When we are reviewing new designs at our factory, we often see clients who use the terms "propeller" and "impeller" interchangeably. Both components feature spinning blades and move fluids, which makes the confusion understandable. However, using the wrong component for your machinery can lead to massive inefficiencies and . We have spent years perfecting the casting of these rotating parts, and we know that their differences are fundamental to how your equipment performs.

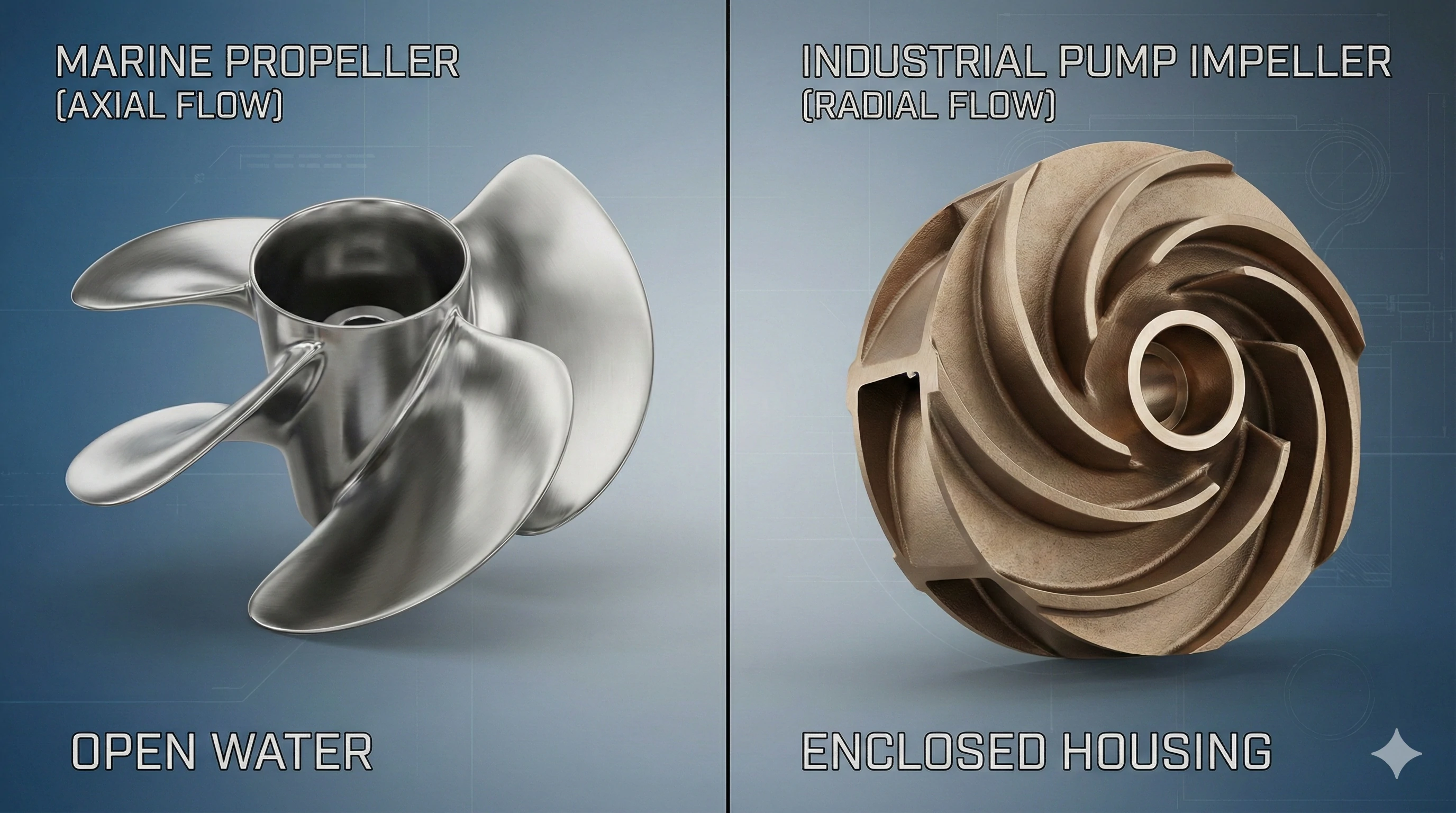

The primary difference is that a propeller is designed to move a vehicle forward by creating thrust through axial flow, while an impeller is designed to move fluid through a pipe or casing by creating pressure through radial or centrifugal force.

Understanding these mechanical distinctions is the first step toward choosing the right manufacturing process for your industrial or marine project. Let’s look at the physics that sets them apart.

1. The Physics of Flow: Axial vs. Radial?

In our experience exporting high-precision hardware to the US and Europe, we have found that the direction of fluid flow is the most reliable way to identify these parts. When our engineers analyze a drawing, the first thing they look at is the angle of the blades relative to the shaft. This determines whether the energy is pushed straight back or flung out to the side.

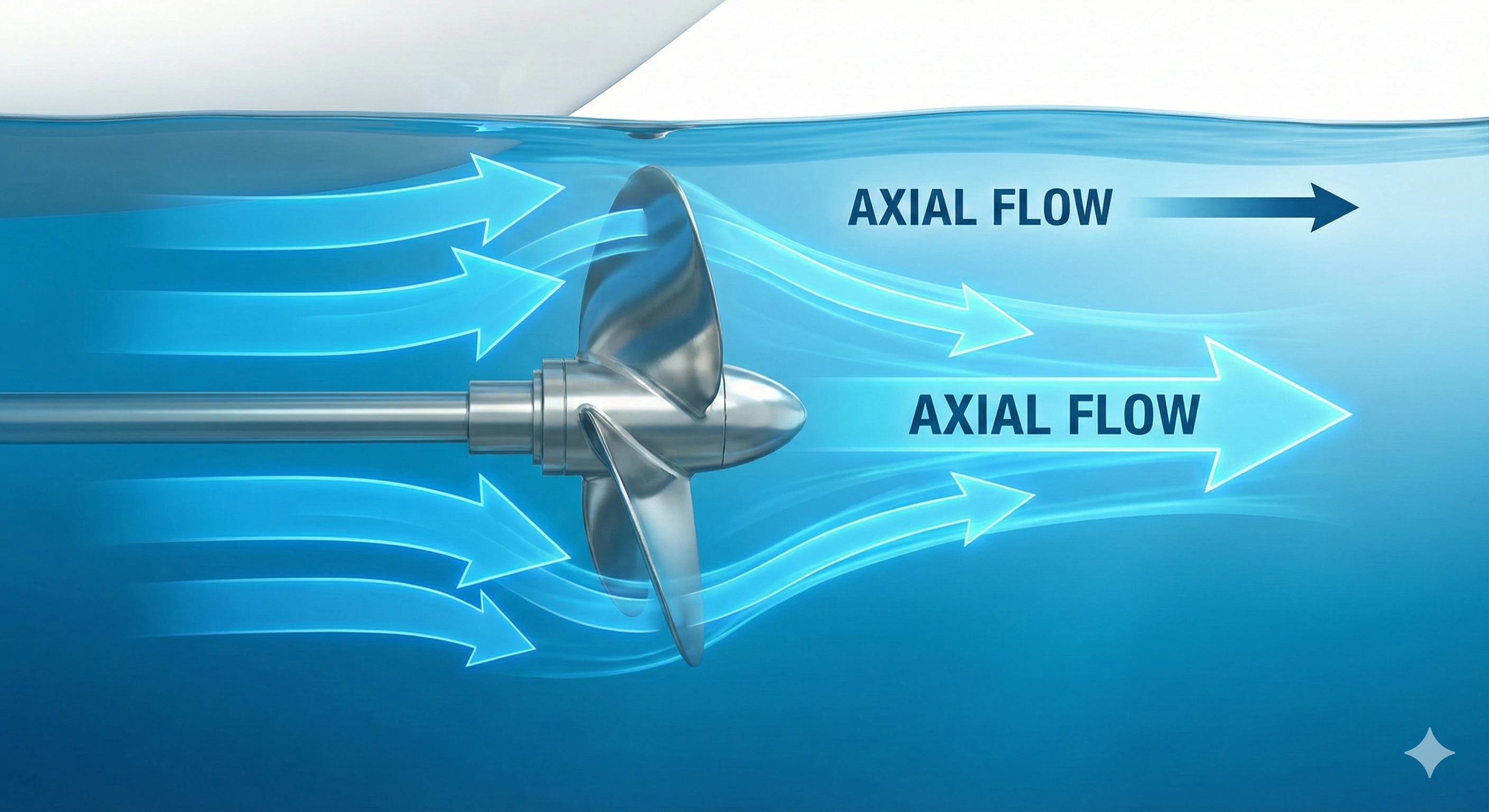

A propeller creates axial flow where fluid moves parallel to the shaft to generate thrust, whereas an impeller creates radial flow by pulling fluid into the center and flinging it outwards at a 90-degree angle using centrifugal force.

Understanding Axial Flow in Propellers

Propellers are the "screws" of the mechanical world. When a propeller spins, it grabs the fluid (water or air) and pushes it directly behind the blades. According to , this action creates an equal and opposite reaction that pushes the vessel forward. This is known as axial flow because the fluid moves along the same axis as the rotating shaft.

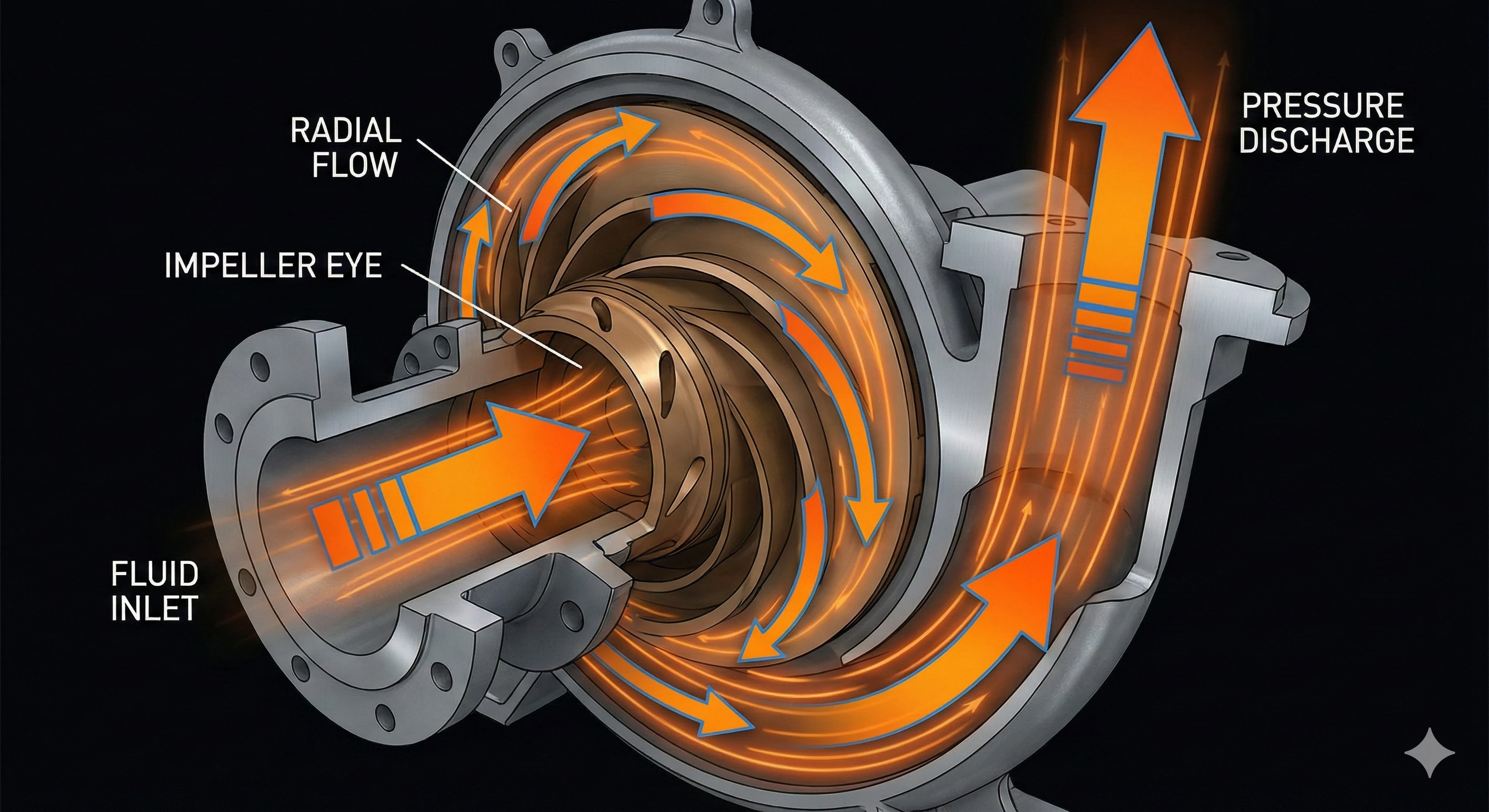

Understanding Radial Flow in Impellers

Impellers work differently. They are almost always found inside a housing. The fluid enters the "eye" or center of the impeller. As the blades spin, they use to accelerate the fluid and fling it toward the outer rim of the housing. This transition from the center to the edge is radial flow, which is excellent for building up high pressure rather than just high speed.

Comparison of Flow Characteristics

| Feature | Propeller (Axial) | Impeller (Radial) |

|---|---|---|

| Fluid Direction | Parallel to the shaft | Perpendicular to the shaft |

| Primary Force | Thrust | Centrifugal force |

| Typical Velocity | High exit speed | High internal pressure |

2. The Purpose: Thrust vs. Pressure?

Our production line handles various requests for both marine drives and industrial pumps. We have learned that the intended "job" of the part dictates its entire geometry. A propeller is a tool for mobility, while an impeller is a tool for transport. If you need to move a boat through the ocean, you need a propeller; if you need to move water through a building's plumbing, you need an impeller.

The main purpose of a propeller is to generate thrust to move a vehicle through a fluid, while the purpose of an impeller is to create pressure (head) to move the fluid itself through a restricted system or pipe.

The Power of Thrust

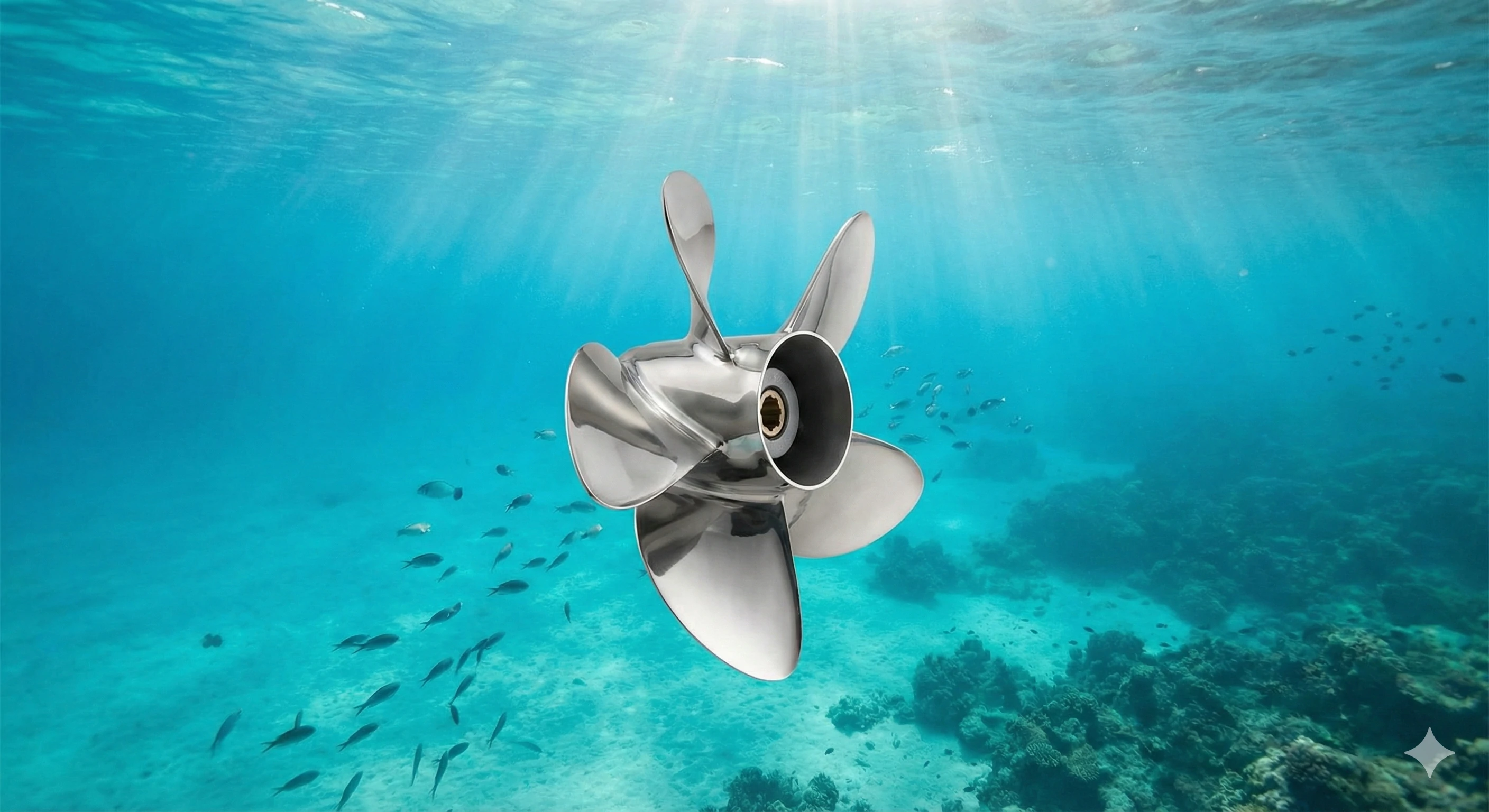

For a propeller, the key metric is how much force it can exert on the surrounding water to achieve a specific speed. Our team focuses on the "pitch" of the propeller, which is the distance it would move forward in one single revolution. Higher pitch usually means more speed but requires more torque from the engine.

The Science of Pressure and Head

In the world of pumps, we talk about "Head." This is the height to which an impeller can lift a column of liquid. Because an impeller is enclosed, it can build up significant energy within the fluid. This energy allows the liquid to overcome friction in long pipes or reach high elevations in a skyscraper.

Performance Metrics Table

| Component | Key Performance Indicator | Industry Application |

|---|---|---|

| Propeller | Knots / Thrust (Lbf) | Shipbuilding, Aviation |

| Impeller | GPM / Head (Feet) | Chemical Processing, HVAC |

3. The Environment: Open vs. Enclosed?

When we calibrate our manufacturing molds, we must consider where the part will live. A propeller is a "social" component—it needs plenty of open space and a constant supply of new fluid to work efficiently. An impeller, however, is a "recluse." It is completely useless without its surrounding casing, which we call the volute.

Propellers operate in open environments like the sea or air to move mass, whereas impellers must operate inside a tight, enclosed housing to capture and channel the pressure generated by the spinning blades.

Why Propellers Need Open Water

If you put a propeller inside a tight box, it would quickly cavitate and lose all efficiency. It relies on a steady stream of "undisturbed" fluid entering the blades. This is why you see boat propellers hanging off the back of the hull in the open water.

The Role of the Volute Casing

The impeller's housing is just as important as the impeller itself. As the water is flung outward by the impeller, the captures that fast-moving water and slows it down. This process converts (speed) into potential energy (pressure). Without the casing, the water would just spray in all directions without going into the discharge pipe.

4. Manufacturing: The Casting Challenge?

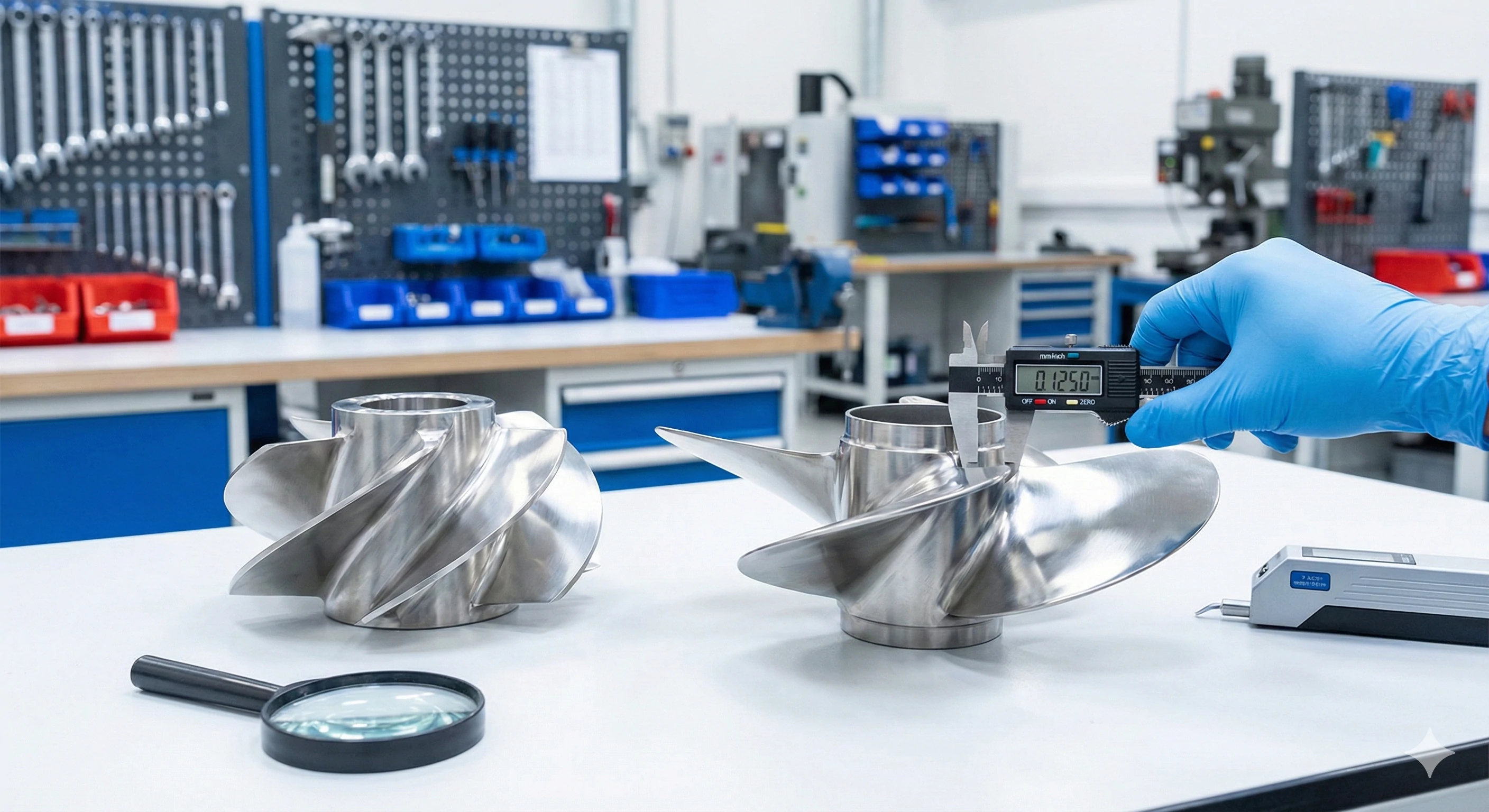

At our factory in Rizhao, we specialize in the complex geometries required for these parts. Both propellers and impellers feature "hydrofoils"—twisted 3D curves that are incredibly difficult to create. In the past, many companies tried to CNC machine these from solid blocks of metal. However, our engineers found that this wastes up to 80% of the material and is painfully slow for mass production.

The best way to manufacture propellers and impellers is through investment casting, which allows for complex twisted blade shapes, perfect balance, and smooth surfaces that prevent efficiency-killing cavitation.

The Advantages of Investment Casting

, often called "lost wax" casting, is the gold standard for these parts. We create a wax replica of the propeller or impeller, coat it in ceramic, and then melt the wax out. This leaves a hollow shell where we pour molten stainless steel (like 316 or Duplex). This method ensures that the thin edges of the blades are sharp and the balance is precise.

Material Selection for Durability

Choosing the right material is vital. For marine environments, we recommend or . These materials resist salt corrosion and are hard enough to withstand the "pitting" caused by . A well-cast part can last decades, whereas a cheap, poorly finished part might fail in a single season.

Material Comparison Table

| Material | Corrosion Resistance | Strength | Best Use Case |

|---|---|---|---|

| SS316 | Excellent | High | Marine & Chemical |

| Duplex 2205 | Superior | Very High | High-Pressure Pumps |

| Ni-Al Bronze | Great | Medium | Large Ship Propellers |

Hybrid Devices: The Inducer?

Sometimes, the lines between these two devices get blurred. In high-performance systems like jet skis or specialized industrial pumps, we use what is called an "inducer." This is essentially a small axial propeller located right in front of a radial impeller. The "propeller" part sucks the water in and feeds it to the "impeller" part, which then blasts it out at high pressure. This hybrid approach helps prevent cavitation in high-speed applications.

Conclusion

Whether you are building a new marine drive or an industrial pump system, knowing the difference between a propeller and an impeller is vital. If your goal is to move a vehicle, stick with the axial flow of a propeller. If you need to move fluids through a system under pressure, an enclosed impeller is your only choice. Both parts require extreme precision in manufacturing to ensure they don't vibrate or fail under stress. At Aleader, we provide the engineering support and investment casting expertise to bring these complex designs to life.

Frequently Asked Questions

Can an impeller act as a propeller?

Generally, no. An impeller is designed to create outward pressure against a casing. If you put an impeller on the back of a boat, it would just churn the water sideways without generating much forward thrust.

Which material is best for marine propellers and impellers?

Stainless Steel (316 or ) or Ni-Al Bronze are the best choices. These materials resist salt corrosion and are hard enough to withstand "cavitation," which is the pitting caused by tiny vacuum bubbles.

What is a "mixed flow" impeller?

It is a hybrid design used in some pumps that pushes water both axially and radially. It offers a balance between high flow rate and high pressure, often used in large-scale irrigation or flood control.

Footnotes

1. Causes and analysis of equipment breakdown in engineering systems.

2. NASA explanation of action and reaction forces in propulsion.

3. Physics overview of apparent outward force in rotation.

4. Function of pump housing in converting velocity to pressure.

5. Energy possessed by an object due to its motion.

6. Industrial process for creating complex metal components.

7. Properties and applications of marine-grade stainless steel.

8. Benefits of copper alloys for seawater corrosion resistance.

9. Impact of collapsing vapor bubbles on metal surfaces.