In modern bathroom design, sliding shower door systems have become the preferred choice for more and more families due to their core advantages of "space-saving, high appearance, and easy use". It is not a simple combination of glass and frames, but an integrated solution centered on the precision collaborative working principle, integrating high-quality materials, precision castings, and diverse processes. To meet the needs of different apartment sizes and usage scenarios, we launch two core models: SD43-SERIES and SD44-SERIES. This article will dissect the overall working logic, core configuration differences of the two products, and reveal the core value behind the materials and casting processes.

I. Core Working Logic of the Dual Series: Homologous Collaboration with Distinct Focuses

Both the SD43 and SD44 series follow the core working cycle of "suspension support - directional sliding - limit fixation - sealing protection", achieving smooth opening/closing and efficient dry-wet separation through precise cooperation between components. However, based on different accessory configurations, they form differentiated advantages in terms of usage flexibility and load-bearing stability:

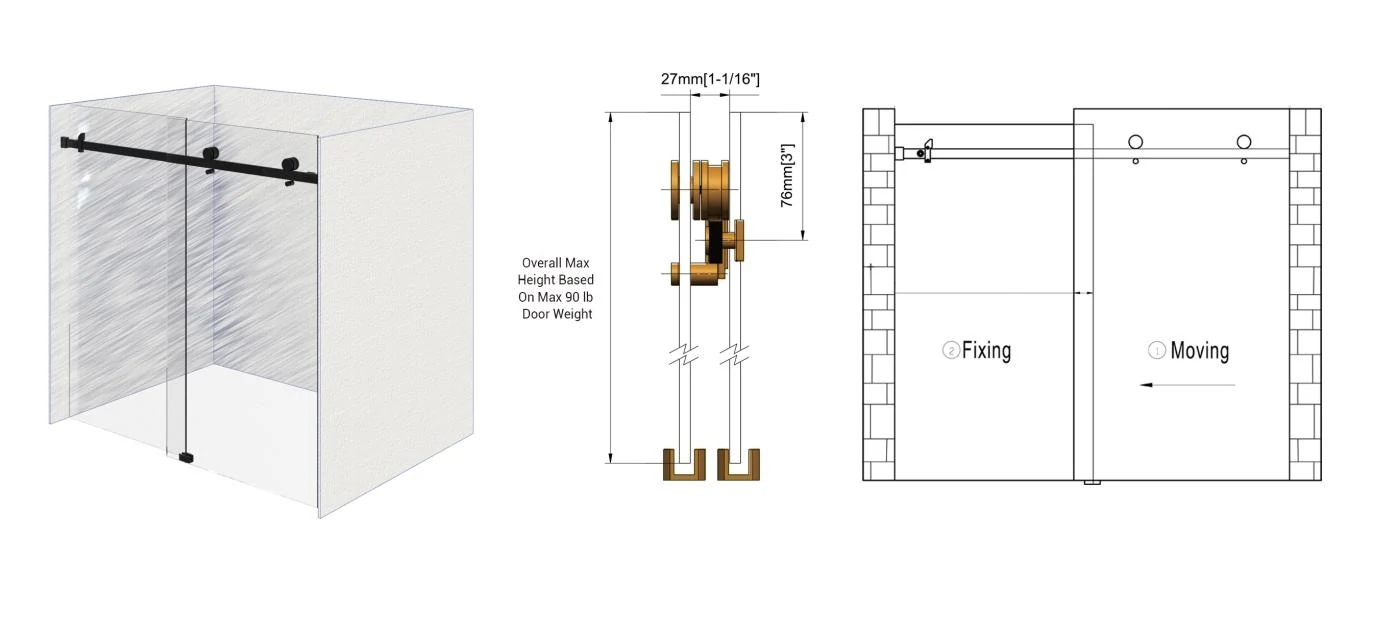

SD43-SERIES: Classic and Practical Type, Suitable for Regular Bathroom Spaces

The SD43 series takes "streamlined efficiency" as its design core, with accessory combinations focusing on the stable performance of basic functions. Its working logic is as follows:

- Suspension Support: A single door panel is suspended from the top track by 2 glass rollers, and the weight is evenly transmitted to 2 wall mount fittings. The pulley brackets and wall mount fittings, precision-cast from 304 stainless steel, stably bear the weight of 10mm (3/8") tempered glass, and the weld-free structure ensures no deformation over the long term;

- Directional Sliding: The dual cooperation of "top pulleys + 2 bottom floor guides"—the ±0.05mm dimensional accuracy of the castings ensures tight fit between the pulleys and the track, achieving silent and smooth pushing/pulling;

- Limit Fixation: 2 stoppers precisely control the door's travel range, while 2 fixed panel fittings and 2 glass adapters lock the fixed glass in place, constructing a stable boundary;

- Sealing Protection: The sealing strip installation grooves reserved in the castings closely fit the edges of the 10mm glass, combined with the waterproof design of the bottom water retaining channel, comprehensively preventing water vapor from leaking out.

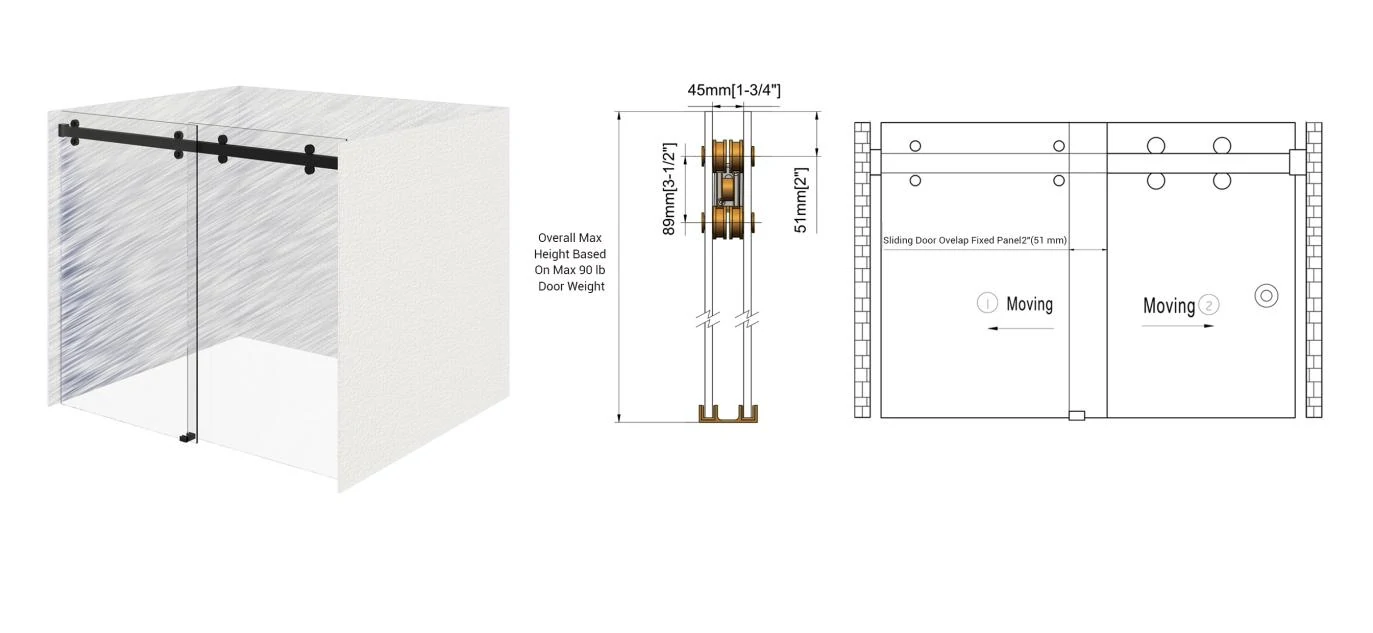

SD44-SERIES: Flexible and Durable Type, Suitable for High-Frequency Use + Multi-Scenario Needs

The SD44 series is optimized for "flexible opening/closing and high-frequency use" requirements. Its core working logic enhances "load distribution" and "sliding flexibility" based on the SD43. The accessory combination includes: 8 glass rollers, 1 bottom guide, 2 sliding panel stoppers, 2 wall mount fittings, and 1 header track. The specific operational advantages are as follows:

- Upgraded Suspension Support:Adopts a distributed load-bearing design with 8 glass rollers. Compared with the 2 rollers of the SD43, it evenly distributes the weight of the 10mm tempered glass to multiple stress points on the top track. Combined with 2 high-strength wall mount fittings, the load-bearing is more uniform and impact-resistant, maintaining long-term stability even with high-frequency opening/closing and avoiding deformation caused by excessive local stress;

- Optimized Directional Sliding:Replaces the 2 bottom floor guides with a combination of 1 integrated bottom guide + 1 integral header track. The integral header track, precision-cast from 304 stainless steel, has a straightness error ≤0.1mm/m. The 8 rollers roll evenly along the track, and both glass panels support independent sliding, allowing flexible adjustment of the opening range according to usage needs (e.g., full opening on one side, double-sided opposite opening). The pushing/pulling feel is lighter, adapting to different usage scenarios;

- Precise Limit Fixation:2 sliding panel stoppers are installed at key positions on the top track. The buffer structure is optimized for the multi-pulley distributed design, which evenly absorbs the impact force when the door reaches the limit position, avoiding hard collision between the pulleys and the track and extending the service life of the accessories, suitable for high-frequency use scenarios;

- Collaborative Sealing Protection:The integral header track and wall mount fittings have tighter connections with smaller gaps. Combined with the sealing strips on the door edges and the bottom water retaining channel, a full-dimensional seal of "top - side - bottom" is formed. The water retaining channel can quickly collect and divert splashed water, and the double-sliding design ensures the sealing area is always effectively covered, preventing water vapor from leaking out regardless of the door's opening state.

II. Shared Core Configurations of the Dual Series: Quality Assurance of Materials and Processes

Both the SD43 and SD44 series adopt unified high-quality core configurations to ensure consistency in durability, safety, and appearance:

1. Core Material: 304 Stainless Steel for "All-Round Adaptation"

The hardware castings (pulley brackets, wall mount fittings, track bases, etc.) of both series are made of 304 stainless steel, with three major advantages:

- Strong corrosion resistance: Resists high temperature, high humidity, and water vapor erosion in bathrooms, with a salt spray test duration of over 480 hours, ensuring no rusting during long-term use;

- Excellent strength: Tensile strength ≥520MPa, strong deformation resistance, perfectly matching the load-bearing requirements of 10mm glass;

- Safe and environmentally friendly: No release of harmful substances, not easy to breed bacteria, complying with bathroom health standards.

2. Glass Specification: 10mm (3/8") Tempered Glass as a Universal Choice

Both series are equipped with 3/8" (10mm) thick tempered glass as standard, balancing safety and practicality:

- Safety protection: Impact resistance is 3-5 times that of ordinary glass; when broken, it shatters into small particles without sharp edges, avoiding scratches;

- Thickness adaptation: The 10mm thickness can meet the stability of regular door panels in the SD43 and support the structural needs of high-frequency opening/closing scenarios in the SD44. It has strong temperature difference adaptability and is not easy to break.

3. Surface Treatment: Diversified Customization to Adapt to Different Styles

Both series offer a variety of surface treatment options, supporting customization on demand:

- Classic basic models: Classic Satin, Mirror;

- Matte texture models: Powder Coat Matte Black/White;

- High-end metal models: PVD-Black/Gold/Rose Gold/Gun Grey;

- Functional customized models: Anti-fingerprint, Anti-conductive Black/White, Transparent Satin/Mirror. These not only enhance the appearance but also improve the wear resistance of the castings.

4. Precision Casting Process: The "Durability Code" of the Dual Series

The core hardware components of both series are manufactured using silica sol precision casting or die-casting processes, ensuring:

- Stable structure: One-piece molding without welds, avoiding fractures caused by stress concentration;

- Precise dimensions: Casting tolerance of ±0.05mm, strong adaptability between accessories, ensuring smooth sliding and sealing effects;

- Uniform texture: Smooth and delicate surface, providing a good foundation for subsequent surface treatment.

III. Selection Guide for the Dual Series: Match Bathroom Spaces as Needed

SD43-SERIES: Suitable for Regular Apartment Types and Basic Needs

- Applicable Scenarios: Small bathroom spaces, standard-sized shower enclosures (width ≤1.2m), and families with moderate usage frequency;

- Core Advantages: Streamlined accessories, high cost-effectiveness, and stable basic functions. The combination of the bottom water retaining channel and side sealing strips meets daily dry-wet separation needs.

SD44-SERIES: Suitable for High-Frequency Use + Multi-Scenario Needs

- Applicable Scenarios: Large bathroom spaces, extra-wide shower enclosures (width >2m), and high-frequency use scenarios such as hotels/apartments;

- Core Advantages: 8-pulley distributed load-bearing and integral track design ensure stronger stability and longer service life. The tight connection between the bottom water retaining channel and precision castings further enhances leakage prevention reliability, making it suitable for large-sized door panels and high-frequency opening/closing needs.

IV. Purchasing and Usage Tips

- Select based on usage needs: Choose the SD43 for moderate daily usage frequency and pursuit of high cost-effectiveness; choose the SD44 for large families, frequent opening/closing, or emphasis on usage flexibility;

- Recognize core configurations: Regardless of the series, confirm the labels of "304 stainless steel material", "10mm tempered glass", and "precision cast hardware";

- Standardize installation and maintenance: For the SD43, ensure the 2 bottom floor guides and the water retaining channel are installed horizontally; for the SD44, focus on calibrating the parallelism of the two sliding glass panels and the installation accuracy of the bottom water retaining channel; regularly clean debris in the track and accumulated water in the water retaining channel during daily use, and apply a small amount of lubricating oil to the pulleys if necessary.

Conclusion

Although the SD43 and SD44 series sliding shower door systems have different accessory configurations and working logics, they both take "precision collaboration" as the core. Relying on 304 stainless steel precision casting technology, 10mm tempered glass, the waterproof design of the bottom water retaining channel, and diverse surface treatments, they achieve the user experience of "combining practicality and beauty, and coexisting stability and durability". Whether it is ordinary families pursuing high cost-effectiveness or scenarios requiring high-frequency opening/closing and flexible use, suitable solutions can be found. With the diversification of bathroom design, we will continue to optimize accessory combinations and processes to bring users a better dry-wet separation experience.

If you want to learn about the specific installation steps, accessory replacement tutorials for a certain series, or need customized suggestions for special apartment types (such as irregular-shaped shower enclosures),We welcome you to contact us for consultation.