In casting manufacturing, the casting process determines the "shape" of the casting, while heat treatment defines its "performance". Whether it’s making brittle and hard cast iron tough or giving soft aluminum alloy high strength, heat treatment’s "precision control" is indispensable. However, many people only understand heat treatment as "heating and then cooling" without knowing the specific functions of different processes: "What’s the difference between annealing and normalizing?" "Why can quenching and tempering make castings both strong and tough?" "Is aging treatment only for aluminum alloys?" Today, we’ll focus on the six core processes of casting heat treatment, explaining the function, application scenario, and principle of each process in plain language to help you understand "why different castings require different heat treatments".

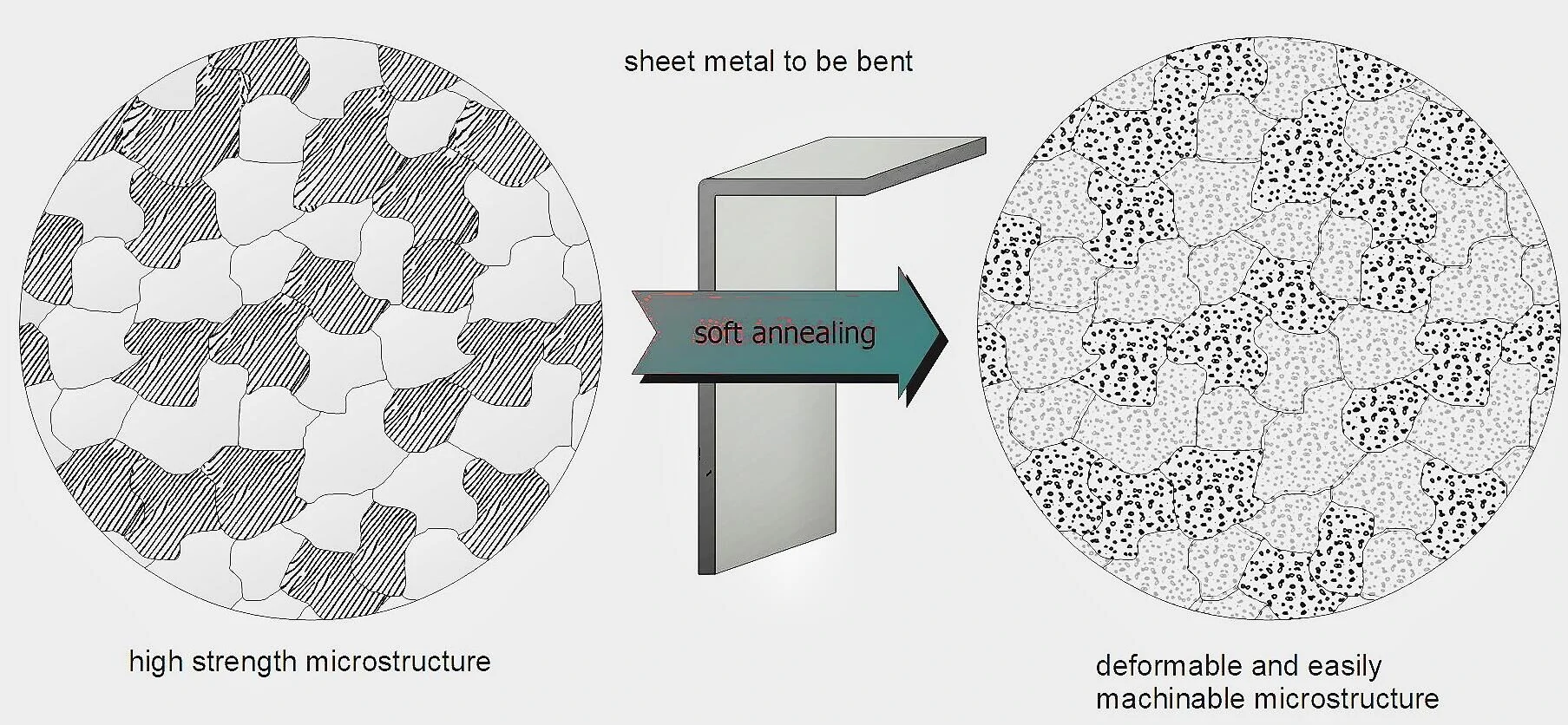

Annealing: Softening and Toughening Castings to Eliminate Internal Stress

Annealing is the most basic heat treatment process for castings. Its core function is to reduce hardness, eliminate internal stress, and improve machinability – essentially "relieving tension" for castings that have just been produced.

Process Principle

Heat the casting slowly to a specific temperature (usually below the material’s phase transformation temperature, e.g., 600–650°C for gray cast iron, 300–350°C for aluminum alloy), hold it at that temperature for a period (1–2 hours per 25mm of casting thickness), then cool it slowly with the furnace (cooling rate ≤ 50°C/hour). This process allows the metal grains inside the casting to rearrange, releasing internal stress caused by uneven cooling during casting and reducing material hardness.

Core Functions

- Eliminate internal stress to prevent deformation and cracking: After casting, the uneven cooling rate between the surface and interior of the casting creates "internal stress". For example, if a large gray cast iron machine tool base is not annealed, it may crack due to stress release when stored. Annealing can eliminate over 80% of internal stress, significantly reducing the risk of deformation during subsequent processing or use.

- Reduce hardness for easier machining: As-cast castings have high hardness (e.g., 220–280 HB for ductile iron), which causes rapid tool wear and low machining efficiency if directly milled or drilled. After annealing, hardness drops to 180–220 HB, cutting resistance decreases by 20%–30%, and tool life doubles.

- Improve microstructure for subsequent heat treatment: For castings requiring further quenching or tempering, annealing refines metal grains, ensuring more uniform microstructure and stable performance during subsequent heat treatment. For example, after annealing stainless steel castings, the hardness deviation can be controlled within ±5 HB during quenching.

Application Scenarios

- Castings with high as-cast hardness and poor machinability (e.g., gray cast iron, ductile iron castings);

- Large, complex-structured castings (e.g., machine tool bases, construction machinery frames) that require internal stress elimination;

- Pre-treatment for castings needing subsequent heat treatment (quenching, carburizing).

Normalizing: Enhancing Strength and Uniformity to Improve Comprehensive Performance

Normalizing is often called the "upgraded version of annealing". Its core function is to refine grains, increase strength and hardness, and improve microstructure uniformity, making it suitable for castings with moderate mechanical property requirements.

Process Principle

Similar to annealing, the casting is heated to the phase transformation temperature (but 50–100°C higher than annealing, e.g., 750–800°C for gray cast iron) and held at temperature, then cooled in air (10–20 times faster than annealing). Rapid cooling prevents metal grains from growing, forming a finer, more uniform microstructure and thus improving performance.

Core Functions

- Increase strength and hardness: Compared with annealing, normalized castings have higher strength. For example, 45# steel castings have a tensile strength of 600 MPa after normalizing – 20% higher than annealing (500 MPa) – and a hardness of 200–240 HB (10%–15% higher than annealing), enabling them to withstand greater external forces.

- Improve microstructure uniformity: Uneven cooling during casting causes microstructure inhomogeneity (e.g., local coarse grains) in different parts of the casting. Normalizing makes the microstructure of the entire casting uniform, avoiding performance fluctuations caused by inhomogeneity. For example, after normalizing aluminum alloy wheel castings, the hardness deviation between different parts is reduced from ±15 HB to ±5 HB.

- Simplify processes and reduce costs: For castings not requiring high toughness, normalizing can be used directly as the "final heat treatment" without subsequent processing, saving over 30% of time and energy compared to the combined annealing + quenching process.

Application Scenarios

- Castings requiring strength and hardness but not high toughness (e.g., automotive chassis brackets, agricultural machinery parts);

- Castings with uneven microstructure and large performance fluctuations (e.g., large steel castings);

- Mass-produced small and medium-sized castings needing a balance between performance and cost.

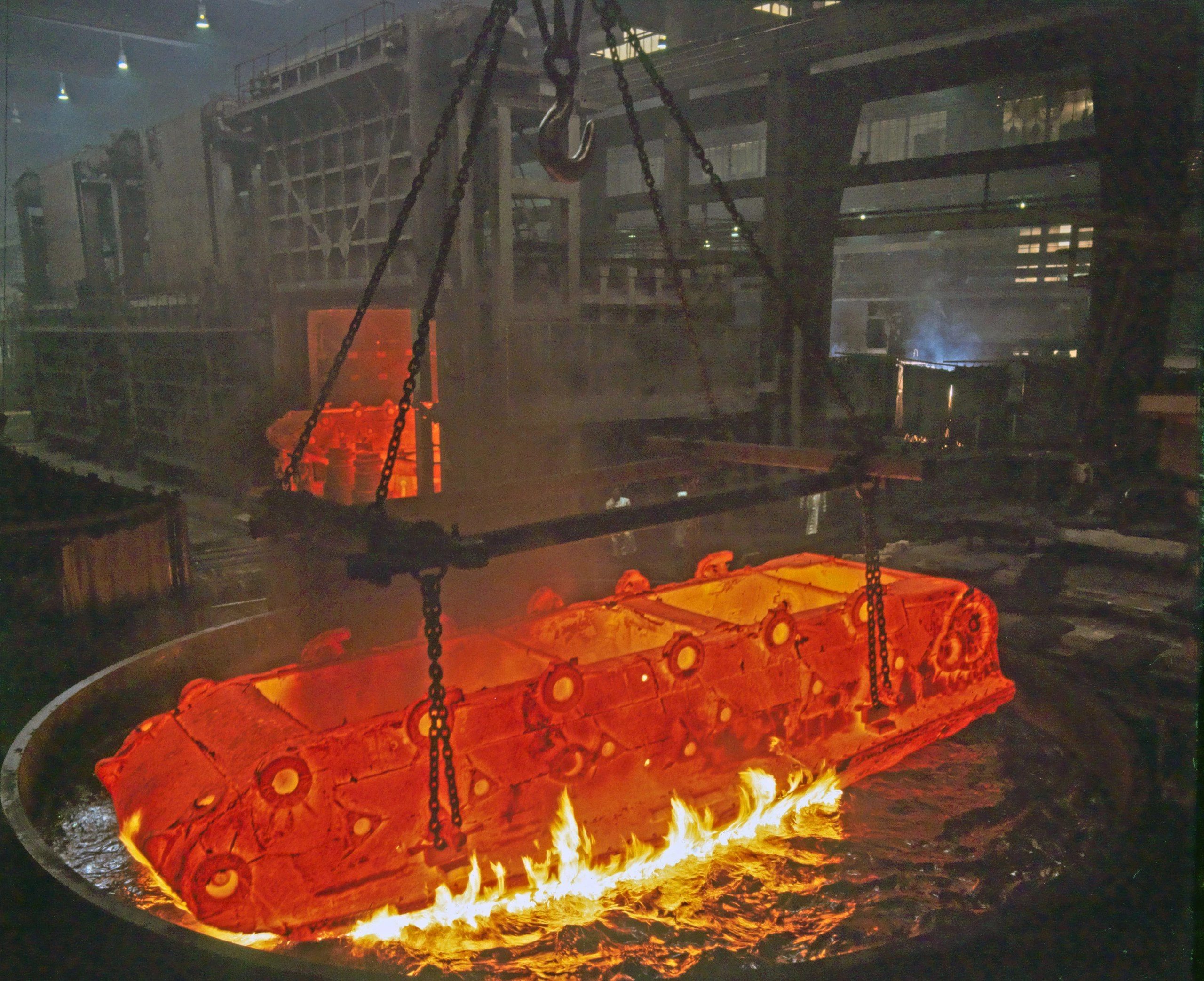

Quenching + Tempering: Achieving High Hardness and Wear Resistance for High-Strength Scenarios

"Quenching + tempering" is a combined process. Its core function is to greatly increase hardness, wear resistance, and strength, making it the "key operation" for manufacturing high-wear, high-load castings. Note: Quenched castings are highly brittle and must be tempered to "eliminate brittleness".

Process Principle

- Quenching: Heat the casting to a high temperature (above the phase transformation temperature, e.g., 850–950°C for carbon steel, 1050–1150°C for stainless steel), hold it at temperature, then cool it rapidly(in water, oil, or salt bath, with a cooling rate of 100–1000°C/s). Rapid cooling forms a "martensite" structure, significantly increasing hardness but also creating high internal stress and brittleness.

- Tempering: Reheat the quenched casting to a lower temperature (150–650°C, adjusted based on requirements), hold it at temperature, then cool it slowly. This process eliminates internal stress from quenching, reduces brittleness, and retains most of the hardness – lower temperatures result in higher hardness and lower toughness, while higher temperatures improve toughness and reduce hardness.

Core Functions

- Achieve high hardness and wear resistance: After quenching + low-temperature tempering (150–250°C), castings have extremely high hardness. For example, Cr12MoV die steel castings reach a hardness of 58–62 HRC, which can withstand long-term friction without wear, making them suitable for manufacturing casting dies and wear-resistant liners.

- Balance strength and toughness: Quenching + medium-temperature tempering (350–500°C) gives castings both strength and toughness. For example, 40Cr steel drive shaft castings have a tensile strength of 800 MPa and an impact toughness of 15 J/cm² after tempering, enabling them to withstand high tensile forces from high-speed rotation and resist accidental impacts without breaking.

- Improve fatigue strength: For castings subject to cyclic loads (e.g., springs, gears), quenching + high-temperature tempering (500–650°C) increases fatigue strength, preventing "fatigue fracture" after long-term use. For example, automotive spring castings have a 2–3 times longer fatigue life after treatment.

Application Scenarios

- High-wear castings (e.g., crusher hammers, machine tool guideways, dies);

- Castings subject to high loads and impact loads (e.g., drive shafts, gears, hydraulic valve cores);

- Dynamic load-bearing castings requiring high fatigue strength (e.g., springs, connecting rods).

Tempering (Quenching + High-Temperature Tempering): Balancing Strength and Toughness for Complex Load Scenarios

Tempering (often referred to as "hardening and tempering") is a specific combination of "quenching + high-temperature tempering" (tempering temperature: 500–650°C). Its core function is to ensure excellent toughness and ductility while maintaining high strength, making it the preferred process for manufacturing "complex load-bearing castings".

Process Principle

First, quench the casting to form a martensite structure, then reheat it to 500–650°C for high-temperature tempering and cool it in air. High-temperature tempering transforms the martensite structure into "sorbite" or "troostite" – a microstructure characterized by fine grains and a balanced strength-toughness ratio. It retains most of the strength from quenching, eliminates brittleness through high-temperature tempering, and improves ductility (allowing the casting to deform slightly under external forces without breaking).

Core Functions

- Balance strength and toughness for complex loads: Tempered castings can withstand high tensile forces and resist impacts. For example, 45# steel crankshaft castings have a tensile strength of 750 MPa and an impact toughness of 25 J/cm² after tempering. During engine operation, they can withstand high pressure from pistons and resist impacts from speed changes without breaking.

- Improve machinability and post-processing performance: Compared with quenched castings alone, tempered castings have moderate hardness (220–280 HB), resulting in slower tool wear during cutting. Their good ductility also prevents cracking during subsequent drilling or tapping. For example, the qualification rate of tapping for large bolt castings increases from 80% to 98% after tempering.

- Enhance surface treatment effects: Tempered castings have a uniform microstructure, ensuring stronger coating adhesion during subsequent electroplating or spraying and preventing peeling or blistering. For example, the adhesion of paint on automotive wheel castings increases by 30% after tempering.

Application Scenarios

- Key castings subject to complex or dynamic loads (e.g., engine crankshafts, connecting rods, reducer gears);

- High-strength castings requiring subsequent machining or surface treatment;

- Core components with high reliability requirements (e.g., hydraulic pump housings for construction machinery).

Aging Treatment: Strengthening Aluminum/Magnesium Alloy Castings and Stabilizing Dimensions

Aging treatment is an exclusive heat treatment process for non-ferrous metal castings such as aluminum and magnesium alloys. Its core function is to gradually increase the strength of castings through room-temperature or low-temperature heating while stabilizing dimensions, solving the problem of "dimensional changes in castings during storage".

Process Principle

After quenching, aluminum/magnesium alloy castings form a "supersaturated solid solution" (metal atoms in an unstable "excess" state in the crystal lattice). Aging treatment allows these unstable atoms to diffuse and aggregate slowly, forming fine "strengthening phases" (e.g., Mg₂Si phases in aluminum alloys):

- Natural aging: Store the quenched casting at room temperature (usually for 48–72 hours) to allow the strengthening phases to precipitate naturally, gradually increasing strength;

- Artificial aging: Heat the quenched casting to 100–200°C (e.g., 120–180°C for aluminum alloys), hold it at temperature for 4–12 hours to accelerate precipitation of strengthening phases and shorten aging time.

Core Functions

- Significantly increase strength: Aging is the key to "hardening" aluminum alloy castings. For example, 6061 aluminum alloy castings have a hardness of 60–80 HB after quenching, which rises to 100–120 HB after natural aging and 120–140 HB after artificial aging. Their tensile strength increases from 200 MPa to over 300 MPa, meeting the dual requirements of lightweight and high strength.

- Stabilize dimensions and prevent deformation: Unaged aluminum alloy castings experience continuous atomic diffusion, leading to slow dimensional changes during storage (e.g., 0.1%–0.2% length shrinkage). After aging, atomic diffusion almost stops, greatly improving dimensional stability. For example, precision aluminum alloy instrument housings have a dimensional deviation of ±0.02 mm after aging, ensuring precise assembly with other components.

- Improve corrosion resistance: The strengthening phases formed during aging refine grains and reduce "intergranular corrosion channels" in the alloy. For example, 3003 aluminum alloy radiator castings have 50% better salt spray corrosion resistance after aging, extending their service life by 2–3 times.

Application Scenarios

- Aluminum alloy castings (e.g., automotive body frames, smartphone middle frames, aerospace parts);

- Magnesium alloy castings (e.g., laptop housings, drone frames);

- Precision non-ferrous metal castings requiring high dimensional stability and strength.

Carburizing/Nitriding: Hardening Surfaces While Maintaining Core Toughness

Carburizing and nitriding are two "surface strengthening" heat treatment processes. Their core function is to form a high-hardness, wear-resistant surface layer on castings while maintaining good core toughness, solving the problem of "excessive brittleness in fully quenched castings". They are suitable for castings requiring "wear-resistant surfaces and impact-resistant cores".

Process Principles and Functions

1. Carburizing

- Principle: Place low-carbon steel castings (carbon content: 0.15%–0.25%) in a carburizing medium (e.g., natural gas, kerosene) at 900–950°C, hold them for 4–12 hours to allow carbon atoms to penetrate the casting surface (forming a 0.5–2 mm thick carburized layer), then quench and temper at low temperature.

- Core Functions: The surface has extremely high hardness (58–62 HRC) and wear resistance, while the core remains low-carbon steel with good toughness. For example, automotive transmission gear castings have wear-resistant tooth surfaces (withstanding long-term meshing friction) and tough cores (resisting impact without breaking).

2. Nitriding

- Principle: Place castings (usually alloy steels containing chromium and molybdenum, e.g., 38CrMoAl) in a nitriding medium (e.g., ammonia gas) at 500–550°C, hold them for 10–50 hours to allow nitrogen atoms to penetrate the surface (forming a 0.1–0.5 mm thick nitrided layer), with no subsequent quenching required.

- Core Functions: The surface has even higher hardness (65–70 HRC) and better wear/corrosion resistance than carburizing, with minimal deformation after heat treatment. For example, precision machine tool spindle castings have wear-resistant surfaces (ensuring long-term high-precision operation) and a deformation of ≤0.005 mm, requiring no secondary processing.

Application Scenarios

- Carburizing: Castings requiring wear-resistant surfaces and impact-resistant cores (e.g., gears, camshafts, clutch plates);

- Nitriding: High-precision, wear-resistant, corrosion-resistant castings (e.g., machine tool spindles, hydraulic valve stems, precision dies).

Conclusion

Casting heat treatment is not a "one-size-fits-all" process but a "customized solution" based on casting material, application, and performance requirements:

- Annealing is the "basic option" for solving internal stress and machining issues;

- Normalizing is the "balanced option" for balancing strength and cost;

- Quenching + tempering is the "high-performance option" for high hardness and wear resistance;

- Tempering is the "all-round option" for balancing strength and toughness;

- Aging is the "non-ferrous option" for aluminum/magnesium alloys;

- Carburizing/nitriding are "surface options" for balancing wear resistance and toughness.

Understanding the core function of each heat treatment process allows you to select the most suitable process for different castings, transforming "blanks" into "qualified components" that meet requirements. If you have questions about "heat treatment parameters for specific casting materials" or "process selection for special scenarios", please leave a comment below – we will continue to share more popular science on casting heat treatment!