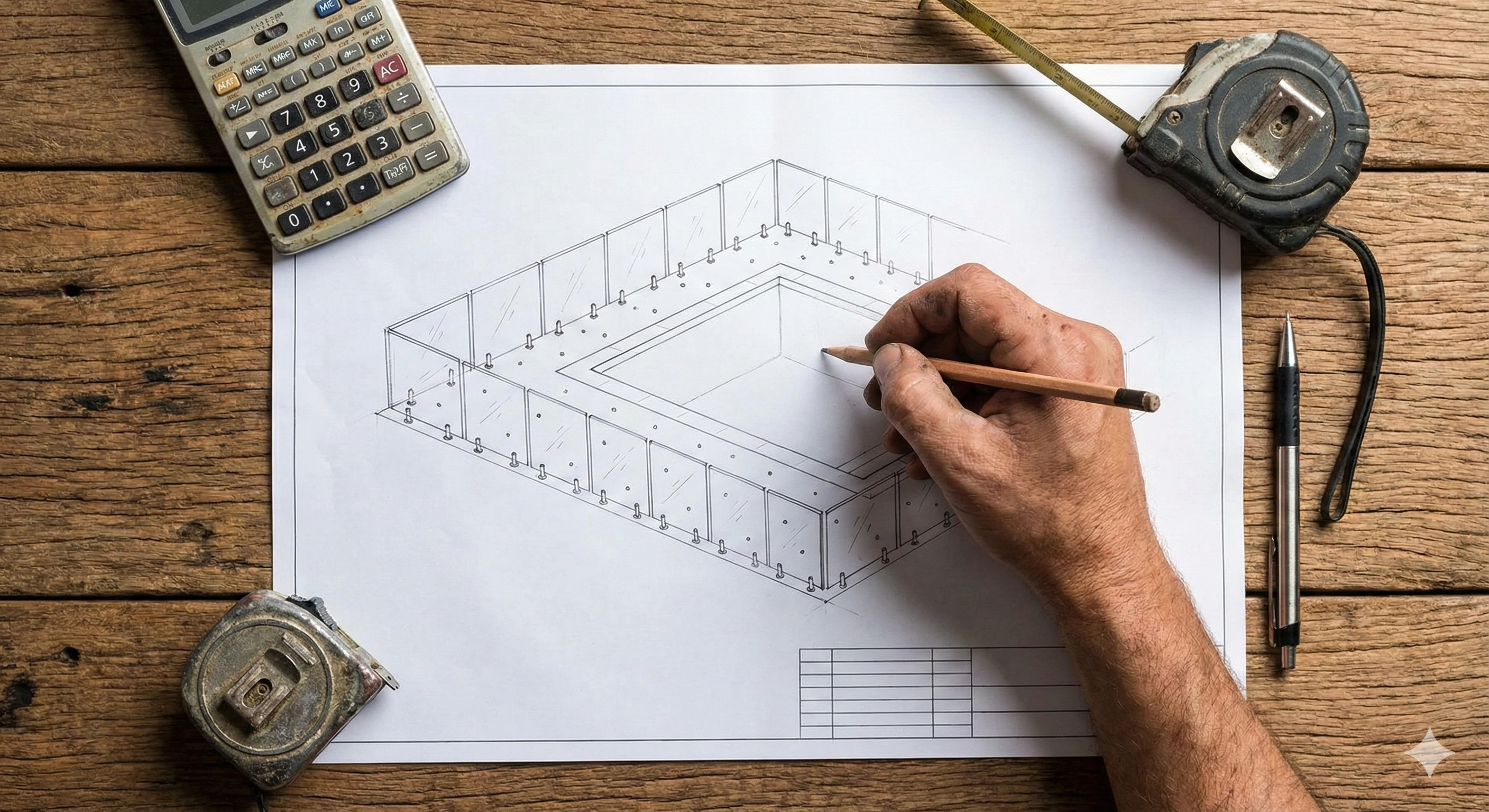

When planning a glass pool fence installation, one of the first questions contractors and DIY installers usually ask is how many spigots are needed for each glass panel. It’s an important decision: too few spigots can compromise safety, while too many simply add unnecessary cost and complexity.

The Direct Answer

For most standard glass panels measuring between 1000mm (39 inches) and 1800mm (71 inches) in width, two spigots per panel is the correct choice. This setup delivers reliable structural support, prevents unwanted panel movement, and preserves the clean, open look that defines frameless glass fencing.

That said, there are exceptions. Extra-wide custom panels, installations in high-wind environments, and certain commercial projects may require a third spigot for added stability. In this guide, we’ll break down the engineering logic, spacing rules, and practical considerations so you can make a decision that’s both safe and cost-effective.

The Standard Rule: Two Spigots is (Almost) Always Enough

Why Two Spigots Work Best

From an engineering standpoint, two spigots create a simple but effective support system. With two fixed mounting points, the glass panel is prevented from rotating or twisting, while still being able to flex slightly under load. This controlled movement is actually beneficial—completely rigid systems tend to concentrate stress, which increases the risk of glass failure over time.

When wind applies pressure to a glass panel, the force is shared between both spigots. This allows the panel to absorb energy through a small amount of deflection at the top. The same principle is used in large structures, where limited, intentional movement is designed into the system to improve long-term durability.

The Aesthetic Advantage

Two spigots also win from a visual standpoint. Frameless glass fencing is all about clean lines and unobstructed views. Adding a third spigot—especially in the middle of a panel—breaks that simplicity and draws attention to the hardware instead of the glass itself.

Installation Reality Check

There’s a practical reason professionals prefer two spigots that rarely gets mentioned: alignment. Installing two spigots correctly establishes a stable plane. Introducing a third creates what many installers refer to as the “three-point problem.”

Concrete surfaces are rarely perfectly flat. When three spigots are involved, even minor surface irregularities can cause the middle spigot to sit unevenly. Installers then face a bad choice: leave it slightly loose, or overtighten it to compensate. Either option can introduce stress into the glass. In practice, two well-aligned spigots are usually safer and more reliable than three that aren’t perfectly positioned.

The Safe Width Range

As a general rule, two spigots are suitable for glass panels between 800mm (31 inches) and approximately 1800mm (71 inches) wide. With standard 12mm (1/2 inch) toughened glass, panels in this range remain stiff enough that deflection between mounting points stays well within acceptable limits.

When Do You Need 3 Spigots per Panel?

Although two spigots cover most situations, some installations legitimately require additional support. Below are the most common cases where adding a third spigot makes sense.

Scenario 1: Oversized Custom Panels

Once panel widths exceed 1800mm (71 inches) and approach 2000mm (79 inches), the span between two edge-mounted spigots becomes too large. Under wind load, the center of the panel can flex noticeably. A third spigot placed at the midpoint helps control this movement and provides the extra clamping force needed for stability.

These oversized panels are more common in commercial settings, infinity-edge pool designs, or premium residential projects where minimizing the number of vertical joints is a priority. If your panels exceed 1800mm, plan for the extra spigot—and the added installation effort—from the start.

Scenario 2: High Wind Zones

Installations in coastal areas, hurricane-prone regions, or consistently windy locations require stronger overall design. In these environments, wind loads can exceed standard assumptions, and a third spigot adds valuable lateral resistance.

In many jurisdictions, local building codes actually mandate additional fixing points in high-wind zones. The extra spigot helps the panel withstand both continuous wind pressure and sudden gusts that might otherwise loosen or shift the glass.

Scenario 3: Heavy Thickness Glass

Most residential pool fencing uses 12mm (1/2 inch) toughened glass, but some commercial projects specify 15mm (5/8 inch) or even 19mm (3/4 inch) glass. Thicker glass means significantly more weight, which increases the load on each mounting point.

Before automatically adding a third spigot, consider using heavy-duty spigots instead. These are designed with stronger clamps and higher load ratings and can often support thicker glass without increasing the number of mounting points—while still being easier to install than a three-spigot setup.

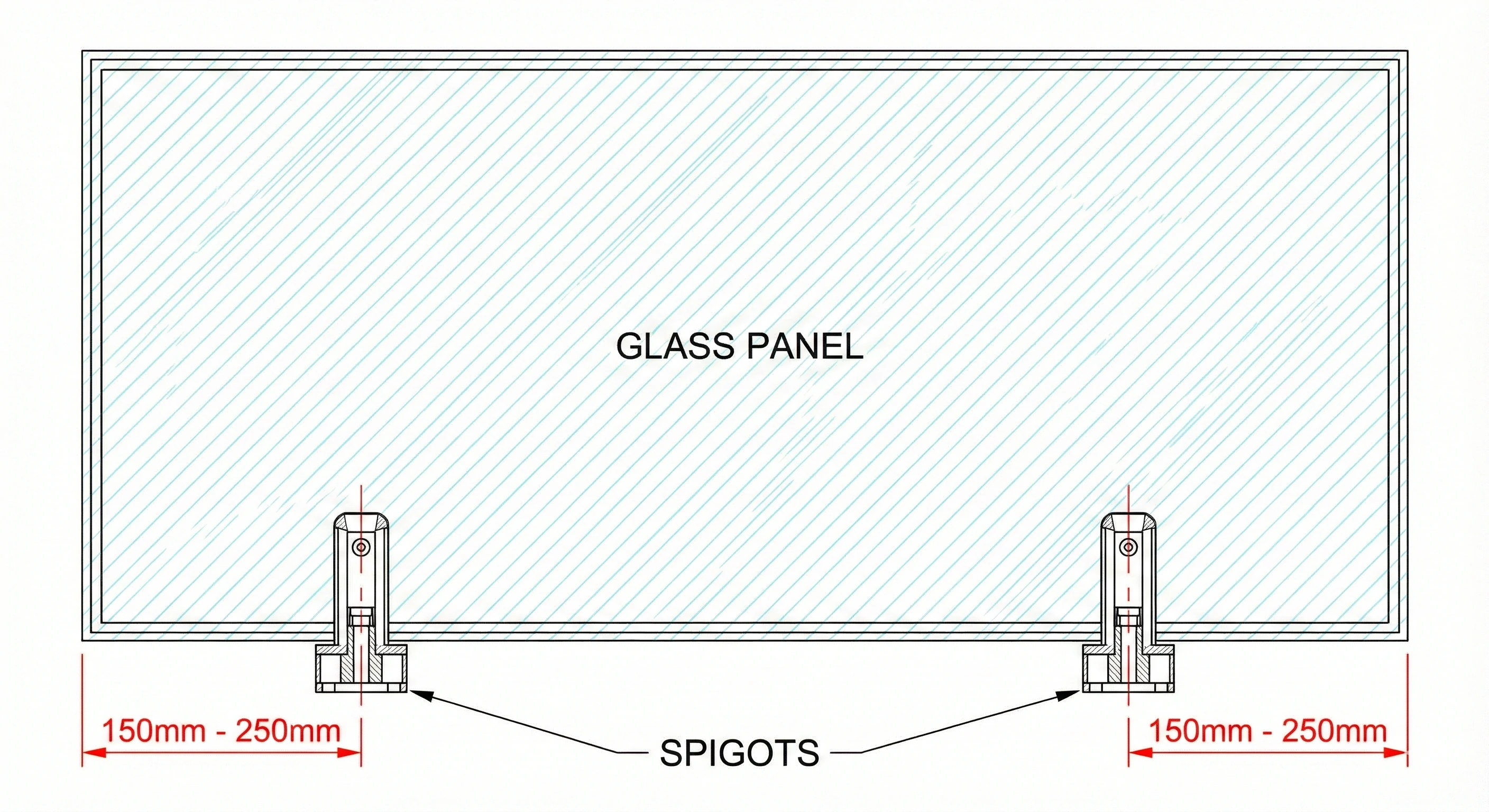

The "Edge Distance" Rule: Where to Position Them

Knowing how many spigots you need is only part of the equation. Proper positioning is just as important.

The Optimal Sweet Spot

Industry best practice places spigots 150mm to 250mm (6–10 inches) in from each edge of the glass panel. This range provides an ideal balance between structural performance and appearance. Many installers standardize on around 200mm (8 inches), as it works well across most panel sizes.

Understanding the Cantilever Effect

The section of glass beyond the spigot is effectively a cantilever—an unsupported overhang. This is why edge distance matters.

Too close to the edge (less than 150mm): While stable, the layout can look cramped and increases the risk of edge damage during installation. It also limits effective load distribution.

Too far from the edge (more than 300mm): This creates long, unsupported corners. When someone leans on the glass—common around pools—the corner acts like a lever, increasing rotational force on the spigot. Over time, this can lead to loosening or even failure.

The Professional Consistency Standard

Once you choose an edge distance, keep it consistent across every panel. Uniform spacing creates a clean, intentional look, while inconsistent measurements immediately stand out.

Using a simple template or jig to mark spigot positions can save time and ensure every panel is installed with identical geometry.

What About Gates and Hinge Panels?

Gate sections require special attention because they experience dynamic loads.

The Gate Panel Itself

Swinging gate panels do not use spigots. Instead, they are mounted with purpose-built gate hinges and a latch system. These components are designed to handle repeated movement and impact loads that spigots are not meant to absorb.

The Critical Hinge Panel

The fixed panel next to the gate—the hinge panel—absorbs significant stress from gate operation. This includes the weight of the gate, impact when it closes, lateral forces from pushing and pulling, and twisting caused by uneven movement.

With residential glass weighing roughly 30kg per square meter (6 lb per square foot), these forces add up quickly. A gate slammed shut can generate loads several times greater than the glass’s static weight.

Critical recommendation: Always use heavy-uty spigots on hinge panels, regardless of panel width. This is not an area to cut costs. Heavy-duty spigots provide the extra safety margin needed to handle repeated stress over time.

Quick Calculator: How Many Spigots Do I Order?

Use this simple formula:

(Number of fixed panels) × 2 = Total spigots required

For example, if your fence includes 10 panels and one is a swinging gate, you have 9 fixed panels:

9 × 2 = 18 spigots

Don't Forget These Additions

Order extras: Adding 1–2 spare spigots helps avoid delays caused by installation damage or future replacement needs.

Gate hardware is separate: Hinges and latches are not included in your spigot count.

Double-check the layout: Walk the site and confirm panel numbers, corners, and returns before ordering.

Making the Right Choice for Your Installation

The two-spigot standard exists for a reason. It balances safety, practicality, and cost, and works for roughly 90% of glass pool fence installations.

Using only one spigot is unsafe and violates basic engineering principles. On the other hand, adding a third spigot to standard-width panels usually adds cost and complexity without meaningful benefit.

The Cost vs. Safety Balance

Glass pool fencing is a significant investment, often ranging from $300–$600 per linear meter installed. Spigots make up a relatively small portion of that cost—typically $30–$80 each.

Saving money by omitting necessary spigots is false economy. A single panel failure can lead to injury, liability, and costly replacement. Conversely, over-engineering by adding unnecessary spigots across the entire fence often wastes budget that could be better spent elsewhere.

When to Consult the Professionals

Seek professional advice if your project involves:

Panels wider than 1800mm (71 inches)

High-wind or coastal locations

Glass thicker than 12mm (1/2 inch)

Uneven mounting surfaces

Local code requirements

Commercial or public installations

Ready to Order?

With these principles in mind, calculating your spigot requirements becomes straightforward. Remember the core rule: two spigots per standard panel, positioned 150–250mm from each edge.

If you’re unsure, send us your panel sizes, layout drawings, and site photos. Our technical team can prepare an accurate Bill of Materials (BOM) tailored to your project—ensuring you order exactly what you need, without overspending or under-engineering.

Frequently Asked Questions

Can I use just 1 spigot for a small panel?

No. A single spigot allows rotation and uplift, regardless of panel size. Two fixing points are the minimum requirement for stable glass mounting.

How far apart should glass spigots be?

Spigot spacing equals panel width minus the edge distances on both sides. For a 1500mm panel with 200mm edge distances, spacing is 1100mm center-to-center.

Do wider panels cost more to install?

Yes. Wider panels require more manpower, often additional spigots, and higher fabrication and transport costs.

What's the difference between standard and heavy-duty spigots?

Heavy-duty models feature stronger clamps, larger bolts, and higher load ratings. They’re recommended for hinge panels, high-wind areas, and thicker or taller glass.

How do I account for corner sections?

Corner panels still require two spigots each, but may need specialized corner or offset spigots. Detailed layout drawings are essential.

Can I retrofit a third spigot later if needed?

It’s possible but difficult and costly. If you’re unsure, it’s better to design for three spigots from the beginning rather than retrofitting later.