Wooden doors, as one of the oldest architectural components, are always looking for a balance between natural texture and artificial techniques - it not only has to convey the warm touch of wood, but also has to withstand the physical challenges of high-frequency use: sagging door sashes, rattling hinges, and cracked screw holes. ......

When the traditional hinge “squeak” sound breaks the silence, when the door gap error destroys the purity of minimalism, a precision revolution for the wooden door quietly came. Hydraulic Door Closer Hinge, a technology once reserved for heavy metal doors, is a cross-domain fusion of material science and mechanical engineering to redefine the value dimension of wooden doors.

The mission of wooden door hinges The problems we face

The demand for hinges for wooden doors is much more than just “being able to turn”. The core challenge stems from the natural properties of wood:

Solid wood doors: uneven density (e.g. walnut ≈ 640kg/m³, pine ≈ 450kg/m³), easy to bend and deform under long-term gravity, hinges need to provide continuous anti-sagging force.

Composite door: the difference in thermal expansion coefficient between core material (honeycomb paper/density board) and surface veneer requires hinges with micron-level displacement compensation capability.

Material Dialog Requirements

The surface treatment of the hinge needs to be symbiotic with the wood grain style (matte black/brushed bronze) to avoid the metallic texture destroying the natural aesthetics.

The design of screw holes must be adapted to the direction of wood fibers to prevent cracking caused by stress concentration.

Sensory experience upgrade

The opening and closing noise should be ≤30dB (equivalent to the ambient sound of the library), eliminating the metal friction sound of traditional hinges.

The closing trajectory should simulate natural damping, avoiding the abrupt stop of mechanical sense.

Aleader wooden doors are adapted to various requirements, realizing a precise balance between force and beauty.

General hinges (M2/M5 series): the art of balancing economy and reliability.

Design positioning: for the mass market, cost-effective, easy to install and maintain as the core, this product in addition to wooden doors, suitable for fire doors, security doors, steel doors, framed glass doors and so on. Covering a variety of customer needs door type

M2 Series Classic Exterior Door Pivot System - Engineering expression of traditional aesthetics and structural strength.

Exterior hinge system

Visual structural design: 6mm decorative hinge frame, available in matte black/gold/bronze/etc. and customized.

Surface adaptation process: micron-level sandblasting treatment, perfectly matching the natural wood grain texture of mahogany/teak/oak, etc.

Monoblock Load: steel hinge base, vertical load 40-80kg (EN 1935)

Safety redundancy: structural deformation ≤0.8mm when sudden lateral force 300N.

M2 Series Parameters

Applicable temperature: -20°C~50°C

Maximum load bearing value

Maximum door weight ≤80 kg

Maximum door height ≤2400mm

Maximum door width ≤1200mm

Door thickness ≥40mm

M5 Series Industrial Heavy Duty Door Systems - An Engineered Balance of High Loads and O&M Efficiency

Core Advantages

Intelligent cushioning

Hydraulic damping system realizes “buffer at touch”, the door opens and closes quietly, bidding farewell to impact noise.

The closing speed at the end is automatically reduced to 0.3m/s, preventing the door from hitting the door frame and protecting the door structure.

Windproof and shockproof, stable and durable

Special hinge structure + high-precision hydraulic oil circuit to resist door shaking in strong wind environment and avoid accidental closure.

Resistant to humidity, temperature difference and other complex environments, corrosion-resistant life increased by 50%.

Convenient installation

The product does not need to distinguish between left and right opening, which is very user-friendly, saves labor and is easier to adjust. All rotating parts are connected with bearings, quiet, efficient and durable.

Maximum tolerance values

Maximum door weight 90 kg

Maximum door height ≤ 2400 mm

Maximum door width ≤1200mm

Door thickness 40-60mm

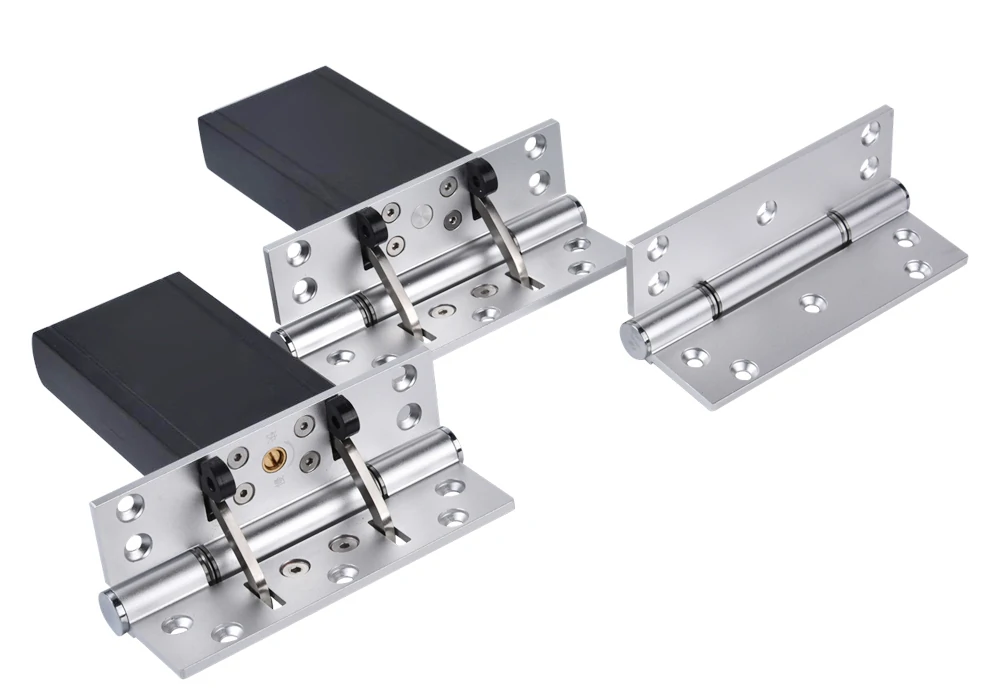

Concealed hinges (M9/M10 series): let the door become a space magician

Design positioning: for the high-end market, with minimalist aesthetics and intelligent adjustment as the core, redefining the relationship between the door and the wall.

M9 series invisible door system - a technical model of precision adjustment and structural integrity

One-piece cantilever design

Adopting the world's first cascading damping integration technology, the load-bearing hinges and cushioning system are integrated into the unilateral structure, realizing the minimalist visual effect of zero exposure of the door opening and closing.

Fully embedded structure: the hinges are completely hidden in the door frame, leaving only 0.3mm micro-adjustment holes on the surface.

Three-dimensional tolerance compensation mechanism

Vertical compensation: ±2.5mm floor height error is automatically corrected.

Horizontal compensation: ±2.5mm wall tilt adjustment.

Depth compensation: ±2.5mm wall flatness adaptation

Durability

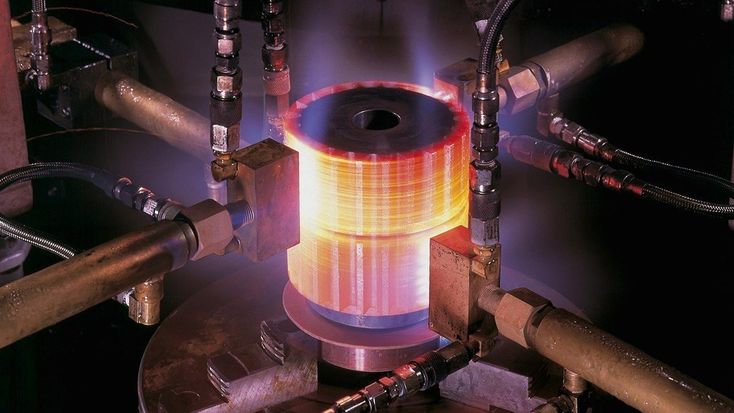

Main structure: 6063-T6 aviation aluminum casting process.

Motion components: zirconia ceramic bearings + PTFE self-lubricating bushings

Measured life: 200,000 times after the opening and closing test to maintain 90% damping efficiency

Hydraulic medium: special silicone-based buffer fluid, -5 ℃ ~ 45 ℃ interval viscosity fluctuation rate of ≤ 5%.

Technical Highlights

Modular side-mounted hydraulic unit

By placing the buffer system parallel to the hinge axis, it maintains the complete structure of the wooden door core and is suitable for 5mm ultra-thin composite door panels.

M10 Series Single Side Concealed Damping System - The Perfect Fusion of Minimalist Aesthetics and Precision Engineering

Intelligent Dynamic Damping System

Three-stage intelligent damping: a unique hydraulic feedback system with 0.1 second response time.

Strong buffer section (80°-40°): Innovative vortex oil circuit design, realizing the industry-leading 25° uniform closing trajectory.

Free swing section (100°-80°): magnetic positioning technology ensures that the stability error of the door is <0.5°.

Wide-angle hovering section (115°-100°): Germany imported self-locking module, supporting the maximum 100kg door weight lasting positioning.

Performance Parameters

Temperature adaptive hydraulic oil (-5 ℃ ~ 45 ℃ performance without attenuation)

Moisture level: IP54 protection certification, humidity 95% RH environment without performance attenuation

Military-grade spring components: 100,000 fatigue tests after the damping force attenuation ≤ 8%.

Make every door, a ritual to the ideal

In Aleader's belief, hinges are not only mechanical components, but also translators of spatial emotions.

Choosing Aleader means choosing an uncompromising way of dialog-

Dialogue with wood, guarding the breath of wood grain with the precision of aviation aluminum;

Dialogue with time, fighting physical entropy increase with 200,000 cycle life;

Dialogue with human nature, with anti-pinch force ≤ 12N gentle against the coldness of industry.

We don't make hinges, we only create the ultimate tacit understanding between door and space.