax models are randomly selected for size testing, focusing on key dimensions (such as positioning hole diameter, distance between reference surfaces). If the size deviation exceeds the tolerance (usually ±0.1mm), parameters such as pressing pressure and holding time should be adjusted to ensure the stability of subsequent wax model accuracy.

2. Surface quality control: eliminate defects and ensure the effect of coating shell

The surface quality of wax mold directly affects the surface quality of castings, which should be checked and controlled:

- Surface roughness: measure the surface of wax mold with a surface roughness meter to ensure that Ra value is less than or equal to 3.2μm. If there are obvious mold grooves or scratches on the surface, it should be polished and repaired to avoid corresponding defects on the surface of castings in the later stage.

- Bubbles and material shortage: through visual or magnifying glass inspection of the wax mold surface, no bubbles with diameter>0.5mm or material shortage with area>5mm² are allowed. These defects will lead to the occurrence of sand holes and meat shortage in the casting, which will affect the performance of use.

- Deformation: For slender and thin-walled wax models (e.g., length> 200mm, thickness <2mm), the straightness and flatness should be measured with a percentage gauge or platform. The deformation should be controlled within 0.1mm/m to avoid casting deformation leading to bending of castings in the later stage.

3. Control of density uniformity: avoid shrinkage and shrinkage of castings

The uneven density of wax mold will lead to the uneven wall thickness of the cavity after the subsequent casting and baking, and the shrinkage and shrinkage holes are easy to occur when pouring the metal liquid. The key to control the uniformity of density is:

- Deaeration during wax melting: In the process of heating and melting wax material, vacuum deaeration or stirring deaeration is used to remove bubbles in wax material and ensure uniform density of wax material (usually the density of wax mold is controlled at 0.9-1.1g/cm³).

- Exhaust during pressing: set an exhaust groove (width 0.1-0.2mm, depth 0.05-0.1mm) at the highest point of the mold cavity to allow the air in the mold cavity to be discharged smoothly during pressing, so as to avoid the air trapped in the wax mold to form bubbles and affect the uniformity of density.

Typical application scenarios of wax die die casting: Which castings can not be separated from this process?

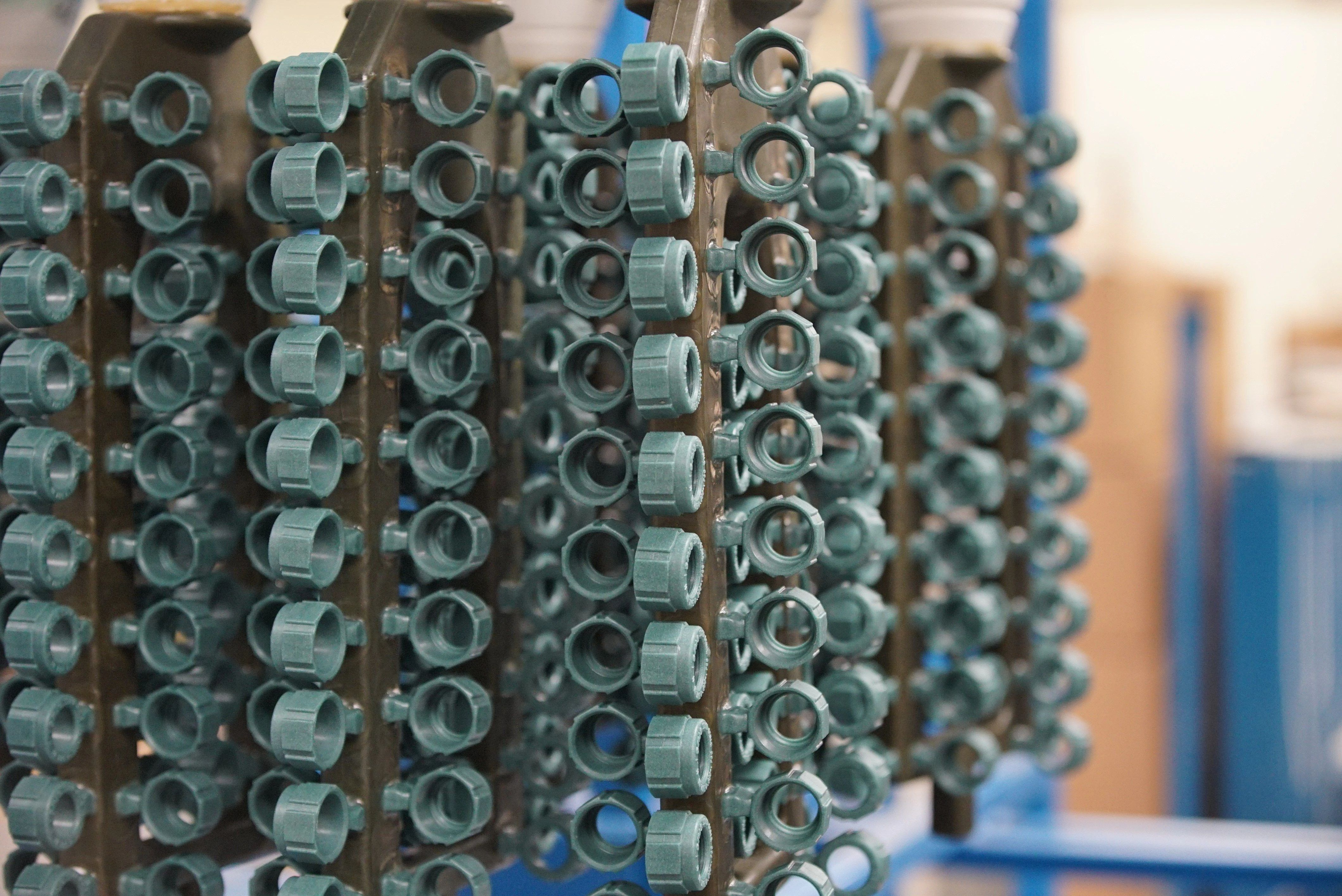

Wax die die casting is indispensable in the manufacturing of precision castings in many industries due to its advantages of "high precision and complex structure adaptation". The following are three typical application scenarios:

1. Aerospace: complex high temperature alloy castings

In the aerospace industry, castings such as turbine blades and engine combustion chambers typically feature intricate irregular surfaces and multi-cavity cooling structures, often made from high-temperature alloys like GH4169. These components require exceptional dimensional precision (tolerance ±0.05mm) and superior surface quality. Mold casting technology precisely replicates these complex geometries. Wax patterns created with rosin-based materials maintain structural integrity during high-temperature firing, ensuring castings meet stringent aerodynamic performance and strength standards.

2. Medical devices: precision stainless steel accessories

Casting components in medical devices (such as surgical joints and implantable accessories) require not only IT9-grade dimensional precision but also flawless surface finishes to prevent bacterial growth. The die-casting process employs paraffin-based wax materials, producing castings with a surface roughness of Ra ≤1.6 μm. Subsequent lost-wax casting of stainless steel components achieves medical-grade surface characteristics without extensive machining.

3. Automotive parts: lightweight aluminum alloy castings

Under the trend of automotive lightweighting, an increasing number of complex aluminum alloy castings (such as transmission valve bodies and engine cylinder heads) are adopting wax injection molding technology. Paraffin-based wax materials, with their low cost and excellent fluidity, can rapidly produce wax patterns featuring densely packed oil passage holes. After casting, these components demonstrate high precision in oil passage holes (tolerance ±0.1mm), reducing subsequent machining processes and lowering production costs while achieving lightweight design in castings.

Conclusion

As the "first process" in precision casting, wax piece die-casting directly determines the accuracy and performance of final castings ——. Every step—from selecting wax material formulations to controlling pressing parameters and inspecting mold quality—requires meticulous operation and control. For professionals in precision casting manufacturing, understanding the process logic and quality control essentials of wax piece die-casting can better optimize production workflows, improve casting yield rates, and enhance product competitiveness.

If you have any questions about "the choice of wax material for castings with different materials" and "the pressing scheme for wax models with complex structures", please leave a message in the comment section. We will continue to share more popular science knowledge related to die casting!