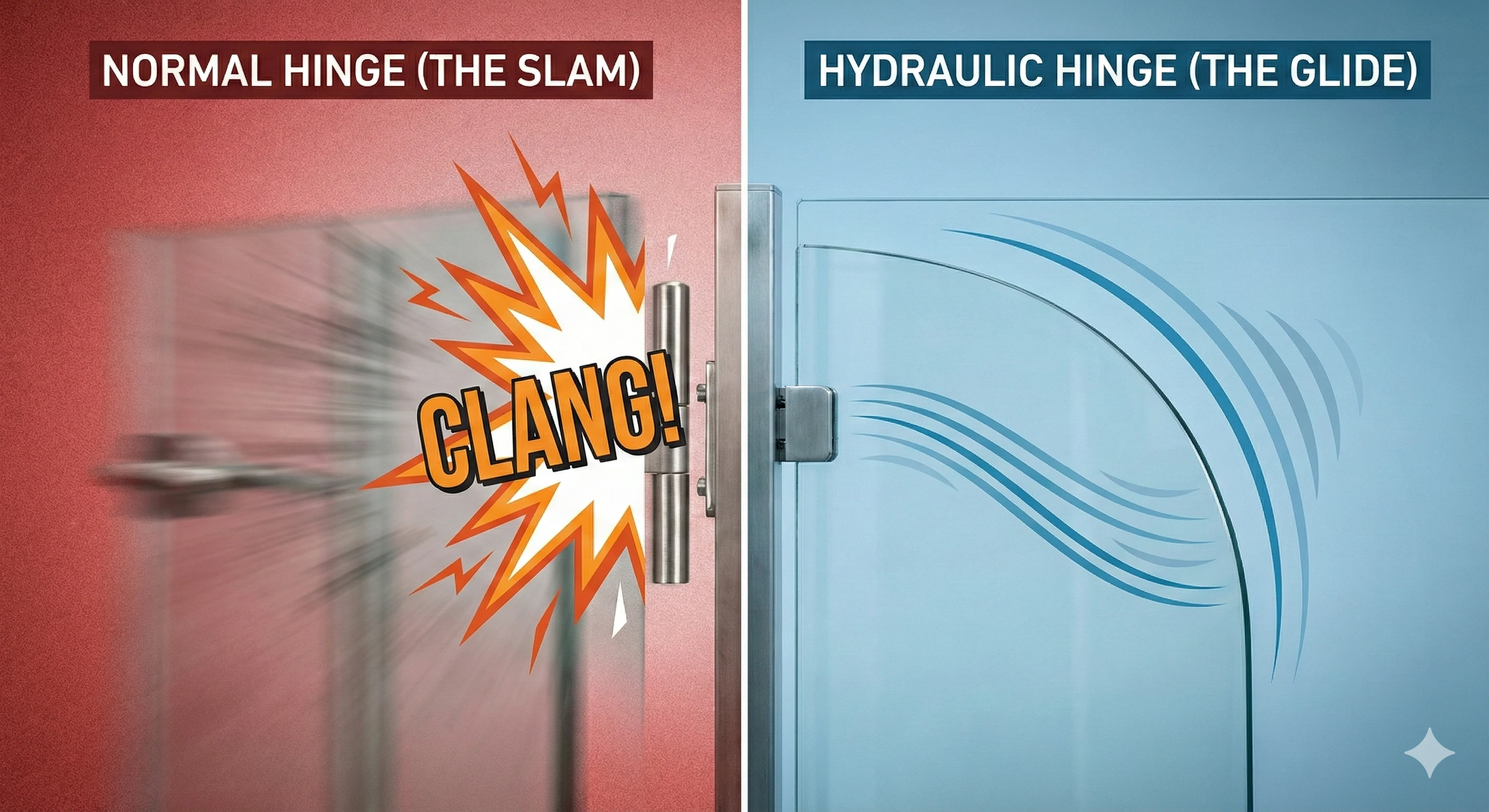

Imagine this: you’ve just spent thousands of dollars on a sleek glass pool fence that completely transforms your backyard. The installation crew wraps up, and you watch them test the gate. It swings open smoothly—then bang. The gate slams shut with a sharp crash, echoing across the yard and sending vibrations through the entire fence line.

Now picture the same gate behaving differently. It swings closed, gains speed naturally, then slows down just before reaching the latch, settling into place quietly and smoothly. No noise. No shock. Just controlled, confident movement.

That contrast sums up the difference between a standard spring hinge and a hydraulic soft-close hinge. And while noise is the most obvious distinction, it’s far from the only one.

Understanding the Basics

Before comparing performance, it helps to clarify what each hinge type actually does.

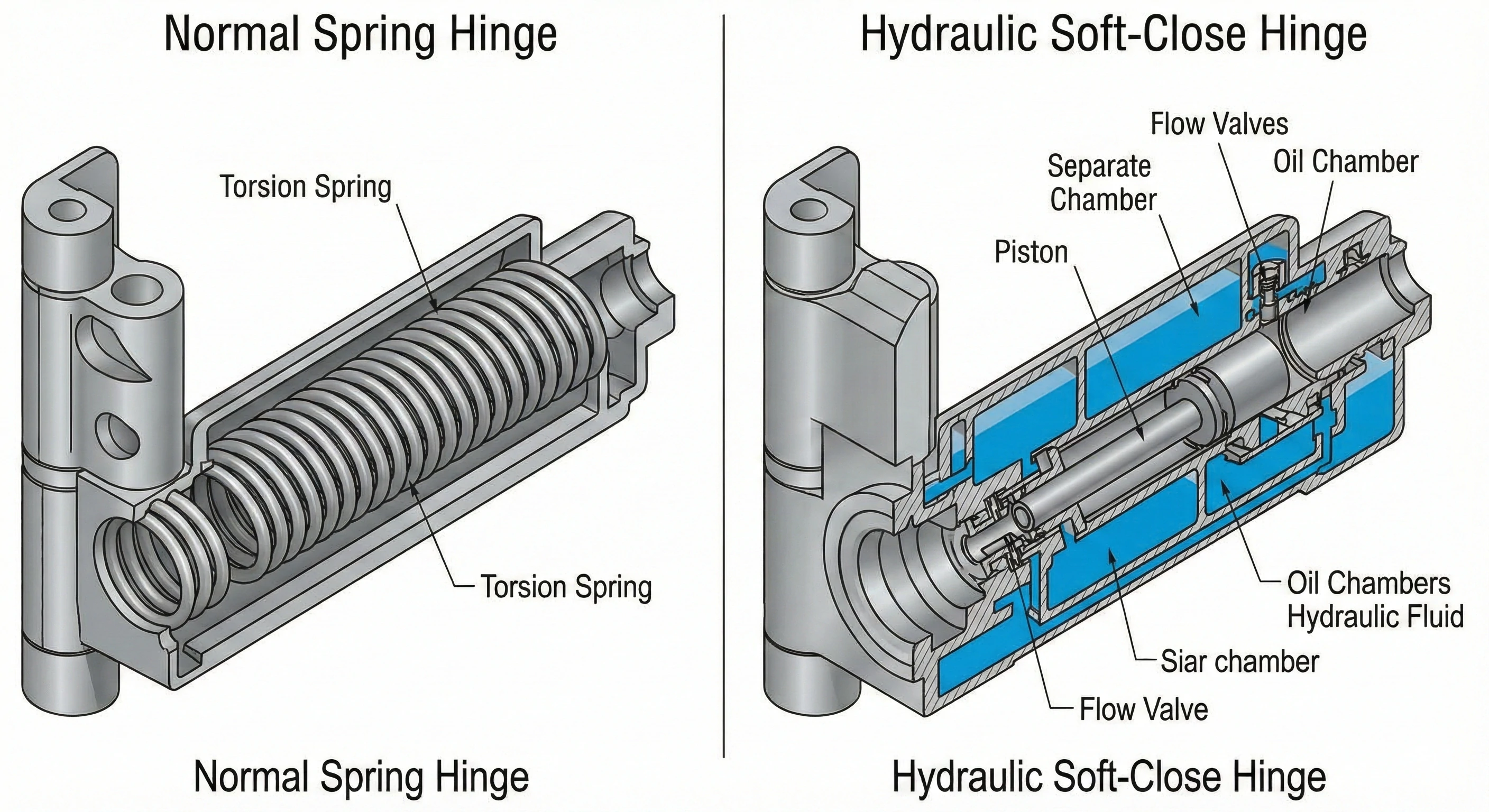

Normal (Spring) Hinges rely on mechanical spring tension. When the gate opens, the internal spring is wound tighter. Once released, that stored energy snaps back, forcing the gate shut. It’s a simple and effective mechanism—but also a very aggressive one. Think of it like a mousetrap: straightforward, reliable, and anything but gentle.

Hydraulic (Soft-Close) Hinges work on a completely different principle. Inside the hinge body is a sealed system filled with hydraulic oil. As the gate moves, the oil is pushed through precisely engineered valves that regulate speed. The result is controlled motion rather than raw force—similar to car shock absorbers or premium cabinet drawers that never slam.

The purpose of this guide is simple: to explain how these differences affect real-world performance, safety, durability, and long-term value—so you can choose the right solution for your project.

1. The Mechanics: Tension vs. Viscosity

Normal (Spring) Hinges: The Mousetrap Effect

Spring hinges operate on stored mechanical energy. Opening the gate compresses the spring; closing releases that energy all at once. As a result, the gate doesn’t just close—it accelerates toward the latch.

The issue is that the force peaks at the worst possible moment: right before impact. The faster the gate moves, the harder it hits. Over time, this repeated stress transfers directly to the latch, the glass panel, and the mounting hardware, increasing wear and failure risk.

Hydraulic (Soft-Close) Hinges: Controlled by Design

Hydraulic hinges manage motion instead of fighting it. Inside the sealed chamber, fluid resistance slows the gate in a predictable, adjustable way. Kinetic energy is absorbed and dissipated gradually, not released all at once.

One major advantage is consistency. Gate weight has far less influence on closing behavior. Whether the gate weighs 50 pounds or 100 pounds, a properly specified hydraulic hinge delivers the same smooth, controlled close.

2. The User Experience: "The Slam" vs. "The Glide"

This is where the technical differences become noticeable in daily use.

Living with a Spring Hinge

In ideal conditions, a spring hinge may seem acceptable. But real environments introduce problems quickly:

Wind: A sudden gust can turn a gate into a battering ram, slamming shut with alarming force

Noise: The sharp metallic impact disrupts conversations and undermines the calm, modern feel of a glass installation

Vibration: Shock travels through the fence line, loosening fittings over time

Inconsistency: Temperature affects spring tension, so the gate behaves differently in summer than in winter

The Hydraulic Experience

A hydraulic hinge feels deliberate and refined. The gate moves freely at first to ensure reliable closing, then slows automatically as it approaches the latch. The final movement is quiet and controlled—no bounce, no slam.

It’s the same sensation you get when closing a luxury car door or a high-end cabinet: subtle, reassuring, and unmistakably premium.

3. Adjustability: Speed Zones Matter

Spring Hinges: One Setting, One Trade-Off

With spring hinges, adjustment usually means tightening or loosening the spring:

More tension: faster closing, louder impact

Less tension: quieter motion, but unreliable latching

There’s no way to separate speed from force. Every adjustment is a compromise.

Hydraulic Hinges: Fine-Tuned Control

Quality hydraulic hinges allow independent control over different phases of movement:

Sweep speed: from fully open to roughly 15° before closing

Latching speed: the final degrees before contact

Some models even offer a hold-open zone that keeps the gate at 90° until pushed closed. This level of control allows the gate to close reliably without sacrificing safety or comfort.

4. Safety and Reliability

For pool gates and child-safe enclosures, this section is critical.

Latch Bounce: A Serious Risk

With spring hinges, excessive closing force can cause the gate to rebound off the latch and remain slightly open—often unnoticed. This is a common reason gates fail pool safety inspections.

Hydraulic hinges prevent this by reducing speed before impact, ensuring the latch engages cleanly every time.

Finger Protection

A wind-driven spring gate can close fast enough to cause serious finger injuries. Hydraulic systems act as a natural brake, limiting speed even when external forces are involved and giving users time to react.

Long-Term Performance

Springs wear out. Metal fatigue reduces tension over time, leading to unreliable closing and frequent replacements.

Hydraulic hinges are sealed systems. The oil remains stable, and performance stays consistent for years. A high-quality hydraulic hinge can function reliably for a decade or more.

5. Aesthetics: How It Looks Matters

Spring Hinges: Visible and Functional

Spring hinges typically require exposed hardware. While functional, the appearance can clash with the clean lines that make glass fencing attractive in the first place.

Hydraulic Hinges: Clean and Architectural

Hydraulic solutions enable much cleaner installations:

In-ground floor springs: completely hidden beneath the surface

Patch fittings: minimalist stainless steel or matte black designs that complement modern architecture

The hardware becomes part of the design, not a distraction from it.

6. The Cost Question

There’s no avoiding it: hydraulic hinges cost more.

Spring hinges: roughly $60–$160 per gate

Hydraulic hinges: $400–$1,600+ depending on type

That’s a significant difference—but context matters.

For low-use or secondary gates, spring hinges may be sufficient. For main entrances or pool safety gates used daily, the added cost pays off in durability, safety, and user experience.

You’ve already invested heavily in glass, installation, and landscaping. Compromising on the one component you interact with every day rarely makes sense.

Comparison at a Glance

|

Feature |

Spring Hinge |

Hydraulic Hinge |

|

|

Closing Action |

Slams shut |

Controlled soft-close |

|

|

Noise |

Loud impact |

Nearly silent |

|

|

Adjustability |

Single tension setting |

Multi-zone control |

|

|

Safety |

Risk of bounce and injury |

Secure, finger-safe |

|

|

Durability |

Springs fatigue |

Long-term consistency |

|

|

Appearance |

Visible hardware |

Hidden or architectural |

|

|

Cost |

Lower upfront |

Higher upfront |

|

|

Best For |

Budget or low-use gates |

|

The Bottom Line

Spring hinges work. They close gates and meet basic requirements.

Hydraulic hinges do more than that—they elevate the entire experience. They protect the gate, enhance safety, and reinforce the quality of the installation every single time the gate is used.

If you’ve invested in premium glass and thoughtful design, a slamming gate shouldn’t be the weak link. Hydraulic soft-close technology delivers peace of mind, long-term reliability, and a level of refinement that matches the rest of your project.

Frequently Asked Questions

Can I replace spring hinges with hydraulic ones?

Often yes, depending on existing glass cutouts and mounting details. Floor springs may require structural changes. A professional assessment is recommended.

Do hydraulic hinges work in cold climates?

High-quality models use temperature-stable hydraulic oil and perform consistently from extreme cold to heat. Cheaper units may slow down in winter.

Are hydraulic hinges better for heavy gates?

Yes. They dissipate momentum gradually, reducing stress on glass and hardware and making them ideal for larger or heavier gates.